Steckel Mills Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435032 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Steckel Mills Market Size

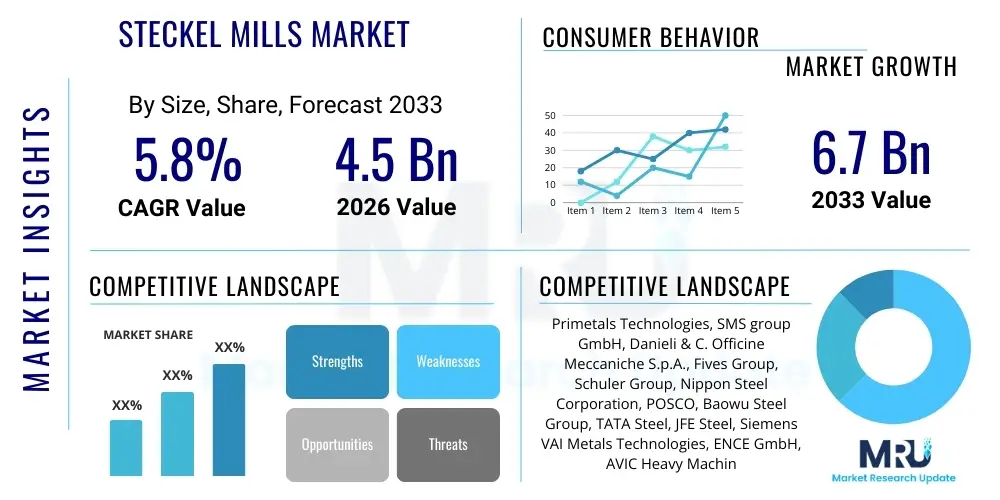

The Steckel Mills Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Steckel Mills Market introduction

The Steckel mill represents a specialized type of rolling mill primarily used for the hot rolling of thin strips and plates, particularly when production volumes do not necessitate a full-scale continuous hot strip mill. It is characterized by the presence of coiling furnaces on both sides of the reversing rolling stand, which maintain the temperature of the strip during the multi-pass rolling process. This design allows for the efficient production of high-quality flat products, such as hot-rolled coils and medium-width plates, often utilized in applications requiring precise gauge control and uniform material properties. The compact nature and operational flexibility of Steckel mills make them highly valuable in niche markets and developing economies where capital investment constraints limit the deployment of larger, more complex rolling setups.

The primary products derived from Steckel mills include hot-rolled coil (HRC) used extensively in tube and pipe manufacturing, automotive parts, and construction materials, as well as heavy and medium plate for shipbuilding and structural steel projects. The key benefit of employing a Steckel mill lies in its high thermal efficiency, which reduces temperature loss during rolling, consequently allowing for the processing of challenging steel grades and ensuring better mechanical properties in the final product. Furthermore, these mills offer quick product changeover capabilities and require a smaller footprint compared to tandem mills, contributing to lower overall operating costs.

The driving factors for the Steckel Mills Market include the increasing demand for high-strength, low-alloy (HSLA) steels in construction and automotive sectors, the continuous modernization and upgrade of existing rolling facilities, and the rapid industrialization across Asia Pacific and Latin America. The mills’ ability to produce specialized and high-margin products with efficient energy consumption positions them favorably against older rolling technologies. Advancements in automation and process control systems are further enhancing the operational precision and output quality of modern Steckel mills, solidifying their role in the global steel production landscape.

Steckel Mills Market Executive Summary

The Steckel Mills Market is defined by moderate growth driven primarily by ongoing industrial upgrades in emerging economies and the necessity for flexible, energy-efficient production of flat steel products. Business trends indicate a strong focus on retrofitting existing mills with advanced automation and digital twin technologies to optimize rolling schedules and reduce downtimes, shifting capital expenditure from new installations to modernization projects. Manufacturers are prioritizing solutions that enhance the production of advanced high-strength steels (AHSS), crucial for the automotive industry's lightweighting initiatives. Strategic mergers and partnerships between technology providers and steel manufacturers are observed, aimed at offering integrated rolling solutions and comprehensive maintenance contracts.

Regionally, the Asia Pacific continues to dominate market volume due to high demand from infrastructure and manufacturing sectors in China, India, and Southeast Asia, coupled with substantial government investments in domestic steel production capacity. Europe and North America, while having mature markets, focus heavily on technological innovation, process efficiency, and stringent quality control, driving the adoption of high-precision Steckel mills for specialty alloy production. Latin America and the Middle East and Africa (MEA) represent high-potential growth areas, characterized by new capacity additions spurred by urbanization and oil & gas pipeline projects, favoring the cost-effectiveness and versatility of Steckel mill setups.

Segment trends reveal that the Coil Steckel Mills segment, optimized for producing hot-rolled coils, maintains the largest market share due to its wide applicability across downstream industries. However, the Plate Steckel Mills segment is projected to exhibit the fastest growth, supported by the increasing requirement for thick plates in wind energy towers, bridges, and heavy machinery manufacturing. Capacity-wise, the Medium Capacity (1-3 MTPA) segment is preferred globally as it balances operational scale with capital efficiency, catering effectively to mid-sized regional steel producers.

AI Impact Analysis on Steckel Mills Market

User queries regarding AI's influence on Steckel mills commonly revolve around predictive maintenance capabilities, optimizing rolling parameters for complex alloys, and achieving zero-defect production. Users frequently ask: "How can AI minimize energy consumption during hot rolling?", "What is the role of machine learning in dynamic gauge control?", and "Can AI models predict coil quality before the cooling stage?" The analysis indicates that users seek concrete examples of AI integration leading to measurable operational improvements, particularly concerning thermal control, equipment longevity, and yield maximization. The underlying themes are centered on transitioning from reactive maintenance to prescriptive operations and leveraging complex data streams from sensors for real-time decision-making, ensuring highly efficient and sustainable steel production.

The implementation of Artificial Intelligence and Machine Learning (ML) algorithms is revolutionizing the operation of Steckel mills by enabling unparalleled precision in process control and fault detection. AI systems analyze vast amounts of data—including temperature profiles, roll force, rolling speed, and coiler tension—to dynamically adjust rolling parameters in real time. This capability minimizes temperature deviations and ensures the metallurgical integrity of high-grade steel products, substantially reducing scrap rates and optimizing energy consumption. Furthermore, advanced AI models are employed for simulating rolling scenarios (Digital Twins), allowing operators to test process changes virtually before implementing them on the live mill, thereby de-risking complex alloy production.

The most significant impact of AI is visible in predictive maintenance (PdM) systems. By continuously monitoring the vibration, heat, and wear patterns of critical components such as work rolls, backup rolls, and coiler motors, AI can forecast potential failures with high accuracy months in advance. This proactive approach eliminates catastrophic breakdowns, drastically lowers unexpected downtime, and shifts maintenance schedules from time-based to condition-based. Integrating these AI insights into Enterprise Resource Planning (ERP) systems enhances supply chain management for replacement parts, solidifying operational reliability and boosting the overall equipment effectiveness (OEE) of the Steckel mill complex.

- Real-time dynamic control of rolling parameters (speed, force, temperature).

- Predictive maintenance (PdM) for critical mill components (rolls, gearboxes, motors).

- Digital Twin creation for process simulation and optimization before physical execution.

- Enhanced yield maximization through reduced temperature run-out and uniform cooling.

- Automated defect detection and classification using machine vision and deep learning.

- Optimization of coiling furnace operations to minimize energy usage and scaling.

- Improved material traceability and quality documentation using blockchain-integrated AI logs.

DRO & Impact Forces Of Steckel Mills Market

The market dynamics of Steckel mills are shaped by robust industrial demand (Driver) countered by high capital costs (Restraint), while energy transition requirements present a significant growth avenue (Opportunity), all moderated by stringent environmental regulations (Impact Force). The fundamental driver remains the escalating global demand for flat steel products used in infrastructure and renewable energy, specifically high-grade plates and coils where Steckel mills offer superior quality and flexibility. However, the initial investment required for constructing or significantly modernizing a Steckel mill, including the complex rolling stand, coiling furnaces, and sophisticated control systems, acts as a primary restraint, favoring large, established steel conglomerates.

Opportunities are predominantly emerging from the green transition within the steel industry. As global steel producers aim for lower carbon footprints, the inherent energy efficiency of Steckel mills—especially when paired with modern regenerative burner technology in the coiling furnaces—makes them attractive for sustainable production. Furthermore, the rising adoption of specialized steel grades (e.g., pipeline steels, shipbuilding plates) that require meticulous thermal control during rolling offers lucrative niche markets that Steckel mills are uniquely positioned to serve. Technological advancements, particularly in smart sensors and data analytics, continuously open avenues for optimizing existing mill efficiency, reducing reliance on substantial new capital expenditures.

The key impact forces exerting pressure on the Steckel Mills Market include increasingly strict environmental standards regarding CO2 emissions and water usage in steel manufacturing. Steel producers are compelled to invest in flue gas treatment and closed-loop water systems, integrating these costs into mill designs. Additionally, geopolitical trade policies, such as anti-dumping duties on certain steel products, significantly affect the global demand and profitability of steel manufacturers, subsequently influencing investment decisions regarding new Steckel mill capacities. Competition from alternative technologies, such as compact strip production (CSP) processes, also forces Steckel mill providers to continuously innovate and demonstrate superior cost-to-quality ratios, especially for thicker gauge products.

Segmentation Analysis

The Steckel Mills Market is extensively segmented based on the product type rolled, the operational capacity of the mill, the final application of the steel, and the specific end-user industry. This segmentation allows for targeted market analysis, highlighting growth pockets in specialized steel production and technological adaptation. The primary differentiation often lies between mills configured predominantly for plate production versus those optimized for hot-rolled coils, driven by varying end-user demands across different geographies. Further granularity is achieved by evaluating mill capacity, as this dictates the economies of scale achievable and the target market size the producer aims to serve.

- By Product Type:

- Plate Steckel Mills (Optimized for thicker plates for shipbuilding, construction)

- Coil Steckel Mills (Optimized for thin hot-rolled coils and strips)

- Billet Steckel Mills (Niche application for specialty long product feed)

- By Capacity:

- Low Capacity (Under 1 Million Tonnes Per Annum - MTPA)

- Medium Capacity (1-3 MTPA)

- High Capacity (Above 3 MTPA)

- By Application:

- Flat Products (Hot-rolled coils, Strips)

- Long Products (Intermediate processing for bars, rods)

- Specialty Alloys (Stainless steel, High-strength low-alloy steel)

- By End-User Industry:

- Construction and Infrastructure

- Automotive and Transportation

- Machinery and Equipment Manufacturing

- Energy and Oil & Gas (Pipelines, Wind Towers)

Value Chain Analysis For Steckel Mills Market

The value chain for the Steckel Mills Market begins with the Upstream activities, encompassing the supply of raw materials (steel slabs or continuous cast sections) and the critical technology and component providers (rolling equipment, coiling furnaces, automation systems). Key suppliers in this stage include heavy machinery manufacturers (SMS group, Primetals), metallurgical component specialists, and industrial software providers. The efficiency and quality of the upstream technology directly dictate the performance and longevity of the mill. Pricing power often resides with the major technology providers due to the highly specialized nature of the mill engineering and intellectual property involved.

The Core Process involves the steel manufacturer operating the Steckel mill, converting the semi-finished slab into flat products (coils or plates) through multi-pass hot rolling. This stage requires significant energy input, skilled operational staff, and sophisticated process control systems. Margin generation here is highly sensitive to input costs (energy and raw material) and market prices for finished steel. The Downstream phase involves further processing, such as pickling, cutting, and finishing, often conducted by service centers or integrated manufacturers, before the product is sold to the end-users. The distribution channel is bifurcated into Direct sales to large end-users (e.g., automotive OEMs or construction firms) and Indirect sales through steel trading houses or large distributors who manage regional logistics and inventory, adding necessary flexibility to the supply chain.

Steckel Mills Market Potential Customers

The potential customers and end-users of Steckel mill products are diverse, spanning major capital-intensive industries that rely heavily on high-quality, hot-rolled flat steel. These customers primarily belong to sectors requiring structural integrity, durability, and specific metallurgical properties in their input materials. Integrated steel producers seeking to modernize or expand their flat product capacity represent core buyers of the mill technology itself. For the finished products (coils and plates), the primary consumers include large construction conglomerates needing structural steel, automotive original equipment manufacturers (OEMs) requiring chassis and body parts, and specialized manufacturers in the energy sector.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Primetals Technologies, SMS group GmbH, Danieli & C. Officine Meccaniche S.p.A., Fives Group, Schuler Group, Nippon Steel Corporation, POSCO, Baowu Steel Group, TATA Steel, JFE Steel, Siemens VAI Metals Technologies, ENCE GmbH, AVIC Heavy Machinery, Taiyuan Heavy Industry Co., Ltd., CISDI Group Co., Ltd., Qingdao Meishun, Shenyang Longteng, HMT Machine Tools, TMT (Technische Metallurgie), Mitsubishi Heavy Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Steckel Mills Market Key Technology Landscape

The technology landscape of the Steckel Mills Market is characterized by continuous advancements in rolling mechanisms, thermal management systems, and sophisticated process automation. Central to modern Steckel mill technology is the integration of heavy-duty, highly precise hydraulic screwdown systems (HAGC – Hydraulic Automatic Gauge Control) to ensure micron-level accuracy in thickness across the rolled strip, a critical requirement for high-end applications like automotive body panels. Furthermore, the specialized coiling furnaces, which are the defining feature of the Steckel process, now incorporate advanced regenerative burner technology and precise temperature mapping capabilities, significantly improving energy efficiency and reducing natural gas consumption while minimizing oxidation and scaling on the steel surface.

Beyond mechanical and thermal improvements, the rapid adoption of Level 2 and Level 3 automation systems dictates the competitive edge of modern mills. Level 2 systems involve advanced mathematical models for predicting rolling forces and thermal profiles, optimizing the pass schedule automatically based on the incoming slab properties. Level 3 systems integrate these operational controls with enterprise-wide resource planning (ERP) and manufacturing execution systems (MES), enabling seamless coordination from raw material entry to finished product tracking. These integrated systems rely heavily on high-speed data acquisition from thousands of sensors, including pyrometers, load cells, and laser profilometers, to ensure instantaneous feedback and adjustments.

Emerging technologies focus heavily on digitalization and sustainability. Digital Twin technology is becoming standard practice for simulating complex rolling sequences, especially when processing new or difficult-to-roll materials like duplex stainless steels or thick specialty alloys. This virtual environment allows for fine-tuning the mill setup without costly physical trials. Coupled with this is the increasing use of industrial IoT (IIoT) sensors and cloud computing for remote monitoring and diagnostics, allowing technology vendors to offer robust, predictive maintenance services globally. The ongoing transition towards hydrogen-based or electric heating options for coiling furnaces represents the next frontier in minimizing the carbon footprint of the Steckel mill process.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market segment, driven by large-scale infrastructure development and robust growth in automotive manufacturing, particularly in China and India. The region exhibits a high volume of new capacity installations, favoring medium-capacity Steckel mills for their balance of throughput and capital investment. Technological upgrades and government initiatives supporting domestic steel production further solidify APAC's leading position, with a strong focus on high-volume HRC production.

- Europe: Europe is characterized by a mature market focused on quality, efficiency, and sustainability. Investments are primarily directed towards modernization, retrofitting existing mills with advanced Level 3 automation, and adopting specialized Steckel mills for producing premium, low-carbon steel grades and specialty alloys for demanding applications like aerospace and high-pressure gas pipelines. Strict environmental regulations drive the adoption of energy-efficient furnace technology.

- North America: The North American market is highly focused on specialty and high-value flat products. The demand is strong for plates used in heavy machinery and energy infrastructure (oil and gas, wind). Investments are driven by the need to maintain competitive quality against imports, focusing on advanced predictive maintenance and digital integration to maximize operational uptime and reduce labor costs.

- Latin America (LATAM): LATAM represents a high-growth potential region, stimulated by renewed urbanization projects and increasing demand for local production capacity to reduce reliance on imports. Countries like Brazil and Mexico are investing in new medium-scale Steckel mills to cater to growing domestic construction and automotive sectors, prioritizing cost-effective, durable mill designs.

- Middle East and Africa (MEA): The MEA market is largely influenced by large-scale energy projects and rapidly growing construction sectors, especially in the GCC countries. The demand for heavy plates (e.g., for storage tanks, pipelines) is substantial. Investments are often concentrated on integrated steel complexes, favoring Steckel mills for their robust capabilities in processing thick slabs under challenging climate conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Steckel Mills Market.- Primetals Technologies

- SMS group GmbH

- Danieli & C. Officine Meccaniche S.p.A.

- Fives Group

- Schuler Group

- Nippon Steel Corporation

- POSCO

- Baowu Steel Group

- TATA Steel

- JFE Steel

- Siemens VAI Metals Technologies

- ENCE GmbH

- AVIC Heavy Machinery

- Taiyuan Heavy Industry Co., Ltd.

- CISDI Group Co., Ltd.

- Qingdao Meishun

- Shenyang Longteng

- HMT Machine Tools

- TMT (Technische Metallurgie)

- Mitsubishi Heavy Industries

Frequently Asked Questions

Analyze common user questions about the Steckel Mills market and generate a concise list of summarized FAQs reflecting key topics and concerns.What differentiates a Steckel mill from a continuous hot strip mill?

A Steckel mill uses a single, reversing rolling stand flanked by coiling furnaces to maintain strip temperature during multiple passes, making it ideal for smaller volumes and thicker or specialized products. A continuous hot strip mill uses multiple stands in sequence for high-volume, continuous production.

How is digitalization impacting the operational efficiency of Steckel mills?

Digitalization leverages AI, Digital Twins, and advanced sensors to enable real-time dynamic gauge control, optimize pass schedules, and implement predictive maintenance, leading to significant reductions in energy consumption and unplanned downtime.

Which end-user segment drives the highest demand for Steckel mill products?

The Construction and Infrastructure sector globally drives the highest volume, demanding hot-rolled coils and heavy plates for buildings, bridges, and structural applications, followed closely by the Automotive industry requiring high-strength, low-alloy (HSLA) steels.

What are the primary energy efficiency concerns related to Steckel mills?

The main concern relates to the energy consumption of the coiling furnaces, which must maintain the strip temperature. Modern mills address this through regenerative burner systems and AI-optimized furnace control to minimize heat loss and gas usage.

Which geographical region is expected to exhibit the fastest growth in new Steckel mill installations?

The Asia Pacific region, particularly Southeast Asian nations and India, is forecast to show the fastest growth in new installations due to ongoing infrastructure capacity expansion and the push for domestic steel self-sufficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager