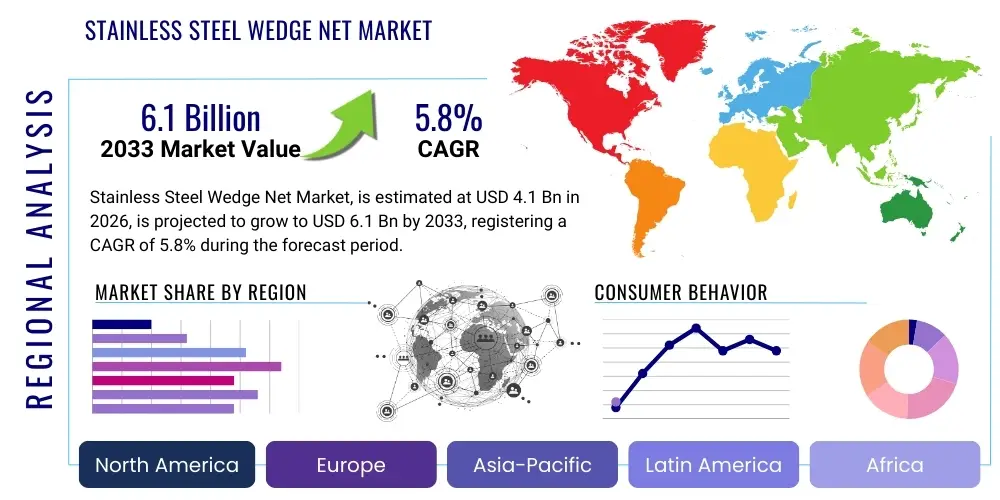

Stainless Steel Wedge Net Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434622 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Stainless Steel Wedge Net Market Size

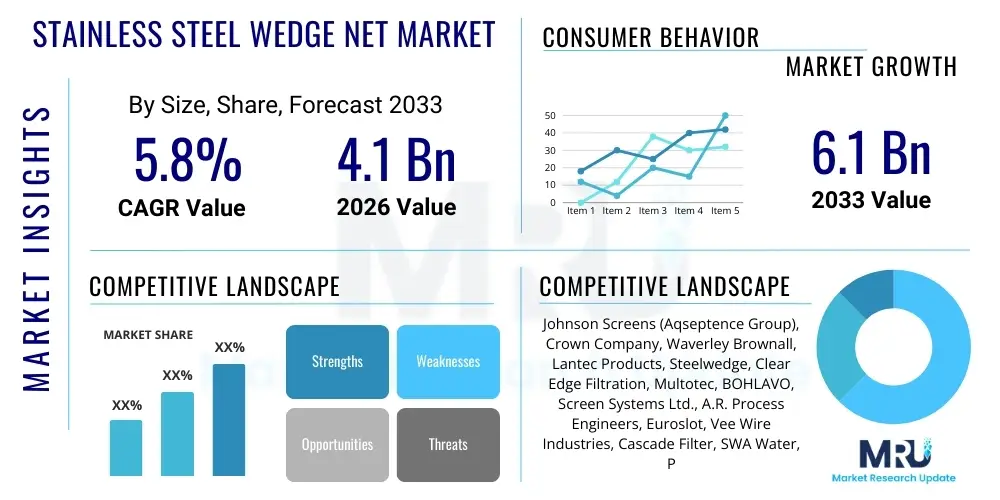

The Stainless Steel Wedge Net Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Stainless Steel Wedge Net Market introduction

The Stainless Steel Wedge Net Market encompasses the global production, distribution, and consumption of screening and filtration products manufactured primarily from high-grade stainless steel wire with a characteristic V-shaped profile. These products, also widely known as wedge wire screens, slotted screens, or profile wire screens, are crucial components in various industrial processes requiring precise separation, filtration, dewatering, and classification. The inherent robust mechanical strength, exceptional corrosion resistance, and high flow capacity of stainless steel, particularly grades like 304 and 316L, make these nets indispensable in harsh operating environments, driving their persistent demand across heavy and processing industries globally.

The product description highlights screens constructed by wrapping V-shaped profile wires around internal support rods, forming continuous slots that minimize clogging and maximize open area. Major applications span critical infrastructure sectors, including municipal and industrial water treatment facilities, where they are used for intake screens and filter elements. Furthermore, the oil and gas industry utilizes them extensively for sand control, well completion, and downhole filtration, while the mining and aggregate sectors rely on them for dewatering and particle sizing. The precise engineering of these nets, allowing for highly accurate slot openings, provides significant benefits such as increased process efficiency, reduced maintenance downtime, and extended operational life compared to traditional mesh or woven screens.

Key driving factors propelling market growth include stringent environmental regulations necessitating advanced water and wastewater treatment solutions, increasing exploration and production activities in challenging oil and gas reserves, and the ongoing modernization of industrial filtration infrastructure worldwide. The demand from the food and beverage industry for sanitary, easy-to-clean filtration media further solidifies the market trajectory. Technological advancements in automated welding and manufacturing techniques are also contributing to the production of screens with higher precision and customized geometries, broadening the scope of application and enhancing overall market attractiveness during the forecast period.

Stainless Steel Wedge Net Market Executive Summary

The Stainless Steel Wedge Net Market exhibits stable growth driven primarily by the essential role these screens play in water security and energy production infrastructure globally. Business trends indicate a strong move towards customization and high-pressure applications, with manufacturers focusing on expanding capacity for specialized stainless steel grades, such as Duplex and Super Duplex steels, to meet the stringent corrosive demands of deep-sea oil recovery and harsh chemical processing. Mergers, acquisitions, and strategic partnerships centered on consolidating manufacturing capabilities and expanding distribution networks in rapidly industrializing regions define the current competitive landscape, prioritizing supply chain resilience and technical expertise. The integration of advanced manufacturing processes, including laser welding and automated assembly, is enhancing product quality and reducing production turnaround times, directly addressing the industry need for highly reliable components.

Regionally, Asia Pacific is anticipated to demonstrate the highest growth rate, fueled by massive infrastructural investments in water management, rapid expansion of mining activities in countries like Australia and Indonesia, and increasing demand for refined petroleum products in China and India. North America and Europe, while mature, maintain dominance in terms of value, driven by strict regulatory standards for environmental protection and the necessary replacement or upgrade of aging filtration systems in municipal and industrial settings. These developed regions are characterized by a higher uptake of premium, high-specification stainless steel wedge nets designed for extreme operating conditions, emphasizing long-term total cost of ownership rather than initial capital expenditure. Latin America and the Middle East & Africa (MEA) are emerging as significant markets due to burgeoning oil exploration projects and expanding agricultural processing sectors.

Segmentation trends highlight the increasing demand for Cylindrical Screens, particularly within the oil and gas sector for well screens and process vessels, owing to their structural integrity under high differential pressure. In terms of application, the Water Treatment segment remains the largest consumer, driven by global urban development and the necessity of recycling and conserving water resources. The trend towards higher material grades, specifically SS 316L, is becoming more pervasive across all segments, reflecting the industry's heightened focus on maximizing component longevity and resistance to chemical attack and pitting corrosion. Furthermore, customized Sieve Bend screens are witnessing increased adoption in mineral processing and wastewater pre-treatment due to their effectiveness in high-flow dewatering applications without moving parts.

AI Impact Analysis on Stainless Steel Wedge Net Market

Common user questions regarding AI's impact on the Stainless Steel Wedge Net Market frequently revolve around optimizing manufacturing efficiency, predicting material quality, and enhancing screen design specificity. Users are keen to understand how AI-driven algorithms can manage the complex variables involved in profile wire welding to ensure uniform slot size and maximize screen integrity, a critical determinant of performance. Concerns also focus on the potential for AI to optimize inventory management of expensive raw materials (like high-nickel stainless steels) and streamline the customized quotation process, which often requires complex engineering calculations. Overall, users expect AI to transition the industry from traditional manual quality control to predictive, real-time monitoring, leading to reduced waste, increased customization accuracy, and faster market response times, thus elevating the competitive landscape.

- AI-powered predictive maintenance scheduling for welding machinery, minimizing downtime and ensuring continuous, high-precision manufacturing processes.

- Optimization of wedge wire screen designs using generative AI algorithms to maximize open area, flow rates, and structural rigidity for specific fluid dynamics applications.

- Enhanced quality control through machine vision and deep learning models, capable of detecting minute defects in slot width uniformity or welding integrity far exceeding human capabilities.

- Streamlining supply chain logistics and inventory management for specialty stainless steel grades (e.g., 904L, Duplex), using AI to forecast demand fluctuations and optimize purchasing strategies.

- Accelerated customization and quotation generation by leveraging machine learning to instantly analyze client requirements (pressure, flow, particle size) and generate optimized engineering specifications.

- Robotics and AI integration in automated welding processes to achieve unprecedented accuracy and repeatability in the fabrication of large-scale cylindrical and flat panel screens.

- Simulating the operational performance and lifespan of wedge nets under various harsh conditions (corrosion, abrasion, high temperature) before physical prototyping, reducing R&D costs.

- Improving energy efficiency in the production line by optimizing machine utilization and power consumption based on real-time operational data analyzed by AI systems.

DRO & Impact Forces Of Stainless Steel Wedge Net Market

The Stainless Steel Wedge Net Market is governed by a dynamic interplay of drivers, restraints, and opportunities that collectively shape its trajectory and competitive environment. The primary drivers stem from critical global needs, notably the escalating demand for clean water due to population growth and urbanization, which mandates efficient filtration technologies in municipal and industrial wastewater treatment plants. Additionally, the inherent advantages of wedge wire over conventional filtration media—such as superior resistance to clogging (due to the V-shaped profile), high mechanical strength, and corrosion resistance—ensure its sustained adoption across high-stress industrial applications. Restraints predominantly revolve around the volatility and high cost of raw materials, particularly stainless steel alloys, whose prices fluctuate based on global nickel and chromium markets. The manufacturing process itself requires significant capital investment in specialized welding machinery and high precision engineering expertise, creating substantial barriers to entry for new players, thereby limiting competition and potentially inflating end-user costs.

Opportunities for growth are significant and largely centered on technological innovation and geographical expansion. The development of specialized alloys, such as high-strength Duplex and Super Duplex stainless steels, tailored for extremely aggressive environments (e.g., acid processing, deep-sea exploration), presents a premium market niche with substantial margins. Furthermore, the increasing global focus on renewable energy sources, particularly geothermal power, requires robust, high-temperature filtration screens, creating new application pathways. The expansion of infrastructure projects in developing nations in APAC and MEA, particularly in water infrastructure and mineral processing, offers untapped market potential for customized screening solutions. These forces combine to create an environment where product differentiation based on material science and manufacturing accuracy dictates market success.

The market is subject to intense impact forces, including stringent environmental legislation (e.g., mandates for zero liquid discharge) that accelerates the need for highly efficient filtration technology. Economic cycles directly influence capital expenditure in key end-user sectors like oil and gas and mining; any slowdown in exploration or resource extraction immediately impacts demand for new equipment. Technological advancements in competing filtration materials, although currently limited, pose a potential disruptive force, necessitating continuous innovation in wedge net design and material coating technologies to maintain competitive superiority. Ultimately, the market’s inherent structural integrity and performance superiority in demanding industrial environments serve as a powerful gravitational force, ensuring sustained relevance despite external economic and regulatory pressures.

Segmentation Analysis

The Stainless Steel Wedge Net market is comprehensively segmented based on Type, Application, and Material Grade, allowing for a detailed analysis of specific demand drivers and end-user requirements across the industrial spectrum. Segmentation by Type reflects the various structural geometries required for optimal performance in different processing environments, ranging from simple flat panels used in stationary vibrating screens to complex cylindrical geometries critical for efficient flow and pressure management in well systems and process towers. Application segmentation dictates the material specifications and slot opening tolerances, as the needs of the highly sanitary Food & Beverage industry differ drastically from the abrasive conditions encountered in the Mining sector. This differentiation allows manufacturers to tailor their production capabilities and marketing efforts towards high-growth, high-value segments.

The segmentation based on Material Grade is perhaps the most critical determinant of product cost and performance, directly reflecting the required resistance to corrosion, temperature, and pressure. While SS 304 remains the economical choice for less demanding applications like municipal water intake, the increasing prevalence of SS 316L highlights the industry's shift towards enhanced durability and chemical resistance in marine and acidic environments. The emerging segment of specialized grades, including Duplex and 904L, caters to highly corrosive niches, representing a premium market segment driven by mission-critical applications where failure is highly costly. Understanding these segments is vital for competitive strategy, allowing companies to invest in R&D for material science and advanced manufacturing techniques tailored to specific industrial needs and regulatory compliance.

This systematic segmentation provides a framework for analyzing market dynamics. For instance, the demand for SS 316L Cylindrical Screens is intrinsically linked to the activity levels in the Offshore Oil & Gas sector, whereas the consumption of Flat Screens made from SS 304 is often tied to capital investments in basic municipal water infrastructure. Geographical segmentation further refines this analysis, showing that regions with significant mining activity (e.g., APAC, Latin America) prioritize durability and abrasion resistance, influencing the dominant material grades and screen designs utilized in those territories. Consequently, manufacturers utilize this segmentation insight to guide product portfolio diversification and optimize their global supply chain to efficiently serve diverse and technically demanding markets.

- By Type:

- Flat Screens / Sieve Bends (Used in dewatering, pre-filtration)

- Cylindrical Screens (Used in well screens, process vessels, resin traps)

- Basket Strainers (Used for coarse filtration, temporary protection)

- Lateral Assemblies / Headers & Hubs (Specialized components for deep bed filtration)

- Custom Profiles and Shapes

- By Application:

- Water and Wastewater Treatment (Municipal and Industrial)

- Oil and Gas (Well completion, Sand Control, Refining)

- Food and Beverage Processing (Juice filtration, Brewing)

- Mining and Aggregate Processing (Dewatering, Classification)

- Chemical and Petrochemical Processing

- Pulp and Paper Industry

- Power Generation (Cooling water intake)

- By Material Grade:

- Stainless Steel 304 (Standard Industrial Use)

- Stainless Steel 316L (High Corrosion Resistance, Marine Environments)

- Duplex and Super Duplex Steel (Extreme Pressure and Corrosive Applications)

- Stainless Steel 904L (Highly Acidic Environments)

Value Chain Analysis For Stainless Steel Wedge Net Market

The value chain of the Stainless Steel Wedge Net Market begins with the highly specialized Upstream segment, dominated by the procurement and processing of raw stainless steel materials, specifically wire rod coils of various grades (304, 316L, Duplex). Critical activities here include wire drawing to achieve the precise V-shaped profile, a technical process requiring specialized equipment and strict quality control to ensure uniform slot opening accuracy, which is the foundational performance metric of the final product. Suppliers in this phase are often large integrated steel mills or specialized wire manufacturers, and their pricing and supply stability significantly influence the total cost of manufacturing. Efficiency in this upstream stage is paramount, as variations in wire quality can compromise the subsequent welding integrity, leading to performance degradation.

The Midstream component involves the core manufacturing process: automated resistance welding of the V-shaped profile wires onto support rods. This stage is capital-intensive, requiring specialized, high-precision robotic welding machines capable of maintaining minute slot tolerances (often down to 25 microns) across large surface areas. Companies at this stage focus heavily on engineering design, quality assurance, and customization capabilities to meet diverse client specifications regarding diameter, length, and slot configuration. The distribution channel then handles the logistics, moving the finished screens from the manufacturing site to the final end-users. Direct distribution channels are favored for large, highly customized projects (e.g., major oil & gas exploration projects or specialized municipal infrastructure contracts), as they allow for close collaboration between the manufacturer's engineering team and the client’s project managers, ensuring seamless integration and technical support.

Conversely, indirect distribution channels involve technical distributors, specialized filtration solution providers, and OEM (Original Equipment Manufacturer) partners who integrate the wedge nets into larger systems, such as water filtration skids or drilling equipment. These channels are crucial for reaching smaller industrial clients and providing readily available replacement parts, especially in geographically dispersed markets. The Downstream end of the value chain consists of the installation, ongoing maintenance, and eventual replacement of the screens by the end-users in sectors like Water Treatment and Mining. The long operational lifespan of stainless steel wedge nets means replacement cycles are lengthy, emphasizing the initial quality and material choice as critical factors driving the total lifetime value derived by the customer. The focus on reliable post-sale support and technical consultation is thus a key differentiator in the downstream segment.

Stainless Steel Wedge Net Market Potential Customers

The potential customers for Stainless Steel Wedge Nets are predominantly high-capital expenditure industrial entities and governmental infrastructure agencies whose operations rely heavily on effective liquid-solid separation, classification, or filtration processes. These buyers prioritize product longevity, mechanical robustness, and precision filtration capabilities to ensure process uptime and regulatory compliance. The largest category includes municipal water authorities and industrial water treatment plants globally, which require screens for raw water intake, final effluent polishing, and specialized tertiary treatments such as ion exchange resin retention. These customers typically purchase large volumes of screens, often requiring robust SS 304 and 316L materials to withstand continuous flow and mild chemical exposure, with procurement cycles often governed by long-term public tenders and infrastructure budget allocations.

Another major buying segment is the Energy sector, encompassing both traditional Oil & Gas companies (onshore and offshore) and emerging renewable energy producers. Within oil and gas, customers include drilling contractors, well service companies, and refinery operators who require high-specification cylindrical screens and lateral assemblies made from premium materials like Duplex stainless steel, capable of resisting high pressures, extreme temperatures, and corrosive downhole environments. The procurement criteria here focus less on cost and more on absolute reliability and compliance with stringent operational safety standards. Similarly, the Mining and Mineral Processing sectors constitute a significant customer base, demanding heavy-duty flat screens and sieve bends for dewatering mineral concentrates and classifying aggregates, where resistance to severe abrasion is the primary requirement, often necessitating specialized coating or extremely robust construction.

Finally, specialized processing industries such as Food & Beverage, Pharmaceutical, and Chemical Processing are high-value customers driven by strict hygienic requirements and precision filtration. The Food & Beverage segment, for instance, requires screens fabricated exclusively from high-grade SS 316L with flawless finishes to prevent bacterial build-up and ensure compliance with sanitary regulations (e.g., FDA standards). These customers often require highly customized basket strainers and conical screens integrated into continuous processing lines. Decisions in these sectors are heavily influenced by supplier certification, cleanability, and the ability of the screen to maintain precise micron ratings over extended periods, reflecting a high technical requirement for custom-engineered filtration solutions rather than off-the-shelf products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Johnson Screens (Aqseptence Group), Crown Company, Waverley Brownall, Lantec Products, Steelwedge, Clear Edge Filtration, Multotec, BOHLAVO, Screen Systems Ltd., A.R. Process Engineers, Euroslot, Vee Wire Industries, Cascade Filter, SWA Water, Prime Screen, LIWELL Screens, Trislot NV, Royce Industries, Koflo Corporation, D&M Filter Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stainless Steel Wedge Net Market Key Technology Landscape

The manufacturing of Stainless Steel Wedge Nets is fundamentally driven by high-precision resistance welding technology, which is paramount for ensuring the accurate and consistent slot openings critical for filtration performance. The core technology involves highly specialized automated welding machines that fuse the V-shaped profile wire to the supporting internal rods at precise intervals. Advances in this landscape focus on multi-wire welding systems that increase production speed while maintaining micron-level accuracy, minimizing heat distortion, and ensuring that the final screen exhibits superior structural integrity under high differential pressure. Furthermore, the shift towards utilizing high-frequency TIG (Tungsten Inert Gas) welding for specific, high-specification applications, particularly those involving Duplex and Super Duplex steels, enhances the weld strength and corrosion resistance in the heat-affected zone, a critical area for product failure.

In addition to welding sophistication, the technological landscape includes significant investments in computational fluid dynamics (CFD) and finite element analysis (FEA) software. These tools are increasingly employed during the design phase to simulate real-world operational scenarios, optimizing the V-wire profile angle and support rod spacing to maximize open area while simultaneously guaranteeing the screen's collapse strength under extreme external pressure, crucial for downhole applications. This virtual prototyping minimizes physical testing costs and accelerates the time-to-market for highly customized solutions. Advanced surface treatment technologies, such as electropolishing and specialized coatings (e.g., polymer or ceramic coatings), are also gaining traction to enhance the surface smoothness of the stainless steel, thereby reducing friction, improving fouling resistance, and extending cleaning intervals, particularly important in water and food processing environments.

Material science innovation also forms a crucial part of the technology landscape. Manufacturers are continually exploring and integrating specialized stainless steel alloys that offer superior resistance to specific corrosive agents (e.g., chlorides, high sulfur content). For example, the increasing use of Duplex stainless steels (e.g., UNS S31803) provides a better combination of strength and corrosion resistance compared to standard austenitic grades, enabling screens to operate effectively in harsher, more demanding environments like deep wells or caustic chemical plants. Overall, the technological maturity of the market is high, with continuous marginal improvements focused on automation, precision engineering, material optimization, and non-destructive testing (NDT) methods like ultrasonic and eddy current testing to ensure every screen meets the exacting specifications demanded by critical infrastructure end-users.

Regional Highlights

The global Stainless Steel Wedge Net Market exhibits distinct regional dynamics driven by varying levels of industrialization, infrastructure spending, and regulatory frameworks.

- Asia Pacific (APAC): Expected to be the fastest-growing region, driven by rapid urbanization and massive government investments in new water treatment facilities and sanitation projects across China, India, and Southeast Asia. The region’s booming mining and mineral processing sector, particularly in Australia and Indonesia, generates substantial demand for large-scale dewatering and screening equipment. The increasing establishment of chemical and petrochemical manufacturing hubs further fuels the need for specialized filtration media.

- North America: Represents a high-value, mature market characterized by stringent environmental protection laws (e.g., Clean Water Act) necessitating upgrades of aging infrastructure. Growth is steady, focused on advanced filtration solutions using premium SS 316L and Duplex alloys, particularly in deep-water offshore oil and gas exploration and complex industrial processing in the US and Canada. Demand is also robust in the high-tech food and beverage and pharmaceutical sectors.

- Europe: A stable market emphasizing technological innovation and high-quality standards. Europe maintains strong demand due to its advanced manufacturing base (chemicals, automotive) and leading position in industrial wastewater recycling. Regulatory mandates like REACH drive the adoption of corrosion-resistant materials. Germany, the UK, and Scandinavia are key markets, prioritizing customized and energy-efficient screen designs.

- Middle East & Africa (MEA): Emerging as a critical growth region, primarily due to large-scale investments in desalination plants and intensive oil and gas production projects, particularly in Saudi Arabia, UAE, and Qatar. The severe operating conditions (high salinity, high temperature) in these regions necessitate the use of high-performance Duplex and other specialty alloys, presenting high-margin opportunities for manufacturers capable of supplying custom, robust wedge nets.

- Latin America: Market growth is fueled by substantial mining operations in countries like Chile (copper) and Brazil (iron ore). The need for high-capacity dewatering screens and resistance to aggressive slurry conditions defines demand. Additionally, expanding agricultural processing and beverage sectors contribute consistently to the market, though economic instability in some countries can introduce purchasing volatility.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stainless Steel Wedge Net Market.- Johnson Screens (Aqseptence Group)

- Crown Company

- Waverley Brownall

- Lantec Products

- Steelwedge

- Clear Edge Filtration

- Multotec

- BOHLAVO

- Screen Systems Ltd.

- A.R. Process Engineers

- Euroslot

- Vee Wire Industries

- Cascade Filter

- SWA Water

- Prime Screen

- LIWELL Screens

- Trislot NV

- Royce Industries

- Koflo Corporation

- D&M Filter Systems

Frequently Asked Questions

Analyze common user questions about the Stainless Steel Wedge Net market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors primarily drive the growth of the Stainless Steel Wedge Net Market?

Market growth is primarily driven by global governmental investments in water and wastewater treatment infrastructure, the necessity for reliable sand control solutions in the oil and gas sector, and the superior performance (non-clogging and high strength) of wedge wire over conventional filtration media in harsh industrial environments.

Which material grades are most commonly used for manufacturing wedge nets and why?

The most common grades are Stainless Steel 304 (for general-purpose water intake and classification) and Stainless Steel 316L. SS 316L is preferred for applications involving higher corrosion risk, such as marine environments, chemical processing, and the food and beverage industry, due to its enhanced resistance to pitting and acid attack.

What is the significance of the V-shaped profile in wedge wire screen design?

The V-shaped (keystone) profile is critical because it creates a non-clogging slot design. Particulates larger than the slot opening are retained on the outer surface, while those that enter through the narrowest point pass easily through the wider inner part, minimizing blockages, maximizing flow, and reducing maintenance frequency.

How does the segmentation by Application affect product customization?

Application segmentation dictates key specifications. For example, Oil & Gas requires cylindrical screens made from high-strength Duplex steel for pressure resistance, whereas Food & Beverage demands SS 316L flat screens with precise slot size and polished finishes for sanitation and easy cleaning, necessitating high degrees of customization in every order.

What challenges are restraining market expansion in developed regions?

Restraints in developed regions include the cyclical volatility and high cost of raw stainless steel alloys (nickel and chromium), which directly impacts manufacturing costs. Additionally, the high capital requirement for specialized automated welding equipment creates substantial barriers to entry, limiting competitive pricing pressure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager