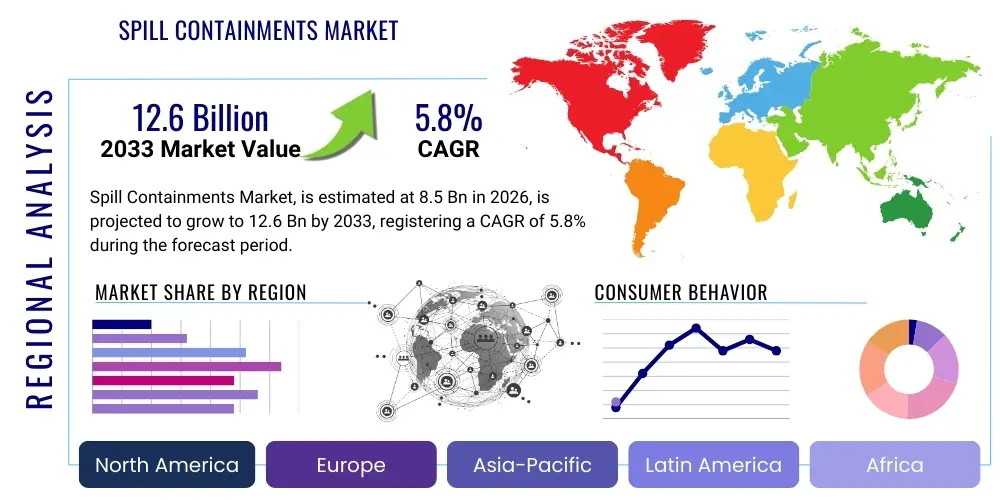

Spill Containments Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440472 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Spill Containments Market Size

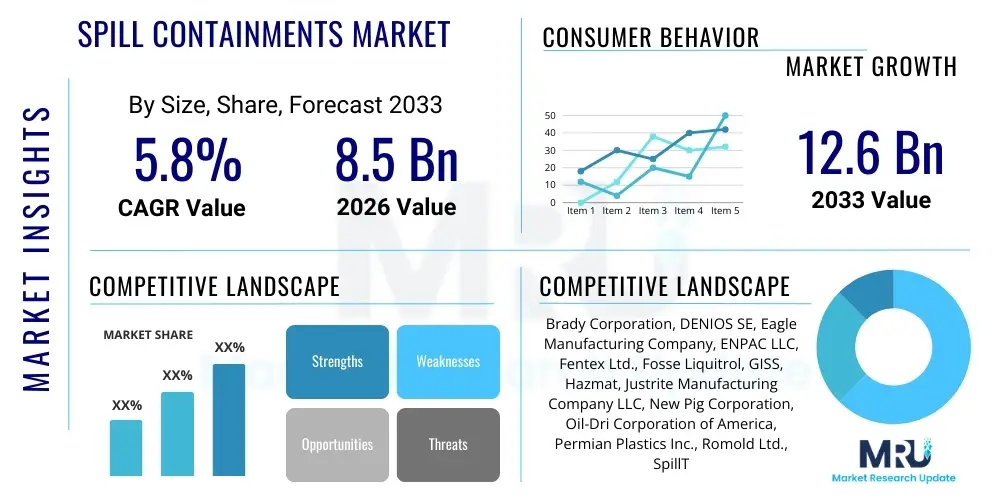

The Spill Containments Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 12.6 Billion by the end of the forecast period in 2033.

Spill Containments Market introduction

The Spill Containments Market encompasses a wide range of products and services designed to prevent, control, and mitigate the spread of hazardous and non-hazardous material spills. These solutions are crucial for environmental protection, workplace safety, and compliance with stringent regulatory frameworks across various industries. Products typically include secondary containment units, absorbents, spill kits, and specialized equipment tailored for different types of liquids and operational environments. The primary objective is to contain spills at their source, preventing contamination of soil, water bodies, and air, thereby protecting ecosystems and human health.

Major applications of spill containments span across sectors such as oil and gas, chemicals, manufacturing, transportation, healthcare, and marine operations. In the oil and gas industry, containment systems are essential for preventing leaks from storage tanks, pipelines, and drilling sites. Chemical manufacturing facilities rely on robust containment solutions for storing and transferring corrosive or flammable substances. The benefits of effective spill containment are multi-faceted, extending beyond immediate cleanup to include significant cost savings from avoiding fines, legal liabilities, and property damage, as well as preserving a company's reputation and operational continuity.

The market is primarily driven by the escalating focus on environmental sustainability, increasing awareness regarding industrial safety, and the imposition of stricter environmental protection regulations globally. Industrial expansion, particularly in emerging economies, further contributes to the demand for advanced spill containment solutions. Additionally, the growing frequency of industrial accidents and natural disasters, which can lead to chemical or oil spills, underscores the critical need for proactive containment strategies and rapid response capabilities. Continuous innovation in material science and intelligent monitoring systems is also enhancing the efficacy and reliability of containment products.

Spill Containments Market Executive Summary

The global Spill Containments Market is experiencing robust growth, propelled by a confluence of evolving business trends. Companies are increasingly investing in sophisticated containment solutions not merely as a compliance measure but as an integral part of their broader environmental, social, and governance (ESG) strategies. This shift is driving demand for higher-quality, more durable, and technologically advanced products that offer superior performance and longer lifecycles. Furthermore, the market is witnessing a trend towards integrated solutions, where containment systems are bundled with real-time monitoring, predictive maintenance, and comprehensive spill response training, offering end-users a holistic approach to risk management. Customization capabilities are also gaining traction, allowing businesses to tailor containment strategies to their specific operational hazards and facility layouts, thereby optimizing safety and efficiency.

Regional trends reveal significant disparities and growth opportunities. North America and Europe currently dominate the market, primarily due to well-established industrial infrastructures, mature regulatory environments, and a high level of environmental consciousness. These regions are characterized by a strong emphasis on compliance and continuous innovation in spill containment technologies. Conversely, the Asia Pacific region is emerging as a high-growth market, driven by rapid industrialization, burgeoning manufacturing sectors, and a gradual tightening of environmental regulations. Countries like China, India, and Southeast Asian nations are experiencing substantial investments in infrastructure and industrial development, which in turn fuels the demand for effective spill containment solutions. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, as industrial activities expand and regulatory frameworks become more formalized.

From a segmentation perspective, the market is characterized by diverse product offerings and application landscapes. Secondary containment products, such as spill pallets, containment berms, and spill decks, continue to hold a significant market share due to their widespread use in preventing spills from stationary containers. The absorbents and spill kits segment is also robust, driven by the need for immediate response capabilities to small to medium-sized spills. The oil and gas industry remains a dominant end-user, demanding specialized and heavy-duty containment solutions for large-scale operations. However, segments like chemicals, manufacturing, and transportation are also contributing significantly to market expansion, with each sector requiring tailored solutions to address their unique hazardous material challenges. The trend towards modular and easily deployable containment systems is gaining momentum across various segments, enhancing flexibility and rapid deployment capabilities in emergency situations.

AI Impact Analysis on Spill Containments Market

User inquiries concerning the integration of Artificial Intelligence (AI) into the Spill Containments Market often revolve around enhancing proactive prevention, improving real-time response capabilities, and optimizing operational efficiencies. Common questions include how AI can predict potential spill risks, the role of smart sensors and IoT in early detection, the feasibility of autonomous systems for containment deployment or cleanup, and the application of machine learning for analyzing incident data to refine safety protocols. Users are keen to understand if AI can reduce human error, minimize environmental damage, and ultimately lower the overall cost associated with spill management, demonstrating a clear expectation for AI to transform reactive spill response into a more predictive and preventive discipline. The overarching theme is the desire for more intelligent, automated, and data-driven containment strategies.

- AI-powered predictive analytics can forecast potential spill events by analyzing operational data, weather patterns, and equipment wear, enabling proactive maintenance and preventive measures.

- Integration of smart sensors and IoT devices with AI algorithms allows for real-time monitoring of containment levels, pressure, temperature, and material integrity, providing instant alerts for anomalies.

- AI-driven autonomous drones and robotics can be deployed for initial spill assessment in hazardous environments, reducing human exposure and expediting response times.

- Machine learning can optimize the inventory management of spill response kits and absorbents based on historical data, material types, and operational risk profiles, ensuring readiness.

- AI assists in optimizing the placement and design of containment infrastructure by simulating various scenarios and identifying the most effective configurations for maximum protection.

- Natural Language Processing (NLP) can analyze incident reports and regulatory documents to extract insights, identify common failure points, and recommend updated safety protocols for spill prevention.

- AI facilitates enhanced training simulations for spill response teams, offering realistic scenarios and personalized feedback to improve preparedness and decision-making under pressure.

DRO & Impact Forces Of Spill Containments Market

The Spill Containments Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, shaping its growth trajectory and strategic landscape. A primary driver is the stringent and continuously evolving global environmental regulations, which mandate industries to implement robust spill prevention and containment measures. Regulatory bodies worldwide, such as the EPA in the US, enforce strict penalties for non-compliance, compelling companies to invest in high-quality containment solutions. Furthermore, increasing industrial activity, particularly in manufacturing, chemicals, and oil and gas sectors, directly translates into a higher demand for equipment and protocols to manage hazardous materials, thereby fueling market expansion. Public and corporate awareness regarding environmental protection and workplace safety has also surged, pushing organizations towards more proactive risk management strategies.

Despite the strong drivers, several restraints pose challenges to market growth. The high initial investment costs associated with advanced spill containment systems can be prohibitive for small and medium-sized enterprises (SMEs), particularly in developing regions. Specialized materials, complex installation procedures, and integrated monitoring technologies contribute to this elevated upfront expenditure. Additionally, a lack of standardized regulations across different regions and industries can create confusion and hinder the adoption of universal containment solutions, leading to market fragmentation. Maintenance and inspection costs for containment infrastructure, especially for large-scale or remote installations, can also add to the operational burden, potentially deterring some companies from upgrading older systems.

Opportunities for growth in the Spill Containments Market are substantial, especially through technological advancements and expansion into emerging economies. The development of smart containment systems, incorporating IoT sensors, AI-powered monitoring, and automated response mechanisms, presents a significant avenue for innovation, offering enhanced predictive capabilities and real-time incident management. Moreover, the increasing focus on sustainability and green technologies is driving demand for spill containment products made from recycled or environmentally friendly materials. Emerging economies, undergoing rapid industrialization and infrastructure development, offer untapped potential for market players to introduce advanced containment solutions as these regions begin to adopt stricter environmental and safety standards. Customization services, tailored to specific industrial needs and operational challenges, also present a robust opportunity for market differentiation and value creation.

Segmentation Analysis

The Spill Containments Market is intricately segmented across various dimensions to cater to the diverse needs of industries and applications. This segmentation allows for a granular understanding of market dynamics, enabling manufacturers to develop targeted products and strategies while helping end-users select the most appropriate solutions for their specific operational risks. The primary segmentation criteria typically include product type, material, application, and end-user, each revealing unique market characteristics and growth opportunities. Understanding these segments is crucial for analyzing market trends, competitive landscapes, and future growth prospects within the broader spill containment ecosystem.

- Product Type

- Spill Pallets

- Spill Decks

- Containment Berms

- Drain Covers

- Spill Kits

- Absorbents

- Boom & Skimmers

- Secondary Containment Tanks

- Overpack Drums

- Socks & Pillows

- Material

- Polyethylene

- Steel

- PVC

- Polypropylene

- Urethane

- Fiberglass

- Others (e.g., geomembranes, specialized fabrics)

- Application

- Oil & Gas

- Chemicals

- Manufacturing

- Transportation (Road, Rail, Marine, Air)

- Healthcare & Pharmaceuticals

- Food & Beverage

- Mining

- Utilities

- Construction

- Environmental Services

- Agriculture

- End-User

- Industrial

- Commercial

- Government & Public Services

- Residential

Value Chain Analysis For Spill Containments Market

The value chain for the Spill Containments Market is a complex network of activities that brings products from raw material extraction to the end-user, encompassing several critical stages. The upstream segment primarily involves suppliers of raw materials such as polymers (polyethylene, polypropylene), metals (steel), PVC, and various absorbent materials (e.g., cellulose, vermiculite, synthetic polymers). These suppliers provide the foundational components necessary for manufacturing containment products. Additionally, upstream activities include the provision of specialized components like pumps, sensors, and monitoring systems that are integrated into advanced containment solutions, requiring close collaboration between material producers and component innovators.

Moving downstream, the value chain encompasses the manufacturing, assembly, and distribution of finished spill containment products. Manufacturers convert raw materials into diverse products such as spill pallets, containment berms, spill kits, and absorbents, often employing specialized molding, fabrication, and assembly processes. Quality control and testing are paramount at this stage to ensure products meet stringent safety and regulatory standards. The distribution channel plays a crucial role in bridging manufacturers and end-users, involving a mix of direct and indirect approaches. Direct distribution often occurs through manufacturers' own sales teams for large industrial clients or customized solutions, facilitating direct consultation and tailored product offerings.

Indirect distribution involves a network of wholesalers, distributors, and retailers who store and deliver products to a broader customer base, including smaller businesses and commercial entities. E-commerce platforms have also emerged as significant indirect channels, offering convenience and wider product accessibility. Beyond product delivery, the downstream segment also includes services such as installation, maintenance, and training for spill containment systems, provided by specialized service providers or the manufacturers themselves. These services are vital for ensuring the effective deployment and longevity of containment solutions, contributing significantly to the overall value proposition for the end-user and reinforcing the market's focus on comprehensive safety and environmental management.

Spill Containments Market Potential Customers

The Spill Containments Market serves a broad and diverse range of potential customers across virtually all sectors that handle liquids, chemicals, or hazardous materials. The primary end-users are industrial facilities, including large-scale manufacturing plants, chemical processing units, petrochemical refineries, and power generation stations. These entities are under immense regulatory pressure to prevent spills and protect both their workforce and the environment, driving a constant demand for robust and compliant containment solutions. The sheer volume and variety of materials managed in these industrial settings necessitate a wide array of containment products, from large-capacity secondary containment systems for bulk storage to specialized absorbents for routine maintenance and emergency response.

Beyond heavy industry, the transportation sector represents another significant customer base. This includes trucking companies, railway operators, marine shipping lines, and aviation industries, all of which transport vast quantities of fuels, lubricants, and various chemicals. Spills during transit, loading, or unloading operations pose considerable risks, making portable containment berms, spill kits, and drain covers essential equipment for these operations. The increasing global trade and complex supply chains further amplify the need for reliable containment solutions throughout the logistics network. Furthermore, healthcare facilities, research laboratories, and pharmaceutical companies require specialized spill containment for biological hazards, radioactive materials, and sensitive chemical reagents, often demanding smaller, highly specific containment products and decontamination kits.

Other notable potential customers include commercial establishments such as automotive repair shops, fueling stations, and janitorial services, which handle oils, cleaning agents, and other potential pollutants. Government agencies, including municipal services, emergency response teams, and environmental protection departments, are also major consumers, utilizing containment products for public infrastructure maintenance, disaster preparedness, and environmental remediation efforts. Even the agricultural sector, with its use of fertilizers, pesticides, and fuels, represents a segment for spill containment, albeit with a focus on less industrial-scale solutions. This diverse customer landscape underscores the pervasive need for spill containment solutions across the modern economy, driven by safety, compliance, and environmental stewardship.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 12.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Brady Corporation, DENIOS SE, Eagle Manufacturing Company, ENPAC LLC, Fentex Ltd., Fosse Liquitrol, GISS, Hazmat, Justrite Manufacturing Company LLC, New Pig Corporation, Oil-Dri Corporation of America, Permian Plastics Inc., Romold Ltd., SpillTech, UltraTech International Inc., AbsorbentsOnline, Chemstore Group, Ecospill, SPC (Brady Worldwide Inc.), Sure-Pak, Empteezy Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Spill Containments Market Key Technology Landscape

The Spill Containments Market is increasingly characterized by a dynamic technology landscape, moving beyond traditional passive barriers to incorporate advanced solutions that enhance prevention, detection, and response capabilities. One of the primary technological shifts involves the widespread adoption of advanced materials. Manufacturers are utilizing high-performance polymers like specialized polyethylenes and polypropylenes that offer superior chemical resistance, UV stability, and durability against a wider range of aggressive substances and environmental conditions. Reinforced composites and engineered fabrics are also gaining traction for containment berms and flexible secondary containment systems, providing enhanced strength-to-weight ratios and ease of deployment.

A significant technological advancement is the integration of sensor technology and the Internet of Things (IoT) into containment systems. Smart containment units are equipped with liquid level sensors, leak detection sensors, and environmental monitors (e.g., pH, temperature, conductivity) that provide real-time data on the status of contained liquids and the integrity of the containment structure. These sensors are connected via IoT networks, allowing for continuous remote monitoring and instant alerts to facility managers or emergency response teams in the event of a potential leak or overflow. This proactive monitoring capability transforms spill containment from a purely reactive measure into a predictive and preventive system, significantly reducing response times and mitigating environmental impact.

Furthermore, data analytics and Artificial Intelligence (AI) are playing an increasingly critical role. AI algorithms can process the vast amounts of data collected from IoT sensors to identify patterns, predict potential equipment failures, and optimize maintenance schedules for containment infrastructure. This predictive maintenance helps prevent spills before they occur, improving overall operational safety and efficiency. Robotics and automation are also emerging, particularly for hazardous spill cleanup, where autonomous vehicles or drones equipped with specialized tools can assess and respond to incidents in environments too dangerous for human intervention. These technological advancements collectively drive the market towards more intelligent, robust, and environmentally responsible spill containment solutions.

Regional Highlights

- North America: A mature market characterized by stringent environmental regulations (e.g., EPA, OSHA), robust industrial infrastructure, and high awareness regarding workplace safety and environmental protection. The US and Canada are significant contributors, with strong demand from oil and gas, manufacturing, and chemical industries.

- Europe: Driven by strict environmental directives from the European Union, a strong focus on sustainability, and advanced manufacturing sectors. Germany, the UK, France, and the Nordic countries are key markets, emphasizing high-quality, durable, and technologically integrated containment solutions.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, burgeoning manufacturing bases (China, India, Southeast Asia), and increasing foreign direct investment. While regulations are still evolving in some areas, the growing industrial activity and heightened environmental awareness are propelling significant market expansion.

- Latin America: Showing steady growth, particularly in countries like Brazil and Mexico, driven by expanding oil and gas exploration, mining activities, and developing industrial sectors. There is a growing adoption of international safety and environmental standards.

- Middle East and Africa (MEA): A developing market with growth primarily concentrated in the Gulf Cooperation Council (GCC) countries due to massive investments in oil and gas infrastructure, petrochemicals, and construction. Demand is also rising in parts of Africa as industrialization takes hold, albeit with varying regulatory landscapes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Spill Containments Market.- AbsorbentsOnline

- Brady Corporation

- Chemstore Group

- DENIOS SE

- Eagle Manufacturing Company

- Ecospill

- Empteezy Ltd.

- ENPAC LLC

- Fentex Ltd.

- Fosse Liquitrol

- GISS

- Hazmat

- Justrite Manufacturing Company LLC

- New Pig Corporation

- Oil-Dri Corporation of America

- Permian Plastics Inc.

- Romold Ltd.

- SpillTech

- SPC (Brady Worldwide Inc.)

- Sure-Pak

- UltraTech International Inc.

Frequently Asked Questions

What is the primary purpose of spill containment products?

The primary purpose of spill containment products is to prevent, control, and mitigate the spread of hazardous and non-hazardous material spills. This ensures environmental protection, enhances workplace safety, and helps industries comply with stringent regulatory standards, minimizing potential damage and liabilities.

Which industries are the major consumers of spill containment solutions?

Major consumers of spill containment solutions include the oil and gas industry, chemical manufacturing, general manufacturing, transportation (road, rail, marine), healthcare and pharmaceuticals, mining, and power generation. Any sector handling significant volumes of liquids or chemicals requires effective containment strategies.

How do environmental regulations impact the Spill Containments Market?

Environmental regulations are a key driver for the Spill Containments Market. Stricter mandates and penalties for non-compliance from bodies like the EPA and EU directives compel industries to invest in advanced and compliant containment solutions, ensuring adherence to environmental protection standards and fostering market growth.

What role does technology play in modern spill containment?

Technology plays a transformative role, integrating smart sensors, IoT for real-time monitoring, AI for predictive analytics, and advanced materials for enhanced durability. These innovations move containment from reactive to proactive, improving early detection, optimizing response, and preventing spills before they occur.

What are the main types of spill containment products?

The main types of spill containment products include spill pallets, spill decks, containment berms, drain covers, various types of absorbents (pads, rolls, socks), comprehensive spill kits, boom and skimmers for water-based spills, secondary containment tanks, and overpack drums.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager