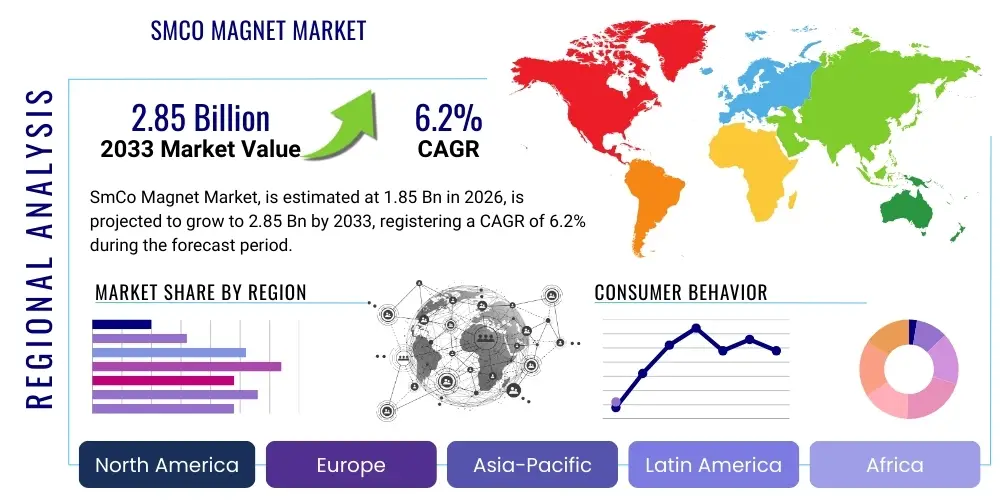

SmCo Magnet Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439918 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

SmCo Magnet Market Size

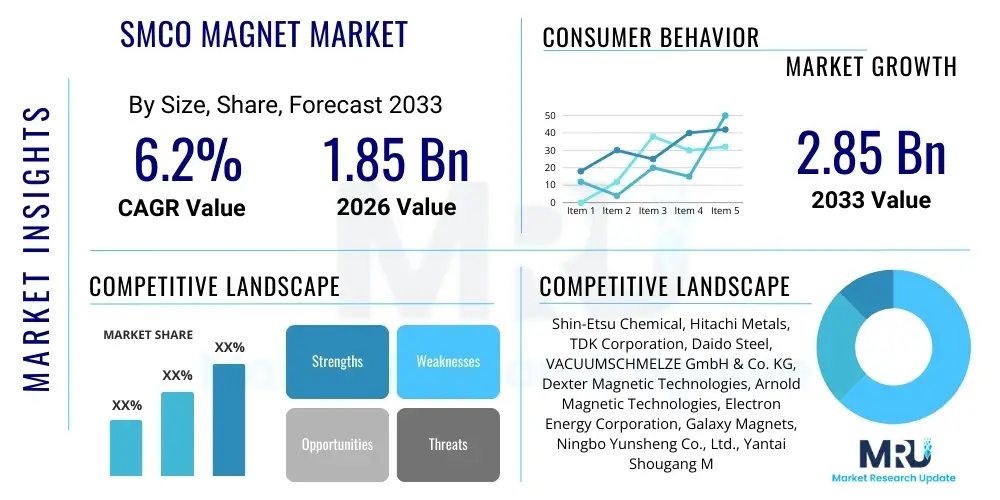

The SmCo Magnet Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.85 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by increasing demand for high-performance magnetic materials in critical sectors such as aerospace, defense, medical devices, and high-temperature industrial applications, where their superior thermal stability and corrosion resistance provide indispensable advantages over alternative magnet types.

The market expansion is also underpinned by technological advancements in manufacturing processes, leading to more efficient production and enhanced magnetic properties, further solidifying SmCo magnets' position in specialized, demanding environments. Despite challenges related to the cost and supply chain volatility of rare-earth elements, the irreplaceable performance characteristics of SmCo magnets in specific high-stress applications ensure sustained market demand and investment in research and development, contributing significantly to the projected valuation.

SmCo Magnet Market introduction

The SmCo Magnet Market encompasses the global trade and utilization of Samarium Cobalt (SmCo) magnets, which are a type of rare-earth permanent magnet renowned for their exceptional magnetic properties, particularly their high coercivity and remarkable thermal stability. These magnets are primarily composed of samarium and cobalt, existing in two main forms: SmCo5 (1:5 alloy) and Sm2Co17 (2:17 alloy), with the latter offering superior performance at elevated temperatures. SmCo magnets are preferred in applications where high operating temperatures, strong magnetic fields, and resistance to demagnetization are crucial, distinguishing them from other permanent magnet materials like Neodymium Iron Boron (NdFeB) magnets, which exhibit lower temperature tolerance.

Major applications for SmCo magnets span critical industries including aerospace and defense for guidance systems, motors, and sensors; medical devices such as MRI machines, pacemakers, and surgical tools; high-performance automotive systems, particularly in electric vehicles for electric power steering and specialized sensors; and industrial automation, encompassing robotics, magnetic couplings, and various high-temperature motors. The inherent benefits of SmCo magnets, such as their excellent magnetic strength at high temperatures (up to 350°C), superior corrosion resistance, and high resistance to demagnetization, make them indispensable in these demanding environments. Key driving factors for market growth include the increasing demand for miniaturized yet powerful components, the expansion of the electric vehicle (EV) market requiring robust high-temperature magnets, rising defense expenditures globally, and continued innovation in medical technology requiring reliable, high-performance materials.

SmCo Magnet Market Executive Summary

The SmCo Magnet market is experiencing dynamic shifts, driven by evolving technological demands and strategic industry developments. Current business trends indicate a strong focus on optimizing manufacturing processes to mitigate the impact of rare-earth element price fluctuations and supply chain vulnerabilities. Companies are increasingly investing in automation and advanced sintering techniques to enhance efficiency and product consistency. Additionally, there is a growing trend towards strategic partnerships and collaborations among raw material suppliers, magnet manufacturers, and end-use industries to secure stable supply lines and co-develop customized magnetic solutions, particularly for burgeoning sectors like advanced robotics and space technology. Innovation in magnet coatings and surface treatments is also a key area, aiming to further enhance corrosion resistance and prolong operational lifespan in harsh conditions.

Regionally, the Asia Pacific (APAC) continues to dominate the market in terms of production and consumption, largely propelled by its robust manufacturing base for electronics, automotive components, and industrial machinery, especially in countries like China, Japan, and South Korea. However, North America and Europe are significant markets for high-value applications in aerospace, defense, and specialized medical devices, driving demand for premium SmCo magnet grades and customized solutions. Emerging economies in Latin America and the Middle East & Africa are also showing nascent growth, stimulated by infrastructure development and increasing industrialization. Segment trends reveal that high-performance motors and sensors in aerospace, defense, and electric vehicle applications are the primary revenue generators. The medical device sector is witnessing accelerated adoption due to the magnets' biocompatibility and stable performance, while industrial automation continues to be a steady consumer, leveraging SmCo magnets for precision and reliability in extreme environments. The market is thus characterized by a delicate balance between cost efficiencies in mass production and the critical performance requirements of niche, high-value applications.

AI Impact Analysis on SmCo Magnet Market

User inquiries concerning the impact of Artificial Intelligence on the SmCo Magnet Market frequently revolve around how AI can enhance material discovery, optimize manufacturing processes, improve quality control, and predict supply chain disruptions. Users are keenly interested in whether AI can accelerate the development of new SmCo alloy compositions with even higher performance characteristics or lower rare-earth content. There's significant curiosity about AI's role in predictive maintenance for magnet-reliant systems, ensuring longevity and efficiency. Furthermore, users often ask about AI's potential to streamline the complex supply chain of rare-earth elements, reducing lead times and costs while ensuring greater stability, and how AI can be leveraged to achieve higher precision and reduce waste in the intricate magnet manufacturing stages, ultimately leading to more cost-effective and superior-quality SmCo magnets.

- AI-driven materials informatics can accelerate the discovery and optimization of novel SmCo alloy compositions, potentially leading to enhanced magnetic properties or reduced reliance on critical rare-earth elements.

- Predictive analytics powered by AI can optimize manufacturing parameters, improving yields, reducing waste, and ensuring consistent product quality in SmCo magnet production.

- AI algorithms can enhance quality control by identifying microscopic defects and inconsistencies in magnets that are difficult to detect through traditional methods, leading to higher reliability.

- Supply chain management benefits from AI by forecasting demand, predicting price fluctuations of raw materials, and identifying potential disruptions, enabling proactive procurement strategies for samarium and cobalt.

- AI-enabled automation in magnet assembly and integration processes can increase efficiency and precision, particularly in complex applications requiring custom magnet shapes and intricate placements.

- AI can facilitate advanced design simulations for magnet applications, allowing engineers to virtually test and refine SmCo magnet designs for specific motors, sensors, or medical devices, reducing development cycles.

- Machine learning models can analyze performance data from SmCo magnets in operational environments to predict degradation, optimize maintenance schedules, and extend the lifespan of critical components.

DRO & Impact Forces Of SmCo Magnet Market

The SmCo Magnet market is shaped by a complex interplay of various drivers, restraints, and opportunities, alongside significant impact forces. Key drivers include the escalating demand for high-performance magnets in extreme conditions, notably within the aerospace, defense, and medical sectors where reliability at elevated temperatures and resistance to demagnetization are paramount. The continuous trend towards miniaturization in electronic components and specialized motors also fuels demand for SmCo magnets, as they offer superior magnetic energy density in smaller volumes. Furthermore, the burgeoning electric vehicle market, requiring robust and stable magnets for propulsion systems and auxiliary functions that can withstand harsh operating environments, is a substantial growth catalyst. Increased global defense spending and advancements in industrial automation and robotics, which rely on precision and durability, additionally contribute to market expansion.

However, the market faces considerable restraints. The primary challenge is the high cost and price volatility of key raw materials, particularly samarium and cobalt, which are rare-earth elements with limited geographical sourcing, creating supply chain vulnerabilities and impacting manufacturing costs. This often makes SmCo magnets more expensive than other permanent magnets like Neodymium, limiting their adoption to highly specialized applications where their unique properties are indispensable. Competition from Neodymium magnets, which offer higher magnetic strength at room temperature and are generally more cost-effective, also poses a restraint, although Neodymium's lower thermal stability differentiates the two for specific applications. Environmental regulations pertaining to rare-earth mining and processing, alongside the complex and energy-intensive manufacturing processes for SmCo magnets, further add to the operational challenges, necessitating continuous innovation in production efficiency and raw material sourcing strategies.

Opportunities within the SmCo magnet market are significant and diverse. Emerging applications in green energy technologies, such as advanced wind turbines and specialized generators requiring stable, high-performance magnets, present new avenues for growth. The development of advanced medical implants and surgical robotics, where biocompatibility, precise control, and thermal stability are critical, also creates substantial demand. Furthermore, ongoing research and development into novel SmCo alloys and manufacturing techniques, aimed at reducing rare-earth content or improving magnetic properties, could unlock new cost efficiencies and performance benchmarks. The increasing adoption of 5G technology and satellite communication systems, requiring high-frequency and temperature-stable components, represents another promising area. Strategic investments in supply chain resilience, including diversification of raw material sources and recycling initiatives, offer a pathway to mitigate existing restraints and secure long-term market stability, transforming current challenges into future opportunities for sustainable growth and technological advancement within the SmCo magnet industry.

Segmentation Analysis

The SmCo Magnet Market is comprehensively segmented based on various critical parameters, offering a detailed understanding of its underlying dynamics, key demand drivers, and competitive landscape across different product types, applications, end-use industries, and geographic regions. This multi-faceted segmentation allows for a precise analysis of specific market niches, growth potential, and strategic opportunities for stakeholders, enabling targeted product development and market penetration strategies. Understanding these segments is crucial for identifying areas of high demand, assessing competitive intensity, and forecasting future market trends, as each segment exhibits distinct characteristics and growth trajectories influenced by technological advancements, regulatory frameworks, and economic factors.

- By Type

- Sm2Co17 (Samarium Cobalt 2:17): Characterized by higher magnetic strength and superior thermal stability, making it ideal for applications operating at elevated temperatures (up to 350°C). This variant typically incorporates additional elements like iron, copper, zirconium, and hafnium to enhance its magnetic properties and temperature performance.

- SmCo5 (Samarium Cobalt 1:5): Offers good magnetic properties but with a lower maximum operating temperature compared to Sm2Co17. It is easier to magnetize and generally simpler to produce, finding applications where high temperature stability is not the absolute primary concern but robust magnetic performance is still required.

- By Application

- Motors: Used in precision motors, servo motors, stepper motors, aerospace actuators, and other high-performance motor systems requiring stability in high-temperature or critical environments.

- Sensors: Employed in position sensors, flow sensors, Hall effect sensors, and various transducers in industrial, automotive, and medical applications due to their stable magnetic field and reliability.

- Medical Devices: Essential components in MRI machines, pacemakers, hearing aids, dental tools, and advanced surgical robotics, where biocompatibility, stability, and precise operation are paramount.

- Aerospace & Defense: Critical for radar systems, guidance systems, avionics, satellite components, missile systems, and specialized actuators that must perform reliably under extreme conditions.

- Automotive: Utilized in electric power steering systems, anti-lock braking systems (ABS) sensors, specialized engine sensors, and other high-temperature automotive electronics, particularly in electric and hybrid vehicles.

- Industrial Automation: Found in robotics, magnetic couplings, pumps, valves, and other industrial machinery where resistance to harsh environments and consistent performance are necessary.

- Other Applications: Includes niche uses in consumer electronics, research instruments, and laboratory equipment where specific high-performance magnetic properties are required.

- By End-Use Industry

- Aerospace & Defense: Largest consumer, driven by stringent reliability and performance requirements for critical systems.

- Medical: Growing segment due to increasing demand for advanced, stable, and miniaturized medical devices.

- Automotive: Significant growth spurred by the electrification of vehicles and demand for high-temperature sensors.

- Industrial: Consistent demand from manufacturing, automation, and heavy machinery sectors.

- Research & Development: Ongoing usage in laboratories and scientific institutions for material science and advanced physics experiments.

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For SmCo Magnet Market

The value chain for the SmCo Magnet Market is intricate and spans from the mining and processing of rare-earth elements to the final integration of magnets into end-use applications, involving several critical stages and a network of specialized participants. The upstream segment primarily involves the extraction and refining of raw materials, predominantly samarium and cobalt, which are critical rare-earth elements sourced from a limited number of global mines, with China being a dominant supplier. This stage includes complex chemical processes to separate and purify the rare-earth elements to the required specifications for magnet manufacturing, necessitating significant capital investment and specialized expertise. The geopolitical landscape and environmental regulations surrounding mining significantly impact the stability and cost of these raw materials, directly influencing the overall production cost of SmCo magnets.

Following raw material procurement, the manufacturing stage is highly technical, involving specialized processes such as powder metallurgy, sintering, and hot pressing to form the magnetic alloys and shape the magnets to precise dimensions. This midstream segment is dominated by a few key players with proprietary technologies and extensive R&D capabilities to optimize magnetic properties, temperature stability, and corrosion resistance. Quality control and precision engineering are paramount at this stage to meet the stringent requirements of high-performance applications. The downstream segment encompasses the final processing, magnetization, testing, and integration of the finished SmCo magnets into various components and systems across diverse end-use industries. This involves further customization, assembly into magnetic assemblies, and rigorous testing to ensure performance within specific applications like aerospace engines, medical implants, or industrial sensors.

Distribution channels for SmCo magnets are typically a mix of direct and indirect approaches. For large-volume orders and highly customized solutions, manufacturers often engage in direct sales to Original Equipment Manufacturers (OEMs) in aerospace, defense, and medical industries, fostering strong technical collaborations. This direct approach ensures technical support, quality assurance, and adherence to specific design requirements. Indirect channels include a network of specialized distributors and value-added resellers who cater to smaller volume buyers, provide technical consultancy, and sometimes offer additional services like custom machining or magnetic assembly. These distributors play a crucial role in reaching a broader customer base and managing inventory. The complexity of SmCo magnet applications often necessitates highly knowledgeable sales and technical support teams, making the distribution channel an extension of the manufacturing expertise rather than just a logistical pathway. The entire value chain is characterized by a high degree of specialization and technical knowledge, emphasizing the importance of collaboration and expertise sharing among all stakeholders to ensure efficiency, quality, and supply chain resilience.

SmCo Magnet Market Potential Customers

The potential customers for SmCo magnets are primarily sophisticated end-users and Original Equipment Manufacturers (OEMs) operating in highly technical and demanding industries where conventional magnetic materials fall short in performance or reliability. These buyers prioritize product quality, consistent performance at extreme temperatures, and resistance to demagnetization over purely cost considerations, given the critical nature of their applications. Key sectors include aerospace and defense, where systems like radar, missile guidance, and satellite components require magnets that can withstand high temperatures, vibrations, and harsh environmental conditions without compromising performance. The medical device industry represents another significant customer base, with demand from manufacturers of MRI scanners, pacemakers, hearing aids, and advanced surgical robotics that necessitate biocompatibility, precise magnetic fields, and long-term stability.

Furthermore, the automotive industry, particularly the rapidly expanding electric vehicle (EV) segment, represents a growing customer segment. OEMs in this sector seek SmCo magnets for electric power steering systems, high-temperature sensors, and specialized motors where heat generation is a significant challenge. Industrial automation and robotics companies are also key buyers, utilizing SmCo magnets in precision motors, magnetic couplings, and sensors that operate in extreme industrial environments, demanding high efficiency and durability. Research and development institutions, alongside specialized electronics manufacturers creating high-frequency components or miniaturized devices, also constitute a vital customer segment. These customers often require customized magnet designs, specific magnetic properties, and comprehensive technical support, indicating a market driven by highly specialized needs and robust engineering solutions rather than mass-market appeal.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.85 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Shin-Etsu Chemical, Hitachi Metals, TDK Corporation, Daido Steel, VACUUMSCHMELZE GmbH & Co. KG, Dexter Magnetic Technologies, Arnold Magnetic Technologies, Electron Energy Corporation, Galaxy Magnets, Ningbo Yunsheng Co., Ltd., Yantai Shougang Magnetic Materials Inc., Hengdian Group DMEGC Magnetics Co., Ltd., Adams Magnetic Products Co., Inc., Hangzhou Permanent Magnet Group, JL MAG Rare-Earth Co., Ltd., Earth-Panda Advanced Magnetic Material Co., Ltd., China Rare Earth Holdings Limited, Chengdu Galaxy Magnets Co., Ltd., Bunting Magnetics Co., Stanford Magnets |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

SmCo Magnet Market Key Technology Landscape

The SmCo Magnet Market is underpinned by a sophisticated technological landscape that continuously evolves to enhance performance, improve manufacturing efficiency, and mitigate reliance on critical raw materials. The foundational technology involves powder metallurgy, where samarium and cobalt, along with other alloying elements, are finely milled into powders. These powders are then compacted under high pressure and subsequently sintered at elevated temperatures in an inert atmosphere. Sintering is a critical process that consolidates the powder particles into a dense, strong, and highly magnetic material, forming the basic magnet structure. Advances in powder processing techniques, such as finer milling and optimized particle size distribution, are crucial for achieving higher magnetic energy products and improved thermal stability in the final magnets. The precise control of temperature and atmospheric conditions during sintering directly influences the crystallographic orientation and magnetic properties of the SmCo alloy, demanding specialized equipment and expertise.

Beyond the fundamental manufacturing processes, the key technology landscape includes advancements in hot pressing and hot deformation techniques, particularly for Sm2Co17 magnets, which can further enhance the magnetic anisotropy and overall performance. Grain boundary diffusion (GBD) technology is also gaining traction, where a small amount of a low-melting-point rare-earth rich alloy is introduced to the magnet's surface, diffusing into the grain boundaries. This process can significantly improve coercivity, making the magnets more resistant to demagnetization without a substantial increase in overall rare-earth content, offering a cost-effective route to higher performance. Furthermore, advanced coating technologies are essential for applications requiring enhanced corrosion resistance, especially in harsh environments. These coatings, ranging from nickel plating to specialized polymers, provide a protective layer, extending the magnet's lifespan and reliability in demanding operating conditions. Innovations in magnetic field alignment during the compaction and sintering stages, often utilizing strong external magnetic fields, are also critical for achieving optimal magnetic performance by aligning the crystal grains in the preferred magnetization direction.

The broader technological environment also encompasses sophisticated characterization and testing methodologies, including electron microscopy, X-ray diffraction, and magnetic property measurements, which are vital for quality assurance, material research, and product development. These tools allow manufacturers to precisely analyze the microstructure, elemental composition, and magnetic characteristics of SmCo magnets, ensuring they meet stringent performance specifications for critical applications. The integration of advanced computational materials science and simulation tools, often leveraging Artificial Intelligence and Machine Learning, is becoming increasingly important for designing new SmCo alloys, predicting their properties, and optimizing manufacturing parameters without extensive trial-and-error experimentation. This holistic technological approach, from raw material processing to final product validation, enables the continuous innovation and high-performance output that defines the SmCo magnet market, ensuring its relevance in future high-tech applications despite inherent material challenges.

Regional Highlights

- Asia Pacific (APAC): Dominates the SmCo magnet market in both production and consumption, driven by robust manufacturing sectors in China, Japan, and South Korea. China, in particular, is a global leader in rare-earth element extraction and processing, forming the backbone of the SmCo magnet supply chain. The region's expanding electronics, automotive (especially EVs), and industrial automation industries fuel high demand for high-performance magnets. Significant investments in R&D and advanced manufacturing capabilities further strengthen APAC's market position, making it a critical hub for both innovation and volume production.

- North America: A key market for high-value and specialized SmCo magnet applications, particularly within the aerospace, defense, and medical device sectors. The stringent performance requirements and technological sophistication of these industries drive demand for premium-grade SmCo magnets. The presence of major defense contractors, aerospace manufacturers, and leading medical technology companies ensures a steady uptake of advanced magnetic solutions. While not a primary raw material source, the region excels in magnet design, integration, and application engineering, often focusing on customized, high-reliability components.

- Europe: Exhibits significant demand for SmCo magnets, especially from its well-established automotive (premium and luxury vehicles, specialized EV components), industrial automation, and energy sectors. European countries are at the forefront of developing advanced industrial machinery and robotic systems that rely on the thermal stability and precision of SmCo magnets. The region also has a strong presence in specialized medical equipment manufacturing and aerospace applications, driving demand for high-performance magnetic solutions. Germany, France, and the UK are prominent contributors to market growth, focusing on technological innovation and high-quality magnet production and application.

- Latin America: Represents an emerging market with gradual growth, driven by increasing industrialization, infrastructure development, and growing investment in specialized manufacturing. While smaller in scale compared to other regions, opportunities are arising in the automotive component manufacturing and some industrial automation segments as economies mature. The region is largely dependent on imports for SmCo magnets but shows potential for increased consumption in the long term as its technological capabilities expand.

- Middle East & Africa (MEA): A developing market for SmCo magnets, primarily influenced by investments in defense, oil & gas (for specialized sensors and drilling equipment), and nascent industrialization projects. Demand is currently more focused on specific, high-durability applications rather than broad industrial use. The region's growth trajectory is tied to its economic diversification efforts and the adoption of advanced technologies across various sectors, leading to a slow but steady increase in the consumption of high-performance magnetic materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the SmCo Magnet Market.- Shin-Etsu Chemical Co., Ltd.

- Hitachi Metals, Ltd. (now part of Resonac Corporation)

- TDK Corporation

- Daido Steel Co., Ltd.

- VACUUMSCHMELZE GmbH & Co. KG

- Dexter Magnetic Technologies, Inc.

- Arnold Magnetic Technologies Corporation

- Electron Energy Corporation

- Galaxy Magnets LLC

- Ningbo Yunsheng Co., Ltd.

- Yantai Shougang Magnetic Materials Inc.

- Hengdian Group DMEGC Magnetics Co., Ltd.

- Adams Magnetic Products Co., Inc.

- Hangzhou Permanent Magnet Group

- JL MAG Rare-Earth Co., Ltd.

- Earth-Panda Advanced Magnetic Material Co., Ltd.

- China Rare Earth Holdings Limited

- Chengdu Galaxy Magnets Co., Ltd.

- Bunting Magnetics Co.

- Stanford Magnets

Frequently Asked Questions

Analyze common user questions about the SmCo Magnet market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are SmCo magnets and what are their primary characteristics?

SmCo (Samarium Cobalt) magnets are a type of rare-earth permanent magnet known for high magnetic strength, exceptional thermal stability (operating temperatures up to 350°C), and excellent corrosion resistance. They are typically available in two main alloys: SmCo5 and Sm2Co17, with Sm2Co17 offering superior performance at higher temperatures. These properties make them ideal for demanding applications where reliability in extreme conditions is crucial.

In which industries are SmCo magnets predominantly used?

SmCo magnets are predominantly used in industries requiring high-performance magnetic materials in challenging environments. Key sectors include aerospace and defense (for guidance systems, motors, sensors), medical devices (MRI machines, pacemakers), high-performance automotive (EV motors, sensors), and industrial automation (robotics, magnetic couplings) due to their stability, strength, and resistance to high temperatures and corrosion.

What are the main advantages and disadvantages of SmCo magnets compared to other permanent magnets?

Advantages include superior thermal stability, high coercivity (resistance to demagnetization), and excellent corrosion resistance. Disadvantages primarily involve their high cost due to expensive and volatile raw materials (samarium and cobalt), and they generally exhibit lower magnetic strength than Neodymium magnets at room temperature, making them a specialized, high-cost solution for niche applications.

What drives the growth of the SmCo Magnet Market?

Market growth is driven by increasing demand for high-performance magnets in high-temperature applications, the miniaturization trend in electronics, the expansion of the electric vehicle (EV) market, rising global defense expenditures, and continuous advancements in medical technology and industrial automation requiring robust and reliable magnetic solutions.

What are the key challenges faced by manufacturers in the SmCo Magnet Market?

Manufacturers face significant challenges primarily related to the high cost and price volatility of rare-earth raw materials (samarium and cobalt), which impact production costs and supply chain stability. Additionally, competition from other magnet types, complex manufacturing processes, and strict environmental regulations for rare-earth mining and processing pose considerable operational and strategic hurdles for market players.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager