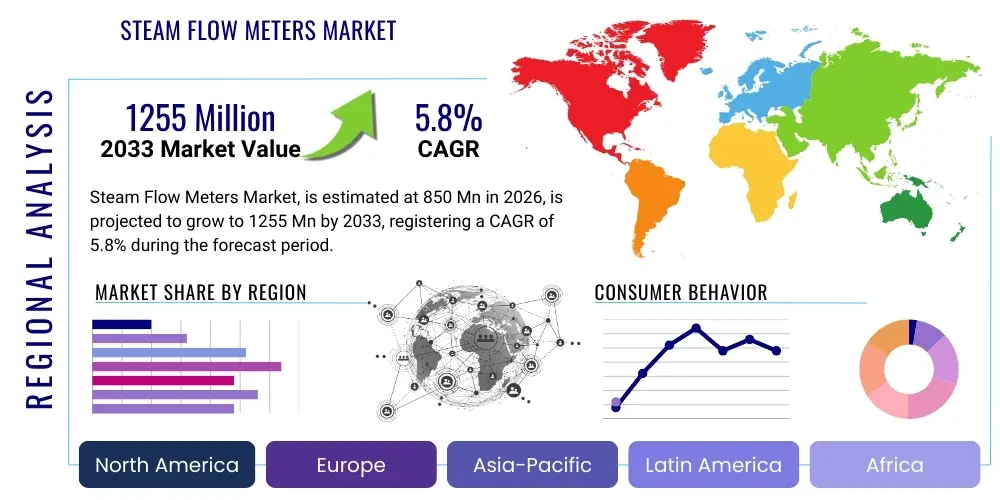

Steam Flow Meters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439569 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Steam Flow Meters Market Size

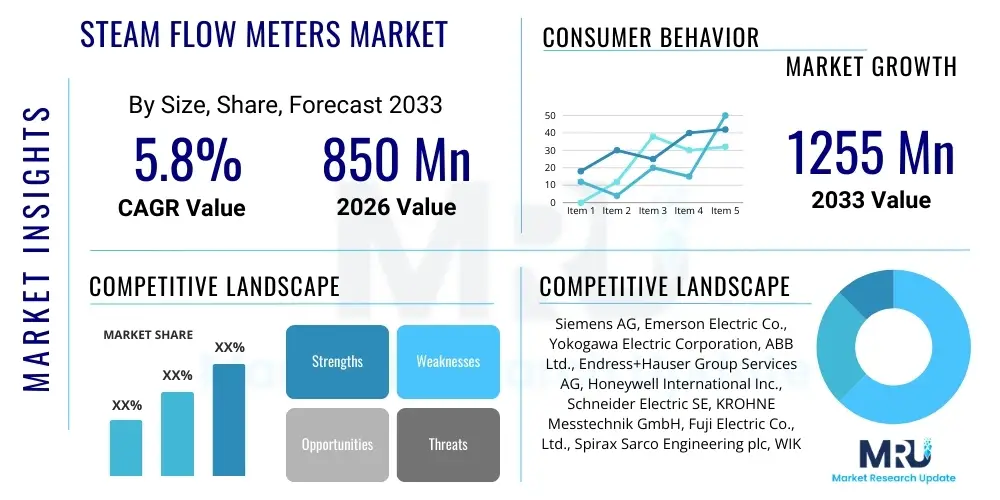

The Steam Flow Meters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1255 Million by the end of the forecast period in 2033.

Steam Flow Meters Market introduction

The global steam flow meters market is an integral component of industrial measurement and control systems, critical for accurately quantifying the mass or volume flow rate of steam in various industrial applications. Steam, being a fundamental energy carrier and process fluid across numerous sectors, necessitates precise measurement for operational efficiency, cost management, environmental compliance, and safety. Steam flow meters are specialized devices designed to withstand high temperatures and pressures, providing reliable data on steam consumption and generation. These instruments play a pivotal role in optimizing boiler performance, ensuring equitable energy billing, detecting leaks, and managing overall energy expenditure within facilities.

Product descriptions for steam flow meters typically encompass various technological principles, including vortex, differential pressure (DP), turbine, ultrasonic, and Coriolis meters, each offering distinct advantages based on specific application requirements such as accuracy, turndown ratio, maintenance needs, and cost-effectiveness. The market is characterized by continuous innovation aimed at improving measurement accuracy, enhancing durability, and integrating smart functionalities. Major applications span across critical industrial processes where steam is used for heating, sterilization, power generation, and motive force. These include power plants, chemical and petrochemical complexes, food and beverage processing units, pharmaceutical manufacturing, and district heating systems.

The benefits derived from the deployment of steam flow meters are multifaceted. They enable significant energy savings through precise monitoring and optimization of steam usage, reduce operational costs by identifying inefficiencies and leaks, and support regulatory compliance by providing verifiable data on energy consumption and emissions. Driving factors for this market include the escalating global demand for energy efficiency, stringent environmental regulations pushing for reduced carbon footprints, the widespread adoption of industrial automation and digitalization initiatives (Industry 4.0), and the increasing need for accurate utility billing and energy management systems in an era of fluctuating energy prices. These factors collectively underscore the indispensable role of advanced steam flow measurement technologies in modern industrial operations.

Steam Flow Meters Market Executive Summary

The Steam Flow Meters Market is undergoing significant transformation, driven by a confluence of evolving business trends. Industry participants are increasingly focusing on the development of smart, connected devices that integrate seamlessly with broader industrial control systems and IoT platforms. This trend towards digitalization is fostering greater data accessibility, enabling advanced analytics for predictive maintenance, real-time performance monitoring, and optimized resource allocation. Manufacturers are also prioritizing solutions that offer enhanced accuracy, wider turndown ratios, and reduced maintenance requirements to meet the demanding operational needs of diverse end-user industries. Furthermore, there's a growing emphasis on modular designs and customizable solutions that can be tailored to specific application parameters, offering greater flexibility and cost-effectiveness for clients.

Regionally, the market exhibits diverse growth patterns influenced by industrial development and regulatory landscapes. Asia Pacific, spearheaded by rapid industrialization in countries like China and India, represents a substantial growth engine, driven by new infrastructure projects and expanding manufacturing capabilities across power, chemical, and food & beverage sectors. North America and Europe, characterized by mature industrial bases, are witnessing growth primarily through retrofitting existing facilities with more efficient and smart steam flow meters, driven by stringent energy efficiency mandates and carbon reduction targets. Latin America, the Middle East, and Africa are showing promising growth trajectories, supported by investments in oil & gas infrastructure, mining, and new power generation projects, alongside growing awareness of energy management best practices.

Segment-wise, the market is influenced by technological advancements and end-user demands. Differential pressure flow meters, particularly orifice plates and Venturi meters, continue to hold a significant share due to their proven reliability and cost-effectiveness for a wide range of applications. However, vortex flow meters are gaining traction for their robust design, high accuracy, and wider turndown capabilities, especially in saturated and superheated steam applications. The "smart" and "connected" aspects are becoming increasingly vital, impacting sales channels by favoring suppliers who can offer comprehensive solutions, including integration services and data analytics platforms, often through a blend of direct sales and specialized system integrators. End-user industries such as power generation, chemicals & petrochemicals, and food & beverage remain dominant consumers, with increasing adoption in pharmaceuticals and water & wastewater treatment driving new growth opportunities.

AI Impact Analysis on Steam Flow Meters Market

Users frequently inquire about how Artificial Intelligence (AI) will enhance the capabilities and efficiency of steam flow meters, seeking insights into areas such as predictive maintenance, data accuracy, operational optimization, and integration with broader smart factory initiatives. Common concerns revolve around the complexity of implementing AI-driven systems, data security, and the return on investment for upgrading to AI-enabled solutions. There is a clear expectation that AI will move beyond basic data collection to provide actionable intelligence, leading to significant improvements in energy management and system reliability. Users are keen to understand how AI can help in real-time fault detection, anomaly identification, and precise forecasting of steam demand, ultimately translating into cost savings and improved environmental performance.

- AI-driven analytics will enable predictive maintenance for steam flow meters, anticipating potential failures and scheduling servicing before breakdowns occur, thereby minimizing downtime and maintenance costs.

- Integration of AI algorithms will enhance the accuracy and reliability of steam flow measurements by compensating for real-time process variations, improving calibration cycles, and filtering out noise from sensor data.

- AI will facilitate real-time optimization of steam generation and consumption across industrial processes by analyzing flow data alongside other operational parameters (e.g., pressure, temperature, load), leading to significant energy efficiency gains.

- Machine learning models will identify subtle anomalies in steam flow patterns, indicating leaks, blockages, or equipment malfunctions much faster than traditional monitoring methods, enabling proactive intervention.

- AI-powered platforms will provide advanced insights into steam system performance, offering recommendations for operational adjustments, equipment upgrades, and energy conservation strategies based on historical and real-time data.

- AI will support seamless integration of steam flow meter data into larger industrial IoT and Industry 4.0 ecosystems, contributing to comprehensive digital twins and centralized control systems for entire facilities.

DRO & Impact Forces Of Steam Flow Meters Market

The Steam Flow Meters Market is fundamentally driven by the escalating global imperative for energy efficiency and conservation across industrial sectors. As energy costs continue to fluctuate and regulatory pressures intensify, industries are compelled to meticulously monitor and manage their steam consumption to reduce operational expenses and improve sustainability. This intrinsic need for precise energy accounting, coupled with stringent environmental regulations aimed at reducing carbon emissions and promoting cleaner production processes, significantly boosts the adoption of advanced steam flow measurement technologies. Furthermore, the relentless march of industrial automation and digitalization, epitomized by Industry 4.0 initiatives, encourages the integration of smart, connected flow meters that can provide real-time data for advanced analytics and process optimization. The inherent benefits of accurate measurement and billing in district heating systems and various utility applications also serve as a strong driver, ensuring equitable distribution and cost recovery.

Despite these powerful drivers, the market faces several notable restraints. The initial investment cost associated with purchasing and installing high-precision steam flow meters can be substantial, particularly for smaller enterprises or facilities with outdated infrastructure, posing a barrier to widespread adoption. The inherent complexity involved in the installation, configuration, and periodic calibration of these sophisticated instruments often requires specialized expertise, adding to operational overheads. Moreover, steam flow meters are susceptible to variations in steam quality, pressure fluctuations, and entrained condensates, which can compromise measurement accuracy and necessitate additional conditioning equipment. The availability of alternative heating methods, such as direct electric heating or thermal oil systems, in certain applications, along with evolving energy mixes that might reduce reliance on steam generation, also present a potential restraint, albeit largely segmented.

Opportunities within the steam flow meters market are largely centered on technological innovation and market expansion. The continuous emergence of smart flow meters equipped with advanced connectivity features (e.g., WirelessHART, Ethernet/IP, PROFINET) and embedded diagnostics offers a significant growth avenue, enabling seamless integration with existing and future industrial control systems. Developing economies, particularly in Asia Pacific, Latin America, and Africa, are experiencing rapid industrialization and infrastructure development, presenting fertile ground for new installations and market penetration. The ongoing trend of integrating steam flow meters with broader Industry 4.0 platforms, including cloud-based analytics and digital twin applications, offers substantial value proposition for end-users seeking holistic operational insights. Furthermore, a substantial market exists for retrofitting older industrial facilities with modern, more efficient steam flow measurement solutions, driven by the desire to modernize existing plants without complete overhaul. Customization of solutions for highly specific industrial applications also provides a niche but growing opportunity for specialized manufacturers.

The market is also shaped by several impact forces. Technological advancements, particularly in sensor design, data processing capabilities, and communication protocols, continuously redefine the accuracy, reliability, and functionality of steam flow meters. Regulatory changes, such as revised energy efficiency standards or new environmental protection mandates, can significantly alter demand patterns and accelerate adoption. Global economic conditions, including industrial output, energy prices, and capital expenditure trends, directly influence investment decisions in new equipment and infrastructure. Growing environmental concerns worldwide amplify the need for efficient steam management to reduce greenhouse gas emissions. Lastly, the competitive landscape, characterized by both established multinational corporations and agile niche players, drives innovation, pricing strategies, and service differentiation, pushing the boundaries of what is possible in steam flow measurement.

Segmentation Analysis

The Steam Flow Meters Market is extensively segmented to reflect the diverse technological offerings, material specifications, varied end-user industry applications, specific operational uses, and the different channels through which these products reach the market. This granular segmentation provides a comprehensive understanding of market dynamics, enabling stakeholders to identify specific growth areas and tailor their strategies effectively. Each segment represents distinct market characteristics influenced by factors such as performance requirements, cost implications, environmental conditions, and regulatory compliance. Analyzing these segments helps in discerning the prevalent trends, competitive intensities, and technological shifts that define the global landscape for steam flow measurement solutions.

- By Type: This segment categorizes steam flow meters based on their underlying measurement technology.

- Vortex Flow Meters: Utilize the Von Kármán vortex street principle, ideal for various steam conditions due to robust design and wide turndown.

- Differential Pressure Flow Meters: Measure flow by creating a pressure drop using an obstruction, including:

- Orifice Plate: Simple, cost-effective, widely used.

- Venturi: Lower permanent pressure loss, good for high flow rates.

- Annubar: Averaging pitot tube, robust for various pipe sizes.

- Turbine Flow Meters: Measure flow by sensing the rotation of a rotor driven by the fluid, offering high accuracy for clean steam.

- Ultrasonic Flow Meters: Non-intrusive, measure flow by transmitting ultrasonic waves through the steam, suitable for varied pipe sizes and less pressure drop.

- Coriolis Flow Meters: Measure mass flow directly based on the Coriolis effect, offering high accuracy for mass, density, and temperature, though often more costly.

- Others: Includes Variable Area Flow Meters (rotameters, less common for high-pressure steam), Thermal Mass Flow Meters (measures heat dissipation, suitable for low-flow applications).

- By Material: This segment defines the construction materials, critical for durability and compatibility with steam properties.

- Stainless Steel: Predominantly used due to corrosion resistance and high-temperature suitability.

- Carbon Steel: Cost-effective for less corrosive, non-critical applications.

- Alloy Steel: Used for extreme temperatures and pressures, offering enhanced strength and corrosion resistance.

- Others: Includes specialized alloys for unique industrial demands.

- By End-User Industry: This segment identifies the major industrial sectors that utilize steam flow meters.

- Oil & Gas: For steam injection, processing, and utility management in upstream and downstream operations.

- Chemicals & Petrochemicals: Essential for process control, reactor heating, and utility management.

- Power Generation: Crucial for boiler efficiency, turbine control, and district heating applications.

- Food & Beverage: Used for sterilization, cooking, and clean-in-place (CIP) processes.

- Pharmaceuticals: Critical for sterile manufacturing, HVAC, and process heating, requiring high purity and precision.

- Water & Wastewater Treatment: For heating, sterilization, and energy recovery systems.

- HVAC: For monitoring steam used in building heating and cooling systems.

- Metals & Mining: For process heating, drying, and ancillary operations.

- Pulp & Paper: For drying, cooking, and other energy-intensive processes.

- Textiles: For dyeing, drying, and various manufacturing stages.

- Automotive: For paint shops, assembly processes, and facility heating.

- Others: Includes semiconductors, marine, general manufacturing, and various research applications.

- By Application: This segment details the specific functional uses of steam flow meters.

- Process Control: Maintaining optimal steam flow for specific manufacturing steps.

- Energy Management: Monitoring steam consumption for efficiency, cost allocation, and conservation initiatives.

- Custody Transfer: Accurate measurement for billing purposes between suppliers and consumers.

- Leak Detection: Identifying abnormal steam losses in piping networks.

- Boiler/Steam System Monitoring: Tracking boiler performance, steam generation, and distribution efficiency.

- By Sales Channel: This segment outlines the primary methods of market distribution.

- Direct Sales: Manufacturers selling directly to large industrial clients or through their own sales force.

- Indirect Sales: Selling through distributors, system integrators, value-added resellers, and agents who provide localized support and integration services.

Value Chain Analysis For Steam Flow Meters Market

The value chain for the Steam Flow Meters Market commences with the upstream activities involving the sourcing and processing of raw materials such as various grades of stainless steel, carbon steel, and specialized alloys, along with electronic components like sensors, microcontrollers, and communication modules. Key suppliers in this stage include metal foundries, semiconductor manufacturers, and precision component fabricators. The quality and availability of these foundational materials and components are crucial for the performance, durability, and cost-effectiveness of the final flow meter product. Efficient supplier management, quality control, and strategic partnerships with raw material providers are essential for manufacturers to maintain competitive pricing and product integrity.

Moving downstream, the value chain encompasses the manufacturing, assembly, and integration of these components into finished steam flow meters. This stage involves complex engineering, precision machining, electronic assembly, software development for smart features, and rigorous testing and calibration procedures to ensure accuracy and compliance with industry standards. Post-manufacturing, distribution channels play a pivotal role in delivering these sophisticated instruments to end-users. Direct sales are often preferred for large-scale industrial clients or projects requiring extensive customization, allowing manufacturers to maintain direct relationships and offer tailored solutions, installation support, and after-sales service. This approach provides greater control over customer experience and market feedback.

Conversely, indirect sales channels, primarily through a network of distributors, authorized resellers, and system integrators, are vital for reaching a broader customer base, particularly small to medium-sized enterprises (SMEs) and geographically dispersed markets. These indirect partners often provide localized technical support, inventory, and value-added services such as installation, integration with existing plant infrastructure, and maintenance, which are critical for comprehensive solutions. System integrators, in particular, play a crucial role by incorporating steam flow meters into larger industrial automation and control systems, offering complete solutions that go beyond just the hardware. The effectiveness of the value chain is thus heavily reliant on strong collaboration between manufacturers and their distribution partners, ensuring efficient product delivery, robust technical support, and comprehensive customer service throughout the product lifecycle.

Steam Flow Meters Market Potential Customers

Potential customers for steam flow meters span a vast array of industrial and commercial sectors where steam is an indispensable utility for heating, power generation, sterilization, or as a direct process input. At the forefront are industries with high energy consumption and stringent process control requirements, such as the power generation sector, including thermal power plants and combined heat and power (CHP) facilities, where accurate steam measurement is critical for boiler efficiency, turbine performance, and overall energy management. Similarly, the chemicals and petrochemicals industry relies heavily on steam for various reactions, heating, and distillation processes, making continuous and precise monitoring of steam flow essential for process optimization, safety, and regulatory compliance. These industries often have large-scale operations requiring robust, high-accuracy meters capable of handling challenging conditions.

Beyond heavy industry, the food & beverage and pharmaceutical sectors represent significant customer bases due to their critical need for sterile processes, heating, and drying operations. In these industries, steam quality and precise flow control are paramount for product safety, quality assurance, and adherence to regulatory standards like FDA guidelines. Manufacturers in these fields seek highly reliable, sanitary-design flow meters that can withstand frequent clean-in-place (CIP) and sterilize-in-place (SIP) cycles. Furthermore, district heating systems, which supply steam or hot water to multiple buildings from a central plant, are major consumers, as accurate flow metering is vital for equitable billing, network optimization, and leak detection across extensive distribution networks, ensuring fair energy accounting for end-users.

Other crucial end-users include the pulp & paper industry, where steam is extensively used in drying and chemical pulping processes; the metals & mining sector for various heating and processing applications; and general manufacturing facilities that utilize steam for diverse purposes such as humidification, cleaning, and equipment heating. The growing focus on building energy management systems and HVAC applications also makes commercial buildings, hospitals, and educational institutions increasingly relevant potential customers, as they seek to optimize their steam-based heating and cooling systems for energy efficiency and cost savings. Essentially, any entity that generates, distributes, or consumes steam in significant quantities, and is driven by operational efficiency, cost reduction, or environmental compliance, stands as a potential customer for advanced steam flow meter solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1255 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Emerson Electric Co., Yokogawa Electric Corporation, ABB Ltd., Endress+Hauser Group Services AG, Honeywell International Inc., Schneider Electric SE, KROHNE Messtechnik GmbH, Fuji Electric Co., Ltd., Spirax Sarco Engineering plc, WIKA Alexander Wiegand SE & Co. KG, Vaisala Oyj, Armstrong International, Inc., Clark-Reliance Corporation, McCrometer, Inc., Badger Meter, Inc., SICK AG, Thermo Fisher Scientific Inc., Pentair plc, Brooks Instrument (ITW Company) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Steam Flow Meters Market Key Technology Landscape

The technological landscape of the Steam Flow Meters Market is characterized by a blend of well-established measurement principles continuously refined for enhanced performance, alongside innovative advancements incorporating digital and smart capabilities. Differential pressure flow meters, utilizing primary elements such as orifice plates, Venturi tubes, and Annubars, represent a foundational technology. These rely on the principle of creating a pressure drop across a restriction to infer flow rate. Continuous innovation in this segment focuses on improving the design of primary elements for better turndown ratios, reducing permanent pressure loss, and developing more robust differential pressure transmitters that can withstand harsh steam conditions, including high temperatures and pressures, while maintaining accuracy and stability.

Vortex flow meters constitute another cornerstone technology, gaining increasing prominence due to their robust design, wide turndown capabilities, and relatively low maintenance requirements. They operate on the principle of Karman vortex shedding, where vortices are shed downstream of a bluff body placed in the flow path, with the frequency of shedding proportional to the flow velocity. Recent technological developments in vortex meters include advanced digital signal processing (DSP) to filter out noise, improve signal-to-noise ratio, and enhance accuracy, particularly for low flow rates and varying steam conditions. Integrated temperature and pressure compensation are now standard, ensuring accurate mass flow calculations even when steam properties fluctuate, which is critical for energy billing and process control.

Emerging and advanced technologies are significantly impacting the market. Coriolis mass flow meters, while traditionally more expensive, offer direct mass flow measurement independent of steam density or pressure, providing unparalleled accuracy for critical applications and custody transfer. Advances in sensor design and manufacturing techniques are slowly bringing down their cost and expanding their applicability to specific high-value steam applications. Ultrasonic flow meters, which measure flow by analyzing the transit time of ultrasonic waves, are also seeing increased adoption, particularly for larger pipe sizes and where non-intrusive measurement is preferred. Innovation in ultrasonic technology is focused on improving penetration through high-temperature media and developing transducers that can withstand aggressive industrial environments. Furthermore, the integration of smart functionalities, including built-in diagnostics, digital communication protocols (e.g., Modbus, Ethernet/IP, HART), and cloud connectivity for remote monitoring and data analytics, is transforming all types of steam flow meters into intelligent instruments capable of supporting Industry 4.0 initiatives and enabling proactive maintenance strategies.

Regional Highlights

- North America: This region maintains a significant market share, driven by a mature industrial base and a strong emphasis on energy efficiency and regulatory compliance. The U.S. and Canada are leading adopters, particularly in the power generation, oil & gas, and chemical sectors, driven by investments in modernizing aging infrastructure and integrating smart technologies for enhanced operational efficiency and reduced carbon footprint. The demand for advanced analytics and IoT-enabled solutions is also a key growth factor.

- Europe: Europe is a key market, propelled by stringent environmental regulations, ambitious decarbonization targets, and the widespread adoption of smart factory initiatives. Countries like Germany, the UK, and France are leading in the integration of highly accurate and energy-efficient steam flow meters across diverse industries such as chemicals, pharmaceuticals, and district heating networks. Innovation in sensor technology and seamless integration with industrial automation systems are primary drivers.

- Asia Pacific (APAC): APAC stands as the fastest-growing region, fueled by rapid industrialization, expanding manufacturing capabilities, and significant investments in infrastructure development, particularly in China, India, Japan, and South Korea. The increasing energy demand from developing economies, coupled with growing awareness of energy conservation and process optimization, is driving the adoption of steam flow meters in power generation, chemicals, food & beverage, and textiles sectors.

- Latin America: This region is experiencing steady growth, largely driven by investments in the oil & gas industry, mining, and food & beverage sectors. Countries such as Brazil and Mexico are leading the adoption of steam flow meters as industries seek to improve operational efficiency and manage energy costs. The market here is also influenced by the modernization of existing industrial plants and the establishment of new facilities.

- Middle East and Africa (MEA): The MEA region is witnessing increasing adoption of steam flow meters, primarily due to significant investments in the oil & gas, petrochemicals, and power generation sectors. Countries like Saudi Arabia, UAE, and South Africa are focusing on diversifying their industrial base and enhancing operational efficiency, which necessitates accurate steam measurement for process control and energy management. The development of new industrial zones and smart city initiatives also contribute to market growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Steam Flow Meters Market.- Siemens AG

- Emerson Electric Co.

- Yokogawa Electric Corporation

- ABB Ltd.

- Endress+Hauser Group Services AG

- Honeywell International Inc.

- Schneider Electric SE

- KROHNE Messtechnik GmbH

- Fuji Electric Co., Ltd.

- Spirax Sarco Engineering plc

- WIKA Alexander Wiegand SE & Co. KG

- Vaisala Oyj

- Armstrong International, Inc.

- Clark-Reliance Corporation

- McCrometer, Inc.

- Badger Meter, Inc.

- SICK AG

- Thermo Fisher Scientific Inc.

- Pentair plc

- Brooks Instrument (ITW Company)

Frequently Asked Questions

What are the primary benefits of implementing steam flow meters in industrial settings?

The primary benefits of implementing steam flow meters include significant energy cost savings through precise monitoring and optimization of steam usage, improved operational efficiency by identifying inefficiencies and leaks, enhanced process control for stable production, and adherence to environmental regulations by tracking energy consumption and emissions. They are crucial for accurate energy billing and ensuring system reliability.

Which type of steam flow meter is best suited for superheated steam applications?

For superheated steam applications, vortex flow meters are generally considered highly suitable due to their robust design, wide turndown ratio, and ability to handle high temperatures and pressures without moving parts. Differential pressure flow meters with integrated temperature and pressure compensation are also effective, as they can accurately calculate mass flow even with varying steam properties.

How does Industry 4.0 impact the evolution and adoption of steam flow meters?

Industry 4.0 significantly impacts steam flow meters by driving the demand for smart, connected devices that can integrate seamlessly into broader industrial IoT ecosystems. This enables real-time data collection, advanced analytics for predictive maintenance, remote monitoring, and autonomous process optimization, leading to higher efficiency, reduced downtime, and enhanced decision-making capabilities within smart factories.

What factors should be considered when selecting a steam flow meter for a specific application?

Key factors to consider include the type of steam (saturated or superheated), operating temperature and pressure, required accuracy and turndown ratio, pipe size and material, available installation space, desired output signal (analog, digital, network), maintenance requirements, initial investment cost, and compatibility with existing control systems. Environmental conditions and specific application objectives, such as custody transfer or process control, are also critical.

What are the common challenges associated with steam flow measurement?

Common challenges include the inherent variability of steam properties (density, temperature, pressure), the presence of condensate or impurities affecting accuracy, high operating temperatures and pressures requiring specialized materials, susceptibility to flow profile distortions, and the complexity of installation and calibration. Ensuring reliable long-term performance under harsh industrial conditions also remains a significant challenge.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager