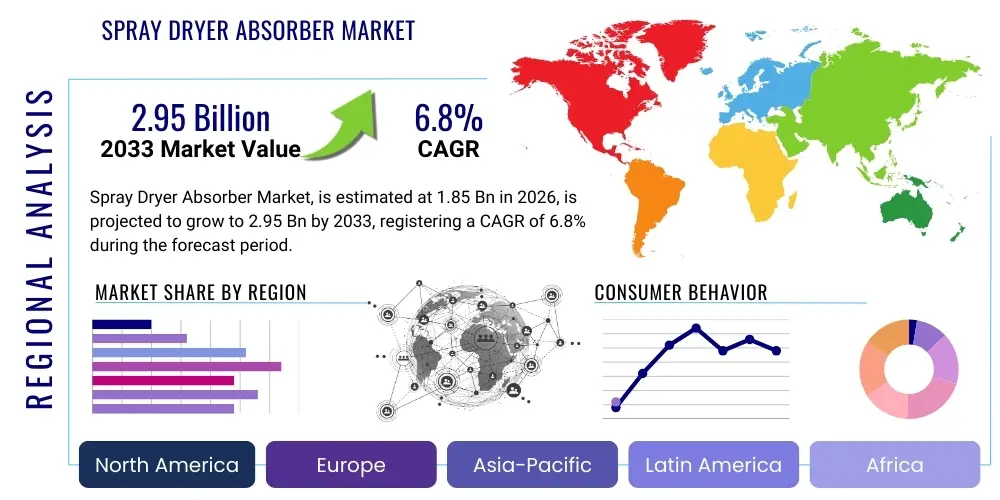

Spray Dryer Absorber Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440419 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Spray Dryer Absorber Market Size

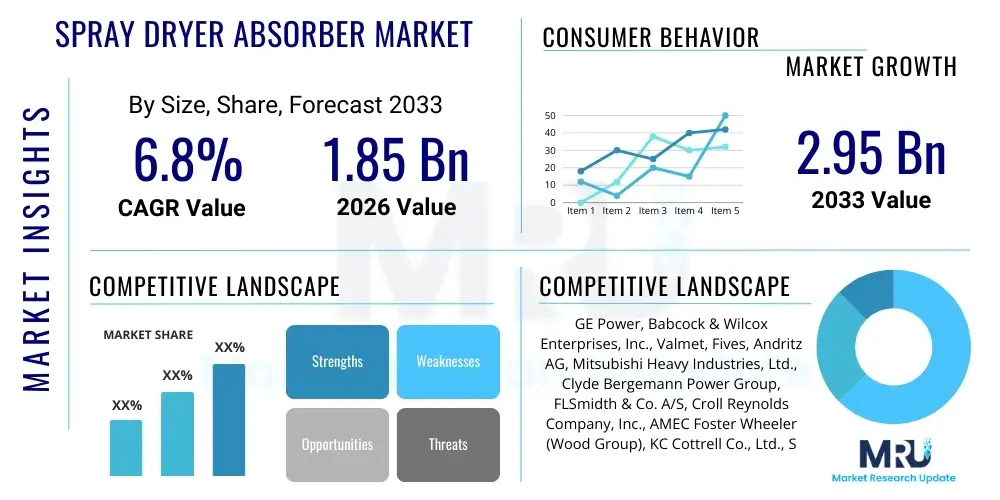

The Spray Dryer Absorber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 2.95 billion by the end of the forecast period in 2033.

Spray Dryer Absorber Market introduction

The Spray Dryer Absorber (SDA) market encompasses advanced air pollution control technologies designed to remove acidic gases and particulate matter from industrial flue gas streams. These systems operate by introducing an atomized lime slurry or other alkaline reagents into a spray dryer, where the hot flue gas rapidly evaporates the water, simultaneously reacting with acid gases like SO2, HCl, and HF to form dry, solid reaction products. This process effectively neutralizes harmful emissions, ensuring compliance with stringent environmental regulations worldwide.

Major applications for SDAs span a diverse range of heavy industries, including coal-fired power plants, waste incinerators, cement production facilities, glass manufacturing, and various chemical processing operations. The primary benefits of employing SDA technology include high removal efficiency for acid gases, effective particulate matter control, simplified waste handling due to the dry nature of the by-product, and relatively lower water consumption compared to wet scrubbers. Moreover, SDAs offer operational flexibility, capable of handling varying gas flow rates and pollutant concentrations with high reliability.

Driving factors for the growth of the SDA market are primarily centered on the escalating global imperative for cleaner air and sustainable industrial practices. Stricter environmental policies and emission limits, particularly in rapidly industrializing regions, compel industries to invest in advanced pollution control solutions. The increasing global energy demand, often met by fossil fuel combustion, further necessitates robust flue gas desulfurization technologies. Additionally, the operational advantages of SDAs, such as their compact footprint and adaptability to existing infrastructure, contribute significantly to their market adoption.

Spray Dryer Absorber Market Executive Summary

The Spray Dryer Absorber market is currently experiencing robust growth, driven by an intensified global focus on environmental protection and the promulgation of stricter emission control regulations across various industrial sectors. Key business trends indicate a strong emphasis on developing more energy-efficient and cost-effective SDA systems, incorporating advanced automation and predictive maintenance features to enhance operational performance and reduce total cost of ownership. Strategic collaborations and partnerships among technology providers, engineering firms, and end-users are becoming more prevalent, aiming to offer integrated solutions and expand market reach. Furthermore, there is a noticeable shift towards modular and customizable SDA designs to cater to diverse industrial needs and facility constraints.

From a regional perspective, the Asia Pacific region continues to dominate the market, propelled by rapid industrial expansion, particularly in countries like China and India, coupled with increasing governmental pressure to mitigate air pollution. North America and Europe also maintain significant market shares, characterized by a mature regulatory environment and continuous upgrades of existing industrial facilities with state-of-the-art pollution control technologies. Latin America, the Middle East, and Africa are emerging as high-potential markets, driven by new industrial projects and a growing awareness of environmental responsibilities, although market penetration is still in its nascent stages.

Segment trends within the SDA market highlight the increasing demand for semi-dry SDA systems due to their balance of efficiency and lower water usage compared to fully wet systems. The power generation sector remains the largest application segment, with ongoing investments in coal-fired and biomass power plants requiring stringent SOx and NOx control. The waste incineration and chemical industries are also significant contributors, demonstrating consistent demand for advanced acid gas removal. The market is also seeing innovation in reagent utilization, exploring alternatives to traditional lime-based slurries for enhanced performance and reduced waste generation, leading to more sustainable operational profiles.

AI Impact Analysis on Spray Dryer Absorber Market

User questions regarding AI's impact on the Spray Dryer Absorber market frequently revolve around how artificial intelligence can enhance operational efficiency, improve emission control accuracy, predict maintenance needs, and optimize resource consumption. There's significant interest in AI's potential to revolutionize the monitoring and control of SDA processes, moving beyond traditional control systems to more intelligent, adaptive approaches. Concerns often include the cost of AI implementation, the complexity of integrating AI with existing infrastructure, and the need for specialized skills to manage these advanced systems. Users expect AI to offer solutions for real-time data analysis, predictive modeling of pollutant removal, and automated fault detection, ultimately leading to more stable and compliant operations with reduced downtime.

The application of AI in SDA systems is poised to usher in a new era of optimized performance and operational intelligence. AI algorithms can process vast amounts of operational data, including gas flow rates, temperature, humidity, reagent injection rates, and emission levels, far more efficiently than human operators or traditional control logic. This capability allows for dynamic adjustments to process parameters in real time, ensuring optimal pollutant removal efficiency under varying load conditions and flue gas compositions. Predictive analytics, a core AI capability, can foresee potential equipment malfunctions or performance degradation, enabling proactive maintenance that minimizes unscheduled downtime and extends the lifespan of critical components.

Moreover, AI can significantly enhance the sustainability profile of SDA operations by optimizing reagent consumption. By precisely predicting the required amount of absorbent based on incoming flue gas characteristics and desired emission targets, AI systems can reduce chemical waste and operational costs. This intelligent resource management not only improves economic efficiency but also lowers the environmental footprint of the entire process. The integration of machine learning into SDA control systems facilitates continuous learning and adaptation, allowing the system to refine its operational strategies over time, leading to increasingly efficient and robust environmental compliance. The overall impact of AI is expected to be transformative, leading to smarter, more reliable, and environmentally superior SDA solutions.

- Enhanced predictive maintenance schedules through anomaly detection in operational data.

- Real-time optimization of reagent injection rates for maximum efficiency and minimal consumption.

- Improved emission control accuracy by dynamically adjusting SDA parameters based on real-time sensor data.

- Automated fault diagnosis and proactive alerts, reducing downtime and operational risks.

- Energy consumption optimization by intelligent control of fan speeds and atomization processes.

- Data-driven insights for process improvements and long-term strategic operational planning.

- Autonomous control capabilities for stable performance under fluctuating industrial loads.

DRO & Impact Forces Of Spray Dryer Absorber Market

The Spray Dryer Absorber market is shaped by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces. Key drivers include stringent environmental regulations globally, particularly concerning sulfur dioxide (SO2), hydrogen chloride (HCl), and particulate matter emissions from industrial sources. The increasing industrialization and urbanization in emerging economies, coupled with growing energy demands often met by fossil fuels, further necessitate the adoption of advanced flue gas treatment technologies. Additionally, the operational advantages of SDAs, such as their ability to produce a dry, easily manageable by-product and their relatively compact footprint, contribute significantly to their market growth and preference over wet scrubbing systems in certain applications.

However, the market also faces considerable restraints. The high capital investment required for the installation of SDA systems can be a deterrent for small and medium-sized enterprises (SMEs), particularly in developing regions. Operational costs, including reagent consumption, energy for atomization, and maintenance of specialized components, can also be substantial. Fluctuations in the prices of key raw materials, such as lime or other alkaline reagents, introduce cost uncertainties that can impact project viability. Furthermore, the availability of alternative emission control technologies, some of which may offer lower upfront costs or different operational advantages, presents a competitive challenge to SDA market penetration.

Opportunities for market expansion are abundant, primarily in the continuous technological advancements leading to more efficient and cost-effective SDA designs, including improvements in atomization nozzles, chamber designs, and control systems. The increasing focus on circular economy principles and resource recovery creates avenues for developing SDA by-products that can be repurposed, adding value to the waste stream. Moreover, the retrofit market for upgrading existing industrial facilities with modern pollution control technologies, especially in regions with aging infrastructure, represents a significant growth opportunity. Emerging applications in niche industries or for novel pollutant removal also present future prospects.

Impact forces on the SDA market are multifaceted. Regulatory shifts, such as the introduction of new emission standards or tighter enforcement of existing ones, directly influence demand for these systems. Technological innovation, particularly in areas like advanced materials for corrosion resistance, sensor technology for improved monitoring, and artificial intelligence for process optimization, can dramatically alter market dynamics. Economic cycles and global industrial output directly correlate with investment in new industrial projects and environmental infrastructure. Lastly, the increasing global awareness and corporate social responsibility initiatives push industries towards sustainable practices, thereby bolstering the demand for effective air pollution control solutions like SDAs.

Segmentation Analysis

The Spray Dryer Absorber market is intricately segmented to provide a detailed understanding of its various facets, allowing for precise market analysis and strategic planning. These segmentations are crucial for identifying specific market niches, understanding competitive landscapes, and forecasting demand trends across different product types, operational modes, application areas, and regional geographies. Each segment is driven by unique sets of factors, including regulatory requirements, industry-specific operational needs, and economic considerations. This structured approach helps stakeholders, including manufacturers, investors, and end-users, to navigate the complexities of the market and capitalize on emerging opportunities effectively.

Segmentation provides a granular view of market dynamics, revealing how different technological approaches or industrial demands contribute to the overall market size and growth trajectory. For instance, classifying SDAs by type, such as dry and semi-dry systems, highlights distinct advantages and applications based on water usage, by-product characteristics, and removal efficiencies. Similarly, segmenting by end-use industry showcases the varying needs and adoption rates across sectors like power generation, waste incineration, and chemical manufacturing, each facing unique environmental challenges and operational constraints. Understanding these divisions is fundamental for developing targeted product offerings, refining marketing strategies, and anticipating future market shifts based on evolving industrial requirements and environmental policies.

- By Type:

- Dry Spray Dryer Absorbers

- Semi-Dry Spray Dryer Absorbers

- By Reagent Type:

- Lime-based Absorbers

- Soda Ash-based Absorbers

- Other Reagents (e.g., Sodium Bicarbonate, Caustic Soda)

- By End-Use Industry:

- Power Generation (Coal-fired, Biomass, Industrial Boilers)

- Waste Incineration Plants

- Chemical and Petrochemical Industry

- Metallurgical Industry (Steel, Non-ferrous Metals)

- Cement Industry

- Glass Manufacturing

- Pharmaceutical Industry

- Others (e.g., Food Processing, Pulp & Paper)

- By Capacity:

- Small Capacity (Below 100 MW equivalent)

- Medium Capacity (100-300 MW equivalent)

- Large Capacity (Above 300 MW equivalent)

- By Component:

- Absorber Towers

- Atomizers

- Reagent Preparation Systems

- Dust Collectors (Baghouses, ESPs)

- Control Systems

- Ancillary Equipment

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Spray Dryer Absorber Market

The value chain for the Spray Dryer Absorber market is a complex network involving several stages, starting from raw material sourcing to the final installation and after-sales service. Upstream analysis primarily focuses on the procurement of critical components and raw materials necessary for manufacturing SDA systems. This includes suppliers of various metals (stainless steel, carbon steel), ceramic materials for nozzles, specialized pumps, fan systems, and robust control instrumentation. Reagent suppliers, typically providing lime, soda ash, or other alkaline compounds, form another crucial upstream segment. The quality, availability, and cost fluctuations of these materials and reagents significantly impact the production costs and overall market competitiveness of SDA manufacturers. Efficient supplier relationship management and robust procurement strategies are vital at this stage to ensure timely delivery and cost control.

Midstream activities involve the design, engineering, manufacturing, and assembly of the Spray Dryer Absorber units. This stage includes sophisticated processes such as CFD modeling for optimal chamber design, precision manufacturing of atomizers, integration of complex control systems, and adherence to stringent quality and safety standards. Manufacturers in this segment leverage their expertise in chemical engineering, mechanical design, and process control to develop high-performance and reliable SDA solutions tailored to specific industrial requirements. Innovation in material science, atomization technology, and system integration is key to differentiating products and gaining a competitive edge in the market.

Downstream analysis encompasses the distribution, installation, commissioning, and ongoing maintenance and support of SDA systems. Distribution channels are typically a mix of direct sales teams, specialized engineering procurement and construction (EPC) firms, and regional distributors who possess local market knowledge and technical capabilities. Direct sales are often preferred for large, complex projects, allowing manufacturers to maintain close client relationships and offer customized solutions. Indirect channels, through EPC contractors, are critical for turnkey projects where SDAs are part of a larger industrial plant setup. After-sales service, including spare parts supply, technical support, and operational training, is paramount for ensuring long-term system performance and customer satisfaction, representing a significant revenue stream and brand reputation builder for manufacturers.

Spray Dryer Absorber Market Potential Customers

The primary potential customers for Spray Dryer Absorber systems are large industrial facilities that generate significant volumes of acidic flue gases and particulate matter as a byproduct of their operations. These end-users are compelled to invest in robust air pollution control technologies due to increasingly stringent environmental regulations and a growing global emphasis on reducing industrial emissions. The diverse range of industries requiring efficient flue gas desulfurization and dust removal makes the customer base broad and geographically widespread, ranging from established industrial hubs to rapidly developing economies where new facilities are being constructed.

Specifically, the power generation sector stands as the largest consumer of SDA technology, particularly coal-fired and biomass power plants, which emit substantial amounts of sulfur dioxide and other pollutants. Waste incineration plants, crucial for municipal and industrial waste management, are another significant customer segment due to the diverse and often highly acidic gases produced during combustion. The chemical and petrochemical industries, involved in various manufacturing processes that release hazardous air pollutants, also represent a substantial demand pool for SDAs. Furthermore, the metallurgical industry, including steel and non-ferrous metal production, along and the cement industry, which generates large volumes of dust and acidic gases, consistently seek effective emission control solutions.

Beyond these major segments, other potential customers include glass manufacturing facilities, pharmaceutical plants, and certain pulp and paper mills, all of which have specific needs for managing their air emissions to comply with environmental standards and maintain responsible operational practices. The recurring need for upgrades, retrofits, and new installations in these diverse industries ensures a sustained demand for advanced Spray Dryer Absorber systems. Understanding the specific regulatory pressures, operational requirements, and budget considerations of each industrial segment is crucial for SDA manufacturers and solution providers to effectively target and serve these potential customers with tailored offerings and comprehensive support.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GE Power, Babcock & Wilcox Enterprises, Inc., Valmet, Fives, Andritz AG, Mitsubishi Heavy Industries, Ltd., Clyde Bergemann Power Group, FLSmidth & Co. A/S, Croll Reynolds Company, Inc., AMEC Foster Wheeler (Wood Group), KC Cottrell Co., Ltd., Sumitomo Heavy Industries, Ltd., Lurgi GmbH (Air Liquide Engineering & Construction), GEA Group Aktiengesellschaft, Ducon Environmental Systems, Inc., Thermax Limited, Rafko, Inc., SPX Flow, Inc., S.E.W. North America, Inc., KCH Group GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Spray Dryer Absorber Market Key Technology Landscape

The Spray Dryer Absorber market's technological landscape is characterized by continuous innovation aimed at enhancing efficiency, reducing operational costs, and improving environmental performance. A cornerstone of SDA technology lies in sophisticated atomization techniques. This involves developing highly efficient rotary atomizers and two-fluid nozzles that can produce extremely fine, uniform droplets of absorbent slurry. The fineness and consistency of these droplets are critical for maximizing the surface area available for reaction with acidic gases, thereby achieving high pollutant removal efficiencies and optimizing reagent consumption. Advancements in atomizer design focus on improving reliability, reducing wear and tear, and enabling operation across a broader range of slurry properties and gas flow rates.

Another crucial aspect of the technology landscape is the evolution of advanced control systems. Modern SDAs integrate complex Supervisory Control and Data Acquisition (SCADA) systems, Distributed Control Systems (DCS), and increasingly, Artificial Intelligence (AI) and Machine Learning (ML) algorithms. These systems are designed to monitor numerous process parameters in real-time, including flue gas temperature, humidity, flow rate, reagent concentration, and emission levels. By analyzing this data, the control systems can dynamically adjust operational parameters such as atomizer speed, slurry feed rate, and gas distribution, ensuring optimal performance under fluctuating plant loads and varying pollutant concentrations. This intelligent control minimizes reagent overuse, energy consumption, and maintains consistent compliance with emission limits.

Furthermore, material science plays a significant role in the durability and longevity of SDA components. Given the corrosive and abrasive nature of the flue gas and absorbent slurries, advancements in corrosion-resistant alloys, ceramic coatings, and wear-resistant materials are continuously being pursued. These innovations extend the operational life of absorber towers, nozzles, and ductwork, reducing maintenance frequency and overall lifecycle costs. The integration of advanced dust collection systems, such as pulse-jet baghouses or electrostatic precipitators (ESPs), downstream of the SDA, is also a critical technological area, ensuring efficient capture of the dry reaction product and unreacted absorbent, contributing to overall particulate matter removal. Future technological developments are expected to focus on even greater energy efficiency, multi-pollutant removal capabilities, and increased automation to further reduce manual intervention and enhance operational stability.

Regional Highlights

- Asia Pacific (APAC): Dominates the global Spray Dryer Absorber market due to rapid industrialization, particularly in China and India, coupled with increasing environmental concerns and the implementation of stringent air pollution control regulations. The region sees significant investments in new power plants, cement factories, and chemical industries, driving high demand for SDAs.

- North America: A mature market characterized by a strong emphasis on environmental compliance and technological upgrades. Demand is driven by retrofitting older industrial facilities with advanced pollution control systems and continuous investments in the power generation and metallurgical sectors to meet federal and state emission standards.

- Europe: A significant market influenced by strict EU directives on industrial emissions and air quality standards. European countries are actively investing in modernizing waste-to-energy plants and industrial facilities, leading to sustained demand for high-efficiency SDA systems. Innovation in green technologies also plays a crucial role.

- Latin America: An emerging market with growing industrial sectors in countries like Brazil and Mexico. Increasing awareness of environmental issues and developing regulatory frameworks are gradually boosting the adoption of SDA technology, primarily in power generation and mining industries.

- Middle East & Africa (MEA): Shows promising growth potential driven by planned industrial expansion, particularly in the petrochemical, power generation, and cement sectors. While adoption rates are currently lower, evolving environmental regulations and large-scale infrastructure projects are expected to accelerate market growth in the forecast period.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Spray Dryer Absorber Market.- GE Power

- Babcock & Wilcox Enterprises, Inc.

- Valmet

- Fives

- Andritz AG

- Mitsubishi Heavy Industries, Ltd.

- Clyde Bergemann Power Group

- FLSmidth & Co. A/S

- Croll Reynolds Company, Inc.

- AMEC Foster Wheeler (Wood Group)

- KC Cottrell Co., Ltd.

- Sumitomo Heavy Industries, Ltd.

- Lurgi GmbH (Air Liquide Engineering & Construction)

- GEA Group Aktiengesellschaft

- Ducon Environmental Systems, Inc.

- Thermax Limited

- Rafko, Inc.

- SPX Flow, Inc.

- S.E.W. North America, Inc.

- KCH Group GmbH

Frequently Asked Questions

What is a Spray Dryer Absorber (SDA) and how does it work?

A Spray Dryer Absorber (SDA) is an industrial air pollution control device used to remove acidic gases and particulate matter from flue gas streams. It operates by atomizing an alkaline slurry (e.g., lime slurry) into a drying chamber where it reacts with hot acidic gases. The water in the slurry rapidly evaporates, leaving behind dry, solid reaction products that are then collected by downstream particulate control equipment like baghouses or electrostatic precipitators. This process efficiently neutralizes pollutants and produces a dry, manageable by-product.

What are the primary applications of Spray Dryer Absorber technology?

SDAs are predominantly used in heavy industries facing stringent emission regulations. Key applications include coal-fired power plants for sulfur dioxide (SO2) removal, waste incineration plants for acid gas control, cement production facilities, chemical and petrochemical industries, and metallurgical plants. They are also employed in glass manufacturing and other industrial processes that generate acidic exhaust gases and fine particulate matter.

What are the main advantages of using a Spray Dryer Absorber compared to other pollution control systems?

Advantages of SDAs include high removal efficiency for acid gases, effective particulate matter control, the production of a dry, easily handled by-product, and relatively lower water consumption compared to wet scrubbers. SDAs offer operational simplicity, adaptability to varying gas flows, and a compact footprint, making them suitable for a wide range of industrial installations and retrofits.

What are the key factors driving the growth of the Spray Dryer Absorber market?

The market growth is primarily driven by increasingly stringent global environmental regulations on industrial emissions, particularly for SO2, HCl, and particulate matter. Rapid industrialization in emerging economies, coupled with growing energy demand met by fossil fuels, necessitates advanced pollution control. Additionally, continuous technological advancements enhancing SDA efficiency and reliability, and the operational benefits they offer, further propel market expansion.

How does AI impact the future of Spray Dryer Absorber operations?

AI is set to revolutionize SDA operations by enabling real-time process optimization, predictive maintenance, and enhanced emission control accuracy. AI algorithms can analyze vast datasets to dynamically adjust parameters for optimal reagent use and pollutant removal, anticipate equipment failures for proactive servicing, and provide data-driven insights for improved system design and operational strategies. This leads to more efficient, reliable, and sustainable SDA performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager