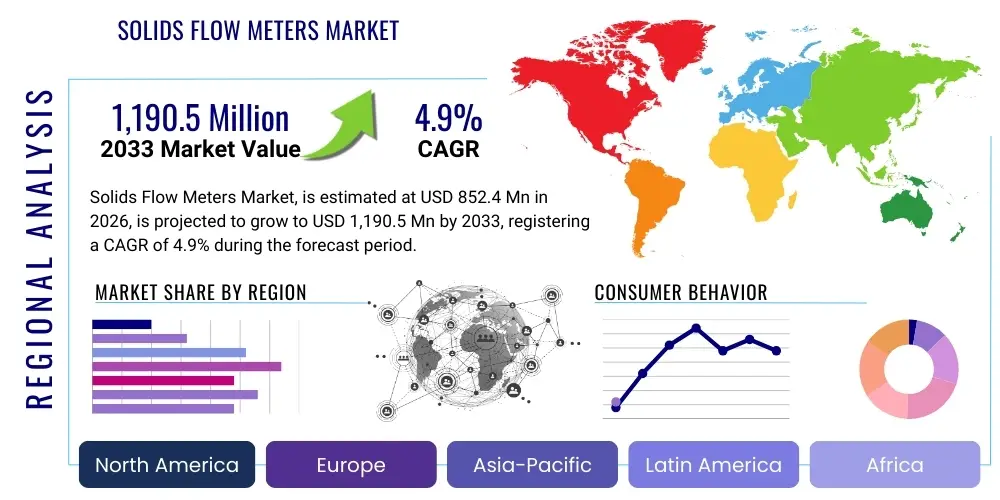

Solids Flow Meters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438918 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Solids Flow Meters Market Size

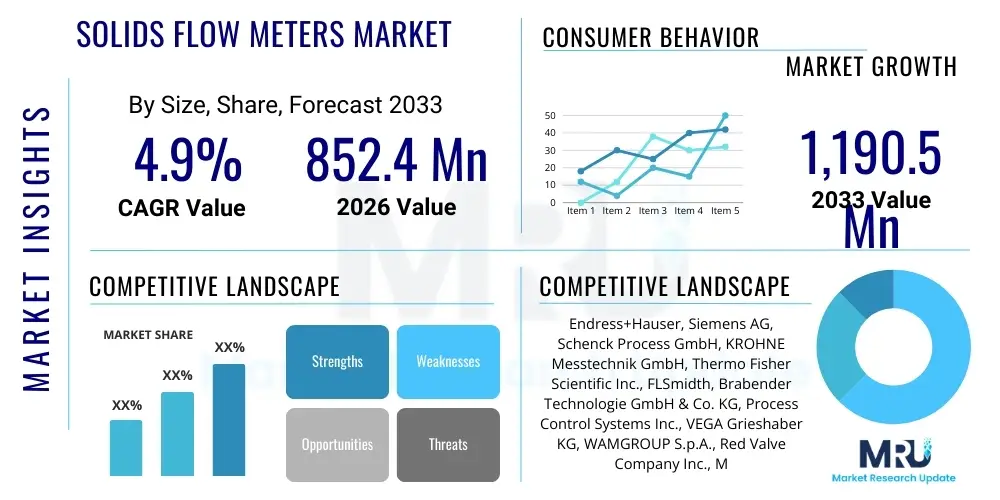

The Solids Flow Meters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.9% between 2026 and 2033. The market is estimated at USD 852.4 Million in 2026 and is projected to reach USD 1,190.5 Million by the end of the forecast period in 2033.

Solids Flow Meters Market introduction

Solids flow meters are specialized industrial instruments designed to measure the rate of mass or volume flow of dry bulk materials, powders, granules, and other solid particles within processing streams. These systems are crucial for achieving precise material balance, ensuring product quality consistency, and optimizing throughput in various industries where handling large volumes of bulk solids is integral. Key technologies utilized include impact flow meters, weighing belt feeders, ultrasonic flow meters, and Coriolis mass flow meters adapted for solid particulates, each suited for different material characteristics, flow rates, and accuracy requirements. The fundamental role of these devices is to provide continuous, reliable data on material movement, which is essential for automation and inventory management.

Major applications of solids flow meters span critical sectors such as cement production, mining and mineral processing, chemical manufacturing, food and beverage processing, and pharmaceuticals. In the cement industry, for instance, they monitor the flow of raw meal and finished cement, directly impacting kiln efficiency and product specification compliance. In the food sector, they ensure accurate proportioning of ingredients like flour, sugar, and additives, critical for recipe consistency and regulatory adherence. The primary benefits derived from the deployment of these meters include significant reduction in material waste, enhanced operational safety through monitoring potential blockages or uneven flow, and accurate transactional billing based on metered quantities.

The market is predominantly driven by the escalating demand for industrial automation, particularly the implementation of Industry 4.0 principles across manufacturing and processing plants globally. The necessity for real-time data collection and enhanced process transparency compels companies to invest in advanced flow measurement solutions. Furthermore, stringent regulatory requirements concerning material handling, emissions control, and product traceability, especially in the food and pharmaceutical sectors, necessitate highly accurate and verifiable flow measurement systems. The continuous innovation in sensor technology, including the integration of non-contact measurement principles and robust design to withstand abrasive materials, further propels market expansion by improving durability and measurement precision in harsh industrial environments.

Solids Flow Meters Market Executive Summary

The Solids Flow Meters Market is undergoing robust growth driven primarily by large-scale industrialization in emerging economies and the imperative for operational efficiency improvements in developed regions. Key business trends indicate a strong shift towards non-contact measurement technologies, such as advanced microwave and ultrasonic sensors, which minimize wear and tear associated with abrasive solids, thereby lowering maintenance costs and increasing equipment lifespan. Furthermore, the integration of flow meters into interconnected Industrial Internet of Things (IIoT) ecosystems is a significant trend, enabling remote monitoring, predictive maintenance scheduling, and deeper data analytics for yield optimization. Manufacturers are focusing on developing highly customized solutions that cater specifically to challenging materials, such as sticky powders or highly heterogeneous mixtures, ensuring high accuracy across diverse applications.

Regionally, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by massive investments in infrastructure development, expansion of the chemical and cement industries in countries like China and India, and the rising adoption of sophisticated automation technologies to meet global quality standards. North America and Europe remain mature markets, characterized by high adoption rates of advanced Coriolis and gravimetric systems, particularly within the pharmaceutical and high-value chemical processing sectors, where extreme measurement accuracy is non-negotiable. Regional strategies are centered on regulatory compliance, energy consumption reduction targets, and the modernization of existing legacy systems, driving the demand for retrofit solutions featuring enhanced digital connectivity.

In terms of segment trends, the continuous flow meter segment, primarily consisting of gravimetric and mass flow technologies, dominates the market due to its necessity in high-throughput applications requiring constant process control. Technology-wise, Coriolis mass flow meters, despite their higher initial cost, are gaining traction due to their ability to measure true mass flow independent of density changes, offering unparalleled accuracy crucial for complex chemical reactions and formulation processes. Industry-wise, the mining, metals, and minerals segment holds a substantial market share, relying heavily on durable impact and radiometric flow meters to handle extremely abrasive and high-volume bulk materials efficiently. The trend across all segments is towards greater miniaturization, improved ruggedness, and standardized digital communication protocols (e.g., HART, Profibus, Ethernet/IP) for seamless integration into enterprise resource planning (ERP) systems.

AI Impact Analysis on Solids Flow Meters Market

Common user questions regarding the influence of Artificial Intelligence (AI) on the Solids Flow Meters Market frequently revolve around optimizing complex material handling processes, reducing calibration downtime, and predicting equipment failure caused by abrasive flow. Users are keenly interested in whether AI algorithms can utilize sensor data (flow rate, pressure, temperature, vibration) to auto-calibrate meters, thereby significantly improving long-term measurement accuracy without manual intervention. Another major concern is how AI-driven analytics can identify subtle anomalies in material flow—such as rat-holing or bridging in hoppers—which are often invisible to traditional control systems, leading to unplanned production halts. Expectations center on AI transforming basic measurement tools into intelligent diagnostic platforms capable of offering prescriptive advice, dramatically enhancing the reliability and efficiency of solids handling operations, especially in dusty and harsh environments like cement and mining operations.

- AI facilitates predictive maintenance schedules by analyzing historical flow data and sensor vibrations, anticipating wear caused by abrasive solids.

- Machine learning algorithms enable real-time anomaly detection in material flow, flagging potential blockages or uneven feeding issues before they impact process quality.

- AI-driven optimization assists in dynamic calibration adjustments based on changes in bulk density, moisture content, or particle size distribution, enhancing measurement accuracy.

- Integration with plant-wide optimization tools allows AI to adjust feed rates dynamically to maximize throughput while minimizing energy consumption.

- AI enhances system self-diagnosis capabilities, reducing the mean time to repair (MTTR) by pinpointing the exact location and cause of measurement deviations.

DRO & Impact Forces Of Solids Flow Meters Market

The Solids Flow Meters Market is fundamentally shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO). Key drivers include the global push for industrial automation, particularly the necessity for precise batching and inventory control in high-value industries like pharmaceuticals and specialty chemicals, which directly mandate the use of highly accurate flow meters. The ongoing global capacity expansion in bulk material handling sectors, such as mining, construction, and food processing, further necessitates robust and reliable flow measurement systems to handle increasing volumes efficiently. These drivers are amplified by regulatory pressures requiring strict adherence to material accounting and environmental standards, particularly those governing dust control and fugitive emissions, where continuous monitoring of material inputs and outputs is mandatory for compliance.

Conversely, significant restraints hinder market growth. The high initial capital expenditure associated with purchasing and installing advanced flow meter technologies, especially highly accurate gravimetric systems or specialized Coriolis meters for solids, can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the operational complexity arising from abrasive materials and challenging flow conditions often leads to excessive wear, demanding frequent and costly maintenance, calibration, and replacement of internal components. The variability in the physical characteristics of bulk solids (e.g., changing particle size, moisture content, and density) poses inherent challenges to achieving consistently high measurement accuracy, which can lead to skepticism regarding the return on investment (ROI) compared to simpler, less precise methods.

Opportunities for market growth are abundant, primarily focused on technological innovation and market penetration in emerging economies. The development of next- generation, non-intrusive flow measurement technologies, such as advanced microwave or ultrasonic systems, promises to significantly reduce maintenance requirements and broaden the applicability across highly abrasive or corrosive materials. Moreover, the integration of wireless communication standards and self-diagnostic capabilities enhances the ease of deployment and maintenance in remote or hard-to-access industrial settings. The increasing global focus on sustainability and resource efficiency offers a substantial opportunity, as accurate flow meters are essential tools for minimizing material giveaway, optimizing resource utilization, and supporting circular economy initiatives across manufacturing supply chains, thus cementing their position as indispensable instruments in modern industrial plants.

Segmentation Analysis

The Solids Flow Meters Market is segmented based on technology, type, application, and end-use industry, reflecting the diverse requirements inherent in handling different types of bulk solids. The segmentation helps manufacturers tailor solutions to specific industrial needs, whether prioritizing high accuracy (gravimetric systems) for critical batching or ruggedness (impact meters) for high-volume, abrasive applications. Technological differentiation, specifically between continuous measurement and batch measurement methods, dictates the market dynamics, with continuous measurement dominating high-throughput industries. The increasing complexity of materials handled—from fine, cohesive powders to large, heterogeneous lumps—mandates a wide array of specialized sensor technologies, driving further fragmentation within the technology segments.

- By Type:

- Batch Flow Meters (e.g., Weigh Hoppers, Loss-in-Weight Feeders)

- Continuous Flow Meters (e.g., Impact Flow Meters, Solids Mass Flow Meters)

- By Technology:

- Impact Flow Meters (Momentum Based)

- Coriolis Mass Flow Meters (Specialized Solids Variants)

- Gravimetric Feeders (Belt Weighers, Loss-in-Weight Systems)

- Differential Pressure/Air Flow Meters (for Pneumatic Conveying)

- Ultrasonic Flow Meters (Non-Contact)

- Microwave/Capacitance Flow Meters

- By Application:

- Process Control and Monitoring

- Loading and Unloading

- Inventory Management and Material Accounting

- Batching and Blending

- By End-Use Industry:

- Mining, Metals, and Minerals

- Chemical and Petrochemical

- Food and Beverage

- Cement, Glass, and Aggregates

- Pharmaceutical

- Pulp and Paper

- Power Generation (Coal/Ash Handling)

Value Chain Analysis For Solids Flow Meters Market

The value chain for the Solids Flow Meters Market begins with upstream activities involving raw material suppliers, predominantly providing high-grade metals (stainless steel, specialized alloys for wear resistance), electronic components, and advanced sensors (piezoelectric elements, microwave transmitters). Component quality is critical, especially for meters exposed to highly abrasive materials. Manufacturers then engage in intricate design, fabrication, and assembly, requiring specialized expertise in fluid dynamics for solids, calibration standards, and software integration. Key activities at this stage include R&D focused on improving sensor accuracy under variable flow conditions and ensuring equipment robustness against physical wear, leading to higher manufacturing costs compared to liquid flow measurement devices.

The distribution channel plays a vital role in market penetration, often involving a mix of direct sales channels for large industrial projects and indirect channels utilizing technical distributors and specialized system integrators. Direct sales are common for high-value, customized gravimetric and Coriolis systems where extensive technical consultation and installation support are required. Indirect channels, consisting of regional distributors, provide local inventory, basic technical service, and quick delivery for standardized impact or volumetric meters. System integrators are crucial intermediaries, incorporating flow meters into larger plant automation systems and providing seamless integration with existing control systems (DCS/PLC).

Downstream activities center around installation, commissioning, maintenance, and after-sales services, which are particularly important given the harsh operating environments. End-users require continuous technical support, regular calibration services, and spare parts provision for wear-prone components. The effectiveness of the service network directly impacts customer satisfaction and operational uptime. The final consumption stage involves end-users across various heavy processing industries utilizing the collected flow data for inventory management, process optimization, quality control, and compliance reporting, thus closing the loop and generating demand for service contracts and technology upgrades.

Solids Flow Meters Market Potential Customers

The primary potential customers for Solids Flow Meters are organizations operating within heavy process industries that handle large quantities of bulk solid materials, where accurate mass balancing and continuous process control are critical. These customers prioritize reliability, durability, and compliance with precise measurement standards. Key buyers include large multinational mining corporations that require highly ruggedized impact or radiometric meters for throughput measurement of ores and coal; major cement manufacturers needing accurate flow data for raw meal blending and finished product output; and large chemical processors demanding highly precise gravimetric or specialized Coriolis meters for ingredient batching and blending in polymerization or compounding processes.

Furthermore, the food and beverage industry represents a significant growth area for high-accuracy solids flow meters, particularly those designed to meet hygienic standards (e.g., 3A or EHEDG compliance). Food processors are major buyers, utilizing these instruments to precisely dose and blend ingredients such as flours, sugars, cocoa powder, and additives, ensuring product uniformity and minimizing costly ingredient giveaway. Pharmaceutical manufacturers constitute another crucial segment, prioritizing ultra-high accuracy and validation capabilities (like 21 CFR Part 11 compliance) for loss-in-weight feeders and flow meters used in precise tablet formulation and powder handling, where measurement errors can lead to serious regulatory issues and product quality failures.

Infrastructure and energy sectors, including power plants relying on pulverized coal or biomass, and construction material suppliers dealing with aggregates and asphalt components, are persistent buyers. These users seek flow meters that can withstand high temperatures, high flow rates, and abrasive materials while providing reliable, continuous data for operational efficiency and environmental reporting. The increasing focus on resource optimization and the modernization of legacy plants across all these sectors ensures a steady demand for both new installations and replacement units featuring advanced diagnostic and connectivity features.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 852.4 Million |

| Market Forecast in 2033 | USD 1,190.5 Million |

| Growth Rate | 4.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Endress+Hauser, Siemens AG, Schenck Process GmbH, KROHNE Messtechnik GmbH, Thermo Fisher Scientific Inc., FLSmidth, Brabender Technologie GmbH & Co. KG, Process Control Systems Inc., VEGA Grieshaber KG, WAMGROUP S.p.A., Red Valve Company Inc., Magnetrol International, Inc., Dwyer Instruments, Inc., Milltronics (part of Siemens), ABB Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Solids Flow Meters Market Key Technology Landscape

The technology landscape for solids flow meters is diverse, reflecting the inherent difficulties in accurately measuring bulk solids compared to homogeneous liquids or gases. Current key technologies primarily fall into two categories: mechanical (contact) methods like impact plates and gravimetric feeders, and non-contact methods like ultrasonic, microwave, and radiometric systems. Impact flow meters remain highly popular, utilizing the measurement of momentum change as solids strike a sensing plate; they are cost-effective and rugged but offer moderate accuracy. Gravimetric feeders, including belt weighers and loss-in-weight feeders, represent the gold standard for high accuracy, continuous mass measurement, especially critical for precise batching applications, though they involve more moving parts and higher maintenance complexity.

A major evolution within the landscape is the adaptation and refinement of Coriolis technology for solids measurement. Specialized Coriolis flow meters for powders and granules offer true mass measurement, independent of density variations, overcoming a traditional limitation of volumetric and even impact systems. Although the design requires careful handling of abrasion and material buildup, their superior accuracy justifies their use in high-value chemical and pharmaceutical environments. Simultaneously, non-contact technologies are rapidly advancing to mitigate the perpetual issue of wear and tear. Ultrasonic sensors are increasingly used to measure material velocity in pneumatic conveying lines, while microwave and capacitance sensors are employed to detect material presence, flow/no-flow conditions, and approximate concentration, offering low-maintenance solutions for difficult materials.

Future technological development is strongly focused on enhanced diagnostics and digital integration. Sensors are becoming smarter, embedding microprocessors capable of performing self-calibration checks and providing detailed information about the flow regime (e.g., particle distribution and air velocity in pneumatic systems). There is a concerted effort to standardize digital outputs, ensuring seamless integration into Industry 4.0 platforms using protocols such as IO-Link and Profinet. Furthermore, advancements in sensor materials and surface treatments are continually improving resistance to abrasion and adhesion (stickiness), thereby extending the operational life and reliability of the instruments in the most demanding environments like hot clinker handling or cohesive powder transfer.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand for solids flow meters, influenced by the level of industrial maturity, infrastructure spending, and regulatory frameworks governing material handling and environmental safety.

- Asia Pacific (APAC): APAC is the fastest-growing region, driven by large-scale investments in infrastructure, rapidly expanding cement and construction sectors, and the massive growth of chemical and specialty industrial manufacturing in China, India, and Southeast Asia. The demand here is dual-natured: high-volume, rugged impact meters for raw material handling, and precise gravimetric systems for sophisticated manufacturing processes adopting automation.

- North America: This region represents a mature market characterized by high technology adoption and a strong focus on regulatory compliance, particularly in the pharmaceutical and food and beverage sectors. Demand is driven by the modernization of aging infrastructure and the implementation of advanced IIoT solutions for optimizing existing flow measurement systems, favoring high-accuracy Coriolis and loss-in-weight technologies.

- Europe: Europe is a significant market, primarily emphasizing operational efficiency, energy conservation, and strict environmental standards (e.g., ATEX directives). The market favors sophisticated, digitally integrated flow meters (including advanced gravimetric feeders) capable of providing high data transparency and traceability, critical for specialized chemical and high-value manufacturing processes.

- Latin America (LATAM): Growth is steady, primarily fueled by the strong presence of the mining and metals industries, especially in countries like Brazil and Chile. The market prioritizes robust, durable, and cost-effective flow measurement solutions that can withstand harsh operating conditions, often utilizing impact and simpler volumetric meters for primary ore flow monitoring.

- Middle East and Africa (MEA): The market here is emerging, driven by increasing investments in petrochemical, cement production, and mineral extraction projects. Demand is project-based, focusing on acquiring reliable flow measurement technology as part of new plant construction, emphasizing solutions that offer high reliability in challenging desert environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Solids Flow Meters Market.- Endress+Hauser

- Siemens AG

- Schenck Process GmbH

- KROHNE Messtechnik GmbH

- Thermo Fisher Scientific Inc.

- FLSmidth

- Brabender Technologie GmbH & Co. KG

- Process Control Systems Inc.

- VEGA Grieshaber KG

- WAMGROUP S.p.A.

- Red Valve Company Inc.

- Magnetrol International, Inc.

- Dwyer Instruments, Inc.

- Milltronics (part of Siemens)

- ABB Ltd.

- Monitor Technologies LLC

- Ramsey Products (acquired by Pentair)

- Ohmart Vega Corporation

- J-Tec Material Handling

- Powder & Bulk Solids Technology

Frequently Asked Questions

Analyze common user questions about the Solids Flow Meters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between impact flow meters and gravimetric feeders?

Impact flow meters measure flow rate based on the momentum change of solids hitting a sensing plate, offering moderate accuracy, high robustness, and lower cost for high throughput. Gravimetric feeders (such as loss-in-weight systems) continuously weigh the material being dispensed, providing the highest accuracy true mass flow measurement, essential for precise batching and blending in critical applications.

How does particle size variability affect the accuracy of solids flow meters?

Particle size variability significantly affects the accuracy, especially in volumetric and impact meters, as changes in particle distribution alter bulk density and momentum transfer. Highly accurate systems like gravimetric feeders or specialized Coriolis meters mitigate this by measuring true mass flow, which is less sensitive to density and size variations, maintaining consistent measurement reliability.

Which technology is best suited for pneumatic conveying applications?

For pneumatic conveying, the best suited technologies are specialized microwave or ultrasonic flow meters. Microwave systems monitor density and velocity non-intrusively, handling high velocities and minimizing abrasion. Ultrasonic systems are effective for measuring velocity and presence but may require calibration based on particle concentration profiles within the pipe.

What are the main drivers for adopting IIoT integration in solids flow metering?

The main drivers include the need for centralized monitoring of multiple flow points across large plants, enabling advanced diagnostics, remote troubleshooting, and real-time data feeding into predictive maintenance models. IIoT integration facilitates superior operational visibility and reduces manual intervention in challenging industrial environments, maximizing equipment uptime.

In which industry segment is the demand for high-accuracy solids flow meters most pronounced?

The demand for ultra-high accuracy solids flow meters, specifically specialized Coriolis and advanced loss-in-weight gravimetric systems, is most pronounced in the Pharmaceutical and Specialty Chemical industries. Precision is paramount in these sectors for regulatory compliance, product formulation consistency, and minimizing high-cost ingredient waste.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager