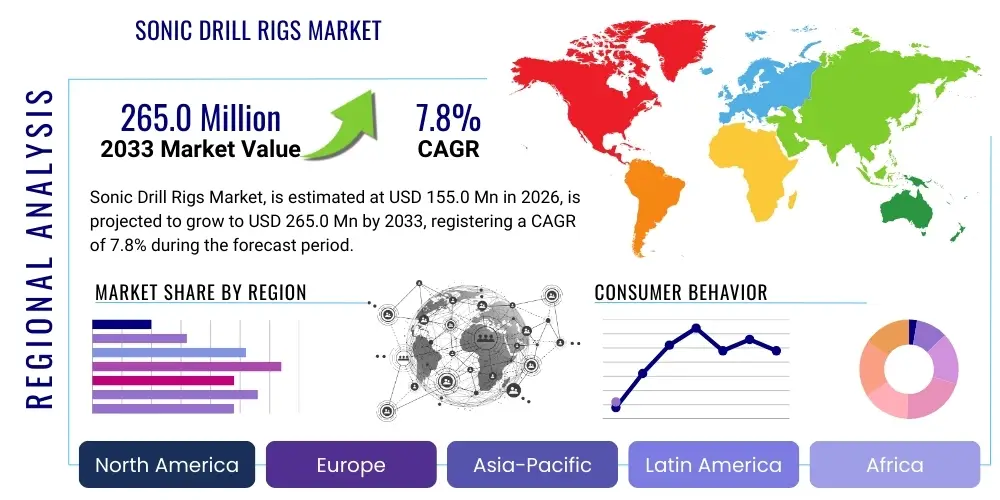

Sonic Drill Rigs Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438324 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Sonic Drill Rigs Market Size

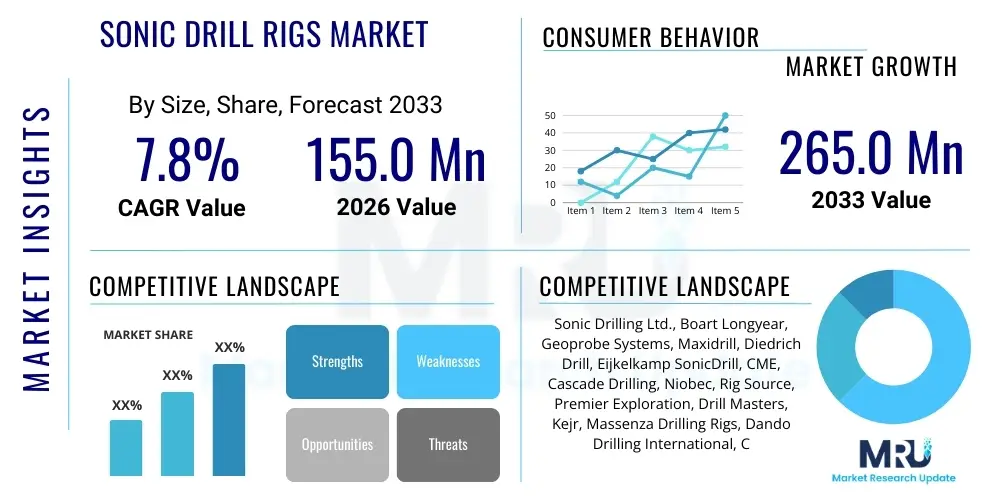

The Sonic Drill Rigs Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 155.0 Million in 2026 and is projected to reach USD 265.0 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for rapid and high-quality subsurface investigation across critical sectors such as infrastructure development, environmental remediation, and mineral exploration, particularly in geologically challenging areas where conventional drilling methods are less efficient or cost-prohibitive. The market size reflects significant investments in advanced drilling technologies that minimize environmental impact while maximizing core sample integrity and retrieval rates.

Sonic Drill Rigs Market introduction

Sonic drill rigs utilize high-frequency, resonant vibrations to fluidize soil particles surrounding the drill string, enabling deep and accurate penetration with minimal rotational force. This technology provides superior core sample recovery (often exceeding 95%) and reduces the volume of drill cuttings, making it highly preferred for environmental and geotechnical applications. Major applications span infrastructure projects like bridge and highway construction, contamination plume mapping, dam stability assessments, and mining operations requiring precise resource delineation. The primary benefits include faster drilling rates in challenging formations (like glacial till and overburden), exceptional sample quality, reduced site disturbance, and the capacity to drill vertically or at various angles. Driving factors propelling this market include global emphasis on sustainable infrastructure development, stricter environmental regulations necessitating accurate site assessments, and technological advancements enhancing rig mobility and operational efficiency in remote locations, coupled with the rising global demand for base metals and critical minerals requiring deeper and more complex exploration methods.

Sonic Drill Rigs Market Executive Summary

The Sonic Drill Rigs Market is characterized by robust business trends centered on technological innovation, focusing on automation, integration of digital monitoring systems, and development of compact, trailer-mounted rigs to enhance maneuverability in urban or confined spaces. Segment trends highlight the dominance of the geotechnical and environmental sectors due to their stringent requirements for non-contaminated and undisturbed samples, alongside significant growth in the mining segment as companies seek efficient methods for deep overburden penetration. Regionally, North America and Europe maintain leading positions due to established infrastructure projects and rigorous environmental standards, while the Asia Pacific region is demonstrating the fastest growth trajectory, fueled by large-scale infrastructure investment initiatives, rapid urbanization, and increasing exploration activities in countries like Australia, India, and China, necessitating advanced subsurface investigation capabilities that sonic technology reliably provides. Key market players are prioritizing strategic mergers, acquisitions, and collaborations to expand their geographical footprint and diversify their application-specific rig portfolios, emphasizing sustainable and energy-efficient drilling solutions to maintain competitive advantages and appeal to environmentally conscious clients.

AI Impact Analysis on Sonic Drill Rigs Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Sonic Drill Rigs Market primarily revolve around operational efficiency gains, predictive maintenance capabilities, and the potential for autonomous drilling processes. Common user questions often ask: "How can AI improve sample quality prediction?", "What role does machine learning play in optimizing drilling parameters based on real-time lithology changes?", and "Will AI integration reduce the necessity for highly specialized human operators in the field?" The underlying theme of these concerns is centered on leveraging AI to minimize operational downtime, enhance drilling speed and accuracy in unpredictable subsurface conditions, and ultimately reduce the overall cost per meter drilled. There is a strong expectation that AI systems will transition sonic drilling from a highly operator-dependent skill to a data-driven, automated process, offering superior geological interpretation and safety protocols by analyzing complex sensor data from the drill string and subsurface environment in real time, leading to significant increases in operational productivity and reduced risk exposure.

- Enhanced Predictive Maintenance: AI algorithms analyze vibration signatures and component stress to forecast equipment failure, minimizing unplanned downtime.

- Real-time Parameter Optimization: Machine learning models adjust frequency, amplitude, and downforce based on instantaneous feedback from ground conditions, maximizing penetration rate and sample integrity.

- Automated Geological Interpretation: AI processes downhole sensor data (e.g., gamma, resistivity) to create instant, high-resolution 3D models of the subsurface, improving decision-making during exploration.

- Improved Safety Protocols: Computer vision and sensor fusion systems monitor site conditions and operator behavior, flagging potential hazards and ensuring compliance with safety standards.

- Autonomous Drilling Cycles: Development of self-regulating drilling routines that optimize sequences and resource utilization with minimal human intervention.

DRO & Impact Forces Of Sonic Drill Rigs Market

The Sonic Drill Rigs Market is influenced by a dynamic interplay of Drivers (D), Restraints (R), and Opportunities (O), which together constitute the critical Impact Forces shaping its trajectory. The primary driver is the unparalleled capability of sonic technology to retrieve high-quality, undisturbed core samples in complex, unconsolidated geological formations, essential for detailed geotechnical and environmental assessments. Additionally, the increasing global investment in large-scale infrastructure and mining projects, coupled with stringent environmental regulations demanding less intrusive site investigation methods, significantly boosts adoption. However, market expansion is restrained by the relatively higher initial capital investment required for sonic rigs compared to conventional rotary systems, and the necessity for specialized operator training to effectively utilize the advanced technology. Opportunities are abundant, specifically in emerging markets where rapid infrastructure development is underway, and through innovation in compact, multi-functional sonic rigs suitable for diverse applications, including geothermal drilling and efficient bedrock sampling. These forces combine to push manufacturers towards developing cost-competitive and versatile equipment, emphasizing long-term operational savings and superior data collection capabilities to justify the high upfront expenditure, thereby ensuring sustained growth and wider market penetration.

Segmentation Analysis

The Sonic Drill Rigs Market segmentation provides a comprehensive view of the industry structure based on key differentiating factors such as drilling depth capacity, mounting type, and primary application area. This granular analysis is crucial for understanding specific consumer needs, market penetration strategies, and regional demand dynamics. The market is primarily divided by the required depth of exploration, influencing the power and size of the rig deployed, and by the application segment which dictates the mandatory regulatory compliance and sample quality requirements. For instance, the environmental segment demands smaller, mobile rigs capable of precision sampling near residential areas, while the mining segment requires high-power rigs capable of penetrating deep overburden efficiently.

Further analysis of the mounting type reveals distinct trends. Truck-mounted rigs dominate segments requiring high mobility across large sites, such as mining exploration, whereas trailer and track-mounted units are preferred for stability and operation in soft ground or confined spaces, common in geotechnical investigations. This detailed segmentation allows manufacturers to tailor their product offerings, focusing on specific performance metrics like penetration rate, vibration isolation, and ease of deployment, ensuring alignment with the end-user's operational environment and specific project goals, thereby optimizing market reach and product relevance across diverse industrial applications globally.

- By Drilling Depth Capacity:

- Shallow (Up to 100 meters)

- Medium (100 to 300 meters)

- Deep (Above 300 meters)

- By Mounting Type:

- Truck-Mounted Rigs

- Track-Mounted Rigs

- Trailer-Mounted/ATV Rigs

- By Application:

- Geotechnical Investigation

- Environmental Monitoring and Remediation

- Mining Exploration

- Construction and Piling

- Geothermal Drilling

Value Chain Analysis For Sonic Drill Rigs Market

The value chain for the Sonic Drill Rigs Market commences with Upstream Analysis, focusing intensely on the sourcing of specialized components, particularly high-frequency oscillator technology, hydraulic systems, and robust materials capable of withstanding constant vibration and stress. Key upstream activities include research and development focused on improving vibration efficiency and noise reduction, component manufacturing, and rigorous quality control of steel alloys and precision-machined parts. Suppliers of custom hydraulic pumps, specialized engines (Tier 4 compliant), and advanced control systems play a critical role, as the reliability and longevity of these components directly determine the performance and lifespan of the final sonic rig. Optimization at this stage is crucial for managing manufacturing costs and ensuring the high technological standard required by the market.

Moving through the midstream, the value chain encompasses the complex process of rig assembly, integration of proprietary sonic heads, advanced control panel installation, and extensive field testing. Manufacturers must possess specialized expertise in integrating mechanical, hydraulic, and electronic systems to produce a synchronized machine capable of maintaining consistent high-frequency oscillation under varying loads. The distribution channel is bifurcated into direct and indirect methods. Direct distribution involves sales teams engaging large mining or environmental consulting firms, offering customized rigs and comprehensive aftermarket service packages. Indirect distribution relies on regional dealers and rental companies, especially for smaller or older models, allowing wider market access and supporting short-term project needs where purchasing a rig outright is not economically feasible for the end-user.

The Downstream Analysis involves the crucial activities of after-sales service, spare parts supply, technical support, and operator training. Given the specialized nature of sonic technology, ongoing maintenance and expert support are major value differentiators. Effective technical support ensures minimal rig downtime, which is highly valued by customers in time-sensitive exploration and remediation projects. Furthermore, strategic partnerships with end-users and site contractors provide valuable feedback, driving continuous product improvement and the development of application-specific tooling. The overall efficiency of the value chain is highly dependent on seamless coordination between component suppliers, rig manufacturers, and the downstream service network to deliver reliable, high-performing drilling solutions.

Sonic Drill Rigs Market Potential Customers

The primary end-users, or potential customers, of sonic drill rigs are concentrated across sectors that demand high-quality, undisturbed subsurface data, rapid drilling penetration, and minimal environmental impact. The most significant segment comprises Geotechnical Consulting Firms and Civil Engineering Contractors, who utilize sonic drilling for foundation testing, soil stratification analysis for major infrastructure projects (bridges, high-rises, dams), and stability assessments. These buyers require precision drilling to validate design parameters and ensure the structural integrity of large capital investments. Their demand is project-based and driven by the superior sample recovery rates offered by sonic technology, which is paramount in heterogeneous and highly variable soil conditions.

Another major customer segment involves Environmental Consulting and Remediation Companies. These organizations leverage sonic rigs for defining the boundaries of subsurface contamination plumes (e.g., volatile organic compounds, petroleum hydrocarbons) and installing monitoring wells and recovery systems. For environmental buyers, the ability to collect continuous, highly representative soil and groundwater samples without cross-contamination is non-negotiable. Furthermore, the low volume of cuttings produced minimizes waste disposal costs, aligning with stringent environmental compliance protocols, which makes sonic drilling a preferred technology over conventional methods that often smear contamination across different layers during penetration.

The third substantial group includes Mining and Mineral Exploration Companies, particularly those focusing on projects with deep overburden or unconsolidated, glacially deposited materials that hinder traditional rotary drilling. Sonic technology allows for fast, cost-effective penetration through these difficult layers to reach the target bedrock or ore body, securing continuous, high-integrity samples of the overburden strata. Additionally, government agencies, including geological surveys and departments responsible for water resource management and defense infrastructure, represent steady institutional buyers, utilizing sonic rigs for scientific research, hazard mapping, and installation of critical monitoring infrastructure, rounding out the diverse base of highly specialized end-users who recognize the technological advantages and cost efficiencies provided by this advanced drilling method.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 155.0 Million |

| Market Forecast in 2033 | USD 265.0 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sonic Drilling Ltd., Boart Longyear, Geoprobe Systems, Maxidrill, Diedrich Drill, Eijkelkamp SonicDrill, CME, Cascade Drilling, Niobec, Rig Source, Premier Exploration, Drill Masters, Kejr, Massenza Drilling Rigs, Dando Drilling International, Comacchio, Sandvik, Atlas Copco, Foraco, Major Drilling Group International |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sonic Drill Rigs Market Key Technology Landscape

The core technology driving the Sonic Drill Rigs Market is the sonic oscillator or sonic head, which utilizes specialized eccentric weights rotated at high speed (typically 50 Hz to 150 Hz) to generate resonant, high-frequency vibratory energy. This energy is transmitted down the drill string, causing the soil matrix directly surrounding the drill bit and casing to momentarily liquefy or fluidize. This process dramatically reduces skin friction, enabling rapid and smooth penetration through dense, heterogeneous formations like glacial till, cobbles, and boulders, where conventional rotary methods often struggle or refuse penetration entirely. Modern technological advancements focus on closed-loop hydraulic systems and sophisticated electronic control units that allow operators precise, real-time tuning of frequency and amplitude to optimize drilling performance based on immediate subsurface conditions, maximizing efficiency and minimizing wear on expensive tooling.

Beyond the core sonic oscillator, the market's technological landscape is shaped by innovations in peripheral systems designed to enhance operational safety, efficiency, and data acquisition. This includes the integration of advanced data logging and telemetry systems, which capture parameters such as drilling speed, down-pressure, torque, and energy consumption, allowing for remote monitoring and centralized data analysis. Furthermore, the push towards automated rig control is gaining momentum, utilizing sensors and programmable logic controllers (PLCs) to maintain consistent drilling parameters and automatically execute complex drilling sequences, significantly reducing the reliance on manual adjustment and decreasing the margin for human error, thereby ensuring higher consistency in core sample recovery and overall project documentation quality.

A crucial area of ongoing innovation involves the development of specialized casing and tooling designed to work synchronously with the high-frequency vibrations. Manufacturers are engineering proprietary casing systems that minimize sample disturbance and prevent cross-contamination, which is paramount for environmental and geotechnical applications. Additionally, there is an increasing focus on developing more fuel-efficient and environmentally friendly rigs, often incorporating hybrid power sources or optimizing hydraulic pump configurations to reduce noise pollution and fuel consumption, aligning with stricter global regulatory standards and the industry's shift towards sustainable practices. The integration of robust telematics and fleet management software is also becoming standard, offering predictive maintenance insights and optimizing asset utilization across large drilling fleets globally, representing a continuous evolutionary push in the technological capabilities of sonic drilling platforms.

Regional Highlights

- North America (USA, Canada): Dominates the market share due to extensive environmental remediation requirements, mature mining exploration sectors, and continuous large-scale infrastructure renewal projects, supported by high adoption rates of advanced drilling technologies and substantial investment in geological surveying.

- Europe (Germany, UK, France): Characterized by stringent geotechnical investigation standards for dense urban development and high demand from the rapidly expanding geothermal energy sector, particularly for low-enthalpy geothermal heat pumps, driving the need for precise, non-intrusive drilling.

- Asia Pacific (APAC) (China, India, Australia): Projected to exhibit the highest growth CAGR, fueled by massive government investment in infrastructure (roads, rail, ports), increased mining activities focusing on critical minerals, and a growing recognition of sonic drilling's efficiency in complex alluvial and weathered rock formations.

- Latin America (Brazil, Chile, Mexico): Growth is primarily linked to robust mineral exploration, especially copper and lithium mining, where sonic drilling offers superior performance in penetrating thick, unconsolidated overburden common in the Andean region, ensuring project viability and resource definition.

- Middle East and Africa (MEA): Emerging as a significant market driven by oil and gas infrastructure expansion, substantial construction mega-projects in the GCC nations, and increased investment in water resource management and exploration activities across Africa, requiring durable and effective drilling solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sonic Drill Rigs Market.- Sonic Drilling Ltd.

- Boart Longyear

- Geoprobe Systems

- Maxidrill

- Diedrich Drill

- Eijkelkamp SonicDrill

- CME (Central Mine Equipment Company)

- Cascade Drilling

- Niobec

- Rig Source

- Premier Exploration

- Drill Masters

- Kejr, Inc.

- Massenza Drilling Rigs

- Dando Drilling International

- Comacchio S.p.A.

- Sandvik AB

- Atlas Copco AB

- Foraco International SA

- Major Drilling Group International Inc.

Frequently Asked Questions

Analyze common user questions about the Sonic Drill Rigs market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of sonic drilling over conventional rotary methods?

Sonic drilling provides superior core sample recovery, often exceeding 95% even in difficult overburden, minimal sample disturbance, and significantly faster penetration rates in unconsolidated materials like gravel, cobbles, and boulders, leading to reduced overall project timelines and higher data quality.

In which applications is sonic drilling considered the most cost-effective solution?

Sonic drilling proves most cost-effective in complex geotechnical investigations, critical environmental remediation projects requiring non-contaminated samples, and mining exploration involving deep penetration through thick, heterogeneous glacial till or overburden where conventional methods frequently stall or fail.

What is the typical depth capacity of modern sonic drill rigs?

Modern sonic drill rigs are generally segmented by capacity; shallow rigs handle depths up to 100 meters, medium rigs reach 100 to 300 meters, and deep exploration rigs, often utilized in mining, are now capable of penetrating well beyond 300 meters, depending on the geology and rig power.

How is the sonic drill rigs market addressing environmental concerns?

The market is addressing environmental concerns through the development of low-noise, reduced-emission engines (Tier 4 compliance), the adoption of biodegradable hydraulic fluids, and the core benefit of the technology itself, which produces minimal drill cuttings, substantially reducing waste disposal requirements and site disturbance.

What factors restrain the widespread adoption of sonic drill rigs globally?

The main restraints include the high initial capital investment required for sonic drilling equipment compared to standard conventional rotary rigs and the necessity for highly specialized training and technical expertise required for operators to efficiently manage and maintain the complex sonic oscillator and hydraulic systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager