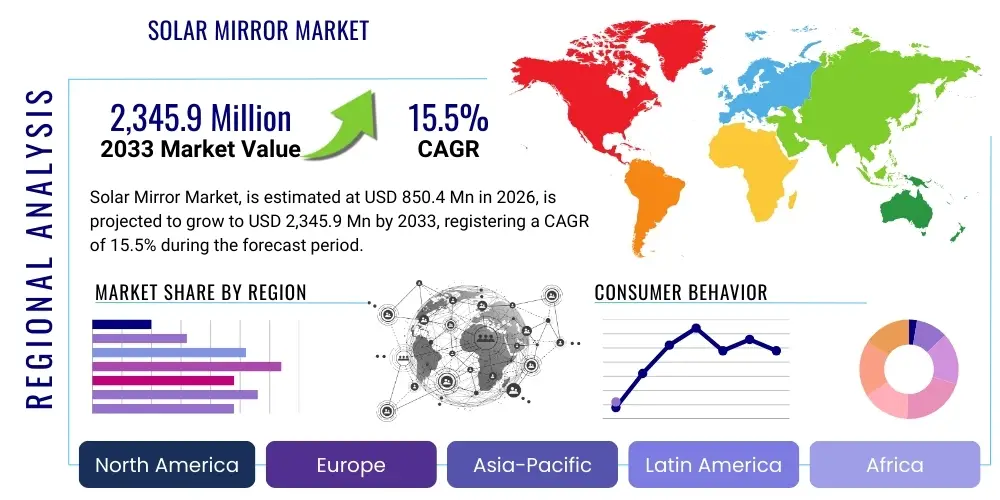

Solar Mirror Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437956 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Solar Mirror Market Size

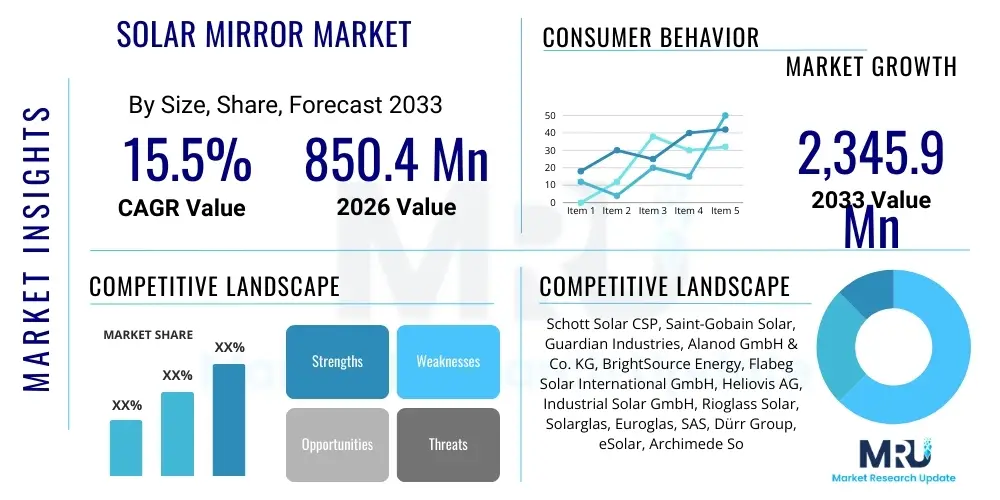

The Solar Mirror Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 15.5% between 2026 and 2033. The market is estimated at USD 850.4 million in 2026 and is projected to reach USD 2,345.9 million by the end of the forecast period in 2033.

Solar Mirror Market introduction

The Solar Mirror Market is fundamentally driven by the escalating global necessity for sustainable and dispatchable renewable energy solutions, primarily serving the Concentrated Solar Power (CSP) sector. Solar mirrors, critical optical components, are engineered to reflect and concentrate solar radiation onto a receiver system, generating high temperatures used to produce steam for turbine-based electricity generation or directly for industrial process heat applications. These mirrors must possess extremely high reflectivity, long-term durability, and resistance to environmental degradation, including corrosion, dust accumulation, and UV exposure. Key applications span utility-scale parabolic trough systems, central receiver (power tower) projects, linear Fresnel reflectors, and dish Stirling systems, each requiring specific geometric and optical tolerances. The market's growth trajectory is strongly correlated with national renewable energy targets and the continuous advancements in CSP technology aimed at reducing the Levelized Cost of Energy (LCOE).

Product descriptions within this market generally emphasize two main material types: glass-based mirrors, which offer superior rigidity and longevity, and metallic or polymer-based reflectors, often used in lighter, more flexible linear Fresnel applications or for temporary installations. Glass-based mirrors typically feature a highly reflective silver backing protected by layers of copper and paint, mounted on a low-iron glass substrate to maximize light transmission. The primary benefit of utilizing solar mirrors in CSP is the ability to integrate thermal energy storage (TES), allowing electricity generation to continue after sunset or during periods of low solar irradiance, addressing the intermittency challenge inherent in photovoltaic (PV) systems. This dispatchability is a major driver stimulating investment, especially in arid and semi-arid regions with high Direct Normal Irradiance (DNI).

Driving factors propelling the Solar Mirror Market forward include supportive government policies such as Renewable Portfolio Standards (RPS) and feed-in tariffs promoting CSP deployment globally, particularly across the Middle East, North Africa, and parts of Asia. Furthermore, technological refinements focusing on enhanced mirror cleaning technologies, anti-soiling coatings, and automated mirror manufacturing processes are steadily improving system efficiency and operational lifespan. The increasing need for decarbonization across industrial sectors, coupled with the desire for energy independence, positions the solar mirror segment as an indispensable element in achieving ambitious global climate change mitigation goals, cementing its role as a high-growth sector within the wider renewable energy landscape.

Solar Mirror Market Executive Summary

The Solar Mirror Market is experiencing robust expansion, characterized by significant geographical shifts in development, particularly towards the Asia Pacific region, led by large-scale projects in China and India, and sustained deployment across the Middle East and North Africa (MENA) due to favorable DNI resources and committed government investments in energy diversification. Current business trends indicate a strong move toward standardizing mirror panel sizes and maximizing reflectivity while concurrently optimizing production processes to achieve economies of scale, thereby lowering capital expenditure for project developers. The market has witnessed intense competition focusing on developing highly durable protective coatings and precision mounting structures that minimize optical loss over decades of operation. Furthermore, the integration of advanced sensors and data analytics for real-time monitoring of mirror performance and structural integrity is becoming a crucial differentiator among leading manufacturers.

Segment trends highlight the dominance of parabolic trough systems, which currently utilize the largest volume of solar mirror surfaces globally, although power tower configurations are gaining traction due to their higher operating temperatures, enabling more efficient integration with molten salt storage systems. The material segment is still predominantly driven by silver-backed, low-iron glass mirrors due to their superior optical quality and proven reliability in harsh desert environments. Regionally, while North America and Europe possess mature CSP infrastructure, growth is primarily focused on operational optimization and refurbishment; the new market impetus is emanating from emerging economies where greenfield CSP projects are essential components of national energy strategies. The ongoing energy transition mandates the replacement of fossil fuel dependency with high-capacity, dispatchable renewables, directly benefiting the solar mirror industry as CSP remains a primary provider of utility-scale thermal power.

Overall, the market outlook remains highly positive, contingent upon continuous technological innovation aimed at cost reduction and performance enhancement. Strategic alliances between mirror manufacturers and major Engineering, Procurement, and Construction (EPC) firms are defining the competitive landscape, ensuring a steady supply chain for large-scale utility projects. Financial indicators suggest that as manufacturing efficiency improves and the installed base expands, the perceived risk associated with CSP projects diminishes, attracting greater institutional investment. This executive summary underscores that the Solar Mirror Market is transitioning from a specialized niche to a mainstream component of the global utility grid, driven by its unique capability to deliver reliable, stored solar energy.

AI Impact Analysis on Solar Mirror Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Solar Mirror Market center around maximizing operational efficiency, predictive maintenance for large mirror fields, and optimizing the manufacturing and quality control processes. Key concerns often revolve around how AI can mitigate the primary challenge of soiling and dust accumulation, which significantly reduces reflectivity and yield. Users seek to understand AI’s capability in scheduling precise, water-efficient cleaning cycles based on real-time weather predictions and optical performance degradation data. Furthermore, there is substantial interest in leveraging machine learning algorithms to fine-tune the tracking mechanisms (heliostat or trough orientation) to maximize energy capture under varying atmospheric conditions. The overarching expectation is that AI integration will substantially reduce Operations and Maintenance (O&M) costs and increase the overall capacity factor of CSP plants, thereby improving the economic viability of solar thermal projects globally.

The integration of AI extends significantly into the manufacturing supply chain, where computer vision and deep learning are revolutionizing the quality assurance process for the mirrors themselves. Traditional manual inspection of large mirror facets is time-consuming and prone to human error, but AI-powered optical systems can rapidly detect microscopic defects, warping, or coating inconsistencies during production, ensuring only high-grade mirrors are deployed. This level of stringent quality control minimizes performance variability across large arrays. On the operational side, AI algorithms process vast amounts of sensor data—temperature, wind speed, dust level, solar irradiance, and structural vibrations—to create highly accurate models of mirror wear and tear, predicting potential failures weeks or months in advance. This shift from reactive maintenance to prescriptive maintenance is pivotal for maintaining the high-reflectivity standard required throughout the typical 25-year lifespan of a CSP plant.

Furthermore, AI plays a critical role in the design and engineering phase, particularly in optimizing the placement and orientation of mirrors within complex terrains to minimize shadowing and cosine losses. Generative AI models are being utilized to simulate thousands of potential layout configurations, factoring in site-specific topography and long-term meteorological data, resulting in design blueprints that maximize energy harvesting efficiency. This systematic optimization, coupled with real-time feedback loops during operation, ensures that every square meter of reflective surface contributes optimally to the overall system output. The technological synergy between advanced solar mirror materials and sophisticated AI management systems is transforming CSP into an intelligent, highly reliable, and competitive dispatchable energy source.

- AI optimizes mirror cleaning schedules based on localized dust models and weather forecasts, maximizing asset uptime.

- Machine learning algorithms enhance real-time heliostat and trough tracking precision, improving solar flux concentration efficiency.

- Computer vision systems enable automated, high-precision quality control during mirror manufacturing, detecting minute surface defects.

- Predictive maintenance analytics forecast material fatigue and potential failure points in mirror support structures, reducing catastrophic downtime.

- AI assists in optimizing CSP plant layout and design, minimizing shading losses across vast mirror fields.

DRO & Impact Forces Of Solar Mirror Market

The dynamics of the Solar Mirror Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the impact forces determining market velocity and direction. A primary driver is the accelerating global mandate for decarbonization and the increasing need for dispatchable renewable power sources, where CSP, facilitated by high-quality solar mirrors, offers a distinct advantage over intermittent renewables due to its inherent thermal storage capability. Supportive government policies, especially in high DNI regions like the MENA and APAC, through mechanisms such as long-term Power Purchase Agreements (PPAs) and favorable financing, further propel project development. Secondly, continuous reductions in the manufacturing cost of solar mirrors and associated components, achieved through process automation and material efficiency, are pushing the LCOE of CSP downwards, making it more competitive against conventional and other renewable technologies.

Restraints, however, pose significant challenges to widespread adoption. The high initial capital expenditure (CapEx) associated with large-scale CSP projects, particularly the cost of extensive mirror fields and tracking systems, remains a considerable barrier compared to photovoltaic (PV) alternatives. Operational challenges, especially those related to soiling and degradation in harsh desert environments, necessitate intensive and costly O&M activities, including frequent mirror cleaning which consumes scarce water resources. Furthermore, the inherent logistical complexity and the lengthy planning and construction timelines associated with utility-scale CSP facilities slow down market deployment compared to modular renewable installations. Regulatory uncertainty or delays in securing land and transmission infrastructure also act as potent restraints, particularly in developing economies.

Conversely, significant opportunities exist, primarily centered on technological convergence and market expansion. The development of advanced, water-free mirror cleaning systems and hydrophobic, anti-soiling coatings presents a major avenue for reducing operational costs and water dependency. Moreover, the opportunity for CSP to integrate seamlessly with industrial process heat applications—supplying thermal energy directly to heavy industries such as cement, chemicals, and mining—opens up vast new market segments beyond electricity generation. Finally, continuous innovation in next-generation mirror materials, such as lightweight composite reflectors or advanced thin-film alternatives, promises to reduce both transportation costs and structural requirements, enhancing overall system flexibility and deployment speed, thereby maximizing the positive impact forces on market growth.

Segmentation Analysis

The Solar Mirror Market is intricately segmented based on material type, application technology, and end-user, reflecting the diverse requirements and technological evolution within the Concentrated Solar Power (CSP) industry. Analyzing these segments provides crucial insights into market penetration rates and identifies the most promising avenues for investment and technological development. The segmentation by type primarily differentiates between the traditional, high-performance glass mirrors and emerging metallic or flexible polymer mirrors, each catering to specific performance and cost requirements of various CSP system designs. The application segmentation delineates the market based on the fundamental CSP technology employed—parabolic trough, power tower (heliostat fields), or linear Fresnel systems—each demanding unique mirror geometry and optical properties, driving specialized manufacturing processes.

Furthermore, segmentation by end-user, principally utility-scale power generation versus smaller industrial process heat applications, illustrates the varying scale and operational intensity demanded by customers. Utility applications require extreme durability and high reflectivity over decades to ensure grid stability and compliance with Power Purchase Agreements (PPAs), necessitating premium materials. In contrast, industrial applications might prioritize lower initial cost and tailored temperature output for specific manufacturing processes. Understanding this multi-dimensional segmentation is critical for market participants, enabling them to align their product development strategies—focusing on advanced coatings for utility customers or cost-efficient designs for industrial users—to capitalize on the fastest-growing sub-markets and ensure a resilient supply chain structure capable of handling diverse demands across the globe.

- By Type:

- Glass/Silver-Backed Mirrors

- Metallic/Polymer Reflectors

- Composite Mirrors (e.g., lightweight materials)

- By Application:

- Parabolic Trough Systems (Dominant Market Share)

- Central Receiver Systems (Power Towers)

- Linear Fresnel Reflectors

- Dish Stirling Systems

- By End-User:

- Utility-Scale Power Generation (Grid-Connected)

- Industrial Process Heat (IPH) Applications

- Research & Development Facilities

- By Region:

- North America (USA, Canada)

- Europe (Spain, Germany, Italy)

- Asia Pacific (China, India, Australia)

- Middle East and Africa (UAE, Morocco, South Africa)

- Latin America (Chile, Mexico)

Value Chain Analysis For Solar Mirror Market

The Value Chain of the Solar Mirror Market begins with the upstream sourcing of raw materials, primarily low-iron glass, silver, copper, and specialized chemicals for protective coatings and paints. Low-iron glass manufacturers form the foundational layer, providing the substrate that ensures maximum light transparency and mechanical stability. Silver and chemical suppliers are crucial for the deposition process, where a thin, highly reflective silver layer is applied, followed by protective metallic and polymeric coatings to shield the silver from oxidation and environmental moisture. Efficiency and cost optimization at this upstream stage are paramount, as the quality and purity of the raw materials directly influence the mirror's reflectivity and lifespan, which are critical performance metrics for CSP project viability.

The midstream segment involves the core manufacturing process, where raw glass sheets are cut, polished, tempered, and shaped (curved or flat) according to the specifications of the CSP technology (e.g., parabolic curvature). This stage requires high precision machinery, specialized vacuum coating chambers, and stringent quality control protocols. Leading manufacturers typically invest heavily in automation to achieve mass production efficiencies and minimize defects. The finished solar mirrors are then packaged and distributed through a channel that is predominantly B2B focused. Distribution channels include direct sales to large Engineering, Procurement, and Construction (EPC) firms, which manage the deployment of massive solar fields, and occasionally, sales through specialized distributors focusing on regional solar project logistics.

The downstream activities involve the project execution phase, led by EPC contractors and project developers (Independent Power Producers or Utilities). These entities are the direct and primary customers, responsible for integrating the mirrors into the larger CSP plant infrastructure, including mounting structures, tracking systems, and thermal receivers. Post-installation, the value chain extends into long-term operations and maintenance (O&M), where specialized service providers ensure optimal mirror performance through regular cleaning and repair. The dominant channel remains direct interaction between the manufacturer and the large-scale project developer, reflecting the highly technical, custom, and high-volume nature of the product, with minimal reliance on indirect consumer channels.

Solar Mirror Market Potential Customers

The primary customers and end-users of solar mirrors are large-scale energy infrastructure developers and operators who require reliable, high-capacity renewable energy sources. This includes major utility companies, both state-owned and private, that are mandated to integrate significant amounts of renewable energy into the electrical grid to meet regulatory standards and consumer demand. These utilities primarily purchase mirrors for constructing or expanding utility-scale Concentrated Solar Power (CSP) plants, which offer the unique advantage of incorporating thermal energy storage (TES), ensuring power dispatchability during peak demand, even after sunset. Their purchasing decisions are heavily influenced by proven durability, guaranteed reflectivity over 20+ years, and manufacturer reliability.

Independent Power Producers (IPPs) represent another crucial segment. IPPs develop, own, and operate power generation facilities, selling the output typically under long-term Power Purchase Agreements (PPAs). These developers are highly sensitive to the Levelized Cost of Energy (LCOE) and seek solar mirrors that offer the best balance between performance and capital cost efficiency, frequently engaging in large-volume contracts with manufacturers. Furthermore, a rapidly emerging customer segment involves industrial entities across energy-intensive sectors such as chemicals, desalination, food and beverage processing, and heavy manufacturing. These industries are increasingly adopting CSP technology to generate process heat (Industrial Process Heat or IPH) directly on-site, displacing reliance on natural gas or fossil fuels, driven by sustainability goals and the need to hedge against volatile energy prices.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850.4 Million |

| Market Forecast in 2033 | USD 2,345.9 Million |

| Growth Rate | 15.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schott Solar CSP, Saint-Gobain Solar, Guardian Industries, Alanod GmbH & Co. KG, BrightSource Energy, Flabeg Solar International GmbH, Heliovis AG, Industrial Solar GmbH, Rioglass Solar, Solarglas, Euroglas, SAS, Dürr Group, eSolar, Archimede Solar Energy, Absolicon Solar Collector AB, TVP Solar SA, ACWA Power, Glassbel, ENF Solar. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Solar Mirror Market Key Technology Landscape

The key technology landscape of the Solar Mirror Market is defined by continuous innovation focused on optimizing reflectivity, improving durability, and minimizing maintenance requirements across harsh operational environments. A major technological focus is the development of ultra-high reflectivity coatings, often achieving 95% or higher solar reflectance, primarily utilizing advanced silver deposition techniques and improved protective layers. These protection layers involve specialized copper and paint formulations designed to resist moisture ingress and chemical corrosion, which are leading causes of mirror degradation and performance loss in high-humidity or coastal desert regions. Furthermore, manufacturers are exploring thin-film glass technologies to reduce material weight and thickness without compromising optical performance, leading to lower transportation costs and less demanding structural support requirements for the mirror fields.

Another crucial area of technological advancement involves the development and application of anti-soiling and hydrophobic coatings. Dust and dirt accumulation, known as soiling, can severely diminish a solar mirror's efficiency, often requiring daily or weekly cleaning, consuming vast amounts of water. Next-generation coatings leverage nanotechnology and specific surface chemistries to repel dust particles and water droplets, making cleaning easier and less frequent, thereby conserving water and reducing operational costs. Electrodynamic screens (EDS) are also being piloted, using electrical fields to repel dust passively, offering a potential waterless cleaning solution that could revolutionize O&M practices in arid climates, directly improving the long-term economic viability of CSP projects globally.

Beyond material science, the engineering and manufacturing process itself are undergoing significant technological refinement. Automated manufacturing lines incorporating robotics and high-precision computer numerical control (CNC) equipment are essential for achieving the necessary large-scale production of accurately curved (parabolic or spherical) mirror facets. Innovations in structural integrity include lightweight composite backing materials and optimized mounting systems that resist high wind loads and thermal expansion stresses while maintaining precise optical alignment. Furthermore, integrating smart sensor technology into the mirror panels allows for real-time monitoring of temperature, vibration, and reflectivity, enabling immediate diagnostic feedback and proactive maintenance interventions, forming the core of an intelligent, resilient CSP infrastructure.

Regional Highlights

- Asia Pacific (APAC) Dominance and Growth Trajectory: The APAC region, spearheaded by China and India, represents the engine of future market growth, primarily due to ambitious government targets for renewable energy capacity expansion and the availability of large, undeveloped areas with excellent Direct Normal Irradiance (DNI). China, in particular, has heavily invested in indigenous CSP technology and has rapidly deployed multiple utility-scale projects, making it the largest contributor to regional capacity additions. India's solar mission also includes CSP components, although growth has been measured. The technological sophistication in China, combined with strong governmental support and favorable economic policies aimed at fostering domestic manufacturing, solidifies APAC's position as the dominant regional market and a critical hub for both demand and supply of solar mirror components.

- Middle East and Africa (MEA) Strategic Importance: The MEA region is strategically vital for the Solar Mirror Market due to its extremely high DNI levels and massive, ongoing investment in utility-scale CSP projects, particularly in countries like the UAE (e.g., Mohammed bin Rashid Al Maktoum Solar Park in Dubai) and Morocco (e.g., Noor Ouarzazate Complex). These regions view CSP not only as an energy source but as a critical tool for economic diversification and long-term water security (through integrated desalination). The focus in MEA is on maximizing mirror durability against severe desert conditions, driving demand for premium, anti-soiling, and highly resilient glass mirrors, making it a high-value market segment despite the inherent logistical and operational challenges.

- North America (NA) Maturity and Innovation: North America, particularly the Southwestern United States, represents a mature market with substantial existing CSP installations. Market activity here is characterized by system optimization, refurbishment of older plants, and focused technological innovation rather than expansive greenfield construction typical of APAC or MEA. The demand is strong for specialized, high-efficiency mirrors and advanced O&M technologies, including sophisticated cleaning robotics and predictive analytics tools. Policy shifts and the renewed emphasis on clean energy tax credits in the US are expected to stimulate moderate capacity additions and drive demand for domestically sourced mirror components, emphasizing high quality and sustainability credentials.

- Europe's Established Expertise and Focus on Spain: Europe, particularly Spain, remains a historical cornerstone of the global CSP industry, holding a vast installed base developed during the early 2000s. While new utility-scale project development has slowed, the region maintains unparalleled expertise in CSP engineering, manufacturing, and R&D. European demand focuses heavily on replacement mirrors, upgrades to increase thermal efficiency, and specialized mirrors for smaller, high-temperature industrial applications. Germany also remains a key player in supplying specialized CSP components and manufacturing equipment globally, maintaining its relevance through technological leadership and export prowess in high-end mirror coatings and system integration.

- Latin America's Emerging Potential: Countries like Chile are emerging as important markets, leveraging the high DNI in the Atacama Desert. CSP projects, often integrated with thermal storage, are viewed as essential for providing stable baseload power to mining operations and national grids. While market penetration is currently lower than in other regions, the vast solar resource potential and increasing energy demand, coupled with governmental interest in diversifying energy portfolios, position Latin America as a high-potential market for solar mirror deployment over the latter half of the forecast period.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Solar Mirror Market.- Schott Solar CSP

- Saint-Gobain Solar

- Guardian Industries

- Alanod GmbH & Co. KG

- Rioglass Solar

- Flabeg Solar International GmbH

- Glassbel

- Euroglas

- Industrial Solar GmbH

- BrightSource Energy

- eSolar

- Absolicon Solar Collector AB

- Archimede Solar Energy

- TVP Solar SA

- Solarglas

- Dürr Group

- ACWA Power (Developer/End-User Influence)

- Abengoa (CSP Engineering)

- Saray Solar

- SAGE Electrochromics (Subsidiary of Saint-Gobain)

Frequently Asked Questions

Analyze common user questions about the Solar Mirror market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Solar Mirror Market?

The primary driver is the global transition towards reliable, dispatchable renewable energy, which utilizes Concentrated Solar Power (CSP). Solar mirrors enable CSP plants to integrate thermal energy storage, allowing electricity generation 24/7 or on demand, addressing the intermittency issues associated with wind and photovoltaic (PV) solar generation.

How do solar mirror materials impact the overall efficiency of CSP projects?

Mirror materials critically impact efficiency through reflectivity and durability. High-grade, low-iron glass mirrors with superior silver backing offer maximum solar reflection (up to 96%), ensuring optimal energy concentration. Material durability, including anti-corrosion coatings, minimizes performance loss over the projected 25-year operational lifespan of the plant, directly influencing the Levelized Cost of Energy (LCOE).

What technological innovations are currently addressing the issue of soiling and dust on solar mirrors?

Technological innovations focus on reducing soiling-related performance loss and lowering water consumption. Key developments include advanced hydrophobic and anti-soiling nanoparticle coatings that repel dust and facilitate easier dry cleaning. Additionally, automated robotic cleaning systems and research into electrodynamic screen (EDS) technology offer potential waterless solutions for harsh desert environments.

Which geographical region holds the largest growth potential for solar mirror deployment in the forecast period?

The Asia Pacific (APAC) region, particularly China and India, holds the largest growth potential due to aggressive renewable energy targets, significant governmental investment in CSP infrastructure, and favorable economic policies promoting large-scale utility projects. The Middle East and North Africa (MEA) also remain critically important due to high DNI levels and sustained commitment to energy diversification through CSP.

What is the primary difference between solar mirrors used in parabolic trough systems versus power tower systems?

Parabolic trough systems primarily use curved, elongated mirrors that focus sunlight onto linear receiver tubes, requiring high uniformity in curvature. Power tower systems utilize vast fields of flat or slightly curved individual mirrors (heliostats) that track the sun and reflect sunlight onto a single central receiver tower, demanding extremely high tracking accuracy and robust structural integrity to handle wind loads.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager