Square Head Screwdriver Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432099 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Square Head Screwdriver Market Size

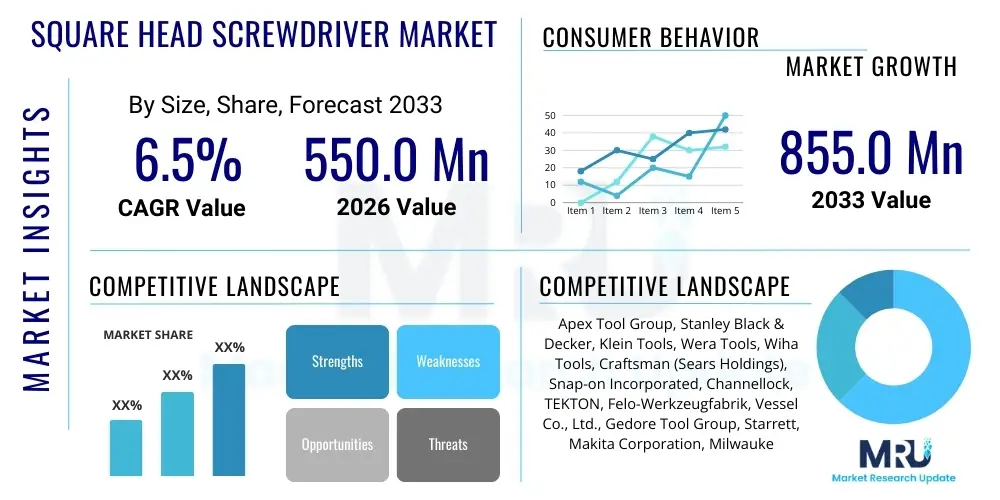

The Square Head Screwdriver Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 550.0 Million in 2026 and is projected to reach USD 855.0 Million by the end of the forecast period in 2033.

Square Head Screwdriver Market introduction

The Square Head Screwdriver Market, fundamentally driven by the robust performance and superior gripping ability of the Robertson drive system, is experiencing sustained growth across diverse industrial and consumer sectors. The square-headed tip, unlike traditional slotted or Phillips systems, offers exceptional torque transmission, significantly reducing cam-out—a common issue where the tip slips out of the fastener head under high pressure. This inherent benefit translates directly into increased efficiency, reduced material damage, and improved safety during high-volume assembly or demanding construction tasks. Consequently, the product is highly favored in applications requiring reliable and secure fastening, particularly in woodworking, electrical installations, and modular construction systems where standardization and rapid assembly are paramount.

The core product description encompasses a range of variations, including insulated square head screwdrivers for electrical work, precision drivers for electronics assembly, and heavy-duty versions designed for industrial maintenance and repair operations (MRO). The primary materials used in manufacturing often involve high-grade alloys such as S2 tool steel or Chrome Vanadium (Cr-V) steel, ensuring maximum durability, resistance to wear, and longevity. The benefits extend beyond sheer torque, encompassing ease of use—as the square head allows for quick, one-handed insertion—and reduced downtime associated with stripped fasteners or damaged bits. This enhanced operational reliability positions the square head screwdriver as an indispensable tool in professional toolkits worldwide.

Major applications driving market expansion include residential and commercial construction, which utilizes square drive screws extensively for decking, framing, and cabinet installation, especially in North America where the Robertson system enjoys widespread adoption. Furthermore, the burgeoning demand for prefabricated housing and modular furniture requires high-precision, repetitive fastening operations, further solidifying the need for reliable square head tools. The primary driving factors are centered around the global infrastructure boom, increasing automation in assembly lines that require precise and consistent fastening, and a rising consumer interest in robust, professional-grade DIY tools capable of handling complex projects with minimal failure.

Square Head Screwdriver Market Executive Summary

The Square Head Screwdriver Market is characterized by steady growth underpinned by robust demand from the construction and manufacturing sectors, showing resilience even amidst cyclical economic shifts. Key business trends indicate a strong move toward ergonomic designs, incorporating bi-material handles and interchangeable bit systems to enhance user comfort and versatility across various applications. Manufacturers are increasingly focusing on offering sets and kits bundled with varying sizes and lengths, catering specifically to professional tradespeople who require comprehensive solutions. Material innovation remains a core focus, with continuous investment in advanced steel alloys and specialized coatings to improve tip durability and magnetic retention capabilities, providing a significant competitive advantage in the high-end tool segment.

From a regional perspective, North America continues to dominate the market share, primarily due to the established historical use and standardization of the Robertson drive in Canadian and specific US construction codes. However, Asia Pacific (APAC) is emerging as the fastest-growing region, fueled by rapid industrialization, large-scale infrastructure development projects in countries like India and China, and the expansion of automotive and electronics assembly plants requiring high-quality fastening tools. Europe exhibits stable demand, particularly within the specialized electrical and precision engineering segments, where strict safety standards drive the demand for insulated and VDE-certified square head tools. This geographical diversity provides a stabilizing factor for overall market growth.

Segment trends reveal that the insulated screwdriver category is gaining traction due to heightened safety regulations in professional electrical work, demanding tools rated for high-voltage protection. By product type, the standard fixed-blade square head screwdriver still holds the majority market share, but the interchangeable bit driver segment is seeing accelerated growth, driven by consumer preference for compactness and multi-functionality. End-use segmentation highlights that the professional user segment (contractors, electricians, maintenance personnel) remains the largest revenue contributor, though the escalating complexity and scale of DIY projects are rapidly increasing the consumer segment's proportional market contribution, necessitating parallel strategies for industrial-grade and consumer-friendly products.

AI Impact Analysis on Square Head Screwdriver Market

User inquiries regarding AI's influence on the Square Head Screwdriver Market primarily revolve around the optimization of manufacturing processes, predictive maintenance of assembly line tooling, and the integration of 'smart' capabilities into handheld tools. Users are keen to understand how AI algorithms can improve the material composition and heat treatment processes during screwdriver production, leading to superior quality and reduced failure rates. A significant concern is the potential for AI-driven robotics to displace manual labor, but also the opportunity for AI to enhance quality control, ensuring every tool meets stringent dimensional and material specifications without human error. Furthermore, expectations are high regarding AI's role in streamlining global supply chains, optimizing inventory based on real-time construction and repair activity data.

The impact of Artificial Intelligence is not seen in replacing the physical tool itself, but rather in optimizing the ecosystem surrounding its production and use. AI-powered algorithms are already being deployed in advanced manufacturing facilities to analyze sensor data from forging and grinding machinery. This analysis allows manufacturers to predict potential equipment failures, thus minimizing production downtime and maintaining consistent quality output for millions of units annually. This predictive capability ensures higher throughput and tighter tolerances in the final product, directly benefitting consumers through more durable and precisely dimensioned tool heads that fit fasteners perfectly, reducing stripping instances.

Furthermore, AI is crucial in enhancing the logistics and distribution of square head screwdrivers. Machine learning models analyze purchasing patterns across different geographies, factoring in variables like seasonal construction schedules, regional regulatory changes (e.g., shifts in required fastening types), and economic indicators. This allows distributors to optimize stock levels and placement, ensuring that the right tools are available at the right time in hardware stores and industrial supply houses, significantly improving fulfillment rates and responsiveness to market demand. The future potentially involves AI-integrated power tool systems that communicate necessary torque settings for specific square drive screws, ensuring application safety and compliance.

- AI optimizes material alloy composition and heat treatment cycles for superior tip hardness and longevity.

- Predictive maintenance schedules for manufacturing equipment driven by AI reduce production variability and downtime.

- Machine Learning algorithms enhance supply chain efficiency, optimizing inventory stocking and regional distribution strategies.

- AI-driven quality control systems rapidly inspect dimensional accuracy of screwdriver tips, minimizing defects in high-volume production.

- Integration of AI could lead to smart tools offering real-time torque feedback and usage analysis for professional users.

DRO & Impact Forces Of Square Head Screwdriver Market

The market for Square Head Screwdrivers is significantly shaped by a confluence of driving factors, market restraints, and compelling opportunities that dictate its trajectory. The primary Driver (D) is the inherent mechanical superiority of the Robertson drive system, which minimizes cam-out compared to older fastening methods, translating to faster, safer, and more reliable assembly processes essential for modern construction and manufacturing efficiency. This operational benefit is amplified by increasing global construction activity and the mandatory adoption of robust fastening standards in critical sectors like automotive and aerospace MRO. The inherent durability and simplicity of the tool further cement its position as a preferred professional instrument.

Conversely, the market faces certain Restraints (R), notably the entrenched global standardization of competing drive systems, primarily Phillips and Pozidriv, which dominate markets outside North America, creating inertia against widespread Robertson adoption. Another restraint involves the potential cost disparity; high-quality square head screwdrivers made from premium tool steels (like S2 or CrV) can be marginally more expensive than mass-produced, lower-grade alternatives, affecting price-sensitive consumer segments. Furthermore, the proliferation of specialized Torx and hexagonal drives in complex industrial machinery presents competition, occasionally limiting the square head's application scope in advanced engineering environments.

Opportunities (O) abound, particularly in emerging markets where construction practices are rapidly modernizing and seeking more reliable fastening solutions. The push towards ergonomic innovation, incorporating vibration dampening and specialized grips, presents a high-value opportunity for manufacturers to differentiate their premium offerings. Furthermore, the integration of non-contact technologies, such as embedded RFID chips for asset tracking in large industrial environments, and the development of square head bits optimized for impact drivers, open lucrative avenues for market expansion. The key Impact Forces acting on the market relate directly to material science advancements (improving tool life) and evolving global trade regulations concerning tool safety and certification (e.g., VDE standards for insulated tools), which continuously reset the bar for quality and compliance.

Segmentation Analysis

The Square Head Screwdriver Market segmentation is critical for understanding specific consumer needs and tailoring product offerings, predominantly revolving around three key dimensions: product type, material composition, and end-user application. Product type segmentation distinguishes between fixed-blade drivers, which offer superior durability and are traditionally preferred by professionals for dedicated tasks, and interchangeable bit systems, which prioritize portability and versatility, attracting both DIY enthusiasts and field service technicians. Furthermore, specialized categories like T-handle drivers for high torque applications and insulated drivers for safety in electrical environments form crucial, high-growth niche segments that command premium pricing due to regulatory compliance.

Segmentation by material is highly indicative of tool performance and pricing. The premium segment is dominated by tools manufactured from high-alloy steels, such as Chrome Vanadium or specialized S2 tool steel, which provide exceptional torque resistance and tip hardness, ensuring longevity in demanding industrial settings. Conversely, lower-cost segments utilize standard carbon steel, catering primarily to basic consumer or introductory DIY kits. The material choice also influences ergonomic factors, as handles are often segmented based on materials like polypropylene, rubberized elastomers, or specialized composite materials designed for comfort and slip resistance, reflecting the manufacturer's target market (professional versus consumer grade).

End-user segmentation clearly separates the professional/industrial segment, encompassing construction contractors, HVAC technicians, automotive mechanics, and specialized assembly line workers, from the DIY/consumer segment. The professional market demands specific sizing, robust certifications (like ANSI or ISO compliance), and bulk purchasing options, making product durability and reliability non-negotiable. The DIY segment, while less focused on extreme durability, prioritizes affordability, ergonomic design for occasional use, and convenient packaging (e.g., multi-piece sets). Understanding these distinct requirements allows manufacturers to optimize distribution channels, utilizing specialized industrial distributors for professional sales and mass-market retail for consumer engagement.

- By Product Type:

- Fixed Blade Square Head Screwdrivers

- Interchangeable Bit Square Head Drivers

- Insulated (VDE Certified) Square Head Screwdrivers

- Precision Square Head Screwdrivers

- T-Handle Square Head Drivers

- By Tip Size (Robertson Size):

- Size #00 (Miniature)

- Size #0 (Yellow)

- Size #1 (Green)

- Size #2 (Red)

- Size #3 (Black)

- Size #4 (Industrial)

- By Material:

- Chrome Vanadium (Cr-V) Steel

- S2 Tool Steel

- Carbon Steel

- Specialized Alloy Steels

- By End-User:

- Professional/Industrial (Construction, Electrical, MRO)

- DIY/Consumer

- Automotive and Aerospace Assembly

Value Chain Analysis For Square Head Screwdriver Market

The value chain for the Square Head Screwdriver Market begins with upstream activities centered on the procurement and processing of high-grade raw materials, primarily specialized steel alloys such as Cr-V and S2 tool steel. Efficient sourcing is critical, as the quality and consistency of these materials directly impact the durability and performance of the final product, especially the highly stressed tip geometry. Manufacturers invest heavily in forging, precision machining, and proprietary heat treatment processes to ensure the tips meet stringent hardness and torque standards. Optimization at this stage involves minimizing material waste and energy consumption, often utilizing advanced computer numerically controlled (CNC) machinery and continuous quality inspection systems to maintain product integrity before moving to the handle molding and assembly stages.

Midstream operations involve the core manufacturing processes: blade preparation, tip grinding to exact Robertson specifications, magnetic treatment, and attachment of the ergonomic handle. Handles are typically molded from polymers or composites, sometimes requiring complex over-molding processes to achieve the bi-material, slip-resistant grips favored by professional users. This stage also includes packaging and certification adherence, particularly for insulated drivers which must meet VDE or similar global safety standards. Effective operational logistics at this stage focuses on just-in-time inventory management of finished goods and ensuring efficient throughput to handle the high volume required by global demand, balancing quality control against production speed.

Downstream activities are dominated by distribution and sales, utilizing both direct and indirect channels. Direct channels involve sales to large industrial Original Equipment Manufacturers (OEMs) or specialized industrial supply houses that cater exclusively to professional trades. Indirect channels, which account for a significant portion of consumer sales, involve distribution through large format retailers (big box stores), specialized hardware franchises, and rapidly expanding e-commerce platforms. The success of the downstream operation relies on effective logistics partners capable of handling diverse SKU assortments and ensuring product visibility across varied retail environments. E-commerce platforms, driven by optimized product listings and effective search engine strategies, have become increasingly vital for reaching the global DIY market and specialized contractors seeking unique sizes or sets.

Square Head Screwdriver Market Potential Customers

The potential customer base for the Square Head Screwdriver Market is broad, extending across major industrial, professional, and consumer segments, all unified by the need for reliable, high-torque fastening tools. The largest segment remains the professional end-user, encompassing individuals whose livelihood depends on the speed and reliability of their tools. This includes general construction contractors who frequently install subflooring, decking, and framing materials; specialized electricians and HVAC technicians who rely on insulated versions for safety and compliance; and maintenance and repair operations (MRO) personnel in manufacturing plants, where minimizing fastener failure is critical for operational uptime. These professional buyers prioritize durability, ergonomic comfort for extended use, and tool certification.

A rapidly expanding segment consists of specialized industrial assembly users, particularly within the cabinet, furniture, and modular construction industries. These sectors utilize square drive screws extensively due to their superior performance in repetitive assembly tasks. Companies involved in prefabricated homes and flat-pack furniture production are significant bulk purchasers, requiring consistent quality and specific sizing (e.g., Robertson #2). Furthermore, the automotive and aerospace MRO sectors, although occasionally leaning toward Torx or Hex, utilize square drives in specific internal components where vibration resistance and reliable high-torque assembly are mandated. These customers are highly sensitive to manufacturing tolerances and tool life, justifying investment in premium S2 steel tools.

The third major segment is the sophisticated DIY enthusiast and homeowner. As home improvement projects become more ambitious and complex, consumers are increasingly seeking professional-grade tools to ensure project success and longevity. While price remains a consideration, this segment is increasingly willing to invest in medium-to-high quality multi-bit sets and durable fixed drivers, often influenced by online reviews and ergonomic features. Retail sales targeting this demographic often emphasize versatility, ease of use, and lifetime guarantees, ensuring that the consumer perceives a high return on investment for their tool purchase. Retail strategy focuses on attractive packaging and clear differentiation from lower-grade, non-professional options.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550.0 Million |

| Market Forecast in 2033 | USD 855.0 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Apex Tool Group, Stanley Black & Decker, Klein Tools, Wera Tools, Wiha Tools, Craftsman (Sears Holdings), Snap-on Incorporated, Channellock, TEKTON, Felo-Werkzeugfabrik, Vessel Co., Ltd., Gedore Tool Group, Starrett, Makita Corporation, Milwaukee Tool, Bosch Power Tools, IRWIN Tools, Bondhus Corporation, Knipex, Facom |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Square Head Screwdriver Market Key Technology Landscape

The technology landscape within the Square Head Screwdriver Market, while rooted in simple mechanical tools, is continuously advancing through material science and ergonomic engineering. A primary technological focus is on enhancing the metallurgical composition of the tip, moving beyond standard steel to proprietary alloys often incorporating Vanadium and Molybdenum to increase tensile strength and fracture resistance under extreme torque loads. Modern techniques involve cryogenic treatment of the steel after initial heat treating, which refines the crystalline structure, dramatically improving wear resistance and edge retention. Furthermore, specialized surface coatings, such as black oxide, chrome plating, or even proprietary diamond-infused tips, are employed to enhance corrosion resistance and improve fastener grip, ensuring maximum power transfer and tool longevity, particularly in challenging environments like high humidity or chemical exposure.

Another pivotal technological development centers on ergonomics and the handle design, leveraging advanced plastics and thermoplastic elastomers (TPE). Contemporary handle technology utilizes computer-aided design (CAD) and finite element analysis (FEA) to create geometries that maximize contact surface area with the hand, thereby reducing pressure points and minimizing user fatigue during prolonged use. Bi-material construction, where a hard core provides strength and a soft outer layer offers grip, is standard practice. For insulated drivers, the technology requires multi-layer insulation systems and rigorous dielectric strength testing to meet internationally recognized standards (such as VDE) up to 1,000 volts, utilizing specific polymer formulations that retain flexibility while ensuring electrical safety and impact resistance.

The third major technological trend is the integration of magnetic and interchangeable systems. Advanced magnetizing techniques ensure robust magnetic retention of the fastener, crucial for working in tight spaces or overhead applications. For interchangeable systems, rapid-change mechanisms, often incorporating spring-loaded collars or locking ball bearings, are engineered to provide fast, secure swapping of square head bits without sacrificing stability or durability. Increasingly, manufacturers are incorporating laser-etched markings for size identification and serialization for quality control and anti-counterfeiting measures. These cumulative technological advancements ensure that even a seemingly simple tool like the square head screwdriver remains optimized for modern industrial requirements for speed, safety, and precision.

Regional Highlights

- North America (Dominance and Standardization): North America holds the largest market share due to the widespread, historical adoption and standardization of the Robertson (square) drive system, particularly in Canada where it originated, and increasingly in US construction and manufacturing sectors for its superior anti-cam-out properties. The region's robust housing and infrastructure market, coupled with high labor costs, drives demand for efficient, durable, professional-grade tools. Key growth areas include the transition to high-quality S2 steel tools and the increased use of insulated square head drivers in the growing renewable energy installation sector.

- Europe (Specialization and Regulation): The European market, while dominated by Pozidriv and Torx standards, exhibits strong, specialized demand for square head screwdrivers, particularly within high-precision engineering, electronics assembly, and electrical installation. Growth here is highly concentrated in VDE-certified insulated tools, driven by stringent workplace safety regulations (IEC standards). Countries like Germany and the UK show steady consumption, focusing on high-end, ergonomic designs and modular bit systems favored by professional technicians seeking versatility and compliance.

- Asia Pacific (APAC) (Fastest Growth and Industrialization): APAC is projected to be the fastest-growing region, fueled by rapid urbanization, massive infrastructure projects (China's Belt and Road Initiative, Indian urban development), and the influx of global manufacturing assembly lines. While traditional fastening systems prevail, the increasing presence of Western manufacturing standards and the demand for automated assembly tools are accelerating the adoption of high-quality square head drivers. Cost-effective manufacturing capabilities in the region also contribute significantly to global supply, focusing on mass-market production alongside professional-grade exports.

- Latin America (LATAM) (Construction and Modernization): LATAM markets demonstrate growing potential, driven by significant investment in residential and commercial construction across major economies like Brazil and Mexico. The demand is slowly shifting from basic tools to higher quality, professional-grade square head drivers as construction practices modernize and standardization improves. Affordability remains a key purchasing criterion, yet there is rising demand for durable tools that can withstand demanding job site conditions.

- Middle East and Africa (MEA) (Oil & Gas and Infrastructure): Growth in MEA is closely tied to energy sector maintenance (Oil and Gas), large infrastructure projects (like GCC construction initiatives), and industrial maintenance. Demand is concentrated in highly durable, specialized square head drivers capable of withstanding extreme environmental conditions (heat, sand). The market relies heavily on imports from European and North American manufacturers, focusing on proven reliability and certified tools for heavy industry applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Square Head Screwdriver Market.- Apex Tool Group

- Stanley Black & Decker

- Klein Tools

- Wera Tools

- Wiha Tools

- Craftsman (Sears Holdings)

- Snap-on Incorporated

- Channellock

- TEKTON

- Felo-Werkzeugfabrik

- Vessel Co., Ltd.

- Gedore Tool Group

- Starrett

- Makita Corporation

- Milwaukee Tool

- Bosch Power Tools

- IRWIN Tools

- Bondhus Corporation

- Knipex

- Facom

Frequently Asked Questions

Analyze common user questions about the Square Head Screwdriver market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using a square head screwdriver over a Phillips screwdriver?

The primary advantage of the square head (Robertson) screwdriver is its superior resistance to cam-out, the tendency of the tip to slip out of the fastener head under torque. The square design provides four large contact surfaces, allowing for greater torque transfer and minimizing damage to both the fastener and the tool tip, which is essential for high-volume construction and assembly.

Which material provides the best durability for professional square head screwdriver tips?

S2 tool steel and Chrome Vanadium (Cr-V) steel are generally considered the best materials for professional square head screwdriver tips. S2 steel, known for its extreme hardness and superior wear resistance, is often preferred for high-stress industrial applications, while Cr-V steel provides excellent balance between hardness, toughness, and corrosion resistance, suitable for general trade use.

How is the Square Head Screwdriver Market segmented by end-user, and which segment drives the most revenue?

The market is segmented into Professional/Industrial and DIY/Consumer users. The Professional/Industrial segment, which includes construction, electrical, and maintenance workers, drives the majority of market revenue. This segment demands higher quality, specific certifications (like VDE insulation), and bulk supply of durable tools designed for continuous daily use.

Are insulated square head screwdrivers required for all electrical work, and what certification must they possess?

Insulated square head screwdrivers are highly recommended, and often mandated by safety standards, for all work near live electrical currents. These tools must possess specialized certification, most commonly the VDE (Verband der Elektrotechnik) certification, ensuring they have been rigorously tested to provide electrical protection up to 1,000 volts AC for user safety and regulatory compliance.

What impact does the growth of modular construction have on the Square Head Screwdriver Market?

The growth of modular and prefabricated construction significantly boosts the Square Head Screwdriver Market. Modular assembly relies on repetitive, consistent, and secure fastening, tasks where the Robertson drive excels due to its efficiency and reduced cam-out rates, driving increased demand for high-quality, standardized square head drivers and related power tool bits in factory environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager