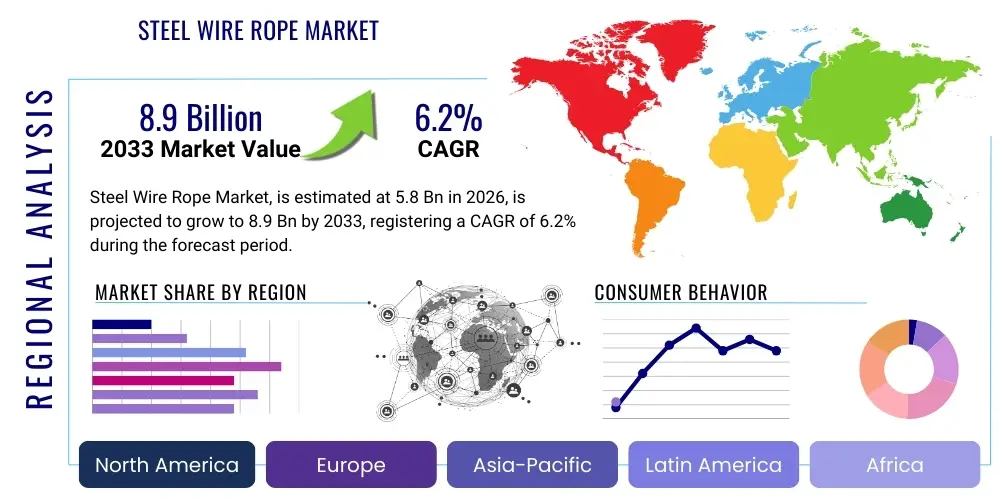

Steel Wire Rope Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440074 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Steel Wire Rope Market Size

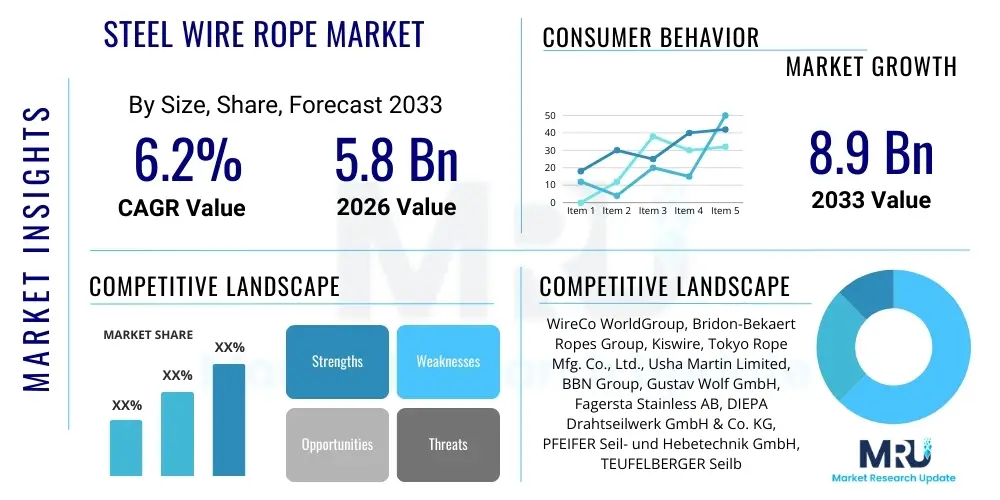

The Steel Wire Rope Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 5.8 billion in 2026 and is projected to reach USD 8.9 billion by the end of the forecast period in 2033. This growth trajectory is underpinned by robust demand across key industrial sectors, including construction, mining, oil and gas, and marine. The increasing global infrastructure development, coupled with continuous advancements in material science and manufacturing techniques for steel wire ropes, contributes significantly to this expansion. The market's resilience is also attributed to the critical safety and operational requirements where steel wire ropes are indispensable, ensuring consistent demand even amidst economic fluctuations. Furthermore, the rising adoption of specialized and high-performance wire ropes designed for extreme conditions and heavier loads in modern industrial applications is a pivotal factor driving this substantial market valuation increase over the forecast period.

Steel Wire Rope Market introduction

The Steel Wire Rope Market encompasses the production, distribution, and utilization of helical strands of steel wire, which are wound together to form a rope. These ropes are engineered for various applications demanding high strength, flexibility, and durability, serving as critical components in lifting, hauling, anchoring, and structural support systems across a multitude of industries. The product range is extensive, including general engineering ropes, structural ropes, and specialized ropes for corrosive or high-temperature environments. Major applications span construction, where they are vital for cranes, elevators, and bridges; mining, utilized in hoist systems and draglines; oil and gas, for offshore drilling rigs and mooring lines; and marine, in ship rigging, fishing nets, and port operations. The inherent benefits of steel wire ropes, such as their high tensile strength-to-weight ratio, excellent fatigue resistance, and predictable failure modes, make them indispensable for critical load-bearing tasks, ensuring operational safety and efficiency in demanding environments.

Driving factors for this market's growth are multifaceted and deeply intertwined with global economic development and industrial expansion. A primary driver is the accelerating pace of infrastructure development worldwide, particularly in emerging economies, necessitating robust and reliable lifting and structural components. The burgeoning construction of skyscrapers, bridges, and complex transportation networks inherently increases the demand for high-quality steel wire ropes. Furthermore, the global energy transition and expansion of renewable energy projects, such as large-scale wind turbine installations and hydroelectric power plants, require specialized wire ropes for construction and maintenance. The oil and gas sector, despite its cyclical nature, continues to be a significant consumer, with ongoing exploration and production activities, especially in deep-water and ultra-deep-water environments, demanding advanced corrosion-resistant and high-strength ropes.

Technological advancements in manufacturing processes, including improved metallurgy, coating technologies, and rope constructions, also act as a crucial catalyst. These innovations lead to the production of lighter, stronger, and more durable wire ropes with extended service lives, reducing maintenance costs and enhancing operational safety, thereby appealing to a broader industrial customer base. The stringent safety regulations and international standards imposed across industries like maritime, construction, and mining further compel end-users to adopt certified and high-performance steel wire ropes, ensuring market demand remains robust. Moreover, the increasing automation in logistics and material handling, coupled with the rising global trade volume, fuels the demand for advanced hoisting and lifting equipment, consequently driving the steel wire rope market forward.

- Product Description: Helical arrangement of steel wires forming a strong, flexible rope for load-bearing applications.

- Major Applications: Construction (cranes, elevators, bridges), Mining (hoists, draglines), Oil & Gas (drilling, mooring), Marine (rigging, fishing), Industrial Lifting.

- Key Benefits: High tensile strength, superior fatigue resistance, excellent durability, predictable performance, critical safety component.

- Driving Factors: Global infrastructure expansion, growth in renewable energy sector, advancements in material science, stringent safety regulations, increasing industrial automation.

- Market Relevance: Essential for safety and operational efficiency in heavy-duty industrial and commercial applications globally.

Steel Wire Rope Market Executive Summary

The Steel Wire Rope Market is experiencing a dynamic phase, characterized by significant business trends driven by global industrial growth, technological innovation, and evolving regulatory landscapes. A prominent trend is the increasing consolidation among market players, as larger entities seek to acquire specialized manufacturers to expand their product portfolios, enhance technological capabilities, and strengthen regional footprints. This consolidation aims to achieve economies of scale and improve competitive positioning in a highly fragmented market. Furthermore, there is a growing emphasis on product differentiation through advanced materials and coatings, such as galvanized, plastic-coated, and compact ropes, which offer superior performance in challenging environments like saltwater exposure or abrasive conditions. The adoption of smart wire ropes integrated with sensors for real-time monitoring of tension, wear, and fatigue is also gaining traction, addressing the critical need for predictive maintenance and enhanced safety in high-stakes applications. Sustainability initiatives are influencing manufacturing processes, with a focus on energy efficiency and waste reduction, as well as the development of recyclable rope materials.

Regional trends indicate varied growth trajectories influenced by localized industrial development and infrastructure spending. The Asia Pacific region stands out as the largest and fastest-growing market, primarily propelled by massive infrastructure projects in China, India, and Southeast Asian nations, alongside thriving manufacturing and mining sectors. North America and Europe, while mature markets, demonstrate steady demand driven by stringent safety regulations, modernization of existing infrastructure, and a focus on high-performance, specialized wire ropes for advanced industrial applications and renewable energy projects. Latin America and the Middle East & Africa regions are also exhibiting considerable growth, supported by investments in oil and gas exploration, mining activities, and urban development projects. Each region's unique economic drivers, regulatory frameworks, and industrial concentration dictate the specific types and volumes of steel wire ropes in demand, leading to distinct market dynamics and competitive landscapes.

Segmentation trends highlight the continued dominance of general engineering ropes due to their widespread utility in basic lifting and pulling tasks. However, the fastest growth is observed in specialized segments such as high-performance ropes and structural ropes, driven by demand for advanced construction techniques and complex engineering projects requiring superior strength and longevity. By material, carbon steel remains the most common, but stainless steel wire ropes are gaining share in corrosive environments. In terms of end-use, the construction and mining sectors continue to be the primary consumers, although the marine and oil & gas industries represent significant, high-value segments due to the critical nature of their operations and the need for highly durable and reliable products. The increasing demand for longer-lasting, low-maintenance, and digitally integrated wire ropes is shaping product development and market offerings across all segments, emphasizing value-added solutions over standard commodities.

AI Impact Analysis on Steel Wire Rope Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Steel Wire Rope Market frequently revolve around how AI can enhance safety, improve operational efficiency, and drive innovation within a traditionally mechanical industry. Key themes often include the potential for AI-powered predictive maintenance, smart monitoring systems, optimization of manufacturing processes, and the development of next-generation wire ropes. Users are keen to understand how AI can move beyond simple automation to provide actionable insights into rope integrity, wear patterns, and remaining useful life, thereby preventing costly failures and ensuring compliance with increasingly stringent safety standards. There is a clear expectation that AI will lead to more intelligent, self-diagnosing, and safer wire rope solutions, transforming how these critical components are managed and maintained throughout their lifecycle, reducing human error and maximizing operational uptime. The discourse also touches upon the challenges of integrating AI into existing infrastructure and the required investment in data collection and analytical capabilities.

The integration of AI technologies is poised to revolutionize several aspects of the steel wire rope market, from raw material sourcing to end-user applications. In manufacturing, AI algorithms can optimize material composition and processing parameters, leading to ropes with enhanced strength, flexibility, and corrosion resistance. Predictive analytics, driven by machine learning, can forecast equipment failures in production lines, ensuring higher quality output and minimizing downtime. Beyond the factory floor, AI's most significant impact is anticipated in real-time monitoring and maintenance. Sensors embedded within or attached to steel wire ropes can collect vast amounts of data on tension, vibration, temperature, and wear. AI systems then analyze this data to detect anomalies, predict potential failures, and recommend optimal maintenance schedules, shifting from reactive to proactive intervention. This capability is particularly crucial in high-risk applications such as crane operations, mining hoists, and offshore drilling, where unexpected rope failures can have catastrophic consequences.

Moreover, AI can play a pivotal role in the design and engineering phase, using generative design principles to explore novel rope constructions and material combinations that might be impossible to conceive through traditional methods. This can lead to lighter, stronger, and more durable ropes tailored for highly specific and demanding applications. In logistics and supply chain management, AI can optimize inventory levels, predict demand fluctuations, and streamline distribution, ensuring that the right types of steel wire ropes are available when and where they are needed, reducing lead times and operational costs. Furthermore, AI-driven simulations can test rope performance under extreme conditions without physical prototypes, accelerating product development cycles and reducing R&D expenses. The cumulative effect of these AI applications is a market that is not only more efficient and innovative but also significantly safer and more reliable, positioning steel wire ropes as smart, interconnected components within larger industrial ecosystems.

- Predictive Maintenance: AI analyzes sensor data (tension, vibration, wear) to predict failures, enabling proactive maintenance and extending rope lifespan.

- Enhanced Safety: Real-time monitoring and anomaly detection reduce the risk of catastrophic failures in critical applications, improving workplace safety.

- Manufacturing Optimization: AI algorithms refine material composition and production processes for superior strength, durability, and cost-efficiency.

- Smart Rope Development: Facilitates the creation of "smart" wire ropes with integrated sensors for continuous performance monitoring and self-diagnosis.

- Design Innovation: Generative AI assists in exploring novel rope designs and material combinations for enhanced performance and specialized applications.

- Supply Chain Efficiency: AI optimizes inventory management, demand forecasting, and logistics, ensuring timely availability and reduced operational costs.

- Quality Control: AI-powered vision systems detect microscopic defects during manufacturing, ensuring higher product quality and reliability.

DRO & Impact Forces Of Steel Wire Rope Market

The Steel Wire Rope Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively shape its growth trajectory and competitive landscape. A primary driver is the accelerating pace of global urbanization and industrialization, particularly in developing economies, leading to extensive infrastructure projects that necessitate vast quantities of steel wire ropes for construction, transportation, and energy sectors. This demand is further amplified by the continuous need for maintenance, repair, and replacement of existing infrastructure worldwide. Restraints include the volatility of raw material prices, primarily steel and related alloys, which can significantly impact manufacturing costs and profit margins. Intense competition from both established global players and regional manufacturers, coupled with the availability of alternative lifting and support technologies such as synthetic fiber ropes in certain niche applications, also presents market challenges. Opportunities arise from technological advancements, including the development of high-performance, corrosion-resistant, and smart wire ropes, alongside the increasing adoption of renewable energy infrastructure requiring specialized solutions.

Impact forces on the market are multifaceted, stemming from economic, technological, environmental, and regulatory factors. Economically, global GDP growth directly correlates with industrial activity and construction spending, thereby influencing demand for steel wire ropes. Fluctuations in currency exchange rates can affect import/export dynamics and the competitiveness of manufacturers. Technologically, innovations in material science, coating technologies, and sensor integration are transforming product capabilities, driving demand for advanced ropes while potentially rendering older technologies obsolete. The shift towards automation and digitalization in industries like logistics and manufacturing also pushes for more integrated and intelligent rope solutions. Environmentally, the growing emphasis on sustainability and energy efficiency impacts manufacturing processes and prompts the development of more eco-friendly products and recycling initiatives for used ropes. Lastly, stringent safety regulations and international standards, particularly in high-risk sectors like mining, marine, and construction, exert immense pressure on manufacturers to adhere to quality and performance benchmarks, shaping product development and market entry barriers.

The combination of these forces creates a dynamic environment where adaptability and innovation are key to success. Manufacturers are compelled to invest in research and development to address current restraints and capitalize on emerging opportunities, focusing on creating products that offer superior performance, longer service life, and enhanced safety features. The increasing awareness of worker safety and environmental protection further necessitates a continuous evolution of product offerings and operational practices. Moreover, geopolitical stability and trade policies can significantly influence supply chain resilience and market access, adding another layer of complexity to the market's impact forces. Understanding and strategically navigating these drivers, restraints, and opportunities, alongside the overarching impact forces, is crucial for stakeholders aiming to maintain competitive advantage and achieve sustainable growth within the global steel wire rope market.

- Drivers:

- Accelerated global infrastructure development and urbanization, especially in emerging economies.

- Growth in mining activities and oil & gas exploration, particularly deep-water projects.

- Increasing demand from the renewable energy sector (wind turbines, hydroelectric dams).

- Strict safety regulations and international standards mandating high-quality components.

- Technological advancements leading to high-performance and durable ropes.

- Rising global trade and expansion of the logistics and material handling industries.

- Continuous need for maintenance, repair, and replacement of existing industrial equipment.

- Restraints:

- Volatile raw material prices (steel, zinc, other alloys).

- Intense competition from both global and local manufacturers.

- Availability of alternative products like synthetic fiber ropes for specific applications.

- High capital investment required for manufacturing and technological upgrades.

- Economic downturns or slowdowns impacting industrial and construction spending.

- Complex regulatory landscape across different regions.

- Challenge of managing inventory and supply chain fluctuations.

- Opportunities:

- Development of smart wire ropes with integrated sensors for predictive maintenance.

- Growing demand for corrosion-resistant and specialized ropes for harsh environments.

- Expansion into untapped markets with nascent industrialization.

- Customization and tailor-made solutions for niche applications.

- Focus on sustainable manufacturing practices and recyclable materials.

- Strategic partnerships and collaborations for technology transfer and market access.

- Leveraging e-commerce and digital platforms for broader market reach.

- Impact Forces:

- Economic Forces: Global GDP growth, industrial output, currency fluctuations, investment in infrastructure.

- Technological Forces: Material science innovations, automation, AI integration, smart manufacturing.

- Environmental Forces: Sustainability mandates, resource efficiency, carbon footprint reduction.

- Regulatory Forces: Safety standards, environmental compliance, trade policies, certification requirements.

- Social Forces: Worker safety awareness, demand for reliable and durable products.

Segmentation Analysis

The Steel Wire Rope Market is extensively segmented across various parameters, allowing for a detailed understanding of its complex structure and diverse applications. This segmentation provides crucial insights into market dynamics, identifying high-growth areas and informing strategic decision-making for manufacturers and suppliers. Key segmentation criteria typically include type, material, end-use industry, and application, each revealing distinct market behaviors and competitive landscapes. For instance, the distinction between general engineering ropes and high-performance ropes highlights varying demand drivers, with the latter catering to more specialized and demanding applications requiring superior strength, fatigue life, and corrosion resistance. The material segment often differentiates between carbon steel, stainless steel, and galvanized options, each chosen based on environmental conditions and specific performance requirements. End-use industries represent the primary demand sources, showcasing the broad utility of steel wire ropes from heavy construction to delicate lifting operations.

Understanding these segments is vital for tailoring product development, marketing strategies, and distribution channels. For example, a manufacturer specializing in stainless steel wire ropes would target marine, food processing, and medical industries where corrosion resistance and hygiene are paramount, rather than general construction. Similarly, high-performance ropes are primarily sought after in sectors like mining, oil and gas, and large-scale infrastructure projects where safety and durability under extreme loads are non-negotiable. The geographical distribution of these segments also plays a critical role, as developing regions often exhibit higher demand for general engineering ropes to support basic infrastructure, while developed regions focus on advanced and specialized ropes for modernization and maintenance of existing facilities. This granular view enables stakeholders to identify underserved markets, mitigate risks, and optimize their product portfolios to align with specific customer needs and industry trends.

Further analysis within these segments often includes sub-segmentations, such as rope construction type (e.g., 6x19, 6x36, 19x7), which dictates flexibility, strength, and resistance to rotation, directly impacting suitability for specific applications like hoisting or mooring. The increasing demand for customized solutions, driven by unique project requirements, further emphasizes the importance of a nuanced segmentation approach. As industries evolve and new technologies emerge, the definitions and importance of these segments may shift, requiring continuous market intelligence and adaptation. Ultimately, a robust segmentation analysis is the foundation for comprehending the intricate demand patterns, competitive forces, and growth opportunities present within the dynamic global steel wire rope market, guiding strategic investments and innovation efforts effectively.

- By Type:

- General Engineering Ropes (GE Ropes)

- High-Performance Ropes

- Structural Ropes

- Rotation Resistant Ropes

- Non-Rotating Ropes

- Compact Ropes

- By Material:

- Carbon Steel Wire Ropes

- Stainless Steel Wire Ropes

- Galvanized Steel Wire Ropes

- Plastic Coated Steel Wire Ropes

- By Construction:

- 6x7 (Small diameter, stiff)

- 6x19 (Good balance of flexibility and wear resistance)

- 6x36 (More flexible than 6x19, good for larger diameters)

- 8x19 / 8x25 (Enhanced flexibility and fatigue resistance)

- 19x7 (Rotation resistant, common for single-part hoist lines)

- 35x7 (Highly rotation resistant, very flexible)

- Specialty Constructions (e.g., compacted, parallel lay)

- By End-Use Industry:

- Construction (Cranes, Elevators, Bridges, Concrete Pumping)

- Mining (Hoist Ropes, Dragline Ropes, Excavator Ropes)

- Oil & Gas (Offshore Drilling Rigs, Mooring Lines, Winch Ropes)

- Marine & Fishing (Ship Rigging, Fishing Trawls, Port Operations)

- Transportation (Aerial Ropeways, Cable Cars, Conveyors)

- Industrial & Manufacturing (Material Handling, General Lifting, Automotive)

- Agriculture & Forestry (Logging, Farm Equipment)

- Energy (Wind Turbines, Hydroelectric Plants, Transmission Towers)

- By Application:

- Lifting & Hoisting

- Towing & Mooring

- Anchoring & Guying

- Support & Suspension

- Transmission & Conveying

Value Chain Analysis For Steel Wire Rope Market

The value chain for the Steel Wire Rope Market is a complex network of interconnected activities, beginning with raw material sourcing and extending through manufacturing, distribution, and end-user application. Upstream analysis reveals that the primary raw material is high-carbon steel wire rod, typically sourced from integrated steel mills. The quality and purity of this steel are paramount, as they directly impact the final rope's strength, durability, and safety characteristics. Key upstream activities involve iron ore mining, steel production, and the drawing of steel wire rods into finer wires through a specialized cold drawing process. Suppliers in this segment face pressures related to commodity price volatility, energy costs, and environmental regulations. Downstream activities focus on the assembly and finishing of the wire ropes, which involve stranding wires into strands and then closing these strands around a core to form the finished rope. This process often includes lubrication, pre-stretching, and specialized coatings to enhance performance and corrosion resistance. The complexity of manufacturing requires significant capital investment in machinery, skilled labor, and rigorous quality control.

The distribution channel for steel wire ropes is multi-layered, encompassing both direct and indirect sales approaches. Direct sales are common for large industrial customers, specialized projects, or custom orders, where manufacturers engage directly with end-users to provide technical consultation, tailor-made solutions, and after-sales support. This approach fosters strong client relationships and ensures precise fulfillment of stringent technical specifications. Indirect channels, conversely, involve a network of distributors, wholesalers, and specialized retailers who serve a broader customer base, including smaller businesses, maintenance operations, and general construction companies. These intermediaries provide warehousing, logistics, and localized customer service, extending the market reach of manufacturers. The choice between direct and indirect channels often depends on market maturity, product complexity, and customer size, with many manufacturers employing a hybrid strategy to optimize market penetration and service efficiency.

The efficiency of the value chain is critical for competitiveness, as disruptions at any stage can significantly impact costs, lead times, and product availability. Factors such as raw material supply chain resilience, manufacturing operational excellence, and the effectiveness of distribution networks are paramount. Moreover, the increasing demand for high-performance and customized ropes necessitates closer collaboration across the value chain, from steel producers to rope manufacturers and end-users, to ensure that material properties and rope designs meet exact application requirements. Value addition occurs at each stage, from the transformation of raw steel into high-strength wires, to the intricate engineering of rope constructions, and finally to the specialized application and maintenance services provided to end-users. Optimizing this value chain through technological integration, automation, and strategic partnerships is a continuous effort to enhance profitability, reduce waste, and improve overall market responsiveness, ultimately delivering superior value to the end customer.

- Upstream Analysis:

- Raw Material Sourcing: High-carbon steel wire rod, steel alloys (e.g., stainless steel), zinc for galvanization.

- Key Suppliers: Integrated steel mills, specialized wire drawing companies.

- Primary Activities: Iron ore mining, steelmaking, hot rolling of wire rod, cold drawing of wires.

- Challenges: Raw material price volatility, energy costs, quality control, environmental compliance.

- Manufacturing Analysis:

- Wire Preparation: Cleaning, coating (e.g., phosphating, galvanizing), lubrication.

- Stranding: Twisting individual wires into strands.

- Closing (Rope Laying): Twisting strands around a core to form the finished rope.

- Finishing: Lubrication, pre-stretching, testing, cutting to length, spooling.

- Technology: Advanced stranding machines, closing machines, induction tempering, coating lines.

- Downstream Analysis:

- Value-Added Services: Installation, inspection, maintenance, re-lubrication, testing, training.

- End-Users: Construction companies, mining operators, oil & gas firms, marine industries.

- Post-Sales: Technical support, warranty services, recycling options for used ropes.

- Distribution Channels:

- Direct Sales: Manufacturers selling directly to large industrial clients, for custom orders, or complex projects.

- Indirect Sales: Through distributors, wholesalers, retailers, and specialized agents serving a wider customer base.

- Online Platforms: E-commerce channels for standardized products and small to medium-sized enterprises.

- Key Stakeholders: Raw material producers, wire rod manufacturers, wire rope manufacturers, distributors, testing and certification bodies, end-users.

Steel Wire Rope Market Potential Customers

The potential customers for steel wire ropes span a vast array of industries, each with unique requirements and operational demands, underscoring the product's fundamental role in modern industrial and infrastructural development. These end-users are typically organizations or businesses that require reliable, high-strength components for lifting, pulling, supporting, or transmitting force in critical applications where safety and durability are paramount. The construction industry represents a colossal segment, comprising developers, general contractors, and specialized subcontractors who utilize wire ropes extensively in cranes, elevators, scaffolding, and bridge construction. Similarly, the mining sector, including both surface and underground operations, heavily relies on steel wire ropes for hoists, draglines, excavators, and conveyor systems, where the ropes endure immense stress and abrasive conditions, necessitating frequent inspection and replacement to ensure continuous operation and worker safety.

- Construction Companies: For cranes, elevators, bridge construction, scaffolding, material lifts, concrete pumping.

- Mining Operators: For hoist ropes in underground and open-pit mines, draglines, excavators, conveyor belts.

- Oil & Gas Industry: For offshore drilling rigs (drilling lines, wireline units), mooring lines, subsea applications, pipe laying.

- Marine & Fishing Industry: For ship rigging, fishing trawls, cargo handling at ports, tugboats, offshore supply vessels.

- Renewable Energy Sector: For wind turbine installation and maintenance, hydroelectric power plant construction, solar farm component lifting.

- Transportation Sector: For aerial ropeways, cable cars, chairlifts, railway signaling, large-scale conveyor systems.

- Logistics & Material Handling Companies: For forklifts, overhead cranes, hoists, winches in warehouses and distribution centers.

- Agriculture & Forestry: For logging operations, farm machinery, irrigation systems.

- General Manufacturing & Industrial: For factory cranes, production line lifting, automotive assembly, heavy machinery operations.

- Public Utilities: For power transmission towers, communication towers, dam maintenance.

- Architectural & Structural Engineering Firms: For specialized structural support in buildings, stadiums, tension fabric structures.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.8 billion |

| Market Forecast in 2033 | USD 8.9 billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | WireCo WorldGroup, Bridon-Bekaert Ropes Group, Kiswire, Tokyo Rope Mfg. Co., Ltd., Usha Martin Limited, BBN Group, Gustav Wolf GmbH, Fagersta Stainless AB, DIEPA Drahtseilwerk GmbH & Co. KG, PFEIFER Seil- und Hebetechnik GmbH, TEUFELBERGER Seilbahnen, DSR Corporation, Guizhou Wire Rope Co., Ltd., Jiangsu Langshan Wire Rope Co., Ltd., ScanRope AS, Verope AG, YoungHeung Iron & Steel Co., Ltd., J.D. Neuhaus GmbH & Co. KG, Condor Hoist & Crane, Inc., Bethlehem Wire Rope. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Steel Wire Rope Market Key Technology Landscape

The Steel Wire Rope Market is experiencing a significant technological evolution, moving beyond traditional manufacturing methods to embrace advanced processes and innovative materials that enhance performance, durability, and safety. A fundamental technology involves sophisticated wire drawing techniques, which control the microstructure of steel wires to achieve desired strength and ductility while maintaining excellent surface finish. This often includes patenting processes (heat treatment) that prepare the wire for drawing, optimizing its tensile strength and toughness. Furthermore, advanced stranding and closing machinery play a crucial role, allowing for the precise assembly of wires into strands and strands into ropes, minimizing internal stresses and maximizing fatigue life. These machines can produce a wide array of rope constructions, from standard 6-strand ropes to complex multi-strand rotation-resistant designs, catering to specific application demands for flexibility, strength, and resistance to torque. The continuous refinement of these manufacturing processes enables producers to create ropes with tighter tolerances and more consistent performance characteristics.

- Advanced Wire Drawing & Heat Treatment: Precision drawing processes and patenting for optimized strength, ductility, and fatigue resistance of individual wires.

- High-Tensile Strength Steel Alloys: Utilization of specialized steel compositions for enhanced load-bearing capacity and reduced rope diameter.

- Sophisticated Stranding & Closing Machinery: Advanced equipment for precise rope construction (e.g., 6x19, 19x7, compacted ropes) to achieve specific performance characteristics like flexibility or rotation resistance.

- Corrosion Protection Technologies:

- Advanced Galvanization: Hot-dip and electro-galvanizing for superior zinc coating and environmental resistance.

- Polymer Coatings & Impregnations: Application of high-performance plastics on wires or cores for abrasion resistance, lubrication retention, and corrosion protection.

- Integrated Sensor Technology (Smart Ropes):

- Fiber Optic Sensors: For real-time monitoring of strain, temperature, and structural integrity.

- Piezoelectric Sensors & Accelerometers: To detect vibrations, load changes, and early signs of fatigue.

- Magnetic Flux Leakage (MFL) Sensors: For detecting internal wire breaks and material loss.

- Non-Destructive Testing (NDT) Methods: Evolution of electromagnetic inspection, acoustic emission testing, and visual inspection techniques for accurate rope condition assessment.

- Digital Twin & Predictive Analytics: Creation of virtual models and AI-driven analysis of sensor data for predictive maintenance and optimized replacement schedules.

- Lubrication & Greasing Technologies: Development of specialized lubricants and greases for extended internal protection and reduced friction.

- Compacted Rope Technology: Process of compacting strands before closing to achieve higher metallic cross-section, increased strength, and improved abrasion resistance.

Regional Highlights

The global Steel Wire Rope Market exhibits distinct regional dynamics driven by varying levels of industrialization, infrastructure spending, regulatory environments, and economic growth patterns. Each region contributes uniquely to the market's overall expansion and presents specific opportunities and challenges for market players. Asia Pacific, for instance, stands as the undisputed leader, propelled by its rapidly expanding economies and colossal investments in infrastructure, manufacturing, and urban development. North America and Europe, while mature, demonstrate stable demand for high-performance and specialized ropes, driven by stringent safety regulations and modernization of existing infrastructure. Latin America and the Middle East & Africa are emerging as significant growth pockets, primarily due to robust activity in resource extraction, energy projects, and burgeoning construction sectors. Understanding these regional nuances is critical for effective market strategy and resource allocation.

- North America: This region is characterized by a mature industrial base and a strong emphasis on safety and advanced technology. The demand for steel wire ropes is primarily driven by infrastructure repair and maintenance, particularly in bridges, railways, and utilities. The construction sector, especially commercial and residential building, remains a consistent consumer. The oil and gas industry, while cyclical, demands high-performance and specialized ropes for drilling and extraction activities. Furthermore, the robust manufacturing sector and ongoing investments in renewable energy, such as wind farms, contribute significantly to market stability and growth. Strict regulatory standards mandate the use of certified and high-quality products, fostering a market for premium wire rope solutions.

- Europe: Europe represents a technologically advanced and highly regulated market for steel wire ropes. Key drivers include significant investments in renewable energy infrastructure, particularly offshore wind farms and hydroelectric projects, which require specialized high-strength and corrosion-resistant ropes. The robust automotive industry, industrial manufacturing, and ongoing modernization of existing infrastructure (bridges, ports, public transport) also contribute substantially. Strict European Union safety and environmental directives influence product development towards more durable, efficient, and environmentally friendly wire ropes. Germany, the UK, France, and Italy are major contributors, with strong manufacturing capabilities and high-tech application sectors.

- Asia Pacific (APAC): The APAC region is the fastest-growing and largest market globally, fueled by rapid industrialization, urbanization, and massive infrastructure development projects, especially in China, India, and Southeast Asian countries like Indonesia and Vietnam. The booming construction sector, extensive mining operations, and significant investments in port infrastructure and logistics drive immense demand for both general engineering and specialized wire ropes. The region also hosts a large portion of the world's manufacturing capacity for steel wire ropes, making it a competitive and innovation-driven hub. Economic development and increasing trade volumes further bolster the demand across various end-use industries, establishing APAC as the powerhouse of the global market.

- Latin America: This region presents a market with considerable growth potential, primarily driven by its rich natural resources and ongoing commodity extraction activities. The mining industry, particularly in countries like Chile, Brazil, and Peru, is a major consumer of steel wire ropes for hoist systems and excavation equipment. Investments in oil and gas exploration, particularly offshore projects in Brazil and Mexico, also contribute significantly. Infrastructure development, albeit at a varied pace across countries, supports demand from the construction and transportation sectors. Economic stability and foreign investment influx are key determinants of market expansion in this region.

- Middle East & Africa (MEA): The MEA market is largely influenced by substantial investments in the oil and gas sector, particularly in Saudi Arabia, UAE, and Qatar, which demand high-specification wire ropes for drilling, production, and marine applications. Rapid urbanization and ambitious infrastructure development projects, including smart cities and transportation networks, are also strong market drivers in the GCC countries. In Africa, growth is predominantly spurred by the expansion of the mining industry (South Africa, Ghana), and the development of port facilities and renewable energy projects. Geopolitical stability and diversification efforts away from oil economies are shaping the long-term demand dynamics in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Steel Wire Rope Market.- WireCo WorldGroup

- Bridon-Bekaert Ropes Group

- Kiswire

- Tokyo Rope Mfg. Co., Ltd.

- Usha Martin Limited

- BBN Group

- Gustav Wolf GmbH

- Fagersta Stainless AB

- DIEPA Drahtseilwerk GmbH & Co. KG

- PFEIFER Seil- und Hebetechnik GmbH

- TEUFELBERGER Seilbahnen

- DSR Corporation

- Guizhou Wire Rope Co., Ltd.

- Jiangsu Langshan Wire Rope Co., Ltd.

- ScanRope AS

- Verope AG

- YoungHeung Iron & Steel Co., Ltd.

- J.D. Neuhaus GmbH & Co. KG

- Condor Hoist & Crane, Inc.

- Bethlehem Wire Rope

Frequently Asked Questions

What is the projected growth rate for the Steel Wire Rope Market?

The Steel Wire Rope Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033, driven by global infrastructure development and industrial demand.

Which industries are the primary end-users of steel wire ropes?

The primary end-user industries include construction, mining, oil and gas, marine, transportation, and renewable energy, all requiring high-strength and durable ropes for critical operations.

How does AI impact the Steel Wire Rope Market?

AI impacts the market by enabling predictive maintenance through sensor integration, optimizing manufacturing processes, enhancing safety with real-time monitoring, and fostering innovation in smart rope design.

What are the main types of steel wire ropes available?

Steel wire ropes are categorized by type into General Engineering Ropes, High-Performance Ropes, Structural Ropes, Rotation Resistant Ropes, Compact Ropes, each designed for specific application requirements.

Which region currently dominates the Steel Wire Rope Market?

The Asia Pacific region currently dominates the Steel Wire Rope Market, driven by extensive infrastructure development, rapid industrialization, and significant investments in manufacturing across countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager