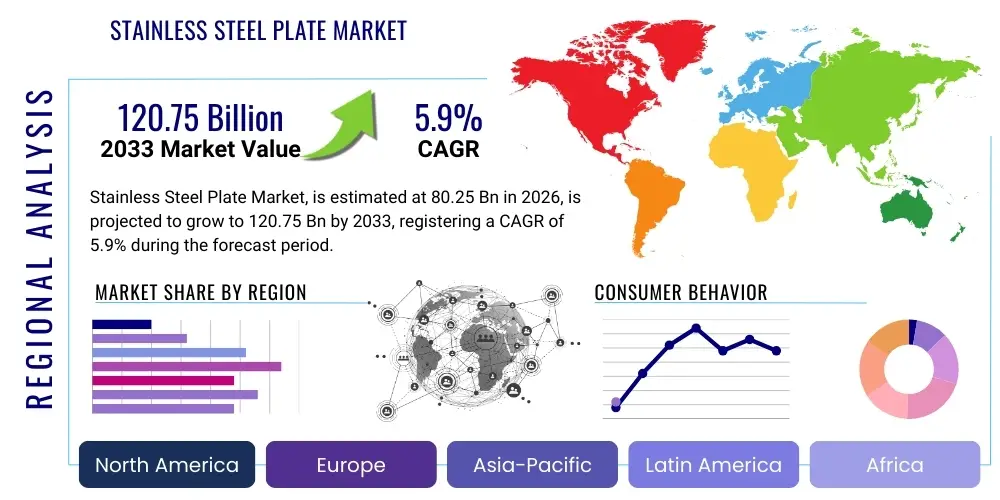

Stainless Steel Plate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440689 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Stainless Steel Plate Market Size

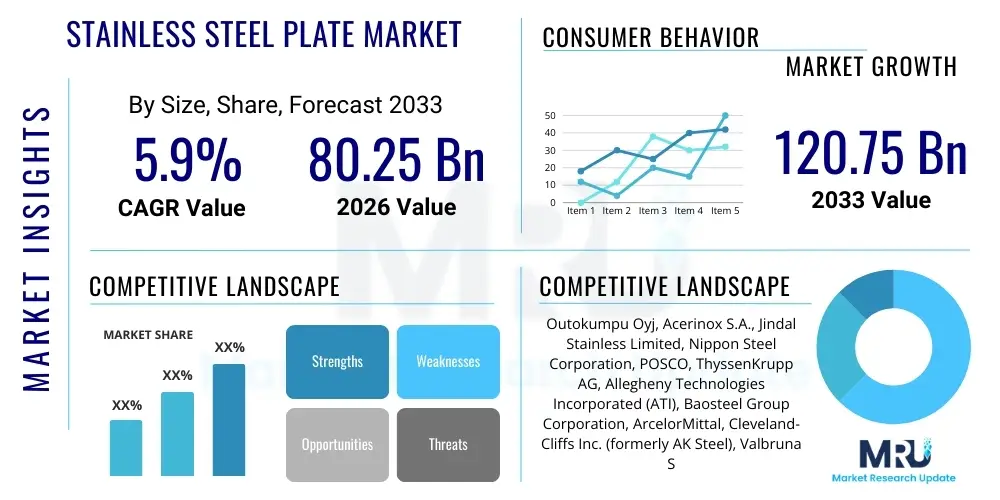

The Stainless Steel Plate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.9% between 2026 and 2033. The market is estimated at USD 80.25 Billion in 2026 and is projected to reach USD 120.75 Billion by the end of the forecast period in 2033. This robust growth trajectory is significantly driven by an escalating demand from diverse end-use industries, particularly in global construction, automotive manufacturing, and heavy industrial sectors, alongside unprecedented levels of infrastructure development worldwide. The inherent and superior properties of stainless steel, such as its exceptional corrosion resistance, high strength-to-weight ratio, hygienic attributes, and inherent aesthetic appeal, solidify its irreplaceable position in numerous critical applications. These intrinsic characteristics contribute profoundly to its sustained market expansion. Furthermore, continuous advancements in production technologies aimed at improving material performance and reducing manufacturing costs, coupled with a growing global emphasis on sustainable and highly recyclable materials, are expected to underpin this consistent and resilient market progression throughout the entire forecast period, ensuring its critical role in various industrial ecosystems.

Stainless Steel Plate Market introduction

The Stainless Steel Plate Market encompasses the comprehensive global ecosystem involved in the production, sophisticated distribution, and extensive consumption of various grades and surface finishes of stainless steel in plate form. These high-performance plates, fundamentally characterized by their high chromium content, typically comprising 10.5% or more, coupled with other alloying elements such like nickel and molybdenum, exhibit unparalleled resistance to corrosion, extreme temperatures, and mechanical wear. Such properties render them absolutely indispensable across a multitude of industrial and commercial applications that demand material integrity and longevity. The product spectrum spans from thin gauge sheets, suitable for aesthetic and lightweight applications, to incredibly heavy plates designed to meet stringent structural and functional requirements in challenging environments. Major applications of these versatile plates permeate critical sectors globally. In building and construction, they are extensively utilized for durable facades, resilient roofing, vital structural components, and sophisticated interior design elements due to their strength and modern appearance. The automotive and transportation industries leverage them for vehicle bodies, high-performance exhaust systems, and crucial structural parts where corrosion resistance and strength are paramount for safety and longevity. Chemical and petrochemical processing relies heavily on stainless steel plates for constructing robust tanks, intricate pipelines, and efficient heat exchangers, owing to their inertness and resistance to aggressive chemical agents. The food and beverage industry finds them essential for hygienic processing equipment, storage tanks, and sanitary surfaces, adhering to the strictest cleanliness standards. Other significant end-uses include precision medical devices, resilient energy infrastructure, and general manufacturing, where reliability is key. The primary benefits derived from using stainless steel plates are numerous and compelling: their exceptional durability ensures a long service life, low maintenance requirements reduce operational costs, hygienic properties prevent contamination, 100% recyclability supports environmental goals, and aesthetic versatility allows for diverse architectural and design applications. These attributes collectively offer a long-term, cost-effective, and sustainable solution, often outperforming alternative materials in demanding scenarios. Driving factors for the sustained market expansion are multi-faceted and interconnected, including rapid global urbanization, a continuously increasing global population leading to expanded infrastructure needs, the widespread expansion of industrial manufacturing capabilities, growing demand for lightweight and fuel-efficient vehicles, increasingly stringent hygiene standards in sensitive sectors like food, pharmaceutical, and healthcare industries, and a profound global pivot towards sustainable, durable, and recyclable materials. Furthermore, continuous technological advancements in stainless steel manufacturing, such as the development of advanced alloys and more efficient production processes, contribute to improved material properties and cost-effective output, continuing to bolster market growth. The escalating demand for modern, resilient architectural designs and the robust expansion of new energy sectors, particularly renewable energy and hydrogen infrastructure, also serve as pivotal drivers, ensuring a steady growth trajectory for the stainless steel plate market for the foreseeable future.

Stainless Steel Plate Market Executive Summary

The Stainless Steel Plate Market is currently experiencing a period of profound transformation and dynamic growth, driven by an intricate convergence of global business trends, pivotal regional economic developments, and continuously evolving demands across its diverse segments. Key business trends indicate an undeniable strategic emphasis on bolstering supply chain resilience, rigorously implementing sustainability practices throughout the lifecycle, and aggressively integrating advanced manufacturing technologies. Manufacturers are increasingly channeling significant investments into automation, digitalization, and predictive analytics to not only enhance operational efficiency but also to substantially reduce production costs and consistently improve product quality, thereby responding effectively to intense competitive pressures and the imperative for greater organizational agility. Furthermore, the market is witnessing a wave of strategic consolidation activities, including mergers, acquisitions, and collaborative partnerships, all fundamentally aimed at expanding geographic reach, diversifying product portfolios to mitigate risks, and gaining access to new technological capabilities. The pervasive global push for green manufacturing initiatives and the widespread adoption of circular economy principles are profoundly shaping current business strategies, with a steadfast focus on maximizing the inherent recyclability of stainless steel and diligently reducing the overall carbon footprint associated with its entire production lifecycle. From a comprehensive regional trends perspective, the Asia Pacific region unequivocally remains the dominant global market force, propelled by unprecedented rates of industrialization, monumental infrastructure projects, and rapidly burgeoning automotive production in economic powerhouses like China, India, and other Southeast Asian nations. North America and Europe, representing more mature market landscapes, exhibit growth primarily driven by relentless innovation, increasingly stringent regulatory standards, and a sustained demand for high-grade, specialized stainless steel plates particularly in advanced sectors such as medical devices, aerospace, and high-performance industrial applications. Latin America, the Middle East, and Africa are progressively emerging as high-growth potential regions, substantially benefiting from increasing foreign direct investment in manufacturing and critical infrastructure development, coupled with an expanding urban consumer base that fuels demand for durable goods. Segment trends reveal a robust and persistent demand for ubiquitous grades such as 304 and 316 due to their versatile applications across a myriad of industries, while specialized duplex and super duplex stainless steels are rapidly gaining significant traction for their superior corrosion resistance and enhanced strength in exceptionally challenging environments, including offshore oil and gas exploration and chemical processing. The traditional construction and industrial machinery sectors continue to be major revenue generators, but there is also remarkable accelerated growth in highly specialized applications, including components for hydrogen energy storage, electric vehicle battery casings and structural parts, and advanced medical equipment. The market is simultaneously witnessing an escalating demand for customized plate finishes and specific thicknesses to meet bespoke aesthetic and exacting structural requirements, indicative of a pronounced trend towards more specialized and high value-added products. These multifaceted trends collectively underscore a vibrant market characterized by continuous technological innovation, proactive strategic adaptation to global changes, and sustained growth across its profoundly diverse and expanding application landscape, reinforcing stainless steel's critical role in global industrial development.

AI Impact Analysis on Stainless Steel Plate Market

User questions related to the profound impact of Artificial Intelligence (AI) on the Stainless Steel Plate Market frequently revolve around the critical themes of optimizing operational efficiency, ensuring stringent quality control, leveraging predictive analytics for strategic decision-making, and enhancing overall sustainability. End-users and industry stakeholders are keenly interested in understanding precisely how AI can revolutionize and streamline manufacturing processes, ranging from the initial stages of raw material sorting and precise furnace control to intricate rolling and meticulous finishing operations. The ultimate goals here are consistently focused on achieving substantially reduced material waste, significantly lower energy consumption, and vastly improved output consistency across all production lines. Significant concerns and expectations also include the immense potential for AI to dramatically enhance quality inspection regimes, enabling the detection of even the most subtle defects at much earlier stages of production, and even to predict potential material failures before they manifest, thereby minimizing costly production errors and profoundly enhancing overall product reliability and safety. There is also substantial interest in AI's transformative role in modern supply chain management, particularly in developing highly accurate demand forecasting models, optimizing complex inventory levels across global networks, and improving intricate logistics to effectively mitigate market volatility and shorten lead times. Furthermore, users frequently inquire about AI's revolutionary potential to accelerate the development of entirely new stainless steel alloys possessing enhanced properties, exploring how sophisticated machine learning algorithms can analyze vast, complex datasets of material science to rapidly predict optimal compositions and ideal processing parameters. The overarching expectation is that AI will undoubtedly drive significant, game-changing advancements in efficiency, precision, and innovation throughout the entire Stainless Steel Plate value chain, while simultaneously presenting new challenges related to seamless data integration, robust cybersecurity measures, and the crucial adaptation and upskilling of the industrial workforce. These questions highlight a clear understanding that AI is not just a tool but a fundamental catalyst for future market evolution.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data from rolling mills and processing equipment to predict potential failures before they occur, reducing downtime and maintenance costs.

- Optimized Production Planning and Scheduling: AI-powered systems can process complex variables like raw material availability, energy costs, and order backlogs to create highly efficient production schedules, minimizing waste and maximizing throughput.

- Advanced Quality Control: Machine vision systems integrated with AI can rapidly inspect stainless steel plates for surface defects, dimensional inaccuracies, and material inconsistencies with greater precision than human inspection, leading to higher quality products.

- Improved Material Design and Metallurgy: AI can analyze vast datasets of material properties and experimental results to accelerate the discovery and optimization of new stainless steel alloys with desired characteristics, such as increased strength or corrosion resistance.

- Smart Supply Chain Management: AI enables more accurate demand forecasting, inventory optimization, and logistics planning, helping manufacturers respond quickly to market fluctuations and improve delivery performance.

- Energy Efficiency Optimization: AI can monitor and adjust energy consumption in high-energy processes like melting and annealing, leading to significant reductions in operational costs and environmental impact.

- Autonomous Operations: In hazardous environments or repetitive tasks, AI-driven robotics and autonomous systems can enhance safety and efficiency in handling and processing stainless steel plates.

DRO & Impact Forces Of Stainless Steel Plate Market

The Stainless Steel Plate Market is profoundly influenced by a complex and dynamic interplay of critical drivers, inherent restraints, promising opportunities, and broader macroeconomic and geopolitical impact forces that collectively shape its growth trajectory, competitive landscape, and long-term sustainability. Key drivers robustly propelling the market forward include the unprecedented rapid expansion of urban infrastructure projects globally, particularly concentrated in rapidly developing economies, which inherently necessitates immense volumes of durable, high-performance construction materials. The escalating and continuous demand from the global automotive sector for increasingly lightweight yet immensely strong materials to significantly enhance fuel efficiency, improve safety, and drastically reduce emissions also substantially contributes to the market's vigorous growth. Furthermore, the inherent and superior benefits of stainless steel plates, such as their exceptional corrosion resistance even in aggressive environments, high tensile strength offering structural integrity, and impeccable hygienic properties, render them absolutely indispensable in critical applications across the stringent chemical processing, sensitive food and beverage, and vital medical industries, where uncompromising material integrity and reliability are paramount. However, the market concurrently faces notable and persistent restraints, primarily the inherent volatility in global raw material prices, particularly for essential alloying elements like nickel, chromium, and molybdenum. These unpredictable price fluctuations directly and significantly impact production costs, erode profit margins, and challenge overall market stability, posing substantial strategic and operational difficulties for manufacturers in terms of consistent pricing, accurate forecasting, and sustained profitability. Additionally, increasingly stringent global environmental regulations pertaining to steel production processes, meticulously aimed at drastically reducing carbon emissions, optimizing energy consumption, and minimizing waste, can inevitably increase operational complexities and necessitate significant capital expenditures for compliance and technological upgrades. Opportunities within the market are abundant and strategically significant, driven by the escalating global emphasis on sustainable, recyclable, and environmentally friendly materials, a profile that aligns perfectly with stainless steel's excellent recyclability and long lifespan. The burgeoning renewable energy sector, encompassing solar panel manufacturing, wind turbine components, and emerging hydrogen production and storage infrastructure, presents entirely new and high-growth avenues for specialized stainless steel applications. Moreover, ongoing technological advancements in advanced manufacturing processes, such as precision additive manufacturing, innovative surface treatments, and advanced welding techniques, offer the immense potential for developing groundbreaking products with exceptionally enhanced performance characteristics and entirely new functional capabilities. The market's broader impact forces extend well beyond these immediate drivers and restraints, encompassing significant global economic cycles that profoundly influence industrial output, consumer spending patterns, and overall investment climates. Geopolitical stability, or the lack thereof, can dramatically disrupt intricate global supply chains, impose trade barriers, and influence raw material availability. The continuous and rapid evolution of technological innovations perpetually redefines material science, production methodologies, and processing efficiencies. Furthermore, evolving environmental policies, international trade agreements, and protectionist measures exert considerable influence, shaping investment decisions, market accessibility, and competitive dynamics. Successfully navigating these multifaceted dynamics effectively requires market participants to maintain an exceptionally high degree of adaptability, strategic foresight, and unwavering commitment to innovation to sustain growth and competitiveness in a complex global landscape.

Segmentation Analysis

The Stainless Steel Plate Market is comprehensively segmented to provide a highly granular and nuanced understanding of its diverse components, intricate demand patterns, and myriad growth opportunities, thereby allowing stakeholders to precisely identify niche markets and tailor their strategic approaches with remarkable effectiveness. This segmentation typically categorizes the market based on various critical and inherent attributes, including the specific type of stainless steel grade (e.g., austenitic, ferritic, duplex), the particular surface finish applied to the plate (e.g., polished, brushed, hot-rolled), its dimensional characteristics such as thickness, and its ultimate end-use application across a wide spectrum of different industries. Each delineated segment invariably exhibits unique demand drivers, distinct competitive dynamics, and varying growth prospects, inherently reflecting the broad utility, exceptional versatility, and specialized functional requirements of stainless steel plates in their myriad applications. A profound understanding of these intricate divisions is absolutely crucial for market participants to effectively optimize their product development cycles, refine manufacturing processes for enhanced efficiency, strategize efficient distribution channels, and implement targeted marketing efforts, ultimately ensuring that highly specific market needs are met with unparalleled precision and operational efficiency. The detailed breakdown provided by this segmentation framework offers invaluable insights into areas of accelerated growth, identifies emerging and high-potential applications, and highlights segments that may be inherently more susceptible to overarching macroeconomic fluctuations or volatile raw material price movements. This invaluable intelligence, in turn, significantly facilitates informed strategic planning, optimized resource allocation, and prudent investment decisions across the entire Stainless Steel Plate value chain, empowering stakeholders to navigate the market landscape with greater confidence. This multi-faceted segmentation framework is essential for dissecting complex market dynamics, revealing specific, underlying trends that might not be readily apparent at a broader, aggregate level, thus offering a much clearer and more actionable picture of the market's intricate structure, inherent characteristics, and future potential.

- By Grade:

- Austenitic (e.g., 304, 316, 321)

- Ferritic (e.g., 430, 409)

- Martensitic (e.g., 410, 420)

- Duplex (e.g., 2205, 2507)

- Super Duplex

- Precipitation Hardening (PH)

- By Finish:

- No. 1 (Hot-Rolled, Annealed, Pickled)

- 2B (Cold-Rolled, Annealed, Pickled, Skin-Passed)

- BA (Bright Annealed)

- No. 4 (Brushed Finish)

- Hairline (HL)

- Mirror Finish (No. 8)

- Etched/Patterned

- By Application/End-Use Industry:

- Building & Construction (Architecture, Infrastructure)

- Automotive & Transportation (Vehicles, Rail, Marine)

- Industrial Machinery (Manufacturing Equipment, Heavy Industry)

- Chemical & Petrochemical (Tanks, Pipelines, Heat Exchangers)

- Food Processing & Catering (Equipment, Storage)

- Medical & Pharmaceutical (Equipment, Sterilizers)

- Energy (Oil & Gas, Power Generation, Renewable Energy)

- Consumer Goods (Appliances, Utensils)

- Aerospace & Defense

- By Thickness:

- Thin Plate (up to 3 mm)

- Medium Plate (3 mm to 10 mm)

- Thick Plate (above 10 mm)

Value Chain Analysis For Stainless Steel Plate Market

The value chain for the Stainless Steel Plate Market represents a complex, multi-stage, and highly integrated process that meticulously begins with the foundational extraction and primary processing of raw materials, ultimately culminating in the precise fabrication and efficient delivery of finished stainless steel plates to an immensely diverse array of demanding end-user industries. Upstream analysis primarily focuses on the diligent sourcing and reliable supply of key raw materials, which are critical alloying elements including high-quality iron ore, nickel, chromium, molybdenum, and a significant proportion of high-grade scrap steel for recycling. Suppliers of these foundational raw materials, often comprising global mining conglomerates and specialized scrap metal recyclers, collectively form the absolutely foundational tier of this intricate value chain. The unwavering quality and consistent availability of these essential materials, coupled with their inherent price volatility, profoundly impact the entire cost structure and long-term profitability of stainless steel producers. Integrated steel mills and specialized stainless steel manufacturers then painstakingly process these raw materials through various technologically advanced stages such as precise melting in electric arc furnaces (EAFs) or argon oxygen decarburization (AOD) converters, meticulous refining, continuous casting into slabs or billets, and subsequent hot or cold rolling processes to produce high-quality stainless steel plates. These advanced manufacturing processes are invariably capital-intensive, requiring immense investments in machinery and infrastructure, and demand profound technological expertise and skilled labor. Downstream analysis intimately involves the strategic distribution, precise fabrication, and diverse final application of the manufactured stainless steel plates. Once produced, these plates are typically sold to an extensive global network of specialized distributors, service centers, and expert fabricators. Distributors act as crucial intermediaries, strategically stocking a wide variety of grades and sizes, and frequently performing initial value-added services such as precise cutting, slitting, or surface finishing to meet highly specific customer requirements. Fabricators further process these plates through advanced operations like laser cutting, precision bending, sophisticated welding, and meticulous finishing to create custom components or complete finished products tailored for specialized end-use industries, including complex construction projects, high-performance automotive parts, advanced chemical processing equipment, and hygienic food processing machinery. The distribution channels are predominantly classified as either direct or indirect. Direct channels involve large-scale manufacturers selling directly to major industrial clients, governmental agencies, or substantial large-scale infrastructure projects, often entailing custom orders, specialized specifications, and long-term contractual agreements. Indirect channels strategically utilize a network of regional and local distributors, wholesalers, and highly specialized service centers that efficiently cater to smaller businesses, individual contractors, and niche markets, providing crucial just-in-time delivery services for a broader range of standard and semi-finished stainless steel products. The overall efficiency, resilience, and responsiveness of this entire value chain, from securing a reliable supply of raw materials to ensuring effective last-mile delivery and expert fabrication, are absolutely critical for maintaining the competitiveness and adaptability of the entire stainless steel plate market in a rapidly evolving global economy.

Stainless Steel Plate Market Potential Customers

The potential customers and end-users of stainless steel plates are remarkably diverse and extensive, spanning almost every major industrial sector globally due to the material's intrinsically superior properties and unparalleled versatility. These buyers range from formidable multinational corporations undertaking colossal infrastructure projects to agile small-scale fabricators meticulously producing custom, high-precision components. In the expansive building and construction sector, general contractors, visionary architects, and structural engineers represent key purchasing entities, acquiring stainless steel plates for robust facades, durable roofing systems, essential structural elements, and sophisticated interior design features, all valuing stainless steel's inherent durability, modern aesthetic appeal, and long-term cost-effectiveness. The dynamic automotive and transportation industries, encompassing major vehicle manufacturers, specialized railway component producers, and innovative marine builders, extensively acquire stainless steel plates for resilient chassis components, corrosion-resistant exhaust systems, and crucial structural parts that demand exceptional corrosion resistance, high strength, and impact resistance for enhanced safety and operational longevity. Within the pivotal industrial machinery sector, manufacturers of heavy equipment, complex processing lines, and highly specialized machinery represent significant and consistent buyers, profoundly valuing the material's wear resistance, high operational reliability, and ability to withstand demanding operational environments. The chemical and petrochemical industries heavily rely on stainless steel plates for constructing critical storage tanks, intricate pipeline networks, efficient heat exchangers, and robust reactors where unwavering resistance to aggressive chemicals and extreme temperatures is absolutely paramount for safety and operational continuity. Furthermore, the global food processing and catering industry, encompassing equipment manufacturers, commercial kitchens, and large-scale processing plants, meticulously procures stainless steel plates for hygienic surfaces, sterile storage vessels, and advanced processing machinery due to its non-corrosive, exceptionally easy-to-clean, and non-reactive properties, which are vital for maintaining stringent food safety standards. The medical and pharmaceutical sectors also form an increasingly crucial customer base, extensively utilizing stainless steel for sterile operating equipment, precision surgical instruments, and meticulously controlled cleanroom applications where absolute hygiene and biocompatibility are non-negotiable. Emerging and rapidly growing end-users include pioneering companies in the renewable energy sector, such as those developing durable solar panel frames, resilient wind turbine components, and innovative hydrogen storage and transportation solutions, all recognizing stainless steel's unparalleled longevity, structural integrity, and resistance to environmental degradation. These varied and expanding customer segments collectively underscore the indispensable and ever-growing role of stainless steel plates across the global economy, consistently driven by fundamental functional requirements for exceptional durability, uncompromising safety, peak performance, and long-term value creation across a multitude of applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 80.25 Billion |

| Market Forecast in 2033 | USD 120.75 Billion |

| Growth Rate | 5.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Outokumpu Oyj, Acerinox S.A., Jindal Stainless Limited, Nippon Steel Corporation, POSCO, ThyssenKrupp AG, Allegheny Technologies Incorporated (ATI), Baosteel Group Corporation, ArcelorMittal, Cleveland-Cliffs Inc. (formerly AK Steel), Valbruna Stainless Steel, Sandvik AB, Tsingshan Holding Group, North American Stainless (NAS), Hyundai Steel Co., Ltd., Taiyuan Iron & Steel (Group) Co., Ltd. (TISCO), Chongqing Iron & Steel Company Limited, Viraj Profiles Ltd., APERAM S.A., Bristol Metals, LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stainless Steel Plate Market Key Technology Landscape

The Stainless Steel Plate Market is continuously shaped by a dynamic and rapidly evolving technology landscape, with relentless ongoing innovations meticulously aimed at significantly enhancing production efficiency, consistently improving fundamental material properties, profoundly reducing environmental impact, and exponentially expanding application possibilities across diverse industries. Core technologies primarily involve advanced metallurgical processes, commencing with high-efficiency electric arc furnaces (EAFs) or sophisticated argon oxygen decarburization (AOD) converters for precise melting and meticulous refining, which permit unparalleled control over alloy composition and the diligent removal of impurities, thereby ensuring superior material quality. Subsequent critical stages leverage highly sophisticated hot and cold rolling mills capable of producing stainless steel plates with exceptional dimensional accuracy, superior flatness, and a wide array of desired surface finishes. Annealing and pickling processes are absolutely critical for achieving desired mechanical properties, relieving internal stresses, and restoring maximum corrosion resistance. Recent technological advancements include the widespread adoption of continuous casting for streamlined and efficient production of slabs, and the innovative development of thinner gauge plates possessing significantly enhanced strength-to-weight ratios, meticulously catering to demanding industries like automotive and aerospace that vigorously pursue weight reduction for improved performance and fuel efficiency. Furthermore, advanced surface treatment technologies, such as plasma nitriding for increased hardness, laser cladding for superior wear and corrosion resistance, and various precision polishing and brushing techniques, are becoming exceedingly refined, offering superior wear resistance, enhanced aesthetics, and specialized functional coatings tailored for specific end-use environments. Digitalization and automation play an increasingly vital and transformative role throughout the production chain, evidenced by the ubiquitous integration of Industrial Internet of Things (IIoT) sensors, real-time data analytics platforms, and sophisticated artificial intelligence (AI) algorithms directly into production lines for predictive maintenance, comprehensive process optimization, and advanced, automated quality control systems. This includes leveraging AI for rapid and accurate defect detection via machine vision systems and for meticulously optimizing energy consumption in notoriously energy-intensive steps such as melting and annealing. Environmentally conscious technologies, such as advanced gas purification systems, highly efficient waste heat recovery units, and water recycling systems, are also gaining significant prominence, driven by increasingly stringent global environmental regulations and a steadfast industry-wide focus on sustainable manufacturing practices. The ongoing intensive research and development in advanced stainless steel alloys, including new generations of duplex and super duplex grades with further improved strength and unparalleled corrosion resistance, and highly specialized precipitation-hardening alloys engineered for extreme applications, continue to profoundly broaden the material's functional envelope. These synergistic technological advancements collectively propel the market forward by enabling the production of demonstrably higher quality, more versatile, economically competitive, and environmentally responsible stainless steel plates, precisely tailored for an ever-expanding array of demanding and critical applications worldwide.

Regional Highlights

- Asia Pacific (APAC): This region dominates the global Stainless Steel Plate Market, primarily driven by rapid industrialization, extensive infrastructure development, and a burgeoning manufacturing sector in countries like China, India, Japan, and South Korea. China, as the world's largest producer and consumer of stainless steel, plays a pivotal role, with massive investments in construction, automotive, and industrial machinery propelling demand. India's growth is fueled by urbanization, government initiatives in manufacturing (e.g., "Make in India"), and expanding energy infrastructure. The region also benefits from a robust shipbuilding industry and increasing adoption of stainless steel in consumer goods. The sheer scale of population and economic expansion ensures sustained high demand, making APAC the engine of global market growth and a critical hub for both production and consumption.

- Europe: Characterized by a mature industrial base and stringent quality standards, Europe represents a significant market for specialized and high-grade stainless steel plates. Demand is particularly strong from the chemical and petrochemical industries, food processing, medical equipment manufacturing, and the automotive sector, especially for premium and luxury vehicles. Countries like Germany, Italy, and France are key consumers, focusing on advanced manufacturing techniques, innovation, and high-performance applications. While growth rates may be lower than in APAC, the emphasis on high-value applications, sustainable production, and technological leadership ensures a stable and innovation-driven market. Environmental regulations also drive demand for durable and recyclable materials like stainless steel, contributing to its continued relevance.

- North America: The North American market is driven by robust demand from the construction, energy (oil & gas, renewable), and automotive sectors, alongside significant investment in manufacturing modernization. The United States is a primary consumer, with substantial usage in infrastructure projects, industrial processing equipment, and a growing aerospace and defense sector that requires high-performance alloys. The emphasis on domestic manufacturing and technological innovation fosters demand for advanced stainless steel plates. Additionally, the region's focus on sustainable building practices and energy efficiency further supports the adoption of long-lasting, recyclable stainless steel materials, contributing to a steady, albeit moderate, growth trajectory bolstered by a strong economy and consistent industrial output.

- Latin America: This region presents emerging opportunities for the Stainless Steel Plate Market, primarily influenced by ongoing urbanization, industrial expansion, and investments in infrastructure development, particularly in economic powerhouses like Brazil, Mexico, and Argentina. Growth is stimulated by increasing demand from the automotive manufacturing sector, mining operations, and the nascent renewable energy projects which are gaining momentum. While economic stability can fluctuate across the region, long-term projections indicate a gradual yet consistent increase in stainless steel consumption as industrial bases mature and living standards improve. Foreign direct investments in manufacturing and infrastructure continue to bolster the market's potential, especially for standard grades of stainless steel plates used in general industrial applications.

- Middle East and Africa (MEA): The MEA region is experiencing significant growth in the Stainless Steel Plate Market, propelled by massive infrastructure projects, strategic diversification away from traditional oil-dependent economies, and rapid urbanization. Countries in the GCC (Gulf Cooperation Council) are investing heavily in commercial and residential construction, tourism infrastructure, and industrial development, driving substantial demand for stainless steel. Furthermore, the region's burgeoning petrochemical and oil & gas industries require high volumes of corrosion-resistant materials for critical infrastructure. Africa's ongoing industrialization efforts and increasing foreign investments in manufacturing and resource processing also contribute to rising demand, making MEA a high-potential market characterized by significant developmental push, large-scale project execution, and an expanding industrial footprint.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stainless Steel Plate Market.- Outokumpu Oyj

- Acerinox S.A.

- Jindal Stainless Limited

- Nippon Steel Corporation

- POSCO

- ThyssenKrupp AG

- Allegheny Technologies Incorporated (ATI)

- Baosteel Group Corporation

- ArcelorMittal

- Cleveland-Cliffs Inc.

- Valbruna Stainless Steel

- Sandvik AB

- Tsingshan Holding Group

- North American Stainless (NAS)

- Hyundai Steel Co., Ltd.

- Taiyuan Iron & Steel (Group) Co., Ltd. (TISCO)

- Chongqing Iron & Steel Company Limited

- Viraj Profiles Ltd.

- APERAM S.A.

- Bristol Metals, LLC

Frequently Asked Questions

Analyze common user questions about the Stainless Steel Plate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of stainless steel plates?

Stainless steel plates are widely utilized across various industries due to their exceptional durability and corrosion resistance. Key applications include building and construction for facades and structural elements, automotive and transportation for vehicle bodies and exhaust systems, chemical and petrochemical processing for tanks and pipelines, food processing for hygienic equipment, and industrial machinery for robust components. Their versatility also extends to medical devices, energy infrastructure, and consumer goods, highlighting their indispensable role in modern industrial and commercial sectors.

What factors drive the growth of the Stainless Steel Plate Market?

The market's growth is propelled by several critical factors. These include rapid urbanization and increasing global infrastructure development, leading to higher demand in the construction sector. Growing automotive production, particularly for lightweight and fuel-efficient vehicles, also drives demand. Additionally, the material's inherent properties such as superior corrosion resistance, high strength-to-weight ratio, and recyclability make it highly favored across numerous industries, contributing significantly to its sustained market expansion. The rising focus on sustainable materials and technological advancements in manufacturing further bolster this growth.

What are the main types (grades) of stainless steel plates available?

Stainless steel plates are categorized into several grades based on their metallurgical composition, which dictates their specific properties and applications. The main types include Austenitic (e.g., 304, 316), known for excellent corrosion resistance and weldability; Ferritic (e.g., 430), recognized for good ductility and resistance to stress corrosion cracking; Martensitic (e.g., 410, 420), offering high strength and hardness; and Duplex (e.g., 2205, 2507) and Super Duplex, which combine properties of both austenitic and ferritic steels for superior strength and corrosion resistance in harsh environments. Precipitation Hardening (PH) grades offer exceptional strength.

How do raw material prices impact the Stainless Steel Plate Market?

Raw material prices, particularly for key alloying elements such as nickel, chromium, and molybdenum, have a substantial impact on the Stainless Steel Plate Market. These prices are often volatile, influenced by global supply and demand dynamics, geopolitical events, and mining operations. Fluctuations directly affect the production costs for stainless steel manufacturers, leading to variations in the final product pricing. This volatility can introduce uncertainty for both producers and consumers, influencing investment decisions, inventory management strategies, and overall market stability, often requiring manufacturers to implement hedging strategies.

What role does sustainability play in the Stainless Steel Plate Market?

Sustainability is an increasingly critical aspect of the Stainless Steel Plate Market. Stainless steel is 100% recyclable without degradation of its properties, making it a highly sustainable material choice that aligns with circular economy principles. Its long lifespan and low maintenance requirements also contribute to reduced resource consumption over time. Manufacturers are continually investing in greener production technologies, such as improved energy efficiency in melting and rolling processes, and advanced waste management systems, to reduce the environmental footprint. This focus on sustainability drives demand from environmentally conscious industries and consumers, enhancing the market's long-term viability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager