Spark Machining Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434682 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Spark Machining Market Size

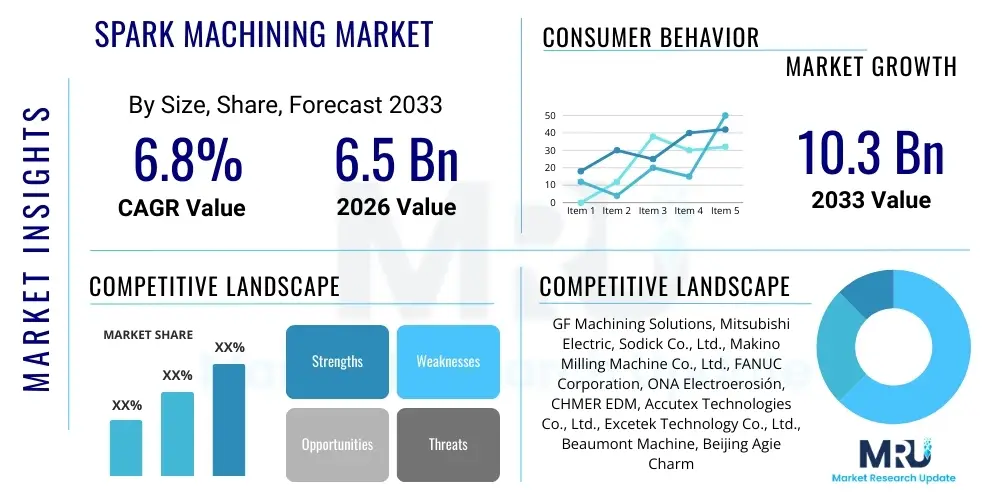

The Spark Machining Market, also known as Electrical Discharge Machining (EDM), is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 6.5 Billion in 2026 and is projected to reach USD 10.3 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily fueled by the increasing global demand for high-precision components across critical industries such as aerospace, medical devices, and complex mold manufacturing, where conventional machining methods struggle with hardness and intricate geometries.

Spark Machining Market introduction

The Spark Machining Market encompasses technologies that utilize controlled electrical discharges (sparks) to erode material from a workpiece. This non-contact thermal process is crucial for manufacturing parts from electrically conductive materials, particularly those that are hardened, exotic, or require extremely complex geometries and tight tolerances. EDM technology is segmented mainly into Wire EDM (W-EDM), Sinker EDM (Ram EDM), and Hole Drilling EDM, each catering to specific machining requirements, ranging from cutting intricate 2D shapes to generating complex 3D cavities.

Major applications of Spark Machining span precision tooling, die manufacturing, turbine blade production in aerospace, surgical instrument fabrication, and the creation of micro-components for the electronics sector. The primary benefit of EDM lies in its ability to machine materials regardless of their hardness, minimizing physical stress on the component and eliminating the risk of burr formation. This makes it indispensable for components made from superalloys like Inconel or titanium, widely used in high-performance engines and medical implants. The quality of the surface finish and the high degree of accuracy achieved further solidify its position in high-value manufacturing chains.

Driving factors for market expansion include the continuous trend toward miniaturization, necessitating extremely fine features and precise hole drilling, particularly in the semiconductor and medical device industries. Furthermore, the integration of advanced computer numerical control (CNC) systems with EDM machines enhances automation, multi-axis capabilities, and process stability, allowing manufacturers to handle more complex designs with reduced cycle times. The rising adoption of advanced materials like ceramics and composites (after metallization) that require specialized processing methods is also a significant catalyst for market growth, pushing manufacturers to invest in newer, high-efficiency EDM systems.

Spark Machining Market Executive Summary

The Spark Machining Market is poised for significant expansion, driven by accelerating demands in the global aerospace and automotive sectors, particularly concerning electric vehicle (EV) component manufacturing and lightweighting initiatives. Business trends indicate a strong shift towards incorporating automation and Industry 4.0 principles, including real-time monitoring and predictive maintenance capabilities, into modern EDM systems, enhancing overall equipment effectiveness (OEE) and reducing operational costs. Vendors are focusing on developing hybrid machines that combine EDM with milling or grinding functionalities to provide comprehensive single-setup machining solutions, thereby streamlining production workflows and optimizing floor space utilization for high-mix, low-volume manufacturing environments.

Regionally, the Asia Pacific (APAC) stands out as the dominant growth engine, primarily fueled by the massive concentration of manufacturing activities in China, Japan, South Korea, and India. These countries demonstrate rapid industrialization and high investment in precision engineering and electronics manufacturing, creating sustained demand for advanced Spark Machining tools. North America and Europe, while mature, exhibit high adoption rates for advanced Sinker EDM systems used in mold and die production, especially those focusing on tight tolerance requirements for high-end consumer electronics and specialized medical instruments, maintaining a leadership role in technological innovation and high-value applications.

Segment trends reveal that the Wire EDM (W-EDM) segment is anticipated to witness the fastest growth rate, attributable to its unparalleled ability to produce intricate profiles and complicated geometrical shapes with exceptional surface integrity, crucial for stamped parts and intricate tooling. Application-wise, the Automotive segment remains foundational, driven by the complex tooling required for powertrain components, body panels, and increasing volumes of specialized connectors and sensors in EVs. Concurrently, the Medical sector is rapidly expanding its consumption of EDM services for fabricating micro-tools, orthopedic implants, and biocompatible components from materials like titanium alloys and stainless steel, demanding ultra-precise machining capabilities.

AI Impact Analysis on Spark Machining Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) on the Spark Machining Market revolve around how AI can optimize challenging process parameters, reduce electrode wear, and enhance surface finish consistency, particularly in unsupervised or lights-out operations. Users are keen to understand if AI can effectively predict and prevent machining instability (arcing), which is a common technical concern limiting productivity in deep cavity or high aspect ratio machining. Furthermore, there is significant interest in AI-driven process planning—specifically, automating the selection of optimal flushing conditions, power settings, and electrode pathways for novel materials or complex geometries without extensive manual trial-and-error.

AI's primary influence lies in leveraging machine learning algorithms to analyze vast datasets generated during the EDM process, including real-time voltage, current, and gap conditions. This data-driven approach enables predictive control, allowing the machine to dynamically adjust parameters to maintain optimal material removal rates (MRR) while minimizing electrode consumption and preventing detrimental arcing events. By integrating AI into CNC controllers, manufacturers can achieve unprecedented levels of process stability and consistency, crucial for high-reliability components in the aerospace and medical industries, where failure tolerance is near zero. This optimization translates directly into reduced cycle times and improved component quality, addressing a core need in precision manufacturing.

Moreover, AI is transforming preventative maintenance within the EDM ecosystem. AI models can monitor the degradation patterns of consumables, such as wire or electrodes, and predict impending component failures or quality deviations long before they occur, scheduling maintenance proactively. This capability dramatically improves machine uptime and operational efficiency, making automated, multi-shift production viable. The ability of AI to learn from past machining successes and failures accelerates the setup time for new jobs, effectively democratizing expertise and allowing less experienced operators to achieve results previously reserved for master machinists, thereby lowering the barrier to entry for highly specialized EDM applications.

- AI-driven optimization of power and flushing parameters for superior surface finish.

- Predictive maintenance algorithms reducing unexpected machine downtime and increasing uptime.

- Real-time adaptive control systems to prevent arcing and maintain process stability in deep machining.

- Automated electrode wear compensation leading to extended tool life and dimensional accuracy.

- Enhanced process simulation and virtual prototyping using machine learning for accelerated job setup.

DRO & Impact Forces Of Spark Machining Market

The Spark Machining Market is fundamentally driven by the escalating demand for components requiring high dimensional accuracy and intricate internal features, particularly those manufactured from difficult-to-machine materials like superalloys, carbides, and tool steels. The key restraint remains the relatively slower material removal rate (MRR) compared to conventional milling or turning, coupled with the high initial capital investment required for sophisticated EDM machinery and specialized consumables like high-purity graphite or copper electrodes. Opportunities are significant in expanding the adoption of EDM into micro-machining for MEMS and semiconductor applications, alongside the development of advanced power supply technologies that can boost MRR without compromising surface integrity or thermal damage layer depth. The core impact force is the necessity for precision in high-growth sectors, dictating the continued relevance and technological evolution of EDM over other subtractive manufacturing processes.

Drivers include the continuous innovation in EDM power supply technology, such as solid-state generators, which offer finer control over spark energy and duration, leading to improved surface quality and reduced electrode consumption. The growing acceptance of EDM for additive manufacturing (AM) post-processing is also a critical driver, as AM components often require precise finishing to meet surface roughness and tolerance specifications. Furthermore, stringent regulatory requirements in sectors like aerospace (e.g., turbine blades) and medical implants demand validated, repeatable, high-precision machining processes, which EDM inherently provides, especially for machining cooling holes and internal passages that are inaccessible by other methods.

Restraints center on operational inefficiencies, notably the need for constant maintenance of the dielectric fluid and filter systems, which adds to operating costs. Furthermore, the specialized skillset required to program, operate, and troubleshoot complex multi-axis EDM machines poses a talent bottleneck in many regions. However, market opportunities are abundant, particularly in integrating robotics for automated workpiece and electrode loading, enabling full-scale automation and reducing labor dependency. The shift towards sustainable manufacturing also opens doors for the development of environmentally friendlier dielectric fluids and more energy-efficient machine designs, aligning with global industrial sustainability goals and attracting new market entrants focused on eco-friendly solutions.

Segmentation Analysis

The Spark Machining Market is systematically segmented based on Type, Application, and End-Use Industry, reflecting the diversity of machining needs and technological capabilities across various industrial landscapes. Understanding these segments is crucial for strategic market positioning, as each segment presents unique growth drivers and competitive dynamics. The core division by Type—Sinker, Wire, and Hole Drilling EDM—defines the fundamental capability of the machine, from deep cavity formation (Sinker) to complex contour cutting (Wire) and fine precision drilling.

Segmentation by Application highlights the crucial role of EDM in key vertical markets. Automotive remains a dominant application due to the continuous demand for high-precision molds and dies for plastic injection and sheet metal forming, essential for modern vehicle production, including EV battery trays and motor components. Conversely, the Aerospace sector focuses on machining high-temperature alloys for turbine components (blades, vanes) and structural elements where material integrity cannot be compromised. The medical industry relies heavily on EDM for producing surgical tools and implants from biocompatible materials, demanding micro-level precision and excellent surface finishes to ensure patient safety and product efficacy.

The End-Use Industry segmentation further refines the market view, distinguishing between large-scale Precision Manufacturing operations, Tool and Die production facilities, and Specialized Electronics manufacturing. This stratification enables market participants to tailor their machine offerings, software solutions, and service contracts to specific customer requirements, such as high-volume, continuous production needs versus highly customized, low-volume tool manufacturing. The convergence of these segments, particularly the use of EDM in micro-electronics, underscores the technology’s adaptability to evolving high-tech demands globally.

- Type

- Wire EDM (W-EDM)

- Sinker EDM (Ram EDM)

- Hole Drilling EDM (Fast Hole Drilling)

- Application

- Tool & Die Manufacturing

- Aerospace & Defense

- Automotive

- Medical Devices

- Electronics & Semiconductor

- Jewelry & Watchmaking

- End-Use Industry

- Precision Manufacturing

- Molding & Stamping

- Job Shops

- High-Value Component Production

Value Chain Analysis For Spark Machining Market

The Value Chain for the Spark Machining Market starts with the upstream segment, encompassing the suppliers of core components, raw materials, and specialized consumables. This includes manufacturers of highly precise CNC controls, power supply units (generators), filtration systems, specialized dielectric fluids (hydrocarbon oils or deionized water), and, critically, the providers of electrode materials (graphite, copper, tungsten carbide) and high-quality EDM wire (brass, coated wire). Innovation in this upstream sector directly impacts the performance metrics of the final machine, such as the material removal rate and the achieved surface roughness. The quality and purity of dielectric fluid and the consistency of the electrode material are foundational to successful and stable EDM operations.

Midstream activities involve the machine manufacturers (OEMs) who design, assemble, integrate, and test the complex EDM systems. This stage involves significant R&D investment in motion control technology, thermal stability management, and the development of proprietary adaptive control software. OEMs establish both direct sales channels, primarily for large industrial customers and global accounts, and indirect distribution networks through authorized dealers and local agents. These indirect channels are vital for reaching small and medium-sized enterprises (SMEs) and providing essential localized technical support, application engineering, and spare parts management, particularly in fragmented markets like Southeast Asia and Eastern Europe.

Downstream analysis focuses on the end-users and the service providers who utilize the EDM machinery. End-users span across diverse industries like aerospace engine builders, medical implant producers, and automotive mold makers. The service component is critical, including application training, post-warranty maintenance contracts, and specialized EDM job shops that offer contract manufacturing services to companies without in-house EDM capabilities. The direct value derived by the end-user is the ability to produce highly complex, high-tolerance components that are often impossible to manufacture economically or physically using conventional methods, thus justifying the specialized capital expenditure and operational costs associated with Spark Machining technology.

Spark Machining Market Potential Customers

Potential customers for Spark Machining technology are predominantly found within manufacturing sectors that require the fabrication of components from hard, exotic, or high-temperature materials, or those requiring extremely complex internal geometries, high aspect ratios, and superior surface finish. The primary buyers are precision tool and die makers who rely on Sinker and Wire EDM to create injection molds, stamping dies, and specialized forming tools used in high-volume production across multiple industries.

Another crucial customer segment is the aerospace and defense industry, including major OEMs and their tier suppliers. These entities purchase EDM machines specifically for manufacturing engine components such as cooling holes in turbine blades, intricate fuel system parts, and structural components made from nickel-based superalloys (e.g., Inconel, Waspaloy). Accuracy, repeatability, and maintaining the structural integrity of the material (avoiding recast layers or microcracks) are non-negotiable requirements that make EDM indispensable for this segment.

Furthermore, medical device manufacturers, particularly those specializing in orthopedics, cardiology, and surgical instrumentation, represent a rapidly growing customer base. They utilize micro-EDM for creating ultra-fine features on implants, stents, and surgical tools made from biocompatible materials like titanium and stainless steel. The electronics and semiconductor industries also represent significant potential buyers, using EDM for micro-hole drilling in printed circuit board fabrication and machining highly precise components required in chip manufacturing equipment. These customers prioritize high precision, reliability, and the ability to process miniaturized components efficiently.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 6.5 Billion |

| Market Forecast in 2033 | USD 10.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GF Machining Solutions, Mitsubishi Electric, Sodick Co., Ltd., Makino Milling Machine Co., Ltd., FANUC Corporation, ONA Electroerosión, CHMER EDM, Accutex Technologies Co., Ltd., Excetek Technology Co., Ltd., Beaumont Machine, Beijing Agie Charmilles Industrial Co., Ltd., Kent Industrial Co., Ltd., Joemars Machine Co., Ltd., Maxsee EDM, SEHO EDM |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Spark Machining Market Key Technology Landscape

The Spark Machining Market's technological landscape is characterized by continuous advancements focused on enhancing speed, accuracy, and automation capabilities. A core area of innovation involves the development of high-speed, adaptive power generators. Modern solid-state generators offer intricate control over the frequency, duration, and intensity of individual sparks, which is vital for minimizing the Heat Affected Zone (HAZ) and recast layer thickness, especially when machining critical components for aerospace or medical applications. These advanced power supplies allow operators to fine-tune processes to prioritize either high Material Removal Rate (MRR) or superior surface finish, depending on the job requirements.

Further technological integration includes the widespread adoption of sophisticated Computer Numerical Control (CNC) systems capable of simultaneous multi-axis control, particularly in Wire EDM and Sinker EDM. These systems incorporate features like automatic wire threading, automatic tool changers, and integrated measurement probes, facilitating complex, unattended machining operations. The incorporation of advanced thermal compensation mechanisms is crucial, ensuring dimensional stability and accuracy even during prolonged operational cycles. Furthermore, the push towards integrating robotics and palletized automation systems is transforming EDM machines into fully automated production cells, significantly reducing manual intervention and increasing overall system throughput for high-mix manufacturing environments.

Material science innovation also plays a critical role, particularly in the development of specialized electrode materials and high-performance EDM wires. The emergence of coated wires (e.g., diffusion-annealed zinc-coated brass wire) improves cutting speeds and surface finish consistency in W-EDM. Concurrently, the focus on non-conventional dielectric fluids and advanced filtration systems is addressing environmental and performance requirements. The newest generation of EDM equipment is increasingly equipped with embedded sensor technology and data analytics capabilities, forming the foundation for IIoT (Industrial Internet of Things) integration, enabling real-time diagnostics, performance tracking, and remote monitoring for optimal machine management.

Regional Highlights

The regional analysis of the Spark Machining Market reveals distinct growth patterns influenced by industrial maturity, technological adoption rates, and governmental support for manufacturing sectors. The Asia Pacific (APAC) region dominates the market share and is projected to exhibit the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This dominance is attributed to the presence of large electronics, automotive, and consumer goods manufacturing bases, especially in countries like China, Japan, and South Korea. Robust investment in high-volume, precision tooling and the rapid expansion of the semiconductor and EV supply chains necessitate constant procurement of advanced EDM systems to maintain competitive production capabilities.

North America and Europe represent mature markets characterized by high adoption of Sinker and multi-axis Wire EDM for high-value applications, particularly in aerospace, defense, and high-end medical device manufacturing. These regions prioritize technological sophistication, automation, and system reliability over absolute cost, driving demand for premium, integrated solutions from leading OEMs. The stringent regulatory environment in these regions, coupled with the reliance on high-performance materials (superalloys, composites), ensures a sustained, specialized demand for EDM technology capable of meeting exacting quality standards and traceability requirements, often incorporating advanced quality control and monitoring features.

Latin America, the Middle East, and Africa (MEA) are emerging markets, showing gradual but accelerating growth, primarily driven by expanding infrastructure projects, localized energy sector needs, and burgeoning domestic automotive assembly. While these regions often lag in adopting the absolute latest EDM technology, there is a steady demand for robust, reliable, and cost-effective EDM solutions, particularly for general tool and die repair and maintenance. Increased foreign direct investment (FDI) into manufacturing zones, particularly in Mexico, Brazil, and parts of the UAE, is expected to accelerate the procurement of mid-range and high-end EDM machines, facilitating local component production and reducing reliance on imports of complex tooling.

- Asia Pacific (APAC): Market leader due to large-scale electronics and automotive manufacturing. Key growth drivers include China, focusing on high-volume mold production, and Japan/South Korea, specializing in micro-machining and semiconductor tooling. The region exhibits the highest growth potential due to ongoing industrialization.

- North America: Strong demand focused on aerospace and defense components, demanding the highest precision Sinker and Wire EDM. High adoption of automation and advanced control systems; key markets include the US and Canada.

- Europe: Characterized by established automotive (Germany, France) and medical device manufacturing (Switzerland, Ireland). Emphasis on technological innovation, sustainable EDM practices, and integrating EDM with other machining processes (hybrid systems).

- Latin America (LATAM): Growth driven by automotive and general industrial tooling, particularly in Brazil and Mexico. Demand focuses on affordable, reliable W-EDM for standard tooling applications.

- Middle East and Africa (MEA): Emerging market primarily driven by specialized tooling needs in the oil & gas sector and localized precision component manufacturing; gradual increase in high-end machinery procurement.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Spark Machining Market.- GF Machining Solutions

- Mitsubishi Electric Corporation

- Sodick Co., Ltd.

- Makino Milling Machine Co., Ltd.

- FANUC Corporation

- ONA Electroerosión S.A.

- CHMER EDM

- Accutex Technologies Co., Ltd.

- Excetek Technology Co., Ltd.

- Beaumont Machine

- Beijing Agie Charmilles Industrial Co., Ltd.

- Kent Industrial Co., Ltd.

- Joemars Machine Co., Ltd.

- Maxsee EDM

- SEHO EDM

- Hansvedt Industries

- Elox EDM

- Zimmer & Kreim GmbH & Co. KG

- Exeron GmbH

- Strojírna Třinec, a.s.

Frequently Asked Questions

Analyze common user questions about the Spark Machining market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Spark Machining Market?

The Spark Machining Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven by increasing demands for complex, high-precision components in aerospace and medical sectors.

Which type of EDM machine holds the largest market share?

Sinker EDM (Ram EDM) machines traditionally hold a significant market share due to their extensive use in creating deep cavities, 3D molds, and complex tooling for the plastics and automotive industries, though Wire EDM is rapidly gaining ground due to versatility.

How does Spark Machining benefit the aerospace industry?

Spark Machining (EDM) is critical for the aerospace industry as it can precisely machine high-temperature superalloys (like Inconel) used in turbine blades and engine components, enabling the creation of intricate cooling holes and complex internal features without inducing material stress.

What role does AI play in modern EDM technology?

AI integrates into modern EDM to provide predictive control over machining parameters, minimizing electrode wear, preventing unstable arcing, and optimizing Material Removal Rate (MRR) for higher efficiency and consistent surface finish, thus supporting unattended operations.

Which geographical region is the primary driver of market growth?

Asia Pacific (APAC) is the dominant and fastest-growing region in the Spark Machining Market, fueled by large-scale manufacturing activities, particularly in electronics, automotive, and high-precision tooling sectors across China, Japan, and South Korea.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager