Steel Pin Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440019 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Steel Pin Market Size

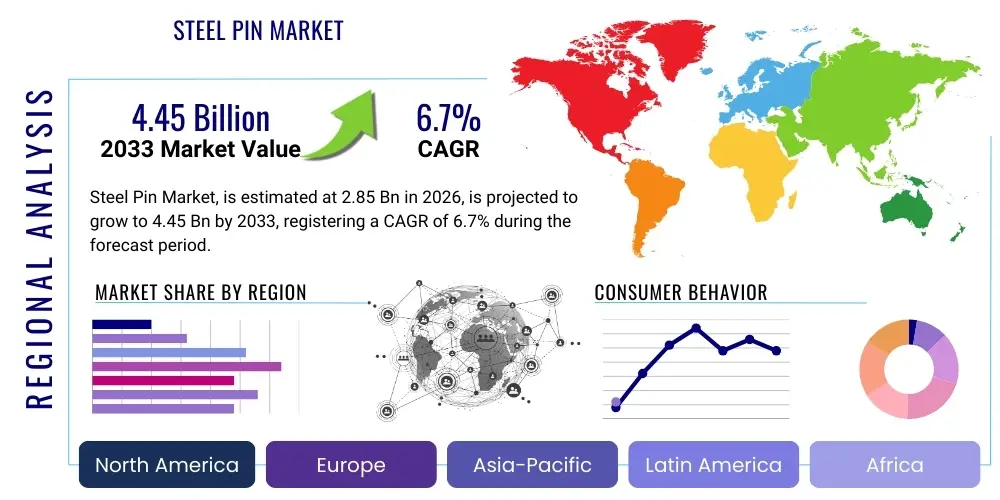

The Steel Pin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2026 and 2033. The market is estimated at USD 2.85 billion in 2026 and is projected to reach USD 4.45 billion by the end of the forecast period in 2033.

Steel Pin Market introduction

The Steel Pin Market encompasses the global production, distribution, and consumption of various types of steel pins, which are essential components used across a multitude of industries for fastening, alignment, pivoting, and structural reinforcement. Steel pins, typically made from high-grade carbon steel, stainless steel, or alloy steel, offer superior strength, durability, and resistance to wear and corrosion, making them indispensable in applications requiring robust and reliable connections. These precision-engineered components come in diverse forms such as dowel pins, clevis pins, cotter pins, spring pins, and grooved pins, each designed to meet specific functional requirements and engineering specifications.

Major applications for steel pins span critical sectors including automotive manufacturing, heavy machinery, construction, aerospace, electronics, and consumer goods, where they play vital roles in everything from engine assemblies and chassis construction to precision instrument alignment and securing structural elements. The inherent benefits of steel pins, such as their high shear strength, dimensional stability, ease of installation, and cost-effectiveness, contribute significantly to their widespread adoption. Key driving factors propelling market growth include sustained industrialization, particularly in developing economies, increased global infrastructure development projects, the continuous expansion of the automotive sector, and the rising demand for high-performance fastening solutions that enhance product reliability and operational safety across various end-use industries.

Steel Pin Market Executive Summary

The Steel Pin Market is characterized by dynamic business trends, evolving regional demands, and significant segmentation shifts, all contributing to its projected growth. Business trends are largely driven by a global push towards automation and precision manufacturing, fostering demand for consistently high-quality and dimensionally accurate steel pins. Companies are increasingly investing in advanced manufacturing technologies, such as CNC machining and automated inspection systems, to meet stringent industry standards and optimize production efficiency. Furthermore, there's a growing emphasis on custom-engineered solutions and specialty pins designed for unique applications, moving beyond standard off-the-shelf products to address complex industrial challenges, alongside a focus on sustainable manufacturing practices and the development of pins from recycled or eco-friendly steel alloys to align with global environmental mandates and consumer preferences.

Regional trends indicate that the Asia Pacific region, led by China and India, continues to dominate the market due to robust industrial expansion, burgeoning automotive production, and massive infrastructure investments. North America and Europe maintain stable demand, driven by well-established manufacturing bases, aerospace and defense sectors, and a strong focus on high-performance and specialty pins. Emerging markets in Latin America and the Middle East and Africa are showing promising growth, fueled by urbanization, industrial development, and increased foreign direct investment in manufacturing capabilities. Within segmentation, the market is experiencing significant demand for stainless steel pins due to their superior corrosion resistance in harsh environments, while grooved and spring pins are seeing increased adoption for their self-retaining properties and ease of assembly, reflecting a broader trend towards efficiency and reduced labor costs in manufacturing processes. The automotive and industrial machinery applications segments are expected to remain the largest contributors to market revenue, consistently driven by production volumes and ongoing maintenance requirements.

AI Impact Analysis on Steel Pin Market

The integration of Artificial Intelligence (AI) across industrial manufacturing processes is poised to significantly transform the Steel Pin Market by enhancing operational efficiencies, improving product quality, and optimizing supply chain dynamics. Common user questions revolve around how AI can contribute to predictive maintenance for manufacturing equipment, ensure higher precision and quality control in pin production, streamline supply chain management to reduce lead times and costs, and potentially even assist in the design and material selection for specialized pins. Users are keenly interested in AI's capability to move beyond traditional automation, offering intelligent solutions that adapt to real-time data and provide actionable insights for continuous improvement.

Key themes emerging from these discussions highlight AI's potential to revolutionize several aspects: from automating complex inspection tasks and identifying defects with greater accuracy than human operators to optimizing production schedules and raw material procurement through advanced analytics. Expectations are high for AI to reduce waste, minimize downtime, and enable manufacturers to respond more agilely to market demands. The underlying concern for many users is the practical implementation, cost-effectiveness, and the necessary data infrastructure to fully leverage AI's benefits within the existing manufacturing ecosystems of the steel pin industry, while also ensuring data security and system reliability.

- Automated Quality Inspection: AI-powered vision systems detect microscopic defects, dimensional inaccuracies, and surface imperfections in steel pins with unparalleled speed and precision, significantly reducing human error and improving overall product quality.

- Predictive Maintenance for Manufacturing Equipment: AI algorithms analyze sensor data from pin manufacturing machinery (e.g., cold headers, grinders, heat treatment furnaces) to predict potential failures, scheduling proactive maintenance and minimizing costly downtime.

- Supply Chain Optimization: AI models optimize inventory management, forecast demand more accurately, identify potential supply chain disruptions, and suggest optimal logistics routes, ensuring timely delivery of raw materials and finished products.

- Process Optimization and Energy Efficiency: AI-driven process control systems fine-tune manufacturing parameters (e.g., temperature, pressure, feed rates) in real-time, leading to reduced material waste, energy consumption, and improved output consistency.

- Generative Design and Material Science: AI can assist in the rapid generation of innovative pin designs tailored for specific applications and recommend optimal steel alloys based on desired mechanical properties and environmental conditions, accelerating R&D cycles.

- Robotics and Automation Integration: AI enhances the intelligence and adaptability of robotic systems used for handling, sorting, and packaging steel pins, allowing for more complex tasks and seamless integration into automated production lines.

- Market Trend Analysis and Demand Forecasting: AI algorithms analyze vast datasets, including economic indicators, industry reports, and customer purchasing patterns, to provide highly accurate market trend predictions and demand forecasts for various pin types.

- Cybersecurity in Smart Factories: AI contributes to detecting and responding to cyber threats within connected manufacturing environments, protecting proprietary designs, production data, and operational integrity from malicious attacks.

DRO & Impact Forces Of Steel Pin Market

The Steel Pin Market is influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces that collectively shape its trajectory and competitive landscape. Key market drivers include the sustained growth of the global manufacturing sector, particularly in automotive, industrial machinery, and construction, which are primary consumers of steel pins for assembly and structural integrity. Rapid urbanization and infrastructure development projects worldwide, especially in emerging economies, are also significantly boosting demand for reliable fastening solutions. Furthermore, continuous technological advancements in product design and manufacturing processes, leading to higher precision and specialized steel pins, along with the increasing emphasis on product reliability and safety standards across various industries, further propel market expansion by requiring high-quality, durable components.

However, the market faces significant restraints such as the inherent volatility of raw material prices, particularly steel, which directly impacts production costs and profit margins for manufacturers. Intense competition among both established and regional players leads to pricing pressures and necessitates continuous innovation to maintain market share. Additionally, stringent environmental regulations regarding material sourcing, manufacturing waste, and energy consumption, along with complex international trade policies and tariffs, can create barriers to market entry and affect global supply chains. Opportunities in the market are abundant, primarily through the exploration of emerging markets with nascent industrial bases, offering untapped potential for growth. Developing customized and specialized pins for niche applications, such as medical devices or advanced robotics, presents avenues for higher value products. Investment in research and development for new materials, coatings, and manufacturing techniques that enhance performance, corrosion resistance, or reduce weight, also provides significant growth prospects, allowing manufacturers to differentiate their offerings and capture premium segments. External impact forces, such as global economic downturns, geopolitical tensions, and unforeseen supply chain disruptions (e.g., pandemics, natural disasters), can profoundly affect market stability by impacting industrial output and consumer demand. The pace of technological innovation, including automation and additive manufacturing, also acts as an external force, potentially disrupting traditional production methods and creating new market dynamics for steel pin manufacturers.

Segmentation Analysis

The Steel Pin Market is comprehensively segmented to provide a detailed understanding of its diverse landscape, enabling stakeholders to identify specific growth areas and tailor strategies effectively. This segmentation is typically based on various parameters including the type of pin, the material used in its construction, the specific application it serves, and the end-use industry that procures it. Each segment represents distinct market characteristics, demand drivers, and competitive dynamics, reflecting the wide array of functions and performance requirements that steel pins fulfill across different industrial contexts.

Understanding these segments is crucial for market participants to identify niche opportunities, allocate resources efficiently, and develop targeted marketing and sales approaches. For instance, the demand for high-strength alloy steel pins in aerospace applications differs significantly from the demand for standard carbon steel dowel pins in general machinery, both in terms of volume, price points, and required certifications. The global market's segmentation highlights the specialized nature of many steel pin products and the necessity for manufacturers to cater to the exacting specifications of various end-user industries, driving innovation in material science, design, and manufacturing processes to meet these diverse needs.

- By Type

- Dowel Pins

- Clevis Pins

- Spring Pins (Roll Pins, Coiled Pins)

- Cotter Pins

- Grooved Pins

- Taper Pins

- Hitch Pins

- Quick Release Pins

- Others (e.g., Lynch Pins, Lock Pins)

- By Material

- Stainless Steel (300 series, 400 series)

- Carbon Steel (Low Carbon, Medium Carbon, High Carbon)

- Alloy Steel (Chromium, Nickel, Molybdenum Alloys)

- Tool Steel

- Hardened Steel

- By Application

- Automotive (Engines, Transmissions, Chassis, Steering)

- Construction (Heavy Equipment, Structural Fastening)

- Industrial Machinery (Robotics, Manufacturing Equipment, Pumps, Valves)

- Aerospace and Defense (Aircraft Assemblies, Control Systems)

- Electronics and Electrical Appliances

- Agriculture Equipment

- Consumer Goods and Appliances

- Marine Industry

- Medical Devices

- Others (e.g., Furniture, Sporting Goods)

- By End-Use

- Original Equipment Manufacturers (OEM)

- Aftermarket (Maintenance, Repair, and Operations - MRO)

Value Chain Analysis For Steel Pin Market

The value chain for the Steel Pin Market encompasses a series of interconnected activities, beginning from the sourcing of raw materials to the final delivery to end-users, highlighting the transformation of steel into precision-engineered components. Upstream analysis involves the procurement of various grades of steel, primarily from integrated steel mills or specialty alloy producers. These raw material suppliers provide steel rods, bars, and wire coils, which are the fundamental inputs for pin manufacturing. Key considerations at this stage include material quality, price stability, adherence to specific metallurgical properties, and sustainable sourcing practices. The relationship between pin manufacturers and steel suppliers is crucial, often involving long-term contracts and quality assurance protocols to ensure consistent material integrity required for high-performance pins.

Further along the value chain, pin manufacturers utilize sophisticated processes such as cold forming, hot forging, CNC machining, grinding, heat treatment, and various surface finishing techniques (e.g., plating, coating) to produce a wide array of steel pins. Downstream analysis focuses on the distribution and sales channels that bridge the gap between manufacturers and end-users. This involves a mix of direct sales channels, where manufacturers sell directly to large OEM customers or specific industrial clients, and indirect channels, which include distributors, wholesalers, and specialized fastener suppliers. These intermediaries play a vital role in providing regional coverage, managing inventory, offering technical support, and consolidating orders for smaller clients. The effectiveness of these distribution channels greatly influences market reach, customer satisfaction, and overall market penetration. Direct distribution often caters to large volume orders and specialized requirements, while indirect channels provide broader market access, especially for MRO segments and diverse smaller industrial customers. The efficiency of the entire value chain, from material procurement to final delivery, is critical for competitive pricing, timely supply, and meeting the stringent quality demands of the varied industries relying on steel pins.

Steel Pin Market Potential Customers

Potential customers for steel pins represent a vast and diverse ecosystem of industries and enterprises that rely on these fundamental components for the assembly, functionality, and structural integrity of their products and operations. These end-users typically include Original Equipment Manufacturers (OEMs) who integrate pins into their new products, as well as companies involved in Maintenance, Repair, and Operations (MRO) for existing machinery and infrastructure. The demand profile of these customers varies significantly, ranging from high-volume standard pins for general assembly to highly specialized, custom-engineered pins requiring specific material properties, finishes, and dimensional tolerances for critical applications.

Key sectors driving consistent demand include the automotive industry, where pins are vital for engine components, transmissions, chassis, and various sub-assemblies, and the construction sector, utilizing pins in heavy machinery, structural connections, and formwork. Industrial machinery manufacturers, aerospace and defense companies, and even producers of consumer electronics and appliances also represent substantial customer segments. Each segment seeks specific performance attributes, such as high shear strength, corrosion resistance, precision fit, or specific hardness, underscoring the necessity for steel pin manufacturers to offer a comprehensive product portfolio and technical expertise to serve this broad customer base effectively.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.85 Billion |

| Market Forecast in 2033 | USD 4.45 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Boker's, Inc., Accurate Screw Machine, SPIROL International Corporation, PIC Design, G.L. Huyett, Century Fasteners Corp., Jergens Inc., PennEngineering, Essentra Components, Pivot Point Inc., Nord-Lock Group, MISUMI Group Inc., W. W. Grainger, Inc., Fastenal Company, Würth Group, ARCONIC (Howmet Aerospace), STANLEY Engineered Fastening, TR Fastenings, EJOT, Fastener Solutions Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Steel Pin Market Key Technology Landscape

The Steel Pin Market is significantly shaped by a sophisticated technology landscape, encompassing a range of manufacturing processes and quality assurance methodologies essential for producing high-precision, durable components. Core to this landscape are advanced machining techniques such as Computer Numerical Control (CNC) milling and grinding, which enable the production of pins with extremely tight tolerances and complex geometries, critical for specialized applications in industries like aerospace and medical devices. Cold forming and hot forging technologies are widely employed for mass production, offering high efficiency and material strength optimization by manipulating steel at ambient or elevated temperatures, respectively, ensuring material integrity and reducing waste.

Furthermore, heat treatment processes, including hardening, tempering, and annealing, are crucial for achieving desired mechanical properties such as hardness, toughness, and ductility, tailored to the specific application requirements of different steel pins. Surface finishing technologies, such as electroplating (e.g., zinc, nickel, chrome), phosphating, and various coating applications, are extensively utilized to enhance corrosion resistance, wear resistance, and aesthetic appeal, extending the lifespan and performance of the pins in harsh environments. The increasing adoption of automated inspection systems, including advanced vision systems and Coordinate Measuring Machines (CMMs), ensures rigorous quality control and adherence to stringent industry standards. Moreover, the emergence of additive manufacturing (3D printing) is beginning to impact the prototyping and short-run production of complex or custom pin designs, offering new avenues for innovation and rapid product development within the steel pin manufacturing sector.

Regional Highlights

- Asia Pacific (APAC): This region is the undisputed leader in the Steel Pin Market, driven by robust industrialization, massive infrastructure development, and burgeoning automotive manufacturing sectors in countries like China, India, Japan, and South Korea. China, in particular, serves as a global manufacturing hub, contributing significantly to both production and consumption of steel pins. The region's growth is further fueled by expanding electronics production and increasing foreign direct investment in manufacturing capabilities, leading to high demand for both standard and specialized pins.

- North America: A mature market characterized by a strong focus on high-performance and specialty steel pins, particularly for its advanced automotive, aerospace, defense, and industrial machinery sectors. The United States and Canada are key contributors, with demand driven by technological innovation, stringent quality standards, and consistent investment in critical infrastructure. The emphasis here is often on high-value, engineered solutions rather than purely cost-driven mass production.

- Europe: This region holds a significant share, with countries such as Germany, the UK, France, and Italy leading the demand. Europe boasts a highly developed manufacturing base, precision engineering industries, and a robust automotive sector. Strict quality regulations and a focus on sustainable manufacturing practices influence product development and material choices. The demand for customized and high-durability steel pins is particularly strong in this region.

- Latin America: An emerging market with promising growth potential, primarily driven by expanding automotive production (especially in Mexico and Brazil), ongoing construction projects, and increasing industrialization. While currently smaller than APAC or North America, urbanization trends and investment in manufacturing capabilities are steadily boosting the demand for steel pins across various applications.

- Middle East and Africa (MEA): This region is witnessing gradual growth in the Steel Pin Market, largely attributed to significant investments in infrastructure development, oil & gas industry expansion, and diversified industrial projects. Countries in the GCC region (e.g., Saudi Arabia, UAE) are at the forefront of this growth, with demand for steel pins tied to large-scale construction and industrial maintenance activities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Steel Pin Market.- Boker's, Inc.

- Accurate Screw Machine

- SPIROL International Corporation

- PIC Design

- G.L. Huyett

- Century Fasteners Corp.

- Jergens Inc.

- PennEngineering

- Essentra Components

- Pivot Point Inc.

- Nord-Lock Group

- MISUMI Group Inc.

- W. W. Grainger, Inc.

- Fastenal Company

- Würth Group

- ARCONIC (Howmet Aerospace)

- STANLEY Engineered Fastening

- TR Fastenings

- EJOT

- Fastener Solutions Inc.

Frequently Asked Questions

Analyze common user questions about the Steel Pin market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary types of steel pins and their common uses?

The primary types of steel pins include dowel pins for alignment, clevis pins for pivoting connections, spring pins (roll or coiled) for self-retaining fastening, cotter pins for securing other fasteners, and grooved pins for robust, permanent connections. These are commonly used across automotive, industrial machinery, construction, and aerospace applications.

Which factors are driving the growth of the Steel Pin Market?

Market growth is primarily driven by global industrial expansion, significant investments in infrastructure development, the robust expansion of the automotive sector, and continuous advancements in manufacturing technologies that demand high-precision and durable fastening solutions for improved product reliability and operational safety across various industries.

What materials are commonly used to manufacture steel pins, and why?

Steel pins are typically manufactured from carbon steel for general applications, stainless steel (e.g., 300 and 400 series) for corrosion resistance in harsh environments, and alloy steel for enhanced strength and specific mechanical properties. These materials are chosen for their superior strength, durability, wear resistance, and ability to be heat-treated for specific performance characteristics.

How does raw material price volatility impact the Steel Pin Market?

Raw material price volatility, particularly for steel, significantly impacts the Steel Pin Market by directly affecting production costs and, consequently, the profit margins of manufacturers. Fluctuations in steel prices can lead to increased operational expenses, pricing pressures, and challenges in maintaining competitive market pricing, necessitating strategic procurement and hedging strategies.

Which regions are key contributors to the Steel Pin Market's revenue?

The Asia Pacific region is the leading revenue contributor, driven by extensive industrialization and robust manufacturing sectors in countries like China and India. North America and Europe also hold substantial market shares due to their advanced automotive, aerospace, and industrial machinery industries, focusing on high-performance and specialty pin demand.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager