Soft Touch Lamination Films Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432361 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Soft Touch Lamination Films Market Size

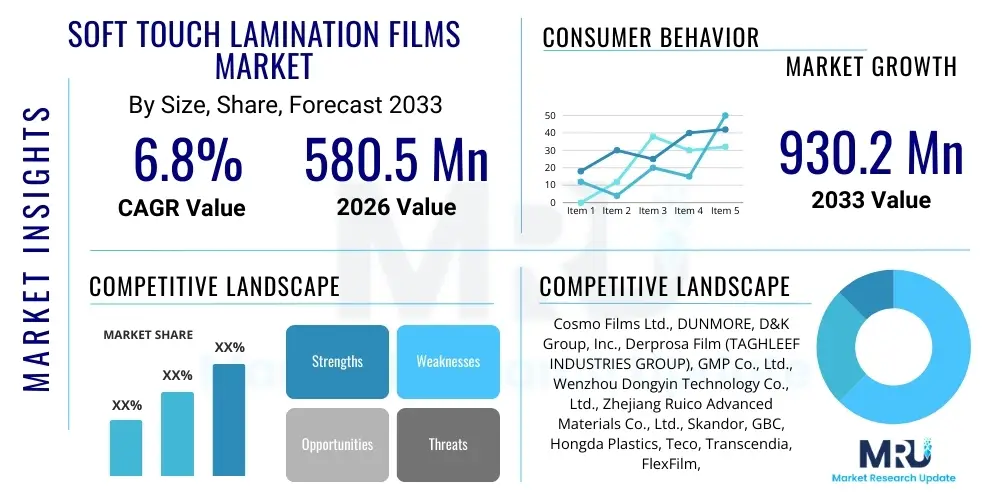

The Soft Touch Lamination Films Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at 580.5 Million USD in 2026 and is projected to reach 930.2 Million USD by the end of the forecast period in 2033. This robust growth trajectory is primarily fueled by the increasing demand for premium packaging and graphic arts applications across diverse end-use industries, particularly luxury goods, high-end cosmetics, and specialized publishing.

Soft Touch Lamination Films Market introduction

The Soft Touch Lamination Films Market encompasses specialty polymer films designed to provide a luxurious, tactile suede-like finish when applied to printed materials or packaging substrates. These films significantly enhance the aesthetic appeal and perceived value of the final product, offering superior protection against scratches, moisture, and fingerprints compared to standard matte or gloss finishes. Soft touch films are predominantly utilized in the packaging of electronics, high-end consumer goods, and promotional literature where sensory experience is paramount to brand differentiation and consumer engagement. The primary material compositions often include BOPP (Biaxially Oriented Polypropylene) or PET (Polyethylene Terephthalate), coated with specialized resins that deliver the signature velvety texture.

Major applications for soft touch lamination films span sectors requiring high-quality visual and tactile feedback. These include protective overlays for mobile device boxes, sophisticated book covers, premium business cards, and luxury folding cartons used in the alcoholic beverage and confectionery industries. The inherent benefits of these films, such as superior scuff resistance, anti-glare properties, and the ability to accept post-lamination processes like spot UV or foil stamping, make them indispensable for brands aiming for a premium market position. The driving factors behind market expansion include the global shift towards experience-based consumer marketing, rising disposable incomes in emerging economies boosting demand for luxury goods, and continuous technological advancements in film adhesion and environmental sustainability, such as the introduction of biodegradable soft touch variants.

Soft Touch Lamination Films Market Executive Summary

The Soft Touch Lamination Films Market is characterized by intense focus on innovation related to sustainability and high-performance adhesives. Business trends indicate a strong move toward water-based and thermal lamination films, reducing reliance on solvent-based systems to meet stringent environmental regulations and improve worker safety. Manufacturers are increasingly integrating advanced anti-microbial and anti-scratch technologies into soft touch formulations to enhance durability, particularly for frequently handled items like menus and electronic packaging. Segment trends show that the thermal lamination film category dominates due to its efficiency and compatibility with high-speed production lines, while the luxury packaging application segment exhibits the fastest growth rate, reflecting the willingness of premium brands to invest in superior tactile finishes.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, driven by massive expansion in the packaging, publishing, and consumer electronics manufacturing sectors in China, India, and Southeast Asian nations. North America and Europe, while mature, maintain substantial market shares due to high per-capita consumption of luxury and specialty printed materials, alongside strict adherence to quality standards necessitating robust, protective finishes. The competitive landscape is moderately fragmented, with key players focusing on expanding their global distribution networks and securing supply chains for high-quality polymer resins. Strategic collaborations aimed at developing bio-based or recycled content soft touch films are defining the future competitive strategy.

AI Impact Analysis on Soft Touch Lamination Films Market

Common user inquiries regarding AI's impact on the Soft Touch Lamination Films Market often revolve around predictive maintenance for lamination machinery, optimized inventory management, and the potential for AI-driven design tools to influence material selection and packaging complexity. Users are primarily concerned with how AI can minimize waste during high-speed lamination, improve quality control by detecting minute surface defects, and forecast fluctuating raw material costs (polymers and adhesives). The key expectation is that AI systems will provide operational efficiencies, moving the industry toward 'Smart Manufacturing' practices where production schedules, material handling, and defect detection are automated and optimized in real-time. This shift promises lower operational expenditure and higher throughput, potentially lowering the total cost of sophisticated finishes and broadening their adoption beyond purely luxury segments.

- AI-driven predictive analytics optimize lamination equipment maintenance schedules, minimizing unplanned downtime and maximizing asset utilization in high-volume production lines.

- Integration of AI-powered vision systems for real-time quality control ensures consistent soft touch texture and immediate detection of film defects, significantly reducing material waste and improving final product integrity.

- Machine learning algorithms enhance demand forecasting for specific film types (e.g., matte vs. soft touch), allowing manufacturers to optimize raw material procurement and inventory levels, mitigating supply chain risks.

- AI optimization of supply chain logistics shortens lead times for specialty adhesive and polymer deliveries, crucial for maintaining rapid turnaround times in customized packaging orders.

- Generative design tools, powered by AI, could accelerate the development of new packaging structures and surface finishes, influencing future requirements for film flexibility and adhesion properties.

DRO & Impact Forces Of Soft Touch Lamination Films Market

The market is primarily driven by escalating consumer preference for premium, sensory packaging that provides a distinctive brand experience, complemented by the superior protective qualities of soft touch films against scratches and abrasion in distribution channels. However, the market faces significant restraints, chiefly the relatively high cost of specialty films compared to conventional lamination materials, which limits adoption in highly price-sensitive markets. Opportunities are abundant in the expansion of sustainable product lines, specifically bio-degradable or compostable soft touch films, catering to corporate sustainability goals and evolving consumer environmental awareness. The impact forces are currently dominated by the high level of product differentiation achieved through tactile finishes, pushing brands across cosmetics and electronics to adopt these films, while simultaneously being pressured by fluctuating petrochemical prices, which affect raw material costs (BOPP, PET, and specialized resins).

The core drivers include the strong growth in the luxury sector globally, necessitating sophisticated packaging solutions that communicate exclusivity and quality. Furthermore, the robust performance benefits, such as enhanced print vibrancy and resistance to handling marks, secure the position of these films over standard alternatives. Restraints primarily involve regulatory hurdles concerning certain non-recyclable multi-layer laminates and the ongoing volatility in the pricing of crude oil derivatives, impacting polymer production costs. Key opportunities lie in penetrating emerging market segments, such as personalized protective overlays for medical devices and high-touch consumer electronics accessories, where durability and aesthetic appeal are critical. The collective impact forces indicate that while demand remains high due to differentiation benefits, profitability is continually challenged by the need for advanced sustainability features and efficient cost management in the procurement of specialty chemicals and films.

Segmentation Analysis

The Soft Touch Lamination Films Market is comprehensively segmented based on material type, film type, application, and geographic region, providing a detailed view of current demand patterns and future growth avenues. Material segmentation reflects the foundational polymer used, typically BOPP, which is cost-effective and widely used, or PET, preferred for its dimensional stability and higher heat resistance. Film type differentiates between thermal lamination, which utilizes heat-activated adhesive, and wet lamination, relying on liquid adhesive applied externally. Application segmentation highlights the diverse end-use spectrum, emphasizing the significant contributions of the luxury packaging and graphic arts sectors. This structure allows stakeholders to analyze specific competitive niches and tailor product development to meet precise industrial requirements, such as superior tear resistance for book covers or enhanced chemical resistance for cosmetic containers.

- By Material Type:

- BOPP (Biaxially Oriented Polypropylene) Soft Touch Films

- PET (Polyethylene Terephthalate) Soft Touch Films

- Nylon Soft Touch Films

- Others (PVC, Specialty Copolymers)

- By Film Type:

- Thermal Lamination Soft Touch Films (Dominant Segment)

- Wet Lamination Soft Touch Films

- By Application:

- Luxury Packaging (Cosmetics, Confectionery, Spirits)

- Graphic Arts and Publishing (Book Covers, Brochures, Annual Reports)

- Consumer Electronics Packaging

- Promotional and Stationery Items

- Flexible Packaging

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LAMEA)

- Middle East and Africa (MEA)

Value Chain Analysis For Soft Touch Lamination Films Market

The value chain for soft touch lamination films commences with the upstream analysis involving raw material suppliers, predominantly chemical companies providing specialized polymer resins (polypropylene, polyester) and proprietary soft-touch coating agents and adhesive formulations. The quality and purity of these raw materials are crucial as they directly influence the final tactile feel and adhesion performance of the film. Midstream operations involve film extrusion and coating, where manufacturers process the polymers into rolls of base film and apply the unique soft-touch varnish layer, often incorporating advanced processes like vacuum metallization or specialty chemical surface treatment. Efficiency in this stage, particularly minimizing internal defects and optimizing coating thickness uniformity, is paramount for product acceptance.

Downstream analysis focuses on the transformation and distribution phases. Film rolls are sold to commercial printers, packaging converters, and specialized lamination service providers who utilize high-speed lamination machines (either thermal or wet) to bond the film to the paper, cardboard, or plastic substrate. Distribution channels are varied, involving direct sales to large converters for volume purchasing, and indirect routes through specialized distributors and regional agents who manage inventory and provide technical support to smaller printing houses. The direct channel offers better price control and customized technical engagement, while indirect channels provide wider geographical reach and cater to localized, immediate requirements. The final stage involves the packaging of goods (e.g., luxury boxes, high-end magazines) where the soft touch film delivers its intended aesthetic and protective functions, reaching the ultimate consumer.

Soft Touch Lamination Films Market Potential Customers

The primary consumers and end-users of soft touch lamination films are entities deeply invested in brand image, product differentiation, and consumer tactile experience. The largest segment of potential customers includes luxury brand owners across cosmetics, premium spirits, and high-end electronics, who seek packaging that conveys superior quality and exclusivity, justifying higher price points. These customers frequently specify soft touch finishes for primary and secondary packaging to create a lasting, positive sensory impact upon unboxing. A second significant customer base comprises commercial printing houses and graphic design agencies specializing in corporate communications, such as annual reports, high-gloss brochures, and marketing collateral, where durability and premium feel are non-negotiable requirements for executive presentation.

Furthermore, specialized packaging converters that cater to the confectionery and gourmet food markets represent substantial buyers, utilizing the films not only for aesthetic appeal but also for enhanced grease and moisture resistance. The rise of sophisticated e-commerce packaging, demanding robust finishes that withstand logistical handling while maintaining a luxury aesthetic, has also generated a new segment of buyers focused on protective mailers and subscription boxes. Ultimately, any business where the tactile interaction with the product packaging or printed material significantly influences purchase decision or perceived brand value is a high-potential customer for soft touch lamination film products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | 580.5 Million USD |

| Market Forecast in 2033 | 930.2 Million USD |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Cosmo Films Ltd., DUNMORE, D&K Group, Inc., Derprosa Film (TAGHLEEF INDUSTRIES GROUP), GMP Co., Ltd., Wenzhou Dongyin Technology Co., Ltd., Zhejiang Ruico Advanced Materials Co., Ltd., Skandor, GBC, Hongda Plastics, Teco, Transcendia, FlexFilm, Jindal Poly Films, Zhejiang Kanon Technology Co., Ltd., KDX (Kangdexin Composite Material Group), Profol GmbH, VPF Films, Film-X. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Soft Touch Lamination Films Market Key Technology Landscape

The technological landscape of the Soft Touch Lamination Films Market is heavily influenced by advancements in polymer chemistry, extrusion methods, and adhesive science, all aimed at improving film performance, tactile quality, and environmental compatibility. A key technology involves the co-extrusion process, where multiple polymer layers are extruded simultaneously to create a composite film structure. This allows manufacturers to optimize different layers for specific properties—one layer for superior adhesion (often ethylene vinyl acetate or EVAs for thermal films) and the outer layer for the unique velvety soft-touch finish. Precision coating technologies, such as micro-embossing and proprietary chemical varnishes, are crucial for achieving the desired haptic feedback consistently across large production runs, ensuring the films resist polish and remain velvety even after intensive handling.

Another major technological focus is the evolution of adhesive systems. Thermal lamination films, the market leaders, rely on advanced thermal adhesives that activate rapidly under heat and pressure, providing an exceptionally strong bond without the need for solvents, thus improving process safety and reducing drying time. The latest innovation involves the development of low-temperature melt adhesives, which are essential for laminating heat-sensitive digital prints and synthetic substrates without causing warping or discoloration. Furthermore, in response to sustainability mandates, there is significant investment in developing soft-touch coatings based on bio-polyethylene (Bio-PE) or other renewable resource polymers, allowing for the creation of soft touch films that maintain premium characteristics while offering higher end-of-life recyclability or compostability credentials, marking a critical area of competitive differentiation.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the engine of growth, demonstrating the highest CAGR, primarily fueled by massive expansion in packaging and printing industries across China, India, and Vietnam. The region's increasing wealth drives demand for high-end consumer goods, necessitating premium packaging finishes like soft touch lamination. Manufacturing hubs in electronics and mobile device packaging are major consumers of these specialty films for protective and aesthetic purposes.

- North America: This region holds a significant market share, driven by stringent quality standards in branded goods and high adoption rates of advanced printing techniques. The US market emphasizes robust anti-scratch and highly durable soft touch finishes, particularly in publishing (textbooks, luxury magazines) and specialized promotional items, maintaining steady, mature growth.

- Europe: Characterized by high environmental awareness and strong regulatory frameworks (e.g., EU packaging directives), Europe exhibits stable demand, especially within the luxury fashion, cosmetics, and confectionery sectors. Growth is increasingly tied to the uptake of certified sustainable and recyclable soft touch films, positioning innovation in eco-friendly materials as a key regional competitive factor.

- Latin America (LAMEA): LAMEA shows emerging growth, predominantly centered in Brazil and Mexico, driven by increasing foreign investment in consumer packaged goods and local brands seeking to elevate their market presence through premium packaging aesthetics, though adoption remains constrained by price sensitivity compared to developed markets.

- Middle East and Africa (MEA): Growth in the MEA region is moderate but accelerating, particularly in the UAE and Saudi Arabia, driven by burgeoning luxury retail sectors and expanding graphic arts industries focused on high-net-worth consumers. The demand is often concentrated on imported, high-quality specialized lamination films.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Soft Touch Lamination Films Market.- Cosmo Films Ltd.

- DUNMORE

- D&K Group, Inc.

- Derprosa Film (TAGHLEEF INDUSTRIES GROUP)

- GMP Co., Ltd.

- Wenzhou Dongyin Technology Co., Ltd.

- Zhejiang Ruico Advanced Materials Co., Ltd.

- Skandor

- GBC

- Hongda Plastics

- Teco

- Transcendia

- FlexFilm

- Jindal Poly Films

- Zhejiang Kanon Technology Co., Ltd.

- KDX (Kangdexin Composite Material Group)

- Profol GmbH

- VPF Films

- Film-X

- Vetro-Lam

Frequently Asked Questions

Analyze common user questions about the Soft Touch Lamination Films market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material used to manufacture soft touch lamination films?

The primary materials are Biaxially Oriented Polypropylene (BOPP) and Polyethylene Terephthalate (PET). BOPP is widely used for its cost-effectiveness, while PET is chosen for applications requiring superior dimensional stability and higher heat resistance.

How do soft touch films contribute to brand perception?

Soft touch films significantly enhance brand perception by providing a luxurious, velvety, and high-quality tactile finish to packaging and printed materials. This sensory experience is highly valued in the luxury and premium goods segments, conveying exclusivity and superior product quality.

Are there sustainable options available within the soft touch films market?

Yes, sustainability is a key development area. Manufacturers are increasingly offering soft touch films made from bio-based polymers (like Bio-PE) or formulations designed to be recyclable or compostable, addressing growing consumer and regulatory demands for eco-friendly packaging solutions.

Which lamination method is most common for soft touch films?

Thermal lamination is the most common method, utilizing films pre-coated with heat-activated adhesives (often EVA). This process is highly efficient, faster than wet lamination, and compatible with high-speed automated production lines, making it dominant in large-volume converting operations.

What are the main application areas driving the market growth?

Market growth is primarily driven by the Luxury Packaging sector (cosmetics, spirits, high-end electronics boxes) and the Graphic Arts and Publishing industry, where the films' protective qualities (anti-scratch, anti-scuff) and premium aesthetic appeal are essential for product differentiation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager