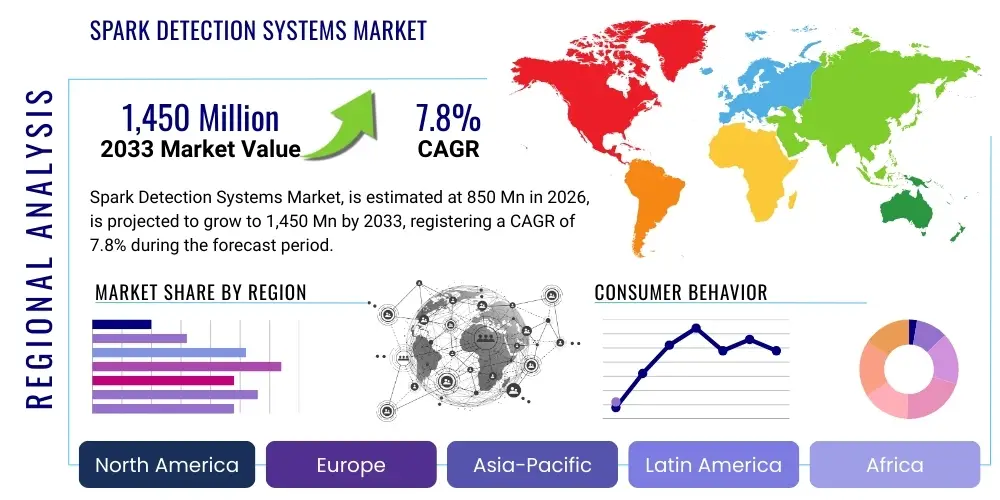

Spark Detection Systems Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439271 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Spark Detection Systems Market Size

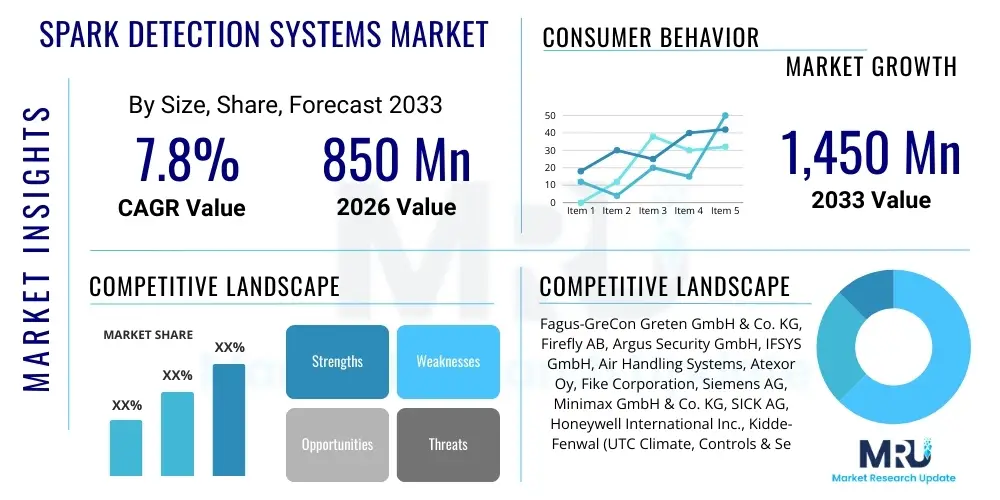

The Spark Detection Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1,450 million by the end of the forecast period in 2033. This growth is primarily driven by escalating industrial safety regulations and the increasing adoption of automated fire prevention solutions across diverse sectors prone to combustible dust and volatile materials.

Spark Detection Systems Market introduction

The Spark Detection Systems Market encompasses a range of specialized technologies designed to identify and extinguish sparks or embers in pneumatic conveying systems, dust collection units, and other industrial processes where combustible materials are handled. These systems typically consist of highly sensitive infrared or optical detectors, a control unit, and an extinguishing module, often utilizing water mist or inert gases. The primary product offering includes sophisticated sensor arrays capable of rapid detection and response, crucial for preventing industrial fires and dust explosions that can lead to catastrophic property damage, production downtime, and loss of life. Major applications span industries such as woodworking, textile, food processing, pharmaceuticals, energy, and recycling, where fine particulate matter is inherent to operations. The inherent benefits of these systems are multifold, including enhanced operational safety, compliance with stringent regulatory standards, significant reduction in insurance premiums, and preservation of capital assets and production continuity. They play a critical role in safeguarding both personnel and infrastructure from potential ignition sources.

Driving factors for this market's expansion include the global emphasis on workplace safety, spurred by regulatory bodies such as OSHA and ATEX, which mandate robust fire and explosion prevention measures in high-risk environments. Technological advancements, particularly in sensor sensitivity, data analytics, and connectivity (IoT integration), are further enhancing the effectiveness and reliability of spark detection systems, making them more attractive to a wider industrial base. The increasing complexity of manufacturing processes, coupled with the rising volume of combustible materials processed across various sectors, necessitates advanced protective solutions. Furthermore, the growing awareness among businesses regarding the economic repercussions of industrial incidents, including direct damages, business interruption losses, and reputational harm, fuels the proactive adoption of these critical safety technologies. This convergence of regulatory push, technological pull, and economic rationale underpins the steady growth trajectory of the spark detection systems market.

Spark Detection Systems Market Executive Summary

The Spark Detection Systems Market is experiencing robust growth, driven by an intensified focus on industrial safety and stricter regulatory frameworks worldwide. Business trends indicate a shift towards integrated solutions that offer not only detection and extinguishing capabilities but also predictive maintenance, remote monitoring, and compatibility with broader industrial automation systems. Companies are increasingly investing in research and development to enhance sensor accuracy, reduce false alarms, and improve system response times, leveraging advanced algorithms and machine learning. Regional trends highlight North America and Europe as mature markets with high adoption rates due to well-established safety standards, while Asia Pacific demonstrates rapid expansion fueled by industrialization, infrastructure development, and growing awareness of safety protocols in emerging economies. Latin America, the Middle East, and Africa are also showing promising growth as industrial sectors mature and global safety standards permeate these regions.

Segmentation trends reveal that the market is predominantly segmented by component (detectors, control panels, extinguishing systems), end-use industry (wood processing, textiles, food & beverage, pharmaceuticals, power generation, recycling), and technology (IR, optical, flame detection). The wood processing and textile industries remain significant contributors to market revenue due to their inherent high risk of combustible dust. However, the food & beverage and pharmaceutical sectors are emerging as strong growth areas, driven by stringent hygiene and safety regulations for handling fine powders. Additionally, there is a rising demand for comprehensive, customizable systems that can adapt to specific operational environments and varying levels of risk. The market is also seeing consolidation, with key players acquiring smaller, specialized technology providers to expand their product portfolios and geographical reach, indicating a strategic push towards more holistic safety solutions.

AI Impact Analysis on Spark Detection Systems Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize spark detection systems, questioning its potential to enhance detection accuracy, minimize false positives, and enable predictive maintenance. There's significant interest in AI's capacity for pattern recognition to distinguish between actual sparks and other thermal anomalies, thereby improving system reliability and reducing operational interruptions. Concerns also emerge regarding the implementation complexity, data privacy, and the potential for AI systems to become overly reliant on learned patterns, potentially missing novel or infrequent spark signatures. Users expect AI to move beyond simple rule-based detection towards intelligent, adaptive systems capable of real-time environmental analysis, offering a more proactive and nuanced approach to industrial fire and explosion prevention. The integration of machine learning for optimized extinguishing responses and system self-diagnosis is also a key area of user expectation and curiosity.

- Enhanced Detection Accuracy: AI algorithms can analyze complex data patterns from sensors, distinguishing genuine sparks from environmental noise (e.g., reflections, hot spots not posing an immediate threat), significantly reducing false alarms.

- Predictive Maintenance: Machine learning models can monitor system performance, identify anomalies, and predict potential equipment failures in detectors or extinguishing components, enabling proactive maintenance and ensuring continuous operation.

- Optimized Response Mechanisms: AI can process real-time environmental data (e.g., airflow, material type, dust concentration) to dynamically adjust extinguishing parameters, improving the effectiveness and efficiency of suppression.

- Adaptive Learning: Systems can learn from past incidents and non-incidents, continuously refining detection thresholds and response protocols to improve overall system intelligence and adaptability to changing operational conditions.

- Integration with Industrial IoT (IIoT): AI facilitates seamless integration with broader IIoT platforms, allowing spark detection systems to contribute to a holistic factory safety ecosystem, sharing data for comprehensive risk assessment and management.

- Improved Root Cause Analysis: AI-powered analytics can correlate spark incidents with operational parameters, helping identify potential root causes and implement preventive measures to avoid recurrence.

- Reduced Operational Downtime: By minimizing false alarms and optimizing responses, AI contributes to fewer unnecessary production stoppages, thereby enhancing operational efficiency and productivity.

DRO & Impact Forces Of Spark Detection Systems Market

The Spark Detection Systems Market is significantly influenced by a confluence of driving factors, critical restraints, and substantial opportunities that collectively define its growth trajectory and impact forces. A primary driver is the stringent enforcement of industrial safety regulations and standards globally, such as those set by OSHA, NFPA, and ATEX directives, which mandate proactive measures against industrial fires and explosions, particularly in environments handling combustible dust. Additionally, the increasing automation and mechanization across various industries, coupled with the rising production volumes of fine particulate materials in sectors like woodworking, textiles, food processing, and pharmaceuticals, inherently elevate the risk of ignition, thereby boosting the demand for sophisticated detection systems. The growing awareness among industrialists regarding the colossal financial and reputational damage incurred from industrial incidents further compels them to invest in advanced safety solutions.

However, the market also faces considerable restraints. The high initial capital investment required for installing comprehensive spark detection and extinguishing systems can be a significant barrier for small and medium-sized enterprises (SMEs), which often operate on tighter budgets. Furthermore, the complexity of integrating these specialized systems with existing industrial control infrastructure, along with the need for highly skilled personnel for installation, calibration, and maintenance, presents operational challenges. Concerns regarding false alarms, which can lead to unnecessary production stoppages and associated costs, also act as a restraint, prompting manufacturers to continuously enhance system reliability and accuracy. The lack of standardized installation and operational guidelines in some developing regions further impedes widespread adoption, creating market fragmentation and uncertainty.

Despite these challenges, substantial opportunities exist for market expansion. The ongoing technological advancements in sensor technology, artificial intelligence, and IoT connectivity offer avenues for developing more intelligent, predictive, and integrated spark detection solutions that can address previous limitations. The increasing demand for customized systems tailored to specific industry needs, materials, and environmental conditions presents a fertile ground for innovation and market differentiation. Furthermore, the expansion of manufacturing and processing industries in emerging economies, coupled with growing investments in industrial safety infrastructure, represents a significant untapped market potential. The shift towards sustainable and environmentally friendly industrial practices also opens doors for systems that minimize water usage or utilize non-toxic extinguishing agents. The impact forces are predominantly positive, propelled by a global imperative for industrial safety and technological innovation, yet tempered by economic considerations and integration complexities.

Segmentation Analysis

The Spark Detection Systems market is comprehensively segmented to provide a granular understanding of its diverse components, technological applications, and end-user industries. This segmentation aids in identifying specific market dynamics, growth drivers, and competitive landscapes within each category, allowing for targeted strategic development and investment. The primary segmentation criteria include the type of component, the technology employed, the end-use industry, and the system's operational design.

- By Component

- Detectors (Infrared Detectors, Optical Detectors, Flame Detectors)

- Control Panels

- Extinguishing Systems (Water Extinguishing Systems, Gas Extinguishing Systems, Diversion Systems)

- Ancillary Components (Sensors, Software, Alarms, Cables, Mounting Hardware)

- By Technology

- Infrared (IR) Detection

- Optical (Visual Light) Detection

- UV Detection

- Multi-Spectrum Detection

- By End-Use Industry

- Wood Processing & Joinery

- Textile & Non-Woven Production

- Food Processing & Agriculture (Flour Mills, Sugar Refining, Grain Handling)

- Pharmaceutical & Chemical

- Power Generation (Biomass, Coal Handling)

- Recycling & Waste Management

- Plastics & Rubber

- Automotive

- Metal Processing

- Other Manufacturing

- By System Design

- Standalone Systems

- Integrated Systems

Value Chain Analysis For Spark Detection Systems Market

The value chain for the Spark Detection Systems market begins with the upstream activities involving research and development of core technologies, raw material sourcing, and component manufacturing. This stage is crucial for innovation in sensor technology, microcontrollers, and extinguishing agents. Suppliers of specialized optical components, infrared emitters/receivers, electronic circuits, and precision mechanical parts form the backbone of this segment. Manufacturers heavily invest in R&D to enhance detection accuracy, speed, and reliability, as well as to develop robust, industrial-grade enclosures and communication interfaces. Quality control at this stage is paramount to ensure the performance and longevity of the final product, which is often deployed in harsh industrial environments. Strategic partnerships with specialized component suppliers are common to ensure access to cutting-edge technology and maintain a competitive edge.

The midstream activities encompass the assembly, integration, and testing of spark detection systems. This involves combining detectors, control panels, extinguishing units, and software into a cohesive, functional system. Manufacturers focus on modular designs to facilitate customization and ease of installation. Rigorous testing and certification against international safety standards (e.g., ATEX, FM Global, UL) are essential before market entry. Downstream activities primarily involve distribution, installation, commissioning, and post-sales services. Distribution channels can be direct, where manufacturers sell directly to large industrial clients, or indirect, leveraging a network of specialized industrial safety distributors, system integrators, and value-added resellers (VARs). These indirect channels often provide localized support, technical expertise, and integration services, playing a crucial role in market penetration, especially for complex installations or in regions with specific regulatory requirements.

The final stage of the value chain is focused on the end-user and the ongoing support provided. This includes initial site assessment, custom system design, professional installation, staff training, and continuous maintenance and support services. Direct distribution allows manufacturers to maintain tighter control over customer relationships and service quality, often preferred for large, strategic accounts. Indirect channels, however, extend market reach and provide regional expertise. Post-sales support, including spare parts availability, software updates, and emergency response services, is a critical differentiator, ensuring the long-term operational efficiency and safety compliance of the installed systems. The overall efficiency and effectiveness of the value chain are optimized through robust logistics, skilled technical personnel, and a strong customer-centric approach, emphasizing the importance of both product quality and comprehensive service delivery.

Spark Detection Systems Market Potential Customers

The potential customers for Spark Detection Systems are predominantly industrial facilities and manufacturing plants that process, store, or convey combustible materials, particularly in fine particulate forms. These include a wide array of sectors inherently susceptible to ignition risks and dust explosions due to the nature of their operations. The primary objective for these customers is to mitigate the risk of industrial fires and explosions, protect their assets, ensure the safety of their workforce, and comply with increasingly stringent occupational safety regulations and environmental standards. Their buying decisions are often influenced by risk assessment outcomes, insurance requirements, regulatory compliance mandates, and the potential for significant financial losses from downtime and damage.

Specific end-user industries that constitute the largest customer base include the wood processing industry, encompassing sawmills, furniture manufacturers, and particleboard producers, which generate substantial amounts of combustible wood dust. Similarly, the textile industry, especially those involved in ginning, spinning, weaving, and non-woven production, face high risks from fibrous materials and dust. The food and beverage sector, including flour mills, sugar refineries, grain elevators, and spice processing plants, are critical markets due to their handling of organic dusts that are highly explosive. Pharmaceutical and chemical manufacturing facilities, dealing with fine powders and volatile organic compounds, also represent a significant customer segment. Furthermore, power generation plants utilizing biomass or coal, recycling and waste management facilities processing various combustible materials, and industries involved in plastics and rubber manufacturing are vital targets for spark detection system providers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,450 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fagus-GreCon Greten GmbH & Co. KG, Firefly AB, Argus Security GmbH, IFSYS GmbH, Air Handling Systems, Atexor Oy, Fike Corporation, Siemens AG, Minimax GmbH & Co. KG, SICK AG, Honeywell International Inc., Kidde-Fenwal (UTC Climate, Controls & Security), Viking SupplyNet, W. D. N. E. International B.V., Hoerbiger Holding AG, Pyroguard (Halma plc), Protectowire FireSystems, FLIR Systems, Inc., MSA Safety Inc., Spectrex Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Spark Detection Systems Market Key Technology Landscape

The Spark Detection Systems market is characterized by a dynamic and evolving technology landscape, primarily centered on enhancing detection accuracy, response speed, and system reliability while minimizing false alarms. At its core, the technology relies heavily on advanced sensor arrays, predominantly infrared (IR) detectors, which are capable of sensing the specific IR radiation signatures emitted by hot particles or sparks. These IR sensors are designed to operate across various wavelengths and often employ sophisticated algorithms to filter out ambient heat sources and other non-critical environmental factors. Optical detection, sometimes utilizing visual light or UV light, also plays a role, especially in specialized applications where specific emission spectra are more prevalent. The integration of multi-spectrum detection capabilities is an emerging trend, combining different sensor types to provide a more robust and comprehensive detection solution, improving overall reliability and reducing false positives in complex industrial settings.

Beyond the detection hardware, the technological landscape extends to sophisticated control units that process sensor inputs in real-time. These control panels incorporate advanced microprocessors and proprietary software algorithms to interpret signals, differentiate between genuine threats and environmental noise, and trigger appropriate responses. Modern systems are increasingly integrating Artificial Intelligence (AI) and Machine Learning (ML) capabilities to further refine detection logic, enable predictive maintenance, and adapt to changing operational environments. This allows systems to learn from historical data, optimize performance over time, and provide more intelligent decision-making. Connectivity plays a crucial role, with many systems featuring IoT (Internet of Things) integration for remote monitoring, data logging, and seamless communication with broader industrial automation and safety management systems. This network capability facilitates centralized control, data analytics, and timely alerts to relevant personnel, enhancing overall facility safety management.

The extinguishing component of spark detection systems also benefits from continuous technological innovation. Water mist systems are being refined for greater efficiency in cooling and suppressing sparks with minimal water usage, reducing potential water damage to sensitive equipment. High-speed solenoid valves are critical for rapid extinguishing agent delivery. For environments where water is unsuitable, such as those with water-reactive materials or sensitive electronics, inert gas extinguishing systems (e.g., nitrogen, argon) or chemical extinguishing agents are utilized. Diversion systems, which reroute contaminated material away from critical equipment, represent another technological approach, often employing high-speed gates or valves. The overall trend is towards a holistic, integrated safety ecosystem where spark detection systems are not isolated units but intelligent, networked components of a comprehensive industrial safety strategy, leveraging cutting-edge sensor, AI, and communication technologies to achieve unparalleled levels of protection.

Regional Highlights

- North America: This region is a mature market driven by stringent regulatory frameworks (OSHA, NFPA) and a high level of industrial automation. The U.S. and Canada are leading adopters, especially in woodworking, food processing, and power generation sectors. Continuous investment in safety technology and a strong presence of key market players characterize this region.

- Europe: Europe is another highly regulated market with strong emphasis on industrial safety, particularly through ATEX directives. Countries like Germany, the UK, and Scandinavia are at the forefront of adopting advanced spark detection systems, driven by a robust manufacturing base and a proactive approach to risk management in industries such as textiles, plastics, and pharmaceuticals.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid industrialization, increasing foreign direct investment in manufacturing, and rising awareness of industrial safety standards in economies like China, India, Japan, and South Korea. The expansion of woodworking, textile, and food processing industries is a key growth driver.

- Latin America: This region is experiencing steady growth, with increasing industrial development in countries like Brazil and Mexico. The adoption of spark detection systems is driven by a growing awareness of international safety standards and the need to protect burgeoning industrial infrastructure in sectors such as mining, agriculture, and manufacturing.

- Middle East and Africa (MEA): The MEA region is an emerging market for spark detection systems. Growth is primarily driven by investments in oil & gas, petrochemicals, and manufacturing sectors, coupled with a rising focus on occupational safety and the adoption of global best practices, particularly in GCC countries and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Spark Detection Systems Market.- Fagus-GreCon Greten GmbH & Co. KG

- Firefly AB

- Argus Security GmbH

- IFSYS GmbH

- Air Handling Systems

- Atexor Oy

- Fike Corporation

- Siemens AG

- Minimax GmbH & Co. KG

- SICK AG

- Honeywell International Inc.

- Kidde-Fenwal (UTC Climate, Controls & Security)

- Viking SupplyNet

- W. D. N. E. International B.V.

- Hoerbiger Holding AG

- Pyroguard (Halma plc)

- Protectowire FireSystems

- FLIR Systems, Inc.

- MSA Safety Inc.

- Spectrex Inc.

Frequently Asked Questions

Analyze common user questions about the Spark Detection Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary industries benefiting from Spark Detection Systems?

Spark Detection Systems primarily benefit industries that handle combustible materials in particulate form, such as woodworking, textile manufacturing, food processing (e.g., flour mills, sugar refineries), pharmaceuticals, power generation (biomass/coal), and recycling plants, where the risk of dust explosions and fires is high.

How do Spark Detection Systems prevent fires and explosions?

These systems work by detecting infrared radiation emitted by sparks or embers in pneumatic conveying lines or dust collection systems. Upon detection, a control unit rapidly activates an extinguishing system, typically water mist or an inert gas, to eliminate the ignition source before it reaches combustible material in filters or silos, thereby preventing catastrophic fires or dust explosions.

What is the typical return on investment (ROI) for installing a Spark Detection System?

The ROI for a Spark Detection System is often substantial, primarily derived from preventing costly production downtime, avoiding significant property damage, reducing insurance premiums, and safeguarding human lives. While direct monetary savings vary, the avoidance of even a single major incident can easily offset the initial investment, making it a critical risk mitigation tool.

Are Spark Detection Systems customizable for different industrial environments?

Yes, modern Spark Detection Systems are highly customizable. Manufacturers offer modular designs and a range of detectors, extinguishing methods, and control logic options to suit specific industrial environments, material types, conveying speeds, and regulatory requirements, ensuring optimal protection for diverse operational setups.

How do AI and IoT integration enhance Spark Detection Systems?

AI and IoT integration significantly enhance these systems by enabling more accurate detection through machine learning algorithms that reduce false alarms. IoT allows for remote monitoring, predictive maintenance, and seamless data sharing with broader industrial automation platforms, leading to a more proactive, intelligent, and interconnected safety ecosystem within a facility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager