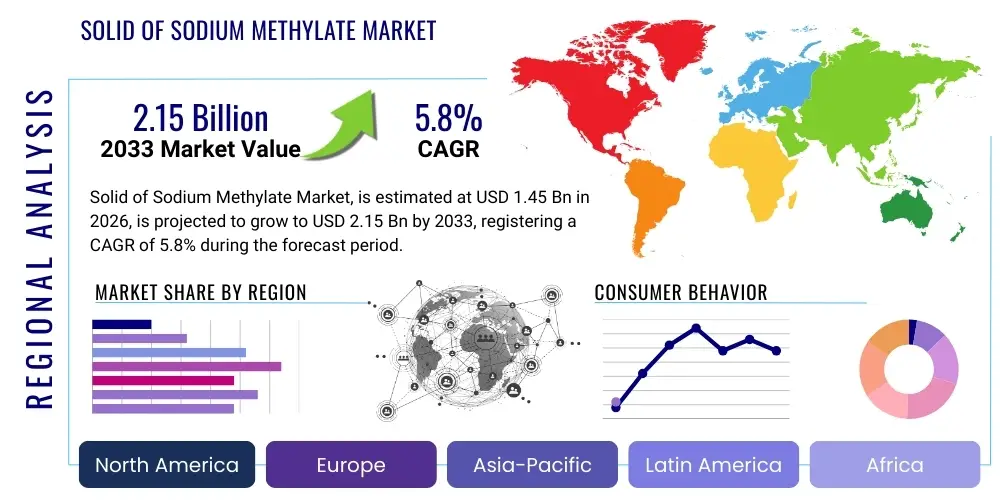

Solid of Sodium Methylate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438440 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Solid of Sodium Methylate Market Size

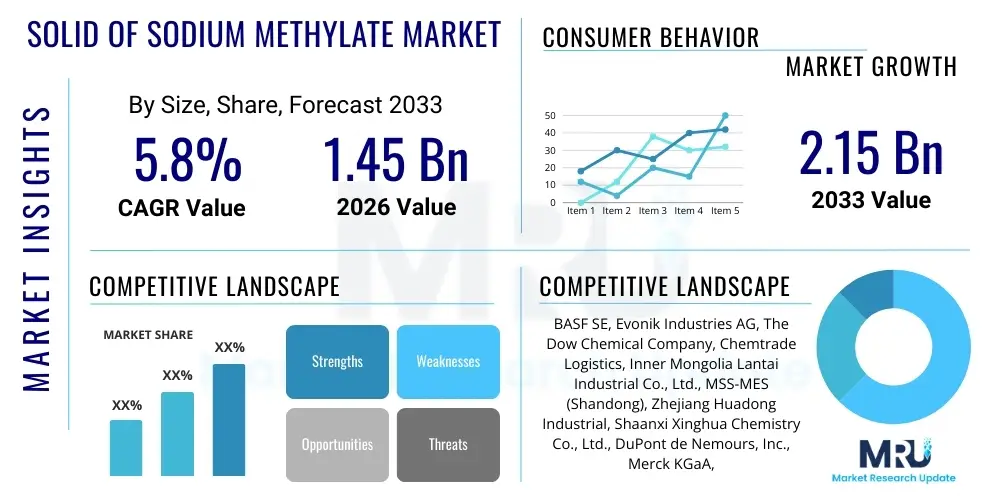

The Solid of Sodium Methylate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.45 billion in 2026 and is projected to reach USD 2.15 billion by the end of the forecast period in 2033. This growth trajectory is primarily fueled by the accelerating global demand for sustainable biofuels, particularly biodiesel, where solid sodium methylate acts as a highly effective transesterification catalyst. Furthermore, the robust expansion of the pharmaceutical synthesis sector, especially in emerging economies, contributes significantly to the market's upward trend, leveraging the compound’s essential role as a strong nucleophile and base in complex organic reactions. The increasing adoption of the solid form is also driven by its advantages in specific large-scale chemical processes regarding stability and handling compared to its liquid solutions.

Solid of Sodium Methylate Market introduction

Solid Sodium Methylate (NaOCH3), also known as Sodium Methoxide, is a white, free-flowing, and highly hygroscopic powder widely recognized as a powerful alkaline condensing agent, catalyst, and base in organic synthesis. This compound is critical across numerous industrial applications, most notably serving as the primary catalyst for the transesterification of vegetable oils and animal fats in the production of Fatty Acid Methyl Esters (FAME), which constitute biodiesel. Its high purity and strong basicity make it an indispensable reagent in processes requiring efficient proton abstraction and nucleophilic attack. The market for the solid form is characterized by its reliance on the downstream performance of the renewable energy sector and the pharmaceutical industry, providing highly reactive sodium ions stabilized by the methoxide group.

The major applications of Solid Sodium Methylate span sectors including chemical synthesis, personal care, and polymers, besides the dominant biodiesel production segment. In pharmaceuticals, it is a crucial intermediate in the synthesis of various compounds, including vitamins, antibiotics (like sulfa drugs), and specialized agrochemicals. Key benefits driving its adoption include superior catalytic efficiency, ease of volumetric dosing compared to liquid forms in certain manufacturing setups, and high reaction selectivity. The primary driving factors for market expansion include stringent global mandates promoting biofuel usage, technological advancements leading to cleaner and safer production methods for NaOCH3, and the rapid growth of the specialty chemical manufacturing base in the Asia Pacific region.

Solid of Sodium Methylate Market Executive Summary

The Solid of Sodium Methylate Market is poised for sustained expansion, driven fundamentally by robust global energy policies favoring biodiesel and accelerated innovation within the pharmaceutical and fine chemical manufacturing sectors. Business trends indicate a strong push towards backward integration among major producers to secure reliable methanol feedstock supply and optimize production costs, enhancing competitiveness. The market structure remains moderately consolidated, with key players focusing on expanding production capacity in high-demand regions like Southeast Asia and Central Europe to minimize logistical complexities associated with hazardous chemical transport. Strategic collaborations aimed at developing safer handling and storage solutions for the solid reagent are also emerging as a pivotal competitive factor, aiming to mitigate user safety concerns.

Regionally, Asia Pacific commands a significant share and is projected to exhibit the highest CAGR, primarily fueled by massive government investments in biofuel programs in countries like India, Indonesia, and China, coupled with the rapid expansion of generic drug manufacturing hubs. North America and Europe, while mature, maintain steady growth driven by the sustained operational requirements of established biodiesel facilities and specialty chemical manufacturers adhering to stringent purity standards. Segment trends highlight that the catalyst application segment, specifically for biodiesel production, remains the dominant revenue generator. However, the fine chemicals and pharmaceutical intermediates segment is expected to show accelerated growth, reflecting the increasing global complexity of synthesized materials requiring high-purity, solid methoxide as a foundational building block.

AI Impact Analysis on Solid of Sodium Methylate Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Solid of Sodium Methylate Market typically revolve around optimizing complex chemical processes, enhancing supply chain transparency for hazardous materials, and predicting demand fluctuations in volatile downstream markets like crude oil and agriculture. Users frequently inquire about AI's role in improving yield and reducing waste in transesterification reactions, minimizing batch variations in pharmaceutical synthesis, and managing the intricate logistics of a highly reactive solid chemical. The primary concerns center on the cost of integrating AI-driven systems into existing production infrastructure and ensuring data integrity and security for proprietary synthesis processes. Expectations are high regarding AI’s ability to predict raw material pricing (especially methanol) and automate quality control checks (purity analysis), ultimately leading to significant operational cost reductions and enhanced product reliability throughout the value chain.

AI’s influence is moving beyond simple data aggregation into predictive modeling and automation. In manufacturing, machine learning algorithms can analyze real-time reactor data—temperature, pressure, and concentration—to dynamically adjust catalyst dosing (Solid Sodium Methylate) for optimal reaction kinetics, thereby maximizing FAME conversion efficiency and minimizing unreacted reagents. Furthermore, AI-powered systems are crucial in managing the volatility of raw material sourcing. By analyzing global methanol prices, agricultural output forecasts, and trade policy shifts, AI tools provide accurate predictive modeling, allowing manufacturers to optimize inventory levels of sodium methylate and secure favorable forward contracts, mitigating financial risk associated with price fluctuations.

Logistically, the handling of solid sodium methylate, a highly flammable and reactive chemical, requires rigorous safety protocols. AI-driven risk assessment platforms utilize sensory data and historical accident records to identify potential hazards in real-time within production facilities and storage warehouses. This predictive maintenance extends to equipment critical for handling and packaging, reducing downtime and preventing exposure incidents. The integration of AI in quality assurance, particularly through automated spectroscopic analysis interpretation, accelerates the release cycle of high-purity grades required by the pharmaceutical sector, ensuring compliance with global pharmacopeia standards with minimal human intervention and error.

- AI optimizes transesterification reaction parameters, increasing biodiesel yield and purity.

- Machine learning algorithms predict methanol feedstock price volatility, improving procurement strategies.

- Predictive maintenance driven by AI reduces equipment failure in highly corrosive handling environments.

- Automated spectroscopic analysis validates the purity of solid sodium methylate for pharmaceutical applications, accelerating quality control.

- AI-enhanced supply chain visibility improves hazardous material tracking and compliance with international transport regulations.

- Risk assessment platforms utilize real-time data to enhance worker safety protocols during handling and storage.

DRO & Impact Forces Of Solid of Sodium Methylate Market

The Solid of Sodium Methylate Market operates under a distinct set of Drivers, Restraints, and Opportunities (DRO) that collectively shape its growth trajectory and competitive landscape. The market is overwhelmingly driven by favorable regulatory environments globally, particularly the mandates in North America and Europe concerning blending ratios for biodiesel, creating a sustained, high-volume demand for effective transesterification catalysts. Opportunities lie significantly in developing specialized high-purity grades for niche pharmaceutical applications and capitalizing on the burgeoning chemical manufacturing shift toward Asia Pacific. Conversely, the market faces significant restraints related to the inherent hazards of handling a highly reactive solid, which necessitates complex, expensive, and specialized storage and transportation logistics, alongside intense competition from liquid sodium methylate solutions which offer easier integration into continuous processes for certain end-users.

The impact forces influencing the market are multifaceted, stemming from technological advancements in catalyst efficiency and environmental sustainability pressures. The increasing focus on bio-based chemicals and renewable energy sources exerts a powerful positive force, pushing manufacturers to refine and expand their sodium methylate production capabilities. However, the volatile pricing of raw materials, chiefly methanol and sodium, introduces economic uncertainty, which acts as a major external constraint. Furthermore, the development of alternative, potentially greener catalytic systems, such as enzymatic catalysts or heterogeneous solid bases, poses a long-term substitution threat. The need for constant innovation in packaging technology to ensure the solid's stability and safe delivery across diverse climatic conditions is a critical internal force driving R&D spending.

Segmentation Analysis

The Solid of Sodium Methylate market is systematically segmented based on Purity Grade, End-Use Application, and Manufacturing Process, reflecting the diverse requirements of downstream industries. Segmentation by Purity Grade is essential as applications ranging from bulk biodiesel production to precise pharmaceutical synthesis demand distinct levels of concentration and impurity control, significantly impacting pricing and production complexity. The major application segments, including Fuels, Pharmaceuticals, Agrochemicals, and Speciality Chemicals, exhibit highly varied growth rates and sensitivity to economic cycles. This rigorous segmentation allows market participants to tailor product offerings and strategic marketing efforts to address the unique performance needs and regulatory requirements of each specific end-use sector, ensuring optimal resource allocation and competitive positioning across the global value chain.

- By Purity Grade:

- Standard Grade (97-98%)

- High Purity Grade (98-99.5%)

- Ultra-High Purity Grade (>99.5%)

- By End-Use Application:

- Biodiesel Production (Catalyst)

- Pharmaceutical Synthesis (Intermediates, Reagents)

- Agrochemicals (Synthesis of Pesticides and Herbicides)

- Specialty Chemicals and Dyes

- Polymerization Catalysts

- By Manufacturing Process:

- Methanol and Sodium Reaction

- Ion Exchange Process

Value Chain Analysis For Solid of Sodium Methylate Market

The value chain for Solid Sodium Methylate begins with upstream activities focused on securing and processing essential raw materials, primarily metallic sodium and high-purity methanol. The stability of methanol supply, which is often derived from natural gas or coal, is a critical bottleneck in the upstream segment, demanding strategic sourcing and risk management from key producers. Manufacturing involves complex, exothermic chemical reactions requiring specialized, corrosion-resistant reactors and highly controlled environments to produce the solid form, followed by rigorous drying and pulverization stages to achieve the required particle size and purity. Due to the high reactivity of the product, robust quality control and safe packaging are integral to the manufacturing process, ensuring the stability of the solid during subsequent logistics.

The midstream segment involves the intricate distribution channels necessary for hazardous chemicals. Direct distribution channels are predominantly used for large-volume customers like major biodiesel manufacturers, ensuring bulk supply efficiency and specific technical support. Conversely, indirect channels, relying on specialized chemical distributors and regional agents, cater to smaller pharmaceutical and fine chemical end-users, providing smaller, customized packaging and localized inventory management. The downstream segment is defined by the diverse application spectrum, where the product is consumed as a catalyst in large-scale biodiesel plants or as a reagent in specialty fine chemical labs, where purity and precise dosing are paramount. The efficiency and safety of the final consumption stage heavily rely on the technical service support provided by the manufacturers and distributors.

Solid of Sodium Methylate Market Potential Customers

The primary consumers of solid sodium methylate are large-scale industrial operators requiring efficient, strong basic reagents or catalysts for high-volume synthesis. Biodiesel producers represent the largest customer base globally, using the solid methoxide as a homogeneous catalyst to convert triglycerides into fatty acid methyl esters (FAME) in massive volumes. This customer segment is highly sensitive to price fluctuations and seeks long-term, stable supply contracts with quality assurance guarantees. Given the scale of operation, biodiesel plants often prefer the solid form for batch processing where precise mass-based dosing is preferred over volumetric solutions, justifying the investment in specialized handling equipment.

Beyond biofuels, the pharmaceutical and specialty chemical industries constitute the second major tier of customers. These buyers prioritize ultra-high purity grades and reliability, using sodium methylate as an essential reagent in complex multi-step organic synthesis, including the production of specialized APIs, intermediates, and life science research chemicals. Their demand is highly inelastic regarding price but extremely sensitive to purity specifications and regulatory compliance. Additionally, manufacturers of polymers, agrochemicals (herbicides and insecticides), and industrial dyes also represent a substantial, though smaller, customer base, utilizing the strong base properties of NaOCH3 in their synthesis pathways, often requiring customized particle sizes and low moisture content specifications to ensure optimal reaction performance and minimal side reactions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.45 Billion |

| Market Forecast in 2033 | USD 2.15 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Evonik Industries AG, The Dow Chemical Company, Chemtrade Logistics, Inner Mongolia Lantai Industrial Co., Ltd., MSS-MES (Shandong), Zhejiang Huadong Industrial, Shaanxi Xinghua Chemistry Co., Ltd., DuPont de Nemours, Inc., Merck KGaA, Avantor, Inc., Deepwater Chemical, Arkema Group, Tokyo Chemical Industry Co., Ltd. (TCI), Sumitomo Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Solid of Sodium Methylate Market Key Technology Landscape

The technological landscape of the Solid of Sodium Methylate market is primarily centered on optimizing the manufacturing process to enhance purity, reduce energy consumption, and ensure safety during the highly exothermic reaction between methanol and metallic sodium. One core technological area involves continuous process design, replacing traditional batch reactors to achieve greater throughput and consistency, which is crucial for meeting the large-scale demand from the biodiesel sector. Furthermore, advancements in drying technology, such as specialized vacuum drying and fluidized bed systems, are pivotal in ensuring the final solid product has extremely low moisture content. Low moisture content is critical because sodium methylate is highly hygroscopic, and water contamination compromises its reactivity and shelf life, particularly for high-purity pharmaceutical applications.

Another significant technological focus is the development of encapsulated or stabilized forms of solid sodium methylate. Since the product is classified as a hazardous chemical requiring special handling, companies are investing in R&D to create formulations that are less prone to spontaneous combustion or reactivity when exposed to trace moisture or air, thereby lowering transportation and storage risks. This includes advanced packaging solutions utilizing inert gas environments and multi-layer barriers. Furthermore, the integration of advanced sensors and process analytical technology (PAT) into manufacturing lines allows for real-time monitoring of residual sodium content and particle size distribution. This precision control is instrumental in producing the ultra-high purity grades demanded by the synthesis of complex active pharmaceutical ingredients (APIs) and high-value specialty chemicals, ensuring compliance with strict industry standards.

Finally, sustainability technologies are gaining prominence, focusing on minimizing waste generation and maximizing solvent recovery, particularly methanol. Manufacturers are implementing closed-loop systems and utilizing efficient catalytic converters to manage and reuse byproducts. Innovations in catalyst separation and recovery techniques within the biodiesel production facilities also indirectly influence the demand for solid sodium methylate, requiring tailored physical properties that facilitate easier filtration or settling post-reaction. These technological shifts are aimed at reducing the total cost of ownership for end-users while simultaneously adhering to increasingly strict environmental regulations regarding chemical production and waste disposal.

Regional Highlights

Regional dynamics play a crucial role in shaping the Solid of Sodium Methylate market, dictated primarily by biofuel policy frameworks, industrial infrastructure, and pharmaceutical manufacturing prowess.

- Asia Pacific (APAC): This region is forecast to exhibit the fastest growth, driven by substantial government support for biodiesel (especially in Indonesia, Malaysia, and India) and the rapid shift of global pharmaceutical and agrochemical manufacturing bases into countries like China and India. APAC is both a major producer and consumer, characterized by competitive pricing and expanding domestic capacity, targeting both bulk and high-purity market segments.

- North America: A mature and stable market segment, characterized by established biodiesel production facilities, particularly in the US. Demand is consistent, driven by the Renewable Fuel Standard (RFS). The region maintains strong demand for high-purity grades required by its advanced pharmaceutical and specialty polymer industries, emphasizing supply reliability and stringent quality assurance.

- Europe: Growth is steady, anchored by the EU's blending mandates (RED II) and advanced chemical manufacturing clusters, especially in Germany and the Netherlands. Europe places a high premium on sustainability and safe handling, driving innovation in stabilized and packaged forms of the product. Strict REACH regulations influence production and distribution methods within this region.

- Latin America (LATAM): This region, particularly Brazil and Argentina, is a significant biodiesel producer and consumer, benefiting from abundant local feedstock (soybean oil). Market growth is robust but subject to local political and economic stability, primarily focused on the standard grade for fuel catalysis.

- Middle East and Africa (MEA): Currently representing the smallest market share, the MEA region shows nascent growth potential linked to developing infrastructure projects and regional chemical diversification initiatives. Demand is focused on specialized applications in petrochemicals and limited localized pharmaceutical production, dependent heavily on imports from European or Asian suppliers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Solid of Sodium Methylate Market.- BASF SE

- Evonik Industries AG

- The Dow Chemical Company

- Chemtrade Logistics

- Inner Mongolia Lantai Industrial Co., Ltd.

- MSS-MES (Shandong)

- Zhejiang Huadong Industrial

- Shaanxi Xinghua Chemistry Co., Ltd.

- DuPont de Nemours, Inc.

- Merck KGaA

- Avantor, Inc.

- Deepwater Chemical

- Arkema Group

- Tokyo Chemical Industry Co., Ltd. (TCI)

- Sumitomo Chemical Co., Ltd.

- Guan Yu Chemical (Shandong) Co., Ltd.

- Lianyungang Kede Chemical Co., Ltd.

- Shandong Xinyu Chemical Co., Ltd.

- Henan Jiandou Chemical Co., Ltd.

- Gelest, Inc.

Frequently Asked Questions

Analyze common user questions about the Solid of Sodium Methylate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary application driving the demand for Solid Sodium Methylate?

The predominant application driving market demand for Solid Sodium Methylate is its use as a highly effective catalyst in the transesterification process necessary for large-scale production of biodiesel (Fatty Acid Methyl Esters or FAME).

How does the Solid form of Sodium Methylate compare to the Liquid solution?

The solid form offers high purity and ease of precise mass-based dosing, making it preferred in certain batch processes and high-purity applications, whereas the liquid solution is often favored for easier integration into continuous flow reactors despite potential solvent handling complexity.

Which purity grade of Solid Sodium Methylate is required by the pharmaceutical industry?

The pharmaceutical industry typically requires Ultra-High Purity Grade (greater than 99.5%) Solid Sodium Methylate to ensure minimal impurities and optimal reaction selectivity in the synthesis of APIs and intermediates, conforming strictly to pharmacopeia standards.

What are the main risks associated with handling and storing Solid Sodium Methylate?

The main risks include high reactivity with moisture and air, posing corrosion and fire hazards, and its classification as a highly regulated, hazardous chemical requiring specialized, controlled storage under inert conditions and rigorous safety protocols during transport and dosing.

Which geographical region is expected to show the highest growth rate?

The Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR), driven by massive governmental investments in biofuel mandates and the rapid expansion of specialty chemical and pharmaceutical manufacturing capabilities across key emerging economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager