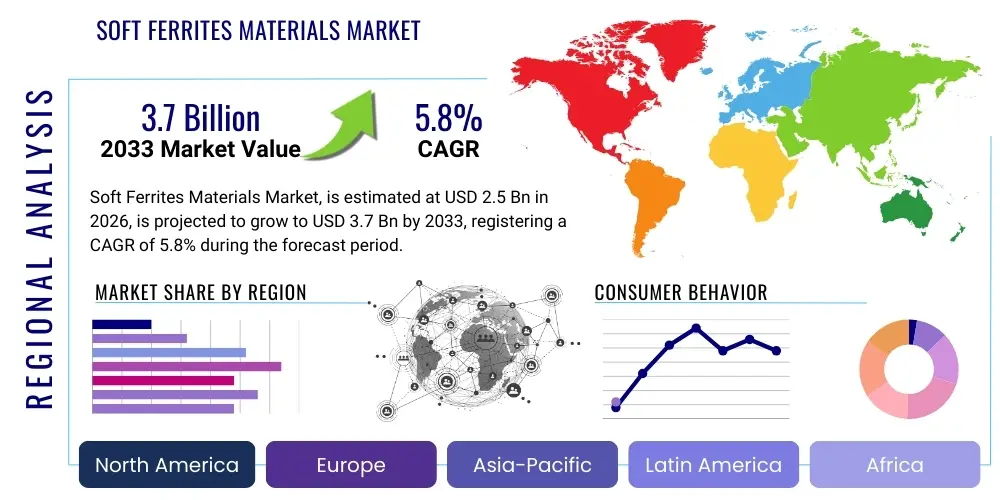

Soft Ferrites Materials Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435901 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Soft Ferrites Materials Market Size

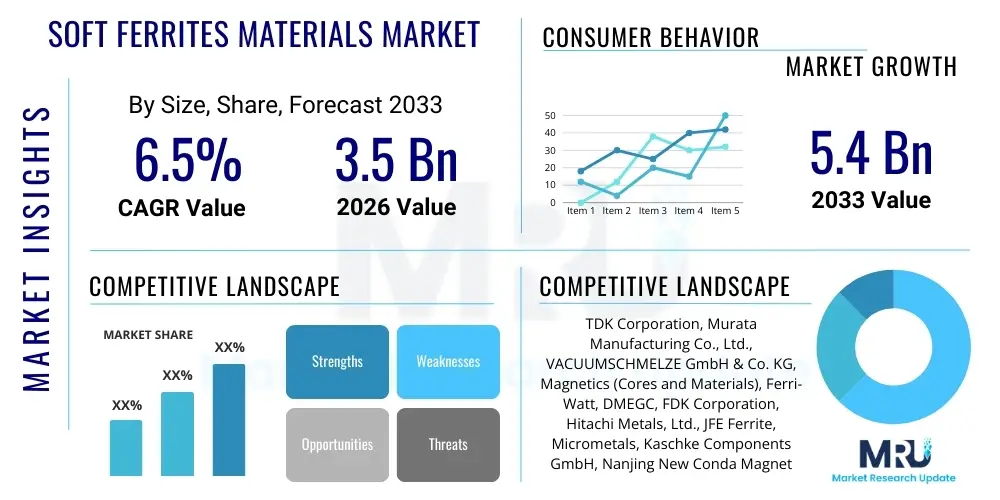

The Soft Ferrites Materials Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.4 Billion by the end of the forecast period in 2033.

Soft Ferrites Materials Market introduction

Soft ferrites are specialized ceramic materials characterized by high magnetic permeability and low coercivity, making them ideal for applications requiring rapid magnetization and demagnetization with minimal energy loss. These materials, primarily composed of iron oxides mixed with other metal oxides such as manganese, zinc, or nickel, are crucial components in modern electronics and power systems. Their non-conductive nature and exceptional performance at high frequencies distinguish them from metallic magnetic materials, ensuring their indispensable role in electromagnetic interference (EMI) suppression, high-frequency power conversion, and signal transmission.

The product portfolio of soft ferrites encompasses various grades, notably Manganese-Zinc (MnZn) ferrites, which excel in low-frequency applications and power transformers, and Nickel-Zinc (NiZn) ferrites, favored for higher frequency noise filtering and telecommunications equipment due to their high resistivity. Major applications span across critical sectors including automotive electronics, where they are used in electric vehicle charging systems and onboard sensors; consumer electronics, particularly in smartphones and computing devices for power inductors and chokes; and telecommunications infrastructure, supporting 5G network rollout through advanced filtering components.

Key benefits derived from soft ferrites include superior volumetric efficiency, excellent thermal stability, and effective electromagnetic compatibility (EMC). Driving factors for market expansion include the global surge in demand for compact and efficient electronic devices, the rapid deployment of 5G technologies necessitating high-frequency passive components, and the accelerating electrification trend in the automotive industry, which requires robust power management solutions utilizing specialized magnetic cores.

Soft Ferrites Materials Market Executive Summary

The Soft Ferrites Materials Market is experiencing robust growth driven primarily by structural shifts across key end-use industries, particularly the escalating integration of power electronics and sensing technologies in industrialized economies. Business trends indicate a strong focus on developing ultra-low loss ferrites optimized for GaN and SiC power architectures, enabling significant advancements in power density and operational efficiency across data centers and renewable energy infrastructure. The market is witnessing increased consolidation among key players who are strategically investing in advanced manufacturing processes, such as thin-film technology for miniature components, to cater to the miniaturization demands of portable electronics and medical devices.

Regionally, the Asia Pacific (APAC) region maintains its dominance, serving as both the primary manufacturing hub for electronic goods and the largest consumer base for soft ferrites, propelled by massive investments in 5G and ongoing industrial automation in China, Japan, and South Korea. North America and Europe demonstrate steady, quality-driven growth, emphasizing high-performance, specialized ferrite cores utilized in electric vehicle charging infrastructure, aerospace systems, and high-reliability industrial power supplies. Geopolitical factors influencing global supply chains are prompting diversification, encouraging investment in localized production capacities, particularly in Southeast Asia and parts of Europe, aiming to mitigate risks associated with centralized raw material sourcing and processing.

Segment trends highlight the significant uptake of MnZn ferrites within high-power applications, benefiting from the growing need for efficient power conversion in electric vehicles (EVs) and photovoltaic inverters. Meanwhile, NiZn ferrites are seeing heightened demand for high-frequency electromagnetic interference (EMI) suppression components essential for maintaining signal integrity in increasingly complex and crowded electronic environments, such as those found in advanced driver-assistance systems (ADAS) and high-speed data communications. Furthermore, the push towards green energy solutions is creating substantial opportunity for soft ferrites in induction heating and wireless power transfer systems, cementing the material’s critical role in future technology landscapes.

AI Impact Analysis on Soft Ferrites Materials Market

Common user questions regarding AI's impact on the Soft Ferrites Materials Market predominantly center on how artificial intelligence and machine learning (ML) optimize material discovery, enhance manufacturing efficiency, and drive the demand for AI-specific components. Users frequently inquire about the potential for AI models to predict optimal ferrite compositions for specific magnetic characteristics (e.g., lower power loss at higher temperatures) and whether AI-driven robotics and quality control systems are standardizing production processes. Key concerns revolve around the increased computational demands of AI hardware (data centers, edge devices), which require high-reliability power inductors and efficient thermal management—components heavily reliant on advanced soft ferrites. The consensus is that AI is not only a consumer of soft ferrites (in powering its hardware) but also a transformative tool in their design and fabrication.

The application of AI in materials science allows researchers to rapidly screen thousands of potential metal oxide combinations, significantly accelerating the development cycle for next-generation soft ferrites characterized by superior magnetic properties under extreme operating conditions. Machine learning algorithms are instrumental in optimizing sintering temperatures, cooling profiles, and pressure settings in the production line, thereby reducing energy consumption and minimizing batch variability. This AI-driven precision ensures that manufacturers can consistently meet the stringent specifications required for components used in sensitive electronics, such as autonomous systems and high-frequency communication modules.

Furthermore, the massive deployment of AI processing capabilities, especially in cloud infrastructure and specialized edge computing platforms, necessitates highly efficient power delivery networks to handle substantial power transients and minimize latency. Soft ferrites play an integral role in the filters and inductors within these power systems, and AI models are being used to design cores tailored precisely for these demanding environments, optimizing shapes and air gaps for maximum performance and minimal electromagnetic crosstalk. This symbiotic relationship—where AI accelerates ferrite innovation and relies on ferrites for its power infrastructure—is a central theme driving forward-looking investment and R&D strategies within the market.

- AI optimizes material composition prediction, leading to faster discovery of high-performance ferrite grades.

- Machine learning enhances manufacturing process control, improving yield rates and reducing energy consumption during sintering.

- Increased demand for AI hardware (data centers, edge devices) boosts the need for high-efficiency soft ferrite power inductors and EMI suppressors.

- AI-driven automated inspection systems improve quality control, ensuring ferrite components meet stringent reliability standards for critical applications.

- Predictive maintenance using AI minimizes downtime in ferrite manufacturing equipment, optimizing operational expenditure (OPEX).

DRO & Impact Forces Of Soft Ferrites Materials Market

The Soft Ferrites Materials Market is profoundly shaped by a combination of strong technological drivers, inherent material constraints, and significant market opportunities, collectively forming complex impact forces. The primary driver is the pervasive technological shift towards miniaturization, higher operational frequencies, and the critical need for power efficiency across almost all electronic systems. This is coupled with the massive electrification push in the automotive sector, where high-power density converters and charging systems demand specialized, thermally stable soft ferrites. Restraints largely revolve around supply chain vulnerability, specifically the volatile pricing and sourcing difficulties associated with key raw materials like iron oxide, manganese, nickel, and zinc, which can significantly impact production costs and market competitiveness. Furthermore, the inherent saturation magnetization limitations of ferrites compared to metallic alloys pose a technical constraint in extremely high-power applications, driving continuous R&D into composite materials.

Significant opportunities emerge from the rollout of global 5G and 6G infrastructure, requiring millions of high-frequency filtering and coupling components for base stations and end-user devices. The rapidly expanding renewable energy sector, including solar inverters and grid stabilization equipment, provides a fertile ground for high-reliability MnZn ferrites. The ongoing development of wireless power transfer (WPT) technology, used in consumer electronics and industrial automation, relies heavily on high-Q factor ferrite sheets and cores, presenting a high-growth niche. The collective impact forces show a positive trajectory, where the necessity for superior electromagnetic compatibility (EMC) in complex electronic systems overrides moderate cost fluctuations, sustaining premium pricing for specialized, high-performance soft ferrite products.

The market faces pressure from substitution risks, particularly from amorphous and nanocrystalline alloys in specific high-end power applications where their higher saturation flux density is advantageous. However, soft ferrites maintain a dominant position in high-frequency, low-loss applications due to their high resistivity and superior cost-performance ratio. The imperative for environmental sustainability also acts as a driver, promoting the use of energy-efficient ferrite-based components over less efficient alternatives, aligning market growth with global efforts to reduce energy consumption in electronics. Overall market momentum is driven by technological advancement and regulatory requirements mandating higher efficiency standards, which soft ferrites are uniquely positioned to address.

Segmentation Analysis

Segmentation of the Soft Ferrites Materials Market provides a granular view of distinct application fields and material preferences, crucial for targeted strategic planning. The market is primarily segmented based on Material Type (MnZn, NiZn, MgZn), Application (Inductors, Transformers, Chokes, EMI Filters), and End-User Industry (Automotive, Consumer Electronics, Telecommunications, Energy & Power). The Material Type segmentation is fundamental, distinguishing between MnZn ferrites, optimized for low loss up to 1 MHz and suitable for power applications, and NiZn ferrites, which offer higher resistance and are essential for applications above 1 MHz, such as high-frequency noise suppression and RF components.

The application segmentation highlights the functional role of ferrites. Transformers and inductors represent the largest segments, underpinned by the continuous growth in power supply units (PSUs) and DC-DC converters required for modern computing and industrial machinery. EMI filters are rapidly growing due to the proliferation of high-speed digital circuits and the regulatory push for enhanced electromagnetic compatibility, necessitating specialized ferrite beads and cores to suppress unwanted noise. End-user segmentation reveals the critical dependence of the Consumer Electronics and Automotive sectors on soft ferrites; the former drives volume demand for miniaturized components, while the latter drives demand for rugged, high-reliability materials capable of operating under harsh thermal conditions.

Analyzing these segments reveals that the power application segments (Inductors and Transformers, utilizing MnZn) are expected to capture the majority revenue share throughout the forecast period due to the global energy transition and the burgeoning EV market. However, the telecommunications and industrial automation segments (heavily utilizing NiZn for filtering and sensing) are projected to exhibit the highest CAGR, reflective of the intensive infrastructure upgrades associated with 5G and Industry 4.0 adoption globally. Strategic focus must therefore balance volume production for traditional markets with R&D intensity for specialized, high-growth niche segments demanding bespoke magnetic characteristics.

- Material Type:

- Manganese-Zinc (MnZn) Ferrites

- Nickel-Zinc (NiZn) Ferrites

- Magnesium-Zinc (MgZn) Ferrites

- Other Ferrite Compositions (e.g., LiZn, BaZn)

- Application:

- Inductors (Power & Signal)

- Transformers (Power & Flyback)

- Chokes and Coils

- EMI/RFI Filters and Absorbers (Ferrite Beads)

- Magnetic Sensors

- End-User Industry:

- Consumer Electronics (Smartphones, PCs, Home Appliances)

- Automotive (EVs, ADAS, Charging Infrastructure)

- Telecommunications & IT (5G Base Stations, Data Centers)

- Energy & Power (Inverters, Power Supplies, Renewable Energy)

- Industrial (Automation, Robotics, Medical Devices)

- Aerospace and Defense

Value Chain Analysis For Soft Ferrites Materials Market

The value chain for the Soft Ferrites Materials Market begins with the highly specialized upstream analysis centered on the sourcing and processing of core raw materials, primarily high-purity iron oxide (Fe2O3), manganese oxide (MnO), nickel oxide (NiO), and zinc oxide (ZnO). This stage involves complex chemical synthesis and refinement to ensure the oxides meet the stringent purity requirements necessary for achieving optimal magnetic properties during the subsequent sintering process. Suppliers in this upstream segment must demonstrate robust quality control and secure supply contracts, as fluctuations in metal commodity prices directly influence the cost structure of the final ferrite product. Strategic partnerships between ferrite manufacturers and specialized chemical suppliers are critical to mitigating supply volatility.

The manufacturing stage involves the precision mixing of powders, calcination, grinding, forming (using techniques like pressing or extrusion), and the critical final high-temperature sintering process where the ceramic microstructure develops its defining magnetic characteristics. Manufacturers invest heavily in proprietary processing techniques to control grain size, porosity, and density, which are determinants of parameters like magnetic permeability and core loss. The midstream involves core shaping and finishing, often customized to specific geometries (E-cores, toroids, rods, beads) dictated by the end-application, requiring sophisticated tooling and high-precision machinery.

Downstream analysis focuses on the distribution channels and end-user integration. Soft ferrites are distributed through a dual system: direct sales to large, Tier 1 electronic manufacturing service (EMS) providers and original equipment manufacturers (OEMs), particularly in the automotive and telecommunications sectors, ensuring technical support and tailored solutions. Indirect distribution involves specialized electronic component distributors who handle small-to-mid volume orders, inventory management, and fulfillment for a vast network of smaller industrial and consumer electronics manufacturers. The final value addition occurs when the ferrite components are integrated into complex systems, serving as vital elements in power management circuits, signal integrity assurance, and electromagnetic shielding within high-value electronic devices, ultimately ensuring the functional reliability and efficiency of the overall system.

Soft Ferrites Materials Market Potential Customers

The primary potential customers for soft ferrites materials are large-scale Original Equipment Manufacturers (OEMs) and Electronics Manufacturing Services (EMS) providers across diverse high-technology sectors. The Automotive Industry represents a critical customer segment, driven by manufacturers focusing on electric and hybrid vehicles, requiring soft ferrites for high-frequency DC-DC converters, on-board chargers (OBCs), wireless charging coils, and noise suppression in complex sensor systems like ADAS. These buyers demand materials that offer high thermal stability and predictable performance across a wide operating temperature range, prioritizing reliability and automotive-grade certification above raw cost.

Another major customer base resides within the Consumer Electronics sector, including leading producers of smartphones, laptops, smart home devices, and gaming consoles. These buyers are volume-driven and prioritize miniaturization and cost efficiency, requiring tiny, high-performance soft ferrite beads and chip inductors to manage power and suppress EMI in increasingly crowded circuit boards. The rapid refresh cycle and intense competition within this sector necessitate fast-paced innovation in ferrite materials that can deliver higher inductance per unit volume without compromising efficiency, often driving the development of specialized NiZn compositions.

Furthermore, telecommunications and IT infrastructure companies, including data center operators and 5G equipment manufacturers (e.g., networking hardware providers), constitute an expanding segment. These customers require MnZn ferrites for high-efficiency power transformers in servers and NiZn ferrites for high-frequency filters in base station transmission paths. Their purchasing decisions are heavily influenced by power loss characteristics and thermal dissipation capabilities, as energy efficiency in massive server farms is paramount to operational costs. The Energy & Power sector, encompassing manufacturers of solar inverters, grid-tied energy storage systems, and industrial automation equipment, also represents a significant high-value customer base seeking robust, high-power soft ferrite solutions designed for sustained, heavy-duty operation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.4 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TDK Corporation, Murata Manufacturing Co., Ltd., VACUUMSCHMELZE GmbH & Co. KG, Magnetics (Cores and Materials), Ferri-Watt, DMEGC, FDK Corporation, Hitachi Metals, Ltd., JFE Ferrite, Micrometals, Kaschke Components GmbH, Nanjing New Conda Magnetic Co., Ltd., Haining Lianfeng Magnet Industry Co., Ltd., Cosmo Ferrites Ltd., KDM Magnetic Materials Co., Ltd., Steward Advanced Materials, Acro-Magnetics, Powertronix, Sinomag Technology Co., Ltd., Toshiba Materials Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Soft Ferrites Materials Market Key Technology Landscape

The Soft Ferrites Materials market is characterized by ongoing technological advancements focused primarily on improving power density, reducing core losses, and expanding operational frequency ranges. A key technological trend is the development of ultra-low loss MnZn ferrites optimized for high-frequency switching applications, which are increasingly necessary for integrating with wide bandgap semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN). These new ferrite formulations minimize energy dissipation at switching frequencies exceeding 1 MHz, thereby supporting the next generation of highly compact and efficient power converters utilized in electric vehicles and solar inverters. Manufacturers employ specialized grain boundary engineering and sophisticated additive techniques to achieve these superior characteristics, moving beyond conventional ceramic processing methods.

Another crucial technological area is the advancement in processing techniques for miniaturization. As electronic devices shrink, there is a heightened requirement for soft ferrite components in chip form factors, such as multilayer chip inductors (MLCIs) and surface-mount device (SMD) ferrite beads. This necessitates breakthroughs in thin-film deposition and low-temperature co-fired ceramic (LTCC) technologies applied to ferrite materials. These fabrication methods allow for highly precise patterning and layer stacking, enabling manufacturers to integrate high-Q factor magnetic elements onto tiny substrates, critical for signal integrity and power management in highly integrated circuits like system-on-chips (SoCs) within consumer electronics.

Furthermore, significant R&D efforts are directed toward improving the temperature stability of soft ferrites. Components in automotive and industrial environments often face extreme thermal cycles, which can degrade magnetic performance. New material compositions are being developed to maintain stable magnetic permeability and low core loss across expanded temperature ranges (e.g., -40°C to +150°C). This stability is paramount for critical applications like ADAS sensors and medical imaging equipment, ensuring consistent operational reliability regardless of ambient conditions. The technology landscape is thus defined by material innovation driven by physics (ultra-low loss) and manufacturing precision driven by engineering (miniaturization and quality control).

Regional Highlights

- North America: Focus on high-reliability, aerospace, and EV technologies.

- Europe: Strong demand driven by automotive electrification and stringent EMC regulations.

- Asia Pacific (APAC): Dominance due to massive manufacturing base and rapid 5G infrastructure deployment.

- Latin America: Emerging market growth linked to industrial modernization and power infrastructure projects.

- Middle East and Africa (MEA): Gradual uptake in renewable energy projects and telecommunications expansion.

The Asia Pacific (APAC) region stands as the dominant market for soft ferrites materials, driven by its unparalleled concentration of electronic manufacturing hubs, particularly in China, Japan, South Korea, and Taiwan. These countries collectively produce the vast majority of consumer electronics, automotive components, and IT hardware globally, creating sustained, massive volume demand for all types of ferrite cores and components. The aggressive rollout of 5G networks throughout APAC has specifically fueled the demand for NiZn ferrites required for high-frequency filtering and EMI suppression in base stations and communication devices. Moreover, substantial government investment in electric vehicle production and renewable energy infrastructure across the region further solidifies APAC's leadership, requiring specialized high-power MnZn ferrites for power conversion systems. The competitive nature of the manufacturing base in APAC, while driving down unit costs, simultaneously encourages innovation in high-volume, cost-effective processing techniques.

North America represents a mature yet highly quality-focused market, characterized by demand for sophisticated, high-performance soft ferrites used in specialized sectors such as aerospace, defense, and high-reliability industrial controls. The U.S. market is significantly influenced by the rapid adoption of advanced driver-assistance systems (ADAS) and domestic electric vehicle manufacturing, creating a consistent need for automotive-grade components with superior thermal stability. Furthermore, the immense scale of cloud computing and data center infrastructure in North America necessitates cutting-edge MnZn ferrites optimized for high-density, low-loss power supplies, often driving the premium segment of the market. Regulatory environments promoting energy efficiency and electromagnetic compatibility standards also compel manufacturers to adopt the highest quality ferrite solutions available.

Europe mirrors North America in its focus on high-reliability and high-efficiency applications, with a strong regional emphasis on automotive electrification and stringent environmental regulations. European automotive OEMs are leaders in integrating advanced power electronics, translating into high demand for MnZn cores in traction inverters and charging systems. Additionally, Europe's robust industrial automation sector (Industry 4.0) relies heavily on soft ferrites for ensuring signal integrity and power quality in sophisticated robotic systems and control modules. The strict regulatory framework governing electromagnetic compatibility (EMC) in the European Union mandates the widespread use of high-performance ferrite solutions across all imported and domestically manufactured electronic goods, ensuring steady, quality-driven growth.

Latin America and the Middle East and Africa (MEA) currently hold smaller market shares but are poised for rapid growth linked to infrastructure development. In Latin America, investments in industrial modernization, coupled with expansion in automotive assembly plants and telecommunications networks, are gradually increasing the local demand for soft ferrites. Countries like Brazil and Mexico are emerging as important manufacturing and consumption centers. MEA's market expansion is primarily contingent on large-scale renewable energy projects (solar farms, wind energy) and extensive telecommunications infrastructure rollouts, particularly in the Gulf Cooperation Council (GCC) countries and South Africa. While these regions currently rely heavily on imports, localized demand for replacement parts and minor assembly operations is incrementally building, indicating future opportunities for regional market penetration and distribution expansion.

The strategic importance of localized supply chains is becoming increasingly evident across all regions. Geopolitical pressures and lessons learned from pandemic-related supply chain disruptions have encouraged electronic manufacturers in North America and Europe to seek regional sourcing options for critical components like soft ferrites, potentially leading to capacity expansion or strategic joint ventures outside of traditional APAC manufacturing strongholds. This trend, known as regionalization, is reshaping the competitive landscape and driving specialized investment in high-automation ferrite production facilities closer to the end-user markets, particularly those serving the high-reliability automotive and defense sectors.

In summary, while APAC drives the volume and competitive pricing aspects of the global market, North America and Europe anchor the high-value, quality-critical segments. Future growth projections indicate sustained dominance by APAC, but with increasingly significant growth contributions from specialized, high-performance applications globally, fueled by the widespread adoption of power-efficient technologies mandated by energy transition goals. Continuous technological collaboration between ferrite material developers and leading OEMs in these key regions is essential for maintaining market vitality and addressing evolving electronic design challenges, such as operating frequency limitations and thermal dissipation requirements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Soft Ferrites Materials Market.- TDK Corporation

- Murata Manufacturing Co., Ltd.

- VACUUMSCHMELZE GmbH & Co. KG

- Magnetics (Cores and Materials)

- Ferri-Watt

- DMEGC

- FDK Corporation

- Hitachi Metals, Ltd. (now owned by JFE Steel)

- JFE Ferrite

- Micrometals

- Kaschke Components GmbH

- Nanjing New Conda Magnetic Co., Ltd.

- Haining Lianfeng Magnet Industry Co., Ltd.

- Cosmo Ferrites Ltd.

- KDM Magnetic Materials Co., Ltd.

- Steward Advanced Materials

- Acro-Magnetics

- Powertronix

- Sinomag Technology Co., Ltd.

- Toshiba Materials Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Soft Ferrites Materials market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between MnZn and NiZn soft ferrites?

MnZn (Manganese-Zinc) ferrites exhibit higher magnetic permeability and lower core losses, making them ideal for high-power, lower-frequency applications (below 5 MHz), such as power transformers and inductors. NiZn (Nickel-Zinc) ferrites offer significantly higher electrical resistivity and are preferred for high-frequency applications (above 5 MHz to GHz range), primarily used for EMI suppression and filtering due to their stability at higher operating frequencies.

How is the electric vehicle (EV) market impacting the demand for soft ferrites?

The EV market is a major growth driver, requiring high volumes of specialized MnZn soft ferrites for critical power electronics components, including on-board chargers, traction inverters, and high-frequency DC-DC converters. These applications demand materials with superior thermal stability and extremely low power loss to maximize battery range and efficiency, thus driving innovation toward advanced ferrite compositions.

What is the role of soft ferrites in 5G infrastructure?

Soft ferrites, particularly NiZn types, are essential in 5G infrastructure for electromagnetic interference (EMI) suppression and signal integrity management. They are used in various forms (beads, chips, cores) within 5G base stations and user equipment to filter high-frequency noise and prevent signal degradation, ensuring reliable and high-speed data transmission required by modern wireless networks.

What are the main technical limitations facing soft ferrites?

The primary technical limitation is the saturation flux density (Bs), which is generally lower than that of metallic magnetic materials (like amorphous or nanocrystalline alloys). This constraint limits their use in extremely high-power applications where high magnetic flux is required. Additionally, maintaining low core loss at increasingly higher operating temperatures and frequencies presents a continuous material science challenge for manufacturers.

Which regions demonstrate the highest growth potential for soft ferrites?

While the Asia Pacific (APAC) region currently holds the largest market share due to its manufacturing dominance, the highest growth potential is concentrated within the segments serving electrification in North America and Europe, alongside the global infrastructure build-out of 5G/6G, particularly across rapidly industrializing parts of APAC and emerging economies investing in new energy infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager