SMS Medical Nonwoven Fabric Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434191 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

SMS Medical Nonwoven Fabric Market Size

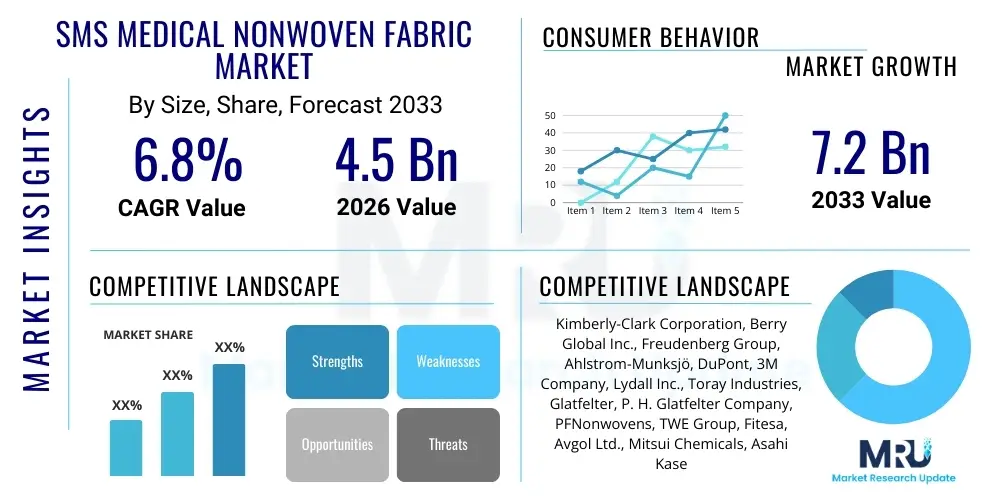

The SMS Medical Nonwoven Fabric Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033. This consistent expansion is fundamentally driven by the escalating global emphasis on infection control within healthcare settings, coupled with increasing surgical volumes worldwide. The versatility and superior barrier properties of SMS (Spunbond-Meltblown-Spunbond) nonwoven fabrics make them indispensable in manufacturing single-use medical protective gear, ensuring patient and professional safety.

SMS Medical Nonwoven Fabric Market introduction

The SMS Medical Nonwoven Fabric Market encompasses the production and distribution of composite nonwoven materials specifically engineered for healthcare and hygiene applications. SMS fabric is a tri-laminate material composed of two layers of spunbond (S) polypropylene surrounding one central layer of meltblown (M) polypropylene. This unique structural configuration provides high tensile strength, exceptional filtration efficiency, and fluid resistance, making it the material of choice for critical barrier applications such as surgical drapes, gowns, and face masks. The inherent lightweight nature, breathability, and cost-effectiveness compared to traditional woven textiles further solidify its position in the medical supply chain.

Major applications of SMS nonwoven fabrics span the entirety of hospital operations, focusing primarily on minimizing cross-contamination risks. Key products include high-performance surgical gowns offering AAMI levels 3 and 4 protection, sterilization wraps for maintaining the sterility of surgical instruments, and high-filtration face masks. The material's ability to resist microbial penetration while allowing sufficient air permeability is crucial for comfort and extended wear in demanding clinical environments. The rapid adoption rate during global health crises has permanently elevated the demand baseline for these essential protective textiles.

Driving factors for sustained market growth include favorable regulatory environments mandating higher standards for disposable medical products, particularly in developed economies. Furthermore, the global shift towards single-use instruments and protective apparel, aimed at reducing laundering costs and optimizing sterile processing, significantly boosts the consumption of SMS fabrics. Advances in polymer science and manufacturing processes, leading to enhanced material strength, improved softness, and increased sustainability options (such as bio-based or recyclable polypropylene), continue to propel innovation and market acceptance across various geographies.

SMS Medical Nonwoven Fabric Market Executive Summary

The SMS Medical Nonwoven Fabric Market exhibits robust growth, primarily propelled by global healthcare infrastructure expansion and a heightened focus on stringent infection control protocols. Business trends indicate a strong move toward supply chain localization and diversification following pandemic-related disruptions, leading major manufacturers to invest in increased production capacity in strategic regional hubs, particularly in Asia Pacific and North America. Companies are also focusing on material innovation, integrating antimicrobial treatments and developing lighter, yet more effective, barrier technologies to meet evolving end-user demands for comfort and superior protection. Mergers and acquisitions remain a key strategy for market consolidation and technology acquisition.

Regionally, the Asia Pacific (APAC) market is forecast to demonstrate the fastest growth rate, fueled by substantial growth in healthcare expenditure, expanding medical tourism, and a massive manufacturing base in countries like China and India. North America and Europe, while mature, maintain dominant market shares due to established regulatory frameworks and high levels of awareness regarding sterile surgical practices. Trends across these developed regions show a preference for premium, sustainable, and specialized SMS fabrics tailored for complex surgical procedures, driving higher average selling prices (ASPs).

Segment-wise, the application segment is dominated by surgical drapes and gowns, representing the largest volume consumers due to high frequency of use in operating theaters. However, the face masks and respirators segment witnessed unprecedented expansion and is expected to stabilize at a significantly higher base compared to pre-2020 levels. Technology trends emphasize composite SMS fabrics with enhanced fluid repellency and improved breathability characteristics. Polypropylene remains the core material, but increasing R&D efforts are focused on integrating sustainable polymers to comply with growing environmental mandates, signaling a future shift in material composition.

AI Impact Analysis on SMS Medical Nonwoven Fabric Market

Analysis of common user questions reveals significant interest regarding AI's role in optimizing the manufacturing process, ensuring quality control, and improving supply chain resilience within the SMS Medical Nonwoven Fabric sector. Users frequently inquire about how machine learning can predict raw material price volatility, automate quality inspection for microscopic defects in the fabric web, and optimize complex meltblown and spunbond extrusion processes for energy efficiency and reduced waste. Key concerns revolve around the capital investment required for AI integration and the potential need for highly specialized workforce retraining. Expectations are high regarding AI's ability to create 'smart fabrics' by precisely controlling fiber morphology and achieving bespoke barrier properties for highly specialized medical applications, ultimately driving efficiency and customization in a traditionally high-volume manufacturing domain.

- AI-driven predictive maintenance optimizes nonwoven production lines, minimizing downtime and increasing overall equipment effectiveness (OEE).

- Machine learning algorithms enhance quality assurance by performing real-time defect detection (pinholes, streaks) in the SMS web far exceeding human visual inspection capabilities.

- AI-powered supply chain management forecasts demand fluctuations (especially during crises), optimizing inventory levels for polypropylene and precursor chemicals.

- Computational fluid dynamics, often integrated with AI, assists in modeling and optimizing meltblown fiber distribution to achieve specific pore sizes and filtration efficiency goals.

- Robotics and AI are increasingly used in automated cutting, packaging, and sterilization processes of finished medical products made from SMS fabrics, ensuring sterile handling.

DRO & Impact Forces Of SMS Medical Nonwoven Fabric Market

The market is primarily driven by escalating global healthcare expenditures, demographic shifts leading to an aging population and higher surgical procedure volumes, and the stringent regulatory pressure demanding superior protective barriers in clinical environments. However, the market faces significant restraints, chiefly related to the volatile pricing of petrochemical-derived raw materials, particularly polypropylene, which directly impacts manufacturing costs and profit margins. Furthermore, growing environmental consciousness and concerns over the disposal of massive volumes of single-use plastics in the medical sector present a long-term challenge requiring innovative, sustainable material solutions. These forces collectively shape the competitive landscape and influence strategic decision-making across the value chain, from polymer suppliers to end-product converters.

Opportunities for growth are abundant in emerging economies where healthcare infrastructure is rapidly developing, driving substantial demand for affordable and effective protective gear. Technological opportunities lie in developing advanced composite nonwovens with antimicrobial coatings, enhanced electrostatic charging for filtration, and the integration of bio-based or biodegradable polymers to address sustainability concerns. The impact forces indicate a highly sensitive market where public health crises (like pandemics) exert an immediate, intense, and positive shock on demand, while economic downturns or sustained increases in oil prices create structural pressure on operational profitability.

The overall impact forces trajectory leans towards high growth, conditional on mitigating supply chain risks and successfully transitioning toward sustainable practices. The necessity of medical nonwovens for infection prevention ensures inherent stability, but market competition is intensifying, putting pressure on manufacturers to innovate in terms of both cost and performance. Successful market players must strategically balance material input costs (Restraint) against meeting strict regulatory compliance and increasing demand for high-performance barriers (Drivers) by leveraging process efficiency improvements (Opportunity) often facilitated by AI and advanced manufacturing techniques.

Segmentation Analysis

The SMS Medical Nonwoven Fabric Market is intricately segmented based on technology, application, end-user, and material type, reflecting the diverse requirements of the global healthcare industry. The core segmentation by technology differentiates between various combinations of spunbond and meltblown layers, such as standard SMS, SMMS (Spunbond-Meltblown-Meltblown-Spunbond), and composites, each offering distinct properties regarding breathability, barrier protection, and tensile strength. Analyzing these segments provides crucial insights into product specialization and market saturation levels across specific medical applications, informing R&D investment and targeted marketing strategies for manufacturers aiming to capture niche demand in highly regulated sectors.

- By Technology:

- Standard SMS

- SMMS (Spunbond-Meltblown-Meltblown-Spunbond)

- S-Meltblown-S (SFS) Composites

- By Material:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyester

- Others (including Bio-based Polymers)

- By Application:

- Surgical Drapes

- Surgical Gowns and Apparel

- Face Masks and Respirators

- Sterilization Wraps

- Wound Care Dressings

- Caps and Shoe Covers

- By End-User:

- Hospitals and Clinics

- Ambulatory Surgical Centers (ASCs)

- Reference Laboratories and Research Institutions

- Nursing Homes and Long-Term Care Facilities

Value Chain Analysis For SMS Medical Nonwoven Fabric Market

The value chain for the SMS Medical Nonwoven Fabric market starts with the upstream segment dominated by petrochemical companies supplying primary raw materials, predominantly polypropylene resin. The quality and stable pricing of these polymers are critical upstream factors influencing the final product cost. Manufacturers of nonwoven fabric utilize complex extrusion and bonding technologies to produce the SMS fabric rolls. Midstream activities involve the conversion of these large fabric rolls into specific medical finished goods, such as cutting, sewing, and specialized finishing (e.g., fluid repellent treatments or sterilization) of gowns, masks, and drapes by specialized converters.

The downstream distribution channel involves a complex network connecting converters to end-users. Direct distribution often occurs through large integrated manufacturers selling proprietary branded medical supplies directly to major hospital systems or government procurement agencies. Indirect distribution relies heavily on regional and global medical supply distributors and wholesalers, who manage inventory, logistics, and localized regulatory compliance, ensuring timely delivery to smaller clinics, ambulatory surgical centers, and long-term care facilities. The efficiency and reliability of this distribution network, particularly during peak demand, significantly impact market performance.

Profit margins tend to be highest in the downstream conversion and branding phases, where high-value added services like sterilization and customization are performed. Transparency and integration across the chain, especially vertical integration from nonwoven production to final product conversion, offer competitive advantages by controlling quality and reducing lead times. Ongoing global logistics challenges necessitate robust distribution strategies that minimize reliance on single-source transportation routes and emphasize regional warehousing capabilities for critical protective equipment.

SMS Medical Nonwoven Fabric Market Potential Customers

The primary customers (end-users/buyers) of SMS medical nonwoven fabrics are large institutional healthcare providers requiring substantial volumes of disposable protective equipment and barrier materials. Hospitals, particularly those with high volumes of surgical procedures, trauma units, and intensive care facilities, represent the largest and most frequent buyers. Their procurement decisions are often driven by stringent regulatory standards (e.g., FDA, European standards) and clinical efficacy requirements, favoring materials offering high AAMI levels of protection.

Ambulatory Surgical Centers (ASCs) and specialized clinics, which focus on outpatient procedures, constitute a rapidly expanding customer segment. While their individual purchasing volumes might be smaller than major hospitals, their collective growth and preference for cost-effective, readily disposable materials make them highly valuable clients. These centers typically prioritize ease of use and standardized product formats that facilitate quick turnover between procedures.

Additional significant customers include government and public health agencies that procure strategic reserves of personal protective equipment (PPE) for emergency preparedness, and pharmaceutical/biotechnology research institutions that require sterile apparel for controlled laboratory environments. The growing segment of elderly care and long-term care facilities also represents a steady customer base, utilizing SMS fabrics primarily for basic isolation gowns, hygiene products, and protective bedding applications, driven by infection prevention mandates.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kimberly-Clark Corporation, Berry Global Inc., Freudenberg Group, Ahlstrom-Munksjö, DuPont, 3M Company, Lydall Inc., Toray Industries, Glatfelter, P. H. Glatfelter Company, PFNonwovens, TWE Group, Fitesa, Avgol Ltd., Mitsui Chemicals, Asahi Kasei, Indorama Ventures, Jofo Nonwovens. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

SMS Medical Nonwoven Fabric Market Key Technology Landscape

The technology landscape of the SMS Medical Nonwoven Fabric market is defined by continuous advancements in polymer extrusion and bonding techniques designed to enhance barrier performance, comfort, and sustainability. The core technology remains the combination of spunbond and meltblown processes. Spunbond layers provide strength and structure, while the central meltblown layer, characterized by extremely fine fibers, delivers the essential microbial barrier and filtration capabilities. Recent technological focuses include improving the uniformity of the meltblown web for consistent pore size distribution, which is critical for filtration efficacy in masks and respirators, and developing composite structures like SMMS (four layers) or SMMMS (five layers) to offer superior hydrostatic pressure resistance demanded by Level 4 protective gowns.

Beyond structural improvements, surface modification technologies are gaining traction. This includes the application of specialized finishes such as fluorocarbons or plasma treatments to achieve high levels of liquid repellency without compromising breathability, a necessary balance for surgical applications. Furthermore, the integration of advanced electrostatic charging methods during or immediately after the meltblowing process is crucial for enhancing the particle capture efficiency of filter media used in N95/FFP2 equivalent respirators, ensuring compliance with rigorous safety standards while maintaining low breathing resistance.

Sustainability is driving innovation in fiber technology, leading to exploration of alternative polymers. While polypropylene remains dominant, key manufacturers are investing heavily in technologies utilizing bio-based polyolefins derived from renewable resources or developing methods to incorporate recycled content (e.g., post-consumer resin) back into non-critical layers of the SMS structure. The goal is to produce materials that maintain medical-grade performance and disposability but possess a lower environmental footprint, catering to institutional buyers increasingly mandated to meet green procurement targets.

Regional Highlights

The global consumption and production of SMS medical nonwoven fabrics show distinct regional patterns influenced by healthcare spending, manufacturing capacity, and regulatory environments. North America, driven primarily by the United States, holds a significant market share characterized by high adoption rates of premium disposable medical products and stringent safety standards set by organizations like the FDA and CDC. The region benefits from a robust and mature healthcare system with substantial investment in advanced surgical procedures and infection control measures.

Europe represents another mature market with high demand, largely influenced by the European Medical Device Regulation (MDR), which enforces high-quality standards for all sterile barriers and protective apparel. Countries like Germany, France, and the UK are major consumers, emphasizing innovative, high-performance, and increasingly sustainable material choices, reflecting strong environmental policies and well-established clinical protocols.

Asia Pacific (APAC) is recognized as the fastest-growing region, simultaneously serving as a massive consumption market (due to large populations and expanding health infrastructure in China, India, and Southeast Asia) and the world's primary manufacturing hub. Investment in local nonwoven production capacity has surged, catering not only to regional demand but also serving as a major exporter of finished medical textiles globally. This region's growth is largely supported by expanding medical tourism and increased public awareness regarding healthcare hygiene.

Latin America and the Middle East & Africa (MEA) are emerging markets, showing consistent, albeit slower, growth. Demand in these regions is primarily concentrated in urban centers with better-funded private healthcare facilities. Adoption is stimulated by improving economic conditions and the gradual implementation of international infection control guidelines, though market penetration remains constrained by price sensitivity and dependency on imported finished goods.

- North America: Dominant market share; driven by high healthcare expenditure, stringent FDA regulations, and adoption of premium protective equipment.

- Asia Pacific (APAC): Highest growth rate; propelled by expanding healthcare infrastructure, high surgical volumes, and robust manufacturing capabilities (China, India).

- Europe: Mature market; emphasis on high regulatory compliance (MDR) and strong preference for technologically advanced and sustainable nonwoven solutions.

- Latin America & MEA: Emerging markets; characterized by increasing adoption rates in private sectors and reliance on cost-effective import solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the SMS Medical Nonwoven Fabric Market.- Kimberly-Clark Corporation

- Berry Global Inc.

- Freudenberg Group

- Ahlstrom-Munksjö

- DuPont

- 3M Company

- Lydall Inc.

- Toray Industries

- Glatfelter

- P. H. Glatfelter Company

- PFNonwovens

- TWE Group

- Fitesa

- Avgol Ltd.

- Mitsui Chemicals

- Asahi Kasei

- Indorama Ventures

- Jofo Nonwovens

- Georgia-Pacific LLC

- Nonwovens of America (NOA)

Frequently Asked Questions

Analyze common user questions about the SMS Medical Nonwoven Fabric market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are driving the growth of the SMS Medical Nonwoven Fabric market?

Market growth is primarily driven by the mandatory adoption of strict infection control practices globally, the increased volume of surgical procedures due to aging populations, and the established regulatory frameworks demanding high-performance, single-use barrier materials in healthcare settings worldwide.

What is the key advantage of SMS material over traditional woven textiles in medical applications?

SMS nonwoven fabric offers superior barrier protection against fluid penetration and microbial transmission due to its integrated meltblown layer, while also providing high tensile strength and cost-effectiveness through single-use disposability, eliminating laundering and sterilization challenges associated with wovens.

Which geographical region holds the largest market share for SMS medical nonwovens?

North America currently holds the largest market share, driven by high per capita healthcare spending and rapid adoption of advanced disposable medical supplies, although the Asia Pacific region is projected to exhibit the fastest Compound Annual Growth Rate (CAGR) through 2033 due to expanding manufacturing bases and healthcare systems.

How are sustainability concerns impacting the future development of SMS fabrics?

Sustainability concerns are driving manufacturers to invest heavily in R&D for bio-based and biodegradable polymers to replace conventional polypropylene, along with improving recycling technologies for non-critical fabric components, aiming to produce medical-grade materials with reduced environmental footprints.

What are the primary applications of SMS medical nonwoven fabrics?

The primary applications include manufacturing essential protective equipment such as surgical drapes, high-level protective gowns, sterilization wraps for instrument kits, and advanced filtration media used in N95/FFP2 face masks and respirators.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager