Soft Robotics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433443 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Soft Robotics Market Size

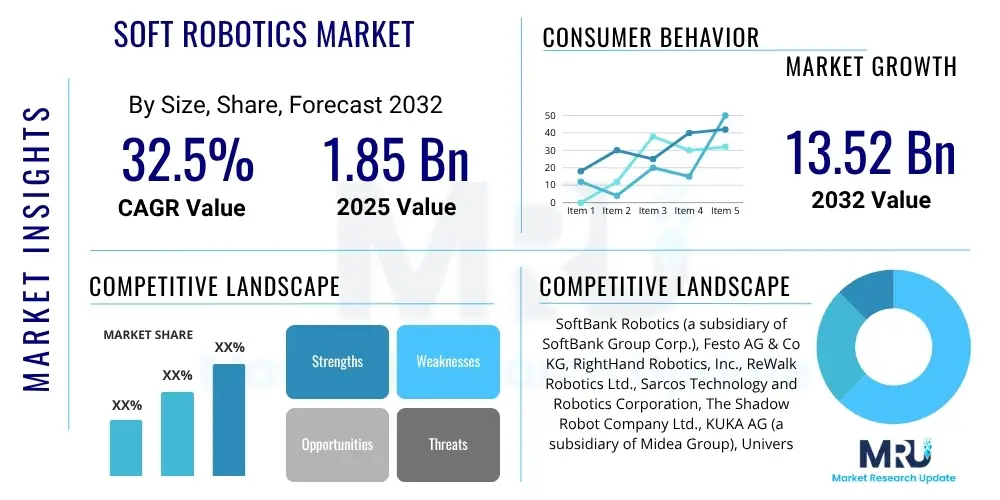

The Soft Robotics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 35.5% between 2026 and 2033. The market is estimated at $850 Million in 2026 and is projected to reach $7,000 Million by the end of the forecast period in 2033. This substantial growth trajectory is underpinned by the increasing necessity for highly dexterous and adaptable robotic solutions across specialized applications, particularly in delicate manufacturing, medical procedures, and challenging environmental exploration. The rapid advancement in material science, specifically compliant polymers and smart actuators, is fundamentally expanding the capabilities and commercial viability of soft robotic systems, moving them from niche research applications into mainstream industrial tools.

Market expansion is also heavily influenced by continuous investment in research and development, primarily focused on enhancing the integration of sensing capabilities and artificial intelligence for complex control algorithms. Soft robots offer inherent advantages over traditional rigid robots, including enhanced safety when operating near humans (co-robotics), better manipulation of fragile or irregularly shaped objects, and greater resilience to impact. These intrinsic benefits position soft robotics as a critical enabling technology for next-generation automation systems, addressing limitations faced by conventional industrial machinery.

Soft Robotics Market introduction

The Soft Robotics Market encompasses the design, production, and application of robotic systems constructed from highly compliant and elastic materials, often utilizing internal fluid pressure (pneumatic or hydraulic), electroactive polymers, or smart material systems for actuation. Unlike conventional rigid robots that rely on discrete joints and solid linkages, soft robots leverage body compliance for motion and interaction, providing unparalleled dexterity and adaptability. These systems are inherently safer for human interaction, making them indispensable for collaborative environments (cobots) and critical in scenarios requiring gentle handling or interaction with organic structures. Key products include flexible grippers, soft wearable devices, highly adaptable manipulators, and miniature surgical tools.

Major applications of soft robotics span critical industries, including advanced manufacturing, where they are used for precise grasping and sorting of delicate components; healthcare, encompassing minimally invasive surgery, prosthetics, and rehabilitation exoskeletons; and logistics, where they optimize handling of heterogeneous packages. The core benefits derived from soft robotics adoption include enhanced system safety, increased operational flexibility, and superior handling capabilities for fragile materials. Furthermore, their ability to navigate and operate in constrained or complex environments, previously inaccessible to rigid systems, fuels their market penetration.

Driving factors for this market are multi-faceted, centered around the global push for higher levels of automation combined with stringent safety standards in human-robot interaction. The convergence of microfluidics, advanced materials, and sophisticated computational control methods is accelerating technological maturity. Specifically, increasing industrial adoption of compliant mechanisms for precision assembly and the rapidly growing demand for advanced surgical devices that reduce patient trauma are pivotal in driving sustained market momentum, transforming how complex physical tasks are executed across diverse operational settings.

Soft Robotics Market Executive Summary

The Soft Robotics Market is exhibiting robust business trends characterized by significant venture capital investment targeting startups specializing in advanced actuation and sensory feedback systems. There is a palpable shift in manufacturing focus towards hybrid rigid-soft systems, leveraging the strength of traditional mechanics with the compliance of soft components to maximize both payload capacity and dexterity. Strategic partnerships between material science firms, academic institutions, and large industrial automation corporations are defining the commercialization pathway, ensuring rapid translation of laboratory breakthroughs into deployable products. Furthermore, the standardization of soft robotic control software platforms is reducing integration barriers for end-users, boosting adoption rates across small and medium enterprises (SMEs).

Regionally, North America maintains market leadership due to substantial governmental and private funding directed towards biomedical and defense applications of soft robotics, coupled with a dense concentration of pioneering research universities. However, the Asia Pacific (APAC) region, particularly China and Japan, is rapidly emerging as a dominant manufacturing hub and a critical consumer market, driven by intense automation needs in high-volume electronics and automotive production. Europe focuses strongly on collaborative robotics and strict worker safety regulations, propelling the demand for inherently safe, compliant soft robotic technologies, particularly in Germany and Scandinavian countries, necessitating continuous investment in regional technology transfer initiatives.

Segmentation trends indicate that the Grippers segment, categorized by end-of-arm tooling (EOAT), currently dominates the market due to its immediate utility in logistics and food handling. However, the Wearable Devices segment, encompassing exoskeletons and assistive technology, is projected to register the highest Compound Annual Growth Rate (CAGR), fueled by demographic changes demanding enhanced elder care and rehabilitation technology. In terms of actuation, pneumatic systems remain prevalent owing to their cost-effectiveness and high force output, but advanced material-based actuation systems, such as dielectric elastomers and shape memory alloys, are gaining traction due to superior integration potential and reduced complexity.

AI Impact Analysis on Soft Robotics Market

Users frequently inquire about how Artificial Intelligence (AI), specifically machine learning and reinforcement learning, enhances the inherent capabilities and control of compliant robotic systems. Common concerns revolve around whether AI can overcome the challenges associated with modeling and precisely controlling the infinite degrees of freedom present in soft bodies, which are governed by highly non-linear dynamics. Key expectations center on AI providing adaptive control strategies that allow soft robots to autonomously react to unpredictable environments, optimize grasping forces without pre-programming, and perform complex tasks like knot tying or highly dexterous surgical manipulation, significantly outpacing the capabilities of traditional kinematic control methods. The overarching theme is the pursuit of 'embodied intelligence,' where the physical compliance and the smart control system work synchronously to achieve human-level adaptability.

The integration of AI, particularly advanced algorithms like Deep Reinforcement Learning (DRL), is essential for realizing the full potential of soft robotics. DRL allows soft robots to learn optimal control policies through trial-and-error interaction within a simulated or real environment, effectively addressing the modeling difficulty inherent in continuum mechanics. This drastically reduces the dependency on complex analytical models and enables real-time adaptation to changes in payload, material fatigue, and environmental shifts. AI-driven soft sensory fusion is also paramount; by processing complex inputs from embedded strain gauges, vision systems, and pressure sensors simultaneously, AI provides the holistic situational awareness necessary for precise, delicate maneuvering, such as minimally invasive procedures or handling biological tissue.

Furthermore, AI facilitates the co-design and optimization of the soft robot’s physical body alongside its control system. Generative AI tools are being used to simulate millions of compliant structure designs under various operating conditions, identifying optimal material compositions and geometries that maximize performance metrics like stiffness, dexterity, and force output while minimizing material waste. This symbiosis between physical design and intelligent control is accelerating the design cycle from months to weeks, ensuring that future generations of soft robots are inherently smarter and more capable from their inception, thereby solidifying AI’s role as the central computational framework for the soft robotics revolution.

- AI enhances adaptive control for compliant structures, managing infinite degrees of freedom.

- Deep Reinforcement Learning (DRL) enables autonomous learning of complex manipulation tasks.

- AI optimizes sensory fusion (tactile, visual, proprioceptive) for precise interaction.

- Generative AI accelerates the co-design of material composition and physical geometry.

- Predictive maintenance driven by AI monitors material fatigue and degradation in compliant components.

- Machine learning algorithms enable sophisticated human-robot collaboration (HRC) by interpreting human intent.

- AI facilitates real-time trajectory planning in unstructured and dynamic environments.

DRO & Impact Forces Of Soft Robotics Market

The Soft Robotics Market is driven by the escalating global need for automation solutions that prioritize safety and precision in unstructured environments, particularly within the biomedical and food processing sectors where rigid robots face limitations. Restraints primarily involve the inherent challenges in achieving high precision and load-bearing capacity simultaneously due to the materials used, coupled with significant research and development (R&D) costs required to develop reliable, durable, and sophisticated compliant actuators and sensors. Opportunities lie in the massive untapped potential of personalized medicine, including advanced drug delivery systems and tailored rehabilitation devices, alongside the rapid expansion of collaborative robotics (cobots) in small-scale manufacturing. These forces combine to create a highly dynamic market environment where technological breakthroughs are consistently challenged by high commercialization costs and material science limitations.

The primary driver accelerating market adoption is the increasing demand for advanced automation in complex handling tasks, particularly those involving irregular, delicate, or perishable goods. Industries such as fruit picking, sorting delicate electronics, and minimally invasive surgery necessitate the low-impact interaction that soft grippers and manipulators inherently provide. Furthermore, stringent regulatory requirements, especially in Europe and North America, mandating closer human-robot proximity in industrial settings, amplify the appeal of soft robots as they minimize collision risks, serving as a critical differentiator against traditional rigid systems.

Conversely, significant restraints hinder widespread immediate adoption. The development of robust, high-performance soft sensors and actuators that can withstand industrial conditions (temperature extremes, chemical exposure, high cycle counts) remains technically demanding and cost-prohibitive. Achieving the same level of precise positional accuracy and payload capacity as conventional robots while maintaining compliance is a major engineering hurdle. Moreover, the lack of standardized design protocols and industry-wide training frameworks for maintaining and programming these complex systems creates integration inertia, particularly for companies lacking specialized robotics expertise, compelling continuous reliance on academic research for basic system understanding.

Opportunities for exponential growth are concentrated in personalized healthcare and consumer robotics. The ability of soft materials to conform seamlessly to the human body opens pathways for advanced, comfortable exoskeletons for mobility assistance, highly precise micro-robotics for targeted drug delivery within the body, and sophisticated prosthetics that closely mimic biological function. Moreover, as material costs decline and 3D printing technologies advance, the scalability of customized soft robotic solutions for niche industrial applications and consumer assistive devices will dramatically improve, fueling market penetration into previously inaccessible consumer segments.

Segmentation Analysis

The Soft Robotics Market is segmented primarily based on material type, component, actuation method, and the specific end-user industry, providing a granular view of the diverse application landscape and technological dependencies. Material segmentation highlights the reliance on flexible polymers and advanced composites that define compliance and dexterity, while the component analysis focuses on the integration of hardware necessary for sensing and control. Actuation methods reveal the core mechanisms generating motion, ranging from fluid dynamics to smart materials. Analyzing these segments is crucial for identifying areas of high investment and technological focus, particularly where demand for highly specialized compliant interaction tools intersects with advanced material science capabilities.

- By Material:

- Silicones and Rubbers

- Electroactive Polymers (EAPs)

- Shape Memory Alloys (SMAs)

- Advanced Composites

- By Component:

- Hardware (Grippers, Actuators, Pumps, Valves)

- Software (Control Systems, Simulation Tools, AI Integration)

- Sensors (Tactile Sensors, Strain Sensors, Pressure Sensors)

- By Actuation:

- Pneumatic

- Hydraulic

- Electric

- Smart Material/Thermal Actuation

- By End-User Industry:

- Healthcare and Medical Devices (Surgical Robotics, Rehabilitation)

- Food and Beverage (Handling, Sorting, Packaging)

- Logistics and Warehouse Automation

- Manufacturing and Automotive (Assembly, Inspection)

- Defense and Aerospace

- Entertainment and Consumer Goods

Value Chain Analysis For Soft Robotics Market

The Soft Robotics value chain begins with the critical upstream segment, dominated by specialized material providers focusing on high-performance elastomers, such as medical-grade silicones and advanced electroactive polymers, which dictate the physical properties and longevity of the robot. This segment also includes specialized component manufacturers providing high-precision microfluidic pumps, miniature valves, and advanced flexible sensing elements, which are essential for functional complexity and control. Success in this initial stage relies heavily on intellectual property regarding material composition and novel fabrication techniques, often involving 3D printing and soft lithography, establishing a high barrier to entry for new market participants.

The midstream involves the design, integration, and manufacturing of the soft robotic systems themselves. Key activities here include the computational design of compliant structures, development of sophisticated control software, and rigorous testing for reliability and safety standards. System integrators play a vital role in customizing these platforms for specific industrial applications, linking standardized soft components with proprietary client hardware and operational requirements. This stage is characterized by intense R&D investment and the need for cross-disciplinary expertise combining mechanical, electrical, and materials engineering with sophisticated control theory.

The downstream segment encompasses distribution channels and end-user adoption. Direct channels are prevalent for highly specialized, high-cost applications, such as surgical robotics, where manufacturers maintain tight control over installation, training, and maintenance to ensure optimal performance. Indirect channels, involving third-party distributors and integrators, facilitate broader market penetration into general manufacturing and logistics, offering localized support and faster deployment. Effective customer service and continuous system updates are crucial for maintaining customer loyalty, given the novel nature and unique maintenance requirements of soft robotic systems.

Soft Robotics Market Potential Customers

The primary customers for Soft Robotics solutions are organizations that require automation for tasks involving interaction with sensitive, fragile, or irregularly shaped objects, or those operating in proximity to human personnel where safety is non-negotiable. Healthcare institutions, including large hospital networks and specialized surgical centers, represent a crucial segment, seeking soft robotic arms for precise, minimally invasive procedures and compliant rehabilitation devices to accelerate patient recovery without causing secondary trauma. The requirement for sterile, biocompatible, and dexterous instruments drives their demand for high-end soft robotic solutions, focusing heavily on safety and precision compliance.

Another major segment is the high-tech manufacturing and consumer electronics industry, particularly companies involved in micro-assembly and quality control. These firms require soft grippers capable of handling fragile circuit boards, lenses, and oddly shaped electronic components without applying damaging force. The move towards highly flexible and reconfigurable assembly lines mandates the use of adaptive soft tools that can quickly change tasks without extensive hardware reconfiguration, making these companies consistent buyers of specialized end-of-arm tooling (EOAT) and compliant manipulation systems.

Furthermore, the food and beverage industry, including large-scale processors and packaging facilities, presents a rapidly growing customer base. The automation of sorting, picking, and packaging delicate produce (e.g., tomatoes, berries, confectionery) demands compliant, food-safe robotic hands to prevent bruising and spoilage, a task traditional rigid robots perform poorly. Logistics and e-commerce companies also represent a significant customer segment, utilizing soft robotics for high-speed, variable-item order fulfillment and warehouse automation, necessitated by the increasing heterogeneity of packaged goods encountered in modern fulfillment centers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850 Million |

| Market Forecast in 2033 | $7,000 Million |

| Growth Rate | 35.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Soft Robotics Inc., Festo Group, RightHand Robotics, ReWalk Robotics, Ekso Bionics, Empire Robotics, Cambridge Soft Robotics, Shadow Robot Company, KUKA AG (partially), ABB (Soft Gripping Solutions), General Electric (GE), Pneubotics, Qb Robotics, Trossen Robotics, Softbank Robotics, Parker Hannran Corporation, Biomechatronics Group, Agilent Technologies, SoftWear Automation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Soft Robotics Market Key Technology Landscape

The technological landscape of the Soft Robotics Market is highly dynamic, driven by breakthroughs in advanced material science and sophisticated manufacturing techniques. A primary enabling technology is the use of high-compliance materials, such as various formulations of silicone elastomer, which can be tailored for specific stiffness and biocompatibility requirements. Coupled with this is the advancement of sophisticated microfluidics and pneumatics, utilizing tiny valves and pumps embedded within the robot’s structure to precisely control deformation and stiffness. Innovations in soft sensing—including conductive polymers and liquid metal pathways that measure strain, pressure, and temperature—are crucial for providing the high-fidelity feedback necessary for closed-loop control in complex manipulation tasks, moving beyond simple open-loop actuation systems.

Furthermore, fabrication technology, particularly high-resolution multi-material 3D printing (additive manufacturing), is fundamentally transforming the design and prototyping speed of soft robots. 3D printing allows for the rapid creation of integrated features, such as internal air channels, sensor cavities, and compliant hinges, all in a single manufacturing step, drastically lowering production lead times and enabling high customization. This accessibility fosters innovation, allowing smaller firms and research labs to quickly iterate on complex designs that were previously too expensive or difficult to fabricate using traditional molding techniques.

Control algorithms, heavily leveraging Artificial Intelligence and data-driven approaches, constitute the third pillar of the technological landscape. Given the complex, non-linear dynamics of soft bodies, traditional kinematic models are often insufficient. Researchers are increasingly relying on machine learning, especially Reinforcement Learning (RL), to develop robust control policies that allow soft robots to autonomously learn effective manipulation strategies, adapt to external disturbances, and compensate for material fatigue over time. The successful integration of these technologies—materials, fabrication, and intelligent control—is the key determinant of commercial success and performance enhancement in soft robotic systems across all industrial applications, ensuring dexterity and reliability.

Regional Highlights

The global Soft Robotics market exhibits distinct regional dynamics, dictated by varying levels of research funding, industrial automation maturity, and regulatory environments concerning human-robot interaction. North America, driven by the United States, commands a significant market share, primarily due to immense governmental and private investment in advanced manufacturing, defense, and biomedical research. The concentration of top-tier universities and technology companies facilitates rapid commercialization of prototypes, particularly in fields requiring high-dexterity surgical and prosthetic devices. This region is characterized by a strong focus on high-value, specialized soft robotic applications.

The Asia Pacific (APAC) region is forecasted to experience the fastest growth, propelled by massive industrial automation demands in economies like China, Japan, and South Korea. These countries leverage soft robotics to enhance productivity in large-scale electronics assembly and automotive manufacturing while seeking safer alternatives for their burgeoning co-robotics segment. Japan, with its strong foundation in conventional robotics and demographic challenges requiring advanced elder care, is a key innovator in soft exoskeletons and assistive technologies. The increasing manufacturing output and competitive drive for efficiency make APAC a critical consumer and production base.

Europe maintains a strong, albeit structurally different, presence, largely steered by strict labor regulations promoting collaborative robotics (cobots) and high standards for workplace safety. Countries such as Germany, Switzerland, and the Netherlands lead in developing standardized, safety-certified soft grippers and manipulation systems suitable for intricate industrial tasks. The European Union's Horizon programs provide substantial funding for cooperative research, focusing heavily on ethical implications and human-centric soft robotic design, ensuring technology adoption aligns with high regulatory compliance requirements.

- North America (NA): Dominant in R&D investment; leadership in surgical and defense soft robotic applications; robust venture capital landscape. Key market drivers include advanced healthcare needs and defense technology integration.

- Asia Pacific (APAC): Highest expected growth rate; significant adoption in high-volume electronics and automotive manufacturing; strong governmental support for automation initiatives in China and South Korea. Major focus on logistics and food handling.

- Europe (EU): Driven by stringent safety regulations and demand for collaborative robotics (cobots); strong focus on precision manufacturing and ethical, human-centric design; robust academic and industrial collaboration programs.

- Latin America (LATAM): Emerging market, primarily driven by mining and agriculture, seeking specialized soft grippers for produce handling and inspection in challenging environments; lower technological maturity but high potential for localized automation solutions.

- Middle East & Africa (MEA): Slowest adoption, concentrated mainly in high-value sectors like oil & gas inspection (remote monitoring robots) and initial investments in smart healthcare infrastructure in Gulf Cooperation Council (GCC) countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Soft Robotics Market.- Soft Robotics Inc.

- Festo Group

- RightHand Robotics

- Shadow Robot Company

- ReWalk Robotics Ltd.

- Ekso Bionics Holdings, Inc.

- Cambridge Soft Robotics

- Pneubotics

- Empire Robotics

- ABB Ltd. (Soft Gripping Solutions)

- KUKA AG

- Fanuc Corporation

- Qb Robotics

- Trossen Robotics

- Softbank Robotics

- Parker Hannran Corporation

- Bastian Solutions (Soft Robotics Integration)

- Agilent Technologies

- Dassault Systèmes (Simulation Tools)

- SoftWear Automation

Frequently Asked Questions

Analyze common user questions about the Soft Robotics market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between soft robots and traditional rigid robots?

Soft robots are constructed from highly compliant, elastic materials, allowing their bodies to deform and adapt to the environment, inherently increasing safety during human interaction and enabling gentle manipulation of fragile objects. Traditional rigid robots use stiff linkages and discrete joints, offering high precision and load capacity but lacking adaptability and posing greater collision risks in shared workspaces.

Which industry segment currently leads the market adoption of soft robotics technology?

The Healthcare and Medical Devices segment currently drives significant adoption, particularly in surgical robotics (minimally invasive procedures) and rehabilitation (prosthetics and exoskeletons). However, the Food and Beverage industry, alongside Logistics, is rapidly increasing its market share due to the immediate need for compliant grippers capable of handling irregular and delicate perishable goods efficiently.

What major technological hurdle must the Soft Robotics market overcome for mainstream industrialization?

The major hurdle is achieving high payload capacity and high positional accuracy simultaneously while maintaining inherent compliance. Developing durable, reliable soft actuators and sensors that can withstand thousands of industrial cycles and improving control algorithms to manage the complex, non-linear dynamics of compliant bodies are crucial challenges that must be addressed for widespread industrial adoption.

How is Artificial Intelligence (AI) enhancing the functionality of soft robotic systems?

AI, specifically Deep Reinforcement Learning (DRL), provides the necessary control framework to manage the infinite degrees of freedom in soft robots. It enables systems to learn sophisticated manipulation strategies autonomously, adapt to unexpected changes in their environment or payload, and process complex sensory data for precise real-time interaction, moving beyond limitations of predefined control models.

What are the key materials used in the construction of compliant robotic systems?

The primary materials include various types of silicone elastomers and rubbers, selected for their flexibility and durability. Advanced systems increasingly utilize smart materials such as Electroactive Polymers (EAPs), which deform in response to electrical fields, and Shape Memory Alloys (SMAs), which change shape based on temperature, providing sophisticated and compact actuation methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Soft Robotics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Wearable Soft Robotics Market Size Report By Type (Hardware, Software), By Application (Human-Machine Interface and Interaction, Locomotion and Exploration, Manipulation, Medical and Surgical Application, Rehabilitation and Wearable Robots, R&D of Humanoids), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Soft Robotics Market Size Report By Type (Hardware, Software), By Application (Human-Machine Interface and Interaction, Locomotion and Exploration, Manipulation, Medical and Surgical Application, Rehabilitation and Wearable Robots, R&D of Humanoids), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Inflated Soft Robotics Market Size Report By Type (Hardware, Software), By Application (Medical and Healthcare, Food and Beverages, Logistics, Entertainment and Gaming, Automotive, Survey and Exploration, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Edible Soft Robotics Market Size Report By Type (Hardware, Software), By Application (Human-Machine Interface and Interaction, Locomotion and Exploration, Manipulation, Medical and Surgical Applications, Rehabilitation and Wearable Robots, R&D of Humanoids), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager