Staurolite Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432057 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Staurolite Market Size

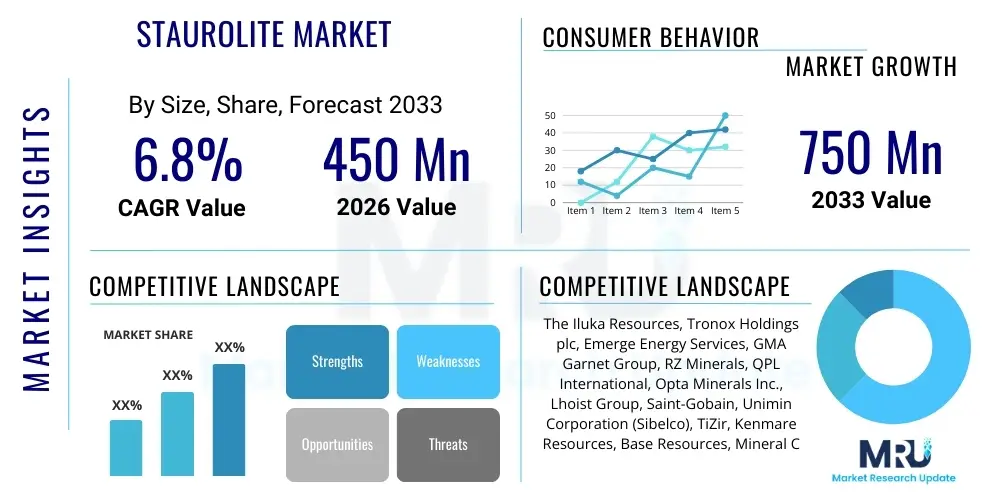

The Staurolite Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $450 Million in 2026 and is projected to reach $750 Million by the end of the forecast period in 2033.

Staurolite Market introduction

The Staurolite market encompasses the extraction, processing, and distribution of staurolite, a nesosilicate mineral characterized by its distinctive prismatic crystals, often forming cruciform twins. Staurolite possesses a high specific gravity and exceptional hardness (ranging from 7 to 7.5 on the Mohs scale), making it highly valuable across various industrial applications, particularly those requiring durable abrasive materials and dense, chemically inert fillers. Historically, staurolite sands—often recovered as a byproduct of heavy mineral sands mining (such as ilmenite and rutile)—have been the primary source, leading to its cost-effectiveness compared to synthetic alternatives. Its industrial prominence is deeply rooted in sectors demanding stringent material performance specifications.

Major applications of processed staurolite center around its role as a high-performance abrasive, specifically in sandblasting and surface preparation processes where environmental safety and low dust generation are critical. Due to its angular grain structure and durability, staurolite abrasive media effectively removes rust, scale, and old coatings from metals and concrete surfaces, preparing them for protective treatments. Furthermore, the mineral is increasingly utilized in the foundry industry as a refractory material and in specialized filtration media dueoting to its density and chemical stability. The inherent physical and chemical stability of staurolite ensures minimal interaction with process fluids or surrounding matrices, thus enhancing its lifecycle and utility in demanding industrial environments.

Driving factors in the market include robust growth in the shipbuilding and infrastructure maintenance sectors globally, which rely heavily on staurolite for surface preparation. Regulatory shifts towards safer, lower-silica abrasive alternatives further accelerate the adoption of staurolite, positioning it favorably against traditional silica sand. Additionally, advancements in mineral processing technology have improved the efficiency and purity of staurolite extraction, ensuring a stable supply chain capable of meeting the escalating demands from Asia Pacific’s rapidly industrializing economies and North America’s revitalized infrastructure projects.

Staurolite Market Executive Summary

The Staurolite Market is poised for significant expansion, driven primarily by strong demand from the anticorrosion and protective coatings sectors, alongside stringent environmental regulations mandating the shift away from hazardous abrasive materials like crystalline silica. Key business trends indicate a heightened focus on optimizing the supply chain for heavy mineral sands to secure stable staurolite feedstock, coupled with strategic investments in beneficiation plants to enhance product purity and particle consistency tailored for specialized applications such as precision foundry work and high-efficiency filtration. The industry is witnessing consolidation among key mining entities aiming to achieve economies of scale and control raw material costs, ensuring competitive pricing against synthetic and garnet alternatives. Innovation is focused on developing engineered staurolite grades with specific particle size distributions (PSDs) to meet high-end requirements in aerospace and specialized construction.

Regionally, the Asia Pacific (APAC) market dominates in terms of consumption and production capacity, spearheaded by massive infrastructure development programs and a burgeoning shipbuilding industry in countries like China, India, and South Korea. North America and Europe, while mature markets, exhibit steady growth largely due to strict adherence to occupational safety standards (driving the shift to safer abrasives) and significant governmental spending on aging infrastructure maintenance, particularly bridges and pipelines. Emerging regional trends point towards increasing localization of processing facilities in the Middle East and Africa (MEA) to serve the oil and gas infrastructure maintenance needs, reducing reliance on long-distance imports and improving supply resilience. Market participants are strategically expanding their footprint in Southeast Asia to capitalize on the rapid industrialization wave and the growing market for specialized refractory materials.

Segment trends reveal that the abrasive blasting segment remains the largest revenue contributor, sustained by its effectiveness and environmental profile. However, the filtration and refractory applications segments are projected to experience the fastest growth rate, fueled by technological advancements requiring thermally and chemically stable media. Within the product type segmentation, processed, refined staurolite sand, characterized by ultra-low levels of free silica and consistent angularity, commands a premium price and is increasingly preferred over unrefined mineral grades. Producers are focusing R&D efforts on enhancing the flow characteristics and packing density of staurolite products to improve efficiency in continuous blast operations and minimize material waste.

AI Impact Analysis on Staurolite Market

Common user questions regarding AI's influence on the Staurolite market frequently revolve around how artificial intelligence and machine learning (ML) can optimize the complex mineral separation processes inherent in heavy sands mining, and whether AI can predict demand fluctuations in infrastructure maintenance, thereby stabilizing supply chain planning. Users are keen to understand if AI-driven geological modeling can identify new, economically viable staurolite deposits more rapidly than conventional methods, and how ML algorithms are being deployed for real-time quality control to ensure strict adherence to particle size distribution and purity specifications required for high-grade abrasives and refractories. Concerns also focus on the potential job displacement in traditional processing roles versus the creation of high-skilled data analysis positions within the industry.

The integration of AI into the Staurolite market primarily targets efficiency improvements across the entire value chain, from initial exploration through to final product quality assurance. In the upstream segment, AI utilizes predictive analytics based on hyperspectral imaging and seismic data to significantly improve the accuracy of orebody modeling and resource estimation, minimizing exploratory drilling costs and maximizing yield from existing reserves. This data-driven approach allows miners to selectively target zones with higher concentrations of valuable minerals, including staurolite, optimizing the mining sequence and reducing overall operational impact. Furthermore, AI systems are crucial in managing the complex flotation and magnetic separation circuits, adjusting parameters in real-time based on slurry composition, thereby achieving higher recovery rates and energy savings during the beneficiation process.

Downstream, AI algorithms are transforming quality control and logistics. Machine vision systems coupled with ML monitor the processed staurolite output, instantly detecting deviations in color, shape, or foreign contaminants, ensuring that the final product meets the highly demanding specifications of end-users in specialized sectors like aviation maintenance. Predictive maintenance (PdM) powered by AI is also reducing unplanned downtime in processing machinery, optimizing throughput, and extending asset life. By forecasting equipment failure before it occurs, production interruptions are minimized, leading to more reliable supply and sustained profitability for staurolite producers. This integration of smart technology is raising the technical barrier to entry while simultaneously enhancing market responsiveness.

- AI optimizes geological exploration models, improving staurolite deposit identification and reducing exploratory costs.

- Machine Learning algorithms enhance mineral processing efficiency (flotation, separation) through real-time parameter adjustments.

- AI-driven predictive maintenance minimizes operational downtime in mining and processing facilities, ensuring stable supply.

- Computer vision and ML ensure stringent, real-time quality control of particle size, shape, and purity for high-grade applications.

- Predictive analytics forecasts demand from major infrastructure projects, aiding strategic inventory management and logistics optimization.

- AI simulation models assist in optimizing blending ratios for specialized refractory and foundry mixes incorporating staurolite.

DRO & Impact Forces Of Staurolite Market

The Staurolite Market is significantly influenced by a confluence of accelerating drivers and constraining factors, balanced against latent opportunities and intense external impact forces. Key drivers include the global mandate for safer abrasive blasting materials, specifically the shift away from crystalline silica due to health hazards, which intrinsically favors low-silica alternatives like staurolite and garnet. Furthermore, increasing government investment in refurbishing aging infrastructure, such as bridges, oil rigs, and maritime vessels, sustains robust demand for efficient, high-durability surface preparation media. Conversely, major restraints involve the inherent dependence of staurolite supply on the production volume of primary heavy mineral sands (like ilmenite and zircon), meaning supply stability is vulnerable to market fluctuations in those co-products. The presence of cost-competitive alternatives, such as coal slag and certain industrial minerals, also places persistent pricing pressure on standard-grade staurolite.

Opportunities for market growth primarily reside in the development of specialized, engineered staurolite products for niche, high-value applications, including advanced ceramic manufacturing and high-temperature refractory linings where its thermal stability is paramount. Expanding the use of staurolite in specialized water and wastewater filtration systems, leveraging its high density and chemical inertness for effective media separation, presents another significant growth pathway. Geographical expansion into rapidly developing economies in Africa and Southeast Asia, where industrial infrastructure is being built from the ground up, offers untapped potential for both abrasive and construction-related applications. Successful market penetration hinges on demonstrating the long-term total cost of ownership (TCO) benefits of staurolite over cheaper, less efficient materials.

Impact forces currently shaping the market include strict global environmental, social, and governance (ESG) criteria, which necessitate responsible sourcing and environmentally sound mineral processing techniques, influencing operational costs and market access. Geopolitical instability in major heavy mineral sands producing regions can severely disrupt the global supply chain, leading to price volatility and prompting end-users to diversify their sourcing strategies. Technological advancements in coatings science, such as the introduction of self-healing or ultra-durable protective paints, could potentially reduce the frequency of surface preparation cycles, acting as a subtle, long-term restraining force on abrasive demand. However, the immediate need for effective surface refurbishment far outweighs these nascent technological shifts, ensuring continued market resilience in the medium term.

Segmentation Analysis

The Staurolite Market segmentation provides a granular view of the diverse product forms, end-user industries, and geographical consumption patterns, which together dictate market dynamics and strategic focus areas. The market is primarily segmented based on product grade, differentiating between natural mineral grades, which are sourced directly from heavy mineral sands, and potentially synthetic or highly processed grades optimized for ultra-high purity requirements. Application segmentation is crucial, highlighting the dominant role of abrasive blasting while acknowledging the high growth potential in specialized areas such as refractory materials, foundry sands, and various types of filtration media. This detailed breakdown allows stakeholders to tailor their product offerings and marketing strategies to specific industry needs, optimizing profitability across different value chains.

- By Grade/Type:

- Mineral Grade Staurolite (Standard Abrasive Sand)

- High-Purity Staurolite (Foundry and Refractory Grade)

- Engineered/Coated Staurolite (Specialized Filtration Media)

- By Application:

- Abrasive Blasting/Surface Preparation

- Shipbuilding and Marine Maintenance

- Pipeline and Infrastructure Refurbishment

- Oil & Gas Equipment Maintenance

- Foundry Industry (Non-Ferrous and Ferrous Casting)

- Refractory Materials (High-Temperature Linings)

- Filtration Media (Water Treatment and Industrial Fluids)

- Construction Fillers and Aggregates

- Abrasive Blasting/Surface Preparation

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Staurolite Market

The Staurolite market value chain initiates with upstream activities, primarily encompassing the exploration, mining, and extraction of heavy mineral sands, typically through dredge mining or dry mining operations on coastal deposits. Staurolite is almost exclusively recovered as a co-product alongside economically significant minerals like ilmenite, rutile, and zircon. The extracted raw materials undergo initial wet separation processes to remove light sands and slimes, resulting in a heavy mineral concentrate (HMC). This phase is capital-intensive and subject to strict environmental regulations regarding land rehabilitation and water management. Efficiency in the upstream stage heavily dictates the cost structure of the final staurolite product, emphasizing the need for robust geological modeling and efficient extraction technologies.

The midstream phase focuses on sophisticated processing and beneficiation. The HMC is transported to dry separation plants where high-intensity magnetic and electrostatic separators, alongside gravity separation tables, are employed to isolate staurolite from other heavy minerals due to their distinct magnetic and specific gravity properties. This processing step is crucial for achieving the required purity and particle size distribution (PSD) for industrial applications. Producers must invest significantly in milling, sieving, and quality assurance technologies to meet the stringent specifications for abrasive grades (angular shape, hardness) and foundry/refractory grades (purity, high melting point). The competitive advantage in the midstream often lies in proprietary separation techniques that maximize yield and minimize impurities, particularly free silica content.

Downstream activities involve logistics, distribution, and end-user consumption. Staurolite, typically sold in bulk bags or packaged smaller units, is distributed globally through a combination of direct sales to large industrial consumers (e.g., major shipyards or infrastructure contractors) and indirect channels utilizing regional distributors and specialized chemical and mineral suppliers. Direct distribution ensures better control over product quality and tailored delivery schedules, while indirect channels provide wider market reach, especially for smaller volumes and localized construction projects. Key end-users, such as surface preparation contractors, foundry operators, and water treatment facility managers, prioritize reliable supply, consistent quality, and efficient material handling features, making strong supply chain partnerships critical for market success and long-term customer retention.

Staurolite Market Potential Customers

Potential customers for staurolite are widely diversified across heavy industry and specialized manufacturing sectors, primarily defined by their need for high-performance, environmentally conscious abrasive media and chemically inert, high-density fillers or refractory materials. The largest consumer base includes contractors and maintenance crews specializing in anticorrosion surface preparation for large metal structures. This group includes shipbuilding and repair yards, companies managing oil and gas pipelines and platforms, and municipal authorities responsible for bridge and tank refurbishment projects. These buyers prioritize staurolite's low dusting properties and its effective cleaning rate compared to traditional silica, aligning with increasingly strict worker safety standards.

Another major segment comprises the foundry industry, where staurolite is utilized as an advanced molding and core sand, valued for its high thermal stability, minimal thermal expansion, and resistance to metal penetration during casting processes, particularly in non-ferrous applications. Foundries seek materials that contribute to high-quality casting finishes and reduce defects. Similarly, the refractory industry serves as a crucial customer segment, utilizing high-purity staurolite in the manufacture of specialized linings and high-temperature ceramics where resistance to thermal shock and chemical corrosion is paramount, servicing industries like steel production and glass manufacturing.

Emerging and specialized customers include industrial water treatment and filtration facilities. These buyers leverage staurolite's high specific gravity to enhance gravity separation processes and utilize it as a dense, reliable layer in multi-media filtration systems, particularly for the removal of heavy solids and contaminants in wastewater streams. Additionally, construction materials manufacturers utilize staurolite as a high-density additive in specialized concrete and floor coatings requiring enhanced durability and wear resistance, expanding its utility beyond traditional surface treatment applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million |

| Market Forecast in 2033 | $750 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | The Iluka Resources, Tronox Holdings plc, Emerge Energy Services, GMA Garnet Group, RZ Minerals, QPL International, Opta Minerals Inc., Lhoist Group, Saint-Gobain, Unimin Corporation (Sibelco), TiZir, Kenmare Resources, Base Resources, Mineral Commodities Ltd., Industrial Minerals Company, Imerys, Advanced Mineral Industries, Strategic Minerals Corporation, Hunan Nonferrous Metals, Shanghai Jinhong Sand. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Staurolite Market Key Technology Landscape

The technology landscape within the Staurolite market is primarily defined by advancements in mineral processing aimed at improving purity, consistency, and yield from complex heavy mineral sand deposits. Core technologies revolve around optimizing the separation processes. This includes sophisticated gravity separation techniques, such as enhanced spiral concentrators and shaking tables, which leverage staurolite's high specific gravity to separate it efficiently from lighter gangue minerals. A major technological focus is the optimization of dry separation plants, incorporating high-gradient magnetic separators (HGMS) and highly efficient electrostatic separators, which are crucial for removing highly magnetic and conductive contaminants, respectively, ensuring the staurolite meets stringent purity requirements for abrasive and refractory uses, especially regarding iron oxide content.

Furthermore, particle size control technology is critical in maintaining product competitiveness. Advanced sieving, screening, and air classification systems are employed to produce narrowly graded staurolite products, essential for applications like precision foundry work or specific abrasive blasting profiles. Technologies ensuring minimal dust generation during processing and final product handling are also paramount, aligning with stricter occupational safety standards globally. Innovations in drying and handling systems are focused on reducing moisture content rapidly and cost-effectively, which is vital for maintaining the flow characteristics and preventing clumping of the final product, enhancing its utility in automated blasting equipment.

On the material science front, research is exploring surface modification technologies, where staurolite particles might be chemically or physically coated to enhance specific performance attributes, such as flowability, moisture resistance, or bonding characteristics when used as a filler in composites or specialized cement formulations. Integration of sensors and automation, often paired with the aforementioned AI analytical tools, is leading to "smart" processing plants capable of self-adjusting parameters in real-time, moving the industry towards greater efficiency, minimal waste generation, and unparalleled consistency in the final staurolite product quality, reinforcing its position as a premium industrial mineral.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for staurolite, primarily fueled by extensive infrastructure investment in China, India, and Southeast Asia. The region’s dominance is supported by massive port expansion projects, increasing shipbuilding activities, and substantial government spending on railways and industrial facilities refurbishment, all requiring large volumes of abrasive media. Furthermore, several key heavy mineral sand production hubs are located in this region (notably Australia and certain parts of India), ensuring favorable access to raw materials and competitive production costs.

- North America: North America is a mature market characterized by stringent environmental and occupational safety regulations, which have strongly favored the adoption of low-silica abrasives like staurolite over traditional silica sand. Market growth is sustained by continuous maintenance work on aging energy infrastructure (pipelines, refineries) and transportation networks (bridges, highways). Demand here focuses on high-grade, certified staurolite products that guarantee minimal environmental impact and superior performance in high-efficiency blasting operations.

- Europe: The European staurolite market exhibits steady demand, driven by high environmental consciousness and robust regulations (such as REACH compliance), necessitating high-quality, non-hazardous abrasives. Key consuming sectors include the maritime repair industry, focused in Western Europe, and specialized manufacturing that utilizes high-purity staurolite in refractory and advanced materials applications. The emphasis in Europe is often on sustainability, with preference given to suppliers demonstrating minimal carbon footprint and responsible sourcing practices.

- Middle East and Africa (MEA): This region is emerging as a significant market, largely due to immense investment in the oil and gas sector and associated downstream infrastructure (refineries, terminals, offshore platforms). The corrosive environment necessitates frequent, high-standard surface preparation, driving demand for durable, efficient abrasives. Localized production and processing capabilities are slowly being developed to serve the rapidly expanding energy sector maintenance requirements, reducing logistics costs.

- Latin America (LATAM): Growth in LATAM is closely linked to mining activities, port infrastructure upgrades, and the expansion of the energy sector. While smaller than APAC or North America, countries like Brazil and Mexico offer potential for increased consumption as industrialization progresses. The market here is often price-sensitive, balancing cost-effectiveness with performance in key industrial applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Staurolite Market.- The Iluka Resources

- Tronox Holdings plc

- Emerge Energy Services

- GMA Garnet Group

- RZ Minerals

- QPL International

- Opta Minerals Inc.

- Lhoist Group

- Saint-Gobain

- Unimin Corporation (Sibelco)

- TiZir

- Kenmare Resources

- Base Resources

- Mineral Commodities Ltd.

- Industrial Minerals Company

- Imerys

- Advanced Mineral Industries

- Strategic Minerals Corporation

- Hunan Nonferrous Metals

- Shanghai Jinhong Sand

Frequently Asked Questions

Analyze common user questions about the Staurolite market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is staurolite and what are its primary industrial uses?

Staurolite is a highly dense, chemically inert nesosilicate mineral primarily used as an abrasive blasting agent for surface preparation (removing rust and scale) due to its superior hardness and low dust generation. It is also utilized as a refractory material and specialized sand in the foundry industry and in high-density filtration media.

How does staurolite compare to silica sand in abrasive blasting?

Staurolite is significantly safer than traditional silica sand as it contains very low levels of free crystalline silica, reducing the risk of silicosis. It offers comparable hardness and angularity, providing an efficient cleaning rate while adhering to stricter occupational health and safety regulations globally.

Which geographical region holds the largest market share for staurolite consumption?

The Asia Pacific (APAC) region currently holds the largest market share, driven by expansive growth in infrastructure, shipbuilding, and industrial maintenance projects, particularly in countries like China and India, alongside strong production capacity in Oceania.

What are the key driving factors influencing the growth of the staurolite market?

Market growth is predominantly driven by increasing global mandates for safer, environmentally friendly abrasive alternatives, coupled with substantial government and private spending on maintaining and refurbishing critical infrastructure, such as pipelines, bridges, and maritime vessels.

Is the supply of staurolite stable, given it is a co-product of other mining operations?

The supply of staurolite is intrinsically linked to the demand and production levels of primary heavy mineral sands (like ilmenite and rutile). While this introduces supply dependency, major producers manage this risk through inventory optimization and continuous beneficiation process improvements to maximize staurolite recovery.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager