Speaker Grill Fabrics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436256 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Speaker Grill Fabrics Market Size

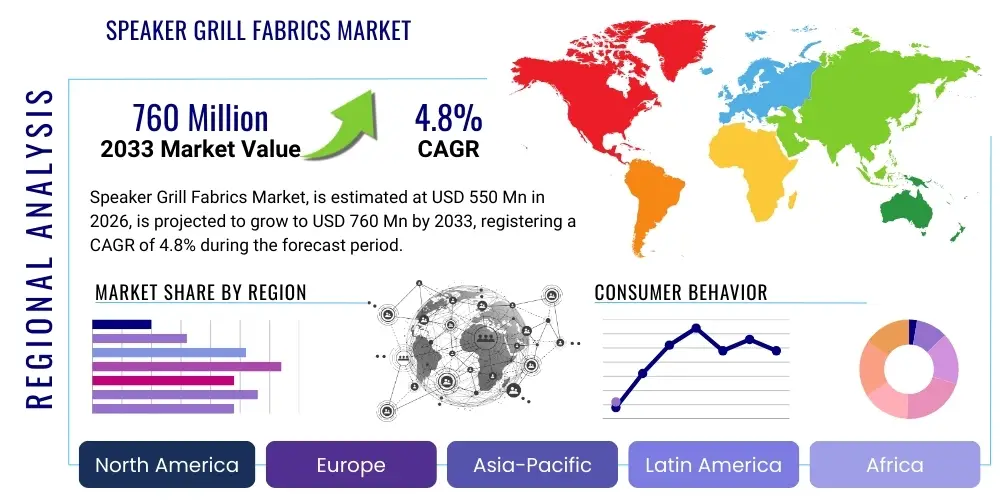

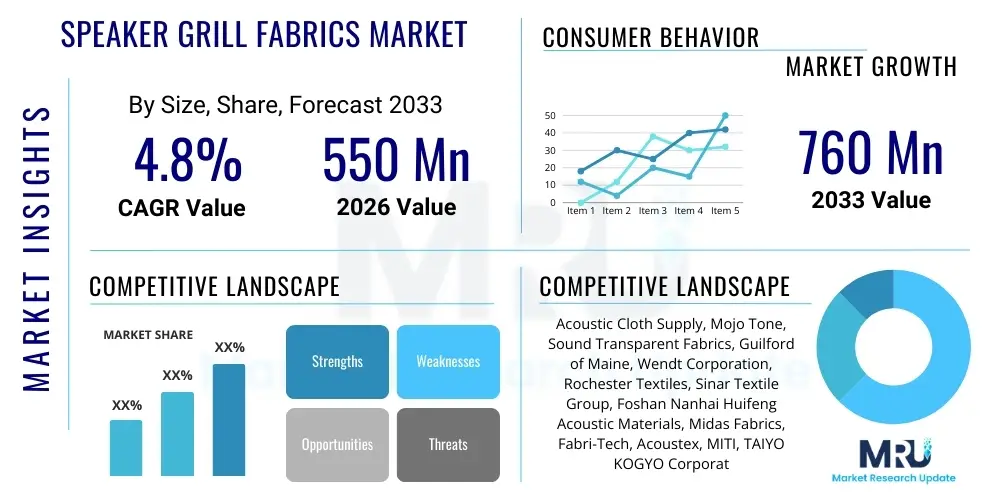

The Speaker Grill Fabrics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 760 Million by the end of the forecast period in 2033.

Speaker Grill Fabrics Market introduction

The Speaker Grill Fabrics Market encompasses the manufacturing, distribution, and sale of acoustically transparent textiles used primarily to protect speaker drivers, acoustic components, and internal electronics while simultaneously enhancing the aesthetic appeal of audio equipment. These specialized fabrics are engineered to offer minimal sonic interference, ensuring high fidelity sound transmission, which is crucial for professional audio systems, home theaters, automotive sound, and portable consumer electronics. The materials used typically include synthetic fibers such as polyester, nylon, and often blends incorporating natural fibers like cotton or wool, selected based on desired tensile strength, elasticity, and acoustic impedance characteristics.

The core application of speaker grill fabrics lies in maintaining the longevity and structural integrity of delicate speaker cones against dust, debris, physical impact, and UV degradation. Beyond protection, these fabrics serve as a key design element, allowing manufacturers to differentiate their products through various colors, textures, and weave patterns. The rising global demand for high-end audio equipment, coupled with the miniaturization of speaker systems that require durable yet highly permeable coverings, significantly propels market growth. Furthermore, the integration of smart home technology and aesthetic focus on consumer electronics demand custom and designer acoustic materials.

Driving factors for this market include the robust expansion of the automotive sector, particularly the increased integration of premium audio systems requiring durable fabrics compliant with automotive safety and environmental standards. The resurgence in vinyl and high-resolution audio formats also fuels demand for specialized fabrics in high-fidelity (Hi-Fi) and audiophile-grade speaker cabinets. Innovations in material science, focusing on enhanced acoustic transparency and improved moisture resistance, continue to broaden the application scope of these textiles in outdoor and marine audio environments, positioning the market for sustained expansion over the forecast period.

Speaker Grill Fabrics Market Executive Summary

The Speaker Grill Fabrics Market is characterized by steady, innovation-driven growth, fueled primarily by the burgeoning global consumer electronics sector and the stringent aesthetic requirements of high-end automotive and home audio manufacturers. Business trends indicate a strong shift towards sustainable and recycled fabric options, addressing consumer preference for eco-friendly products, alongside increasing demand for custom-printed and technologically integrated (e.g., microbial-resistant) fabrics. Strategic collaborations between textile manufacturers and major audio Original Equipment Manufacturers (OEMs) are becoming common, focused on optimizing acoustic performance and streamlining supply chain logistics for faster product development cycles.

Regional trends demonstrate Asia Pacific (APAC) as the dominant market, largely attributed to the immense concentration of consumer electronics manufacturing hubs in countries like China, South Korea, and Japan, driving high volume demand. North America and Europe, however, lead in terms of revenue generation from premium, high-margin fabrics used in luxury home audio and professional recording studios, emphasizing superior quality and specialized acoustic properties. The emerging markets in Latin America and MEA are experiencing rapid growth driven by rising disposable incomes and increased adoption of entry-level and mid-range audio systems, stimulating demand for cost-effective, durable grill fabrics.

Segment trends highlight the dominance of polyester fabrics due to their cost-effectiveness, durability, and versatility in achieving various acoustic specifications and color finishes. The segment based on application sees the Consumer Electronics category maintaining the largest market share, though the Professional Audio segment is projected to register the highest CAGR, propelled by the increasing demand for fabrics meeting demanding specifications in concert venues and broadcast studios. The market is also seeing consolidation, with key players focusing on vertical integration and acquiring niche material technology providers to secure proprietary material designs and control raw material costs.

AI Impact Analysis on Speaker Grill Fabrics Market

User inquiries regarding AI's impact on the Speaker Grill Fabrics Market primarily revolve around how artificial intelligence and machine learning (ML) can optimize material design, acoustic modeling, and supply chain efficiency. Key themes include the potential for AI algorithms to simulate and predict the acoustic performance of novel fabric weaves before physical prototyping, dramatically reducing R&D costs and time-to-market. Users are also concerned with how AI-driven predictive maintenance in automated textile manufacturing lines might improve fabric quality consistency and reduce defects. Furthermore, there is significant interest in how AI can inform consumer trends and aesthetic preferences, influencing decisions on fabric colors, textures, and patterns for upcoming speaker models, thus allowing manufacturers to tailor products more precisely to target demographics and regional tastes.

The application of AI extends significantly into quality control and material sourcing. Machine vision systems powered by deep learning are increasingly deployed on production lines to automatically detect micro-defects, color inconsistencies, and structural irregularities in the fabric, achieving a level of precision unattainable by human inspection alone. In the context of supply chain management, AI algorithms analyze market volatility, raw material pricing, and geopolitical risks to optimize purchasing decisions for synthetic polymers and natural fibers, minimizing procurement costs and ensuring inventory resilience against unexpected disruptions. This technological integration transforms the manufacturing process from reactive to predictive, ensuring consistently high acoustic standards.

However, the implementation of complex AI and ML models requires substantial capital investment in hardware and specialized data science expertise, presenting a barrier to entry for smaller textile manufacturers. While AI optimizes design and manufacturing, it does not replace the physical material itself, meaning the market growth remains fundamentally tied to audio equipment sales. The long-term impact is expected to foster a highly competitive environment where companies leveraging AI for superior acoustic simulation and rapid prototyping will gain a significant competitive advantage, leading to an overall elevation in the quality and performance metrics demanded of speaker grill fabrics across all application segments, particularly in high-fidelity and spatial audio systems.

- AI-driven acoustic simulation reduces material prototyping cycles and optimizes weave density for specific frequency responses.

- Machine learning enhances predictive quality control by identifying microscopic fabric flaws in real-time manufacturing processes.

- AI analyzes consumer data to forecast aesthetic trends, guiding color and texture choices for new product lines.

- Optimization of raw material procurement and inventory management using predictive AI models to mitigate supply chain risks.

- Increased automation and efficiency in textile manufacturing facilitated by robotic systems guided by AI for precision cutting and finishing.

DRO & Impact Forces Of Speaker Grill Fabrics Market

The Speaker Grill Fabrics Market is propelled by several robust drivers, most notably the continuous technological advancements in audio equipment, particularly the proliferation of wireless speakers, soundbars, and premium vehicle audio systems, all requiring high-quality, aesthetically pleasing acoustic coverings. Simultaneously, the market faces restraints such as volatility in raw material prices (especially petroleum-derived polymers) and the challenge of balancing high acoustic transparency with superior durability and aesthetic variety. Opportunities arise from the burgeoning demand for environmentally friendly materials, prompting innovation in recycled polyester and biodegradable fabrics. These factors, alongside technological integration and economic shifts, collectively define the impact forces acting on the market structure and growth trajectory.

Key drivers include the global expansion of the home theater market and the rising consumer willingness to invest in high-fidelity audio experiences, requiring sophisticated, low-acoustic-loss fabrics. The automotive industry’s shift toward luxury and electric vehicles, which prioritize silent interiors and integrated, visually appealing acoustic surfaces, is also a powerful growth catalyst. However, a major restraint is the low barrier to entry for standard, low-cost polyester fabrics, which leads to intense price competition, particularly in the APAC region where volume manufacturing dominates. Furthermore, the stringent regulatory requirements for fire resistance and low volatile organic compounds (VOCs) in automotive and residential applications often restrict material choices, adding complexity to product development.

Opportunities for market players are significant in developing materials tailored for specialized applications, such such as outdoor speakers requiring extreme UV and moisture resistance, or professional audio equipment demanding certified fire-retardant capabilities. The increasing focus on personalized consumer electronics also opens avenues for custom-design and limited-edition fabrics. Impact forces include the high bargaining power of large audio OEMs who dictate specification standards and pricing, and the intense rivalry among material suppliers vying for exclusive contracts. Technological impact remains high, as innovations in nano-fiber technology promise fabrics with even greater acoustic transparency and lighter weight, continually pushing the performance envelope of the market.

Segmentation Analysis

The Speaker Grill Fabrics Market is comprehensively segmented based on material type, application, and distribution channel, providing a granular view of market dynamics and targeted growth areas. Material segmentation is critical as it directly correlates with acoustic performance, durability, and cost. Polyester dominates due to its versatility and cost-efficiency, while synthetic fibers like Nylon and specialized blends cater to high-end and demanding professional applications requiring superior tensile strength and customizable density. The segmentation by application reflects the diverse end-user base, ranging from high-volume consumer electronics to stringent professional and automotive sectors, each imposing unique material specifications and volume requirements on fabric suppliers.

Analyzing the application segment reveals that Consumer Electronics, encompassing standard home speakers, portable devices, and soundbars, represents the bulk of the market volume, benefiting from mass production economies of scale. Conversely, the Automotive application segment, though smaller in volume, demands fabrics that meet stringent temperature, vibration, and UV stability standards, often commanding higher Average Selling Prices (ASPs). The Professional Audio segment, including studio monitors and large-scale public address systems, prioritizes ultra-high acoustic transparency and regulatory compliance (e.g., fire safety), driving innovation in advanced textile weaves and finishes.

The segmentation by distribution channel highlights the critical role of B2B relationships, with Direct Sales and OEM Agreements forming the primary route for high-volume manufacturers. Specialized distributors and retailers serve the aftermarket and customization segment, providing specific colors, textures, and repair kits to smaller audio repair shops and DIY enthusiasts. Understanding these segment dynamics is essential for market participants to tailor their material offerings, pricing strategies, and supply chain logistics to maximize penetration across various end-use sectors, ensuring that fabrics meet the specific acoustic, aesthetic, and durability thresholds required by each unique application environment.

- By Material Type:

- Polyester

- Nylon

- Synthetic Blends (Acoustic Foam/Fiberglass Composites)

- Natural Fibers (Cotton, Wool)

- Recycled and Sustainable Materials

- By Application:

- Consumer Electronics (Home Audio Systems, Soundbars, Portable Speakers)

- Automotive Audio Systems

- Professional Audio Equipment (Studio Monitors, PA Systems)

- Marine and Outdoor Speakers

- Custom and Aftermarket Applications

- By Weave Type:

- Knit Fabrics

- Woven Fabrics

- Non-woven Materials

- By Distribution Channel:

- Direct Sales (OEM Agreements)

- Distributors and Wholesalers

- Online Retail

Value Chain Analysis For Speaker Grill Fabrics Market

The value chain for the Speaker Grill Fabrics Market begins with the sourcing and manufacturing of raw materials, primarily petrochemicals derived for synthetic fibers like polyester and nylon, alongside the procurement of natural fibers. This upstream segment is highly concentrated, involving large chemical and textile raw material suppliers whose pricing power significantly influences downstream production costs. Key activities at this stage focus on polymerization, fiber extrusion, and the development of specialized yarns engineered for acoustic properties, such as high-denier polyester filaments or flame-retardant treated yarns. Efficiency in this stage relies heavily on material science innovation and bulk purchasing agreements to maintain competitive raw material costs and ensure supply stability.

The middle segment of the value chain involves fabric conversion and specialized treatment. Textile mills take the raw yarns and perform weaving, knitting, or non-woven processing, followed by crucial acoustic treatments. These treatments include specialized coatings for UV resistance, waterproofing, microbial protection, and dyeing processes to achieve precise color matches for OEM specifications. This conversion stage requires advanced machinery and proprietary knowledge regarding weave density, acoustic permeability testing, and thermal finishing processes. Direct sales dominate here, as large fabric manufacturers often contract directly with audio equipment OEMs, establishing long-term relationships based on certified performance specifications and strict quality control measures.

The downstream segment encompasses distribution and integration into the final product. Fabrics are sold either directly to major audio manufacturers (OEMs) for mass integration or to specialized distributors who cater to smaller custom builders, repair shops, and the aftermarket. OEMs integrate the fabric into the speaker housing, ensuring precise fit and aesthetic alignment. Indirect channels, such as online retail and physical distributors, handle the B2C and small B2B sales for repair and customization kits. The final stage involves the end-user purchase, where brand reputation and aesthetic appeal, heavily influenced by the grill fabric’s quality, play a crucial role in purchasing decisions, closing the loop of the market value chain.

Speaker Grill Fabrics Market Potential Customers

The primary potential customers and end-users of speaker grill fabrics are categorized into large-scale original equipment manufacturers (OEMs) within the consumer electronics, automotive, and professional audio sectors. These customers require high volumes of fabric meeting precise acoustic specifications, color consistency, and durability standards, often negotiating long-term supply contracts. Consumer electronics giants, including manufacturers of smart speakers, soundbars, and high-fidelity home theater systems, constitute the largest customer base due to the high turnover and volume production of these ubiquitous devices, prioritizing cost-efficiency alongside performance.

Automotive manufacturers represent a premium customer segment, demanding fabrics that are not only acoustically excellent but also compliant with rigorous interior safety standards, including fire resistance, fade resistance under extreme temperatures, and resistance to cleaning agents. These customers procure highly specialized synthetic blends, often integrating the fabric seamlessly into door panels, dashboards, and rear parcel shelves. Professional audio companies, serving broadcast, recording studio, and concert venue needs, prioritize technical performance above all, seeking fabrics that provide near-zero acoustic dampening while offering robust protection for extremely expensive and sensitive driver components.

Beyond these large OEM segments, secondary customers include aftermarket repair services, custom audio system integrators, and DIY enthusiasts who purchase smaller volumes through distribution channels and specialized online retailers. These smaller buyers often seek a wide variety of aesthetic options, unique textures, and specialty vintage restoration fabrics. Moreover, specialized applications such as marine equipment manufacturers (requiring waterproof and UV-stabilized materials) and medical device manufacturers (using acoustic fabrics in specialized diagnostics) represent niche but high-value customer segments requiring highly tailored material solutions and certified compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 760 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Acoustic Cloth Supply, Mojo Tone, Sound Transparent Fabrics, Guilford of Maine, Wendt Corporation, Rochester Textiles, Sinar Textile Group, Foshan Nanhai Huifeng Acoustic Materials, Midas Fabrics, Fabri-Tech, Acoustex, MITI, TAIYO KOGYO Corporation, Tex Tech Industries, PGI Polymer Group Inc., Shawmut Corporation, Glen Raven Inc., Forbo, KnollTextiles, Camira Fabrics. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Speaker Grill Fabrics Market Key Technology Landscape

The technological landscape of the Speaker Grill Fabrics Market is defined by continuous innovation aimed at optimizing the critical balance between acoustic transparency, structural durability, and aesthetic flexibility. A major area of focus is the development of micro-perforated and porous materials engineered at the fiber level to minimize acoustic diffraction and reflection, particularly across the high-frequency spectrum. Advanced weaving techniques, including three-dimensional (3D) knitting and specialized non-woven fabric formation, allow manufacturers to achieve precise, reproducible air permeability and flow resistance, which are crucial for maintaining the speaker's intended frequency response curve. Furthermore, the integration of smart textiles technologies, such as embedded sensors or conductive threads, is beginning to pave the way for fabrics that can interact with smart home systems, though this is currently a nascent segment.

Material science innovation centers on creating hybrid fabrics and composites that offer enhanced performance characteristics beyond standard polyester. This includes the use of flame-retardant chemical treatments that do not compromise acoustic permeability, a requirement particularly critical in professional and automotive applications subject to strict safety certifications. Nano-fiber technology represents a frontier area, potentially yielding fabrics that are significantly thinner and lighter than traditional options while maintaining superior acoustic and protective qualities. The move towards sustainability also drives technological change, pushing manufacturers to develop advanced dyeing and finishing processes that minimize water and chemical usage, while maximizing the utilization of recycled PET fibers without sacrificing material integrity or acoustic fidelity.

Manufacturing process technology has also seen significant improvements, particularly in digital textile printing and computerized cutting systems. Digital printing allows for the rapid and precise application of complex, high-resolution patterns or textures directly onto the fabric, enabling greater customization and reducing waste compared to traditional dyeing. Computer Numerical Control (CNC) cutting and robotic assembly ensure that fabric pieces are sized and shaped with millimeter precision, minimizing fitting errors during the final speaker assembly process. The deployment of AI-powered quality control systems, as mentioned in the AI analysis, is standard practice among leading manufacturers to ensure that every yard of fabric meets stringent OEM specifications for color consistency and weave structure before it leaves the production facility.

Regional Highlights

- Asia Pacific (APAC)

The Asia Pacific region dominates the global Speaker Grill Fabrics Market both in terms of production volume and market consumption. This dominance is primarily driven by the massive concentration of consumer electronics manufacturing powerhouses in countries such as China, South Korea, Japan, and Taiwan. These countries serve as global hubs for the production of everything from budget portable speakers to high-end home theater systems, generating an unparalleled demand for large volumes of acoustically compliant fabrics. The highly competitive manufacturing environment in APAC ensures that the region focuses intensely on cost-efficient production, favoring versatile materials like standard polyester, while simultaneously investing in R&D to meet the growing sophistication of domestic and export audio products.

Economic growth and rising disposable incomes across developing nations like India and Southeast Asia are fueling a massive increase in demand for audio products, further solidifying APAC's market leadership. Furthermore, major global textile suppliers and raw material providers have established deep operational footprints within the region, ensuring robust supply chain logistics and minimized lead times. The regional market is characterized by a strong interplay between high-volume, low-margin segments and a rapidly emerging premium segment that caters to the sophisticated audiophile consumer base now prevalent in major urban centers, necessitating a dual approach to material offerings and pricing strategies.

Local manufacturers are increasingly focusing on vertical integration, controlling the entire process from fiber extrusion to final fabric finishing, which provides a significant cost advantage over international competitors. Government policies promoting high-tech manufacturing and sustainable practices also influence the market, pushing textile producers toward greener manufacturing processes and the use of recycled materials in response to both regulatory pressure and global consumer demand for environmentally responsible products. This dynamic environment positions APAC as the central node for future market innovation and growth volume.

- North America

North America holds a significant share of the Speaker Grill Fabrics Market, particularly in terms of revenue generated from high-value, specialized fabrics. This region is characterized by a mature market with a strong consumer focus on high-fidelity (Hi-Fi) audio equipment, custom installation, and premium automotive sound systems. The demand here centers on superior material quality, certified acoustic performance, and stringent compliance with safety standards such as fire retardation and low VOC emissions, especially within residential and automotive interior applications. Manufacturers in this region often prioritize partnerships with specialized fabric suppliers who can provide unique textures and colors to match luxury branding.

The robust automotive manufacturing sector, coupled with the high adoption rate of electric vehicles that prioritize sound suppression and integrated audio aesthetics, drives consistent demand for technologically advanced grill fabrics. Additionally, the proliferation of smart home technology and custom home installation services contributes significantly to the market. Consumers in North America are generally willing to pay a premium for certified performance and aesthetically pleasing, durable materials, supporting the higher Average Selling Prices (ASPs) seen in this market compared to volume-driven regions.

Technological innovation in North America is centered around material traceability and sustainability. Leading audio companies are demanding transparency regarding the sourcing and manufacturing of fabrics, leading to increased adoption of recycled and domestically sourced materials. The region also acts as an early adopter of new audio technologies, such as spatial audio and specialized digital processing, requiring fabric producers to continuously innovate to ensure that their materials do not interfere with these complex sonic requirements, maintaining the region's position as a leader in premium segment consumption.

- Europe

Europe represents a highly specialized and stable market for Speaker Grill Fabrics, heavily influenced by historical audio traditions, stringent regulatory frameworks, and a strong preference for aesthetic integration within high-end furniture and architectural design. Countries like Germany, the UK, and Scandinavian nations are major consumers of professional audio equipment and luxury home audio systems, creating consistent demand for fabrics that offer exceptional acoustic performance and sophisticated aesthetic qualities, often incorporating natural fibers or high-quality synthetic blends.

Environmental and safety regulations, particularly the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, impose strict standards on the materials used, prompting European manufacturers to lead in the adoption of eco-friendly and non-toxic fabric alternatives. The automotive industry in Europe, dominated by luxury and high-performance brands, demands grill fabrics that are extremely durable, aesthetically refined, and meet the highest safety standards for occupant protection and fire resistance, driving innovation in specialized coatings and treatments for acoustic textiles.

The European market is fragmented but highly specialized, with numerous niche manufacturers of boutique audio equipment who require bespoke fabric solutions, leading to smaller batch sizes but high-margin opportunities for specialized fabric suppliers. The strong focus on design excellence means that fabric suppliers must collaborate closely with industrial designers and furniture makers to ensure seamless integration of audio components into living spaces, emphasizing subtle textures, muted colors, and a non-intrusive aesthetic that supports the 'hidden technology' trend in modern European interiors.

- Latin America (LATAM)

The Latin American market for Speaker Grill Fabrics is currently experiencing dynamic growth, driven by rapid urbanization, increasing middle-class disposable income, and the expanding presence of global consumer electronics brands. While the market volume is lower compared to APAC or North America, the growth rate is accelerating, particularly in large economies such as Brazil and Mexico. The demand initially favors cost-effective polyester fabrics for entry-level and mid-range consumer electronics, focusing primarily on durability and basic acoustic performance rather than highly specialized features.

Market expansion is closely tied to infrastructure development and the increasing accessibility of affordable audio technology. As consumers upgrade from basic audio systems to more sophisticated soundbars and home theater setups, the demand for higher-quality grill fabrics with improved aesthetic appeal and acoustic fidelity is projected to rise significantly. Local manufacturing capabilities are developing, but much of the high-end fabric demand is currently met through imports, presenting opportunities for international suppliers who can manage complex logistics and local distribution challenges effectively.

A key characteristic of the LATAM market is the high sensitivity to pricing, meaning success often depends on efficient supply chain management and the ability to offer competitive pricing on durable, colorful, and UV-resistant fabrics suitable for various climate conditions. The expansion of automotive assembly plants in the region also contributes to market growth, requiring suppliers to meet established global OEM standards for vehicle audio component fabrics.

- Middle East and Africa (MEA)

The MEA region is characterized by diverse market maturity levels, with the Gulf Cooperation Council (GCC) countries showing strong demand for luxury and high-end audio solutions, while Africa represents a rapidly emerging market for entry-level consumer electronics. The GCC nations, fueled by high per capita income and luxury infrastructure projects, generate significant demand for specialized, premium grill fabrics used in custom home installations, high-end automotive systems, and luxury hotel and commercial audio systems. These markets prioritize aesthetics, fire safety compliance, and robust UV stability due to extreme climatic conditions.

In contrast, the broader African market, particularly in sub-Saharan regions, is focused on affordable, robust, and functional fabrics for portable and entry-level home audio equipment. Market growth in this area is driven by increasing electrification, mobile connectivity, and a youthful population adopting media consumption technologies. Suppliers entering the MEA market must navigate complex regional logistics and varied regulatory environments, often focusing on distributor networks to reach dispersed consumer bases effectively.

The regional market offers unique opportunities for fabrics treated for enhanced heat and moisture resistance, crucial for maintaining acoustic integrity and durability in harsh desert and tropical environments. Investment in infrastructure and the construction boom across major urban centers in the Middle East ensure consistent demand for professional installation and architecturally integrated audio solutions, requiring fabrics that meet exacting design and performance specifications for large public spaces and bespoke luxury residential projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Speaker Grill Fabrics Market.- Acoustic Cloth Supply

- Mojo Tone

- Sound Transparent Fabrics

- Guilford of Maine (International Textile Group)

- Wendt Corporation

- Rochester Textiles

- Sinar Textile Group

- Foshan Nanhai Huifeng Acoustic Materials Co Ltd

- Midas Fabrics

- Fabri-Tech

- Acoustex

- MITI (Massachusetts Institute of Technology International)

- TAIYO KOGYO Corporation

- Tex Tech Industries

- PGI Polymer Group Inc (now part of Berry Global)

- Shawmut Corporation

- Glen Raven Inc

- Forbo Group

- KnollTextiles

- Camira Fabrics

Frequently Asked Questions

Analyze common user questions about the Speaker Grill Fabrics market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the most crucial property of speaker grill fabric for sound quality?

The most critical property is acoustic transparency, which refers to the fabric's ability to minimize sound dampening, reflection, and diffraction. High acoustic transparency ensures that the fabric does not interfere with the speaker's frequency response curve, allowing the sound output to remain high-fidelity, especially in the mid to high frequency ranges.

How do polyester fabrics compare to natural fibers in the speaker grill market?

Polyester is dominant due to its superior durability, resistance to moisture, consistency in acoustic permeability, and cost-effectiveness for mass production. Natural fibers, such as cotton or wool, are often used in high-end or vintage reproduction speakers for aesthetic reasons, offering a softer texture but sometimes exhibiting greater acoustic loss and higher material cost compared to engineered synthetic alternatives.

What role does UV resistance play in speaker grill fabric selection?

UV resistance is crucial for speaker systems exposed to sunlight, such as automotive audio, marine speakers, and outdoor systems. Fabrics lacking adequate UV resistance will quickly degrade, fade, and weaken, compromising both the aesthetic appeal and physical protection of the speaker drivers. Specialized synthetic dyes and finishing treatments are used to maximize UV stability in these applications.

Which applications demand the highest standards for fire safety compliance in grill fabrics?

The Automotive Audio segment and the Professional Audio segment (especially fabrics used in public address systems, theaters, and broadcast studios) demand the highest fire safety compliance. These applications require fabrics treated with flame-retardant chemicals and certified to meet stringent governmental and industry-specific fire resistance standards (e.g., UL ratings or automotive interior safety standards).

How is sustainability impacting the raw material trends in this market?

Sustainability is driving a significant trend towards the use of recycled polyethylene terephthalate (RPET or recycled polyester) derived from plastic bottles, reducing reliance on virgin petrochemicals. Manufacturers are also exploring natural alternatives and closed-loop manufacturing processes to reduce waste and carbon footprint, responding to increasing regulatory pressure and consumer demand for eco-friendly audio products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Speaker Grill Fabrics Market Size Report By Type (NaturalFibers, Man-Made Fibers), By Application (Auditoriums, HomeAudioSystems, Sports Arenas, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Speaker Grill Fabrics Market Statistics 2025 Analysis By Application (Auditoriums, Home Audio Systems, Sports Arenas), By Type (Natural Fibers, Man-Made Fibers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager