Stepper Motor Linear Actuators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433215 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Stepper Motor Linear Actuators Market Size

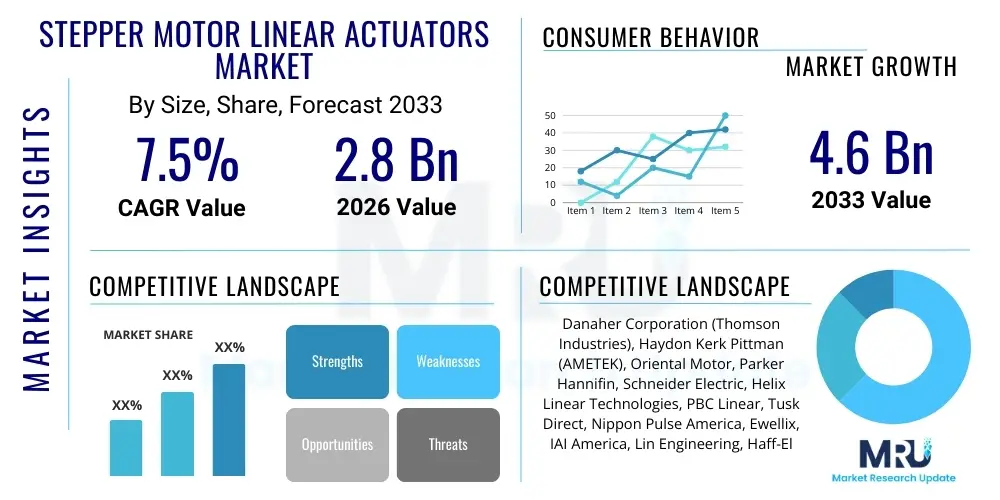

The Stepper Motor Linear Actuators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 2.8 Billion in 2026 and is projected to reach USD 4.6 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by the increasing global demand for high-precision, repeatable positioning systems across advanced manufacturing sectors, particularly semiconductor fabrication and specialized medical instrumentation. Stepper motor linear actuators offer an optimal balance of cost-effectiveness, precision control, and simplified digital interfacing, making them essential components in the ongoing automation revolution.

Stepper Motor Linear Actuators Market introduction

The Stepper Motor Linear Actuators Market encompasses electromechanical devices that convert the rotary motion of a stepper motor into precise linear displacement, providing highly controllable and accurate movement without the need for complex feedback systems in many standard applications. These actuators typically integrate a lead screw or a ball screw mechanism directly coupled to the stepper motor shaft, facilitating incremental, repeatable, and non-back-drivable motion essential for precision tasks. The core function of these devices is to manage thrust and speed with exceptional resolution, often measured in micrometers, which is critical in sophisticated modern machinery.

Major applications of stepper motor linear actuators span a wide array of industries, including diagnostic and surgical robots in the medical field, high-speed dispensing systems in electronics manufacturing, and intricate positioning stages utilized in quality assurance and inspection equipment. Their inherent ability to hold position firmly without continuous power input (holding torque) provides a significant advantage in pick-and-place robotics and focusing mechanisms. The growth trajectory of this market is intrinsically tied to the acceleration of Industry 4.0 initiatives globally, where automation and interconnected smart factory components require robust, digitally controllable motion systems that can operate reliably under varied operational loads and environmental conditions.

The primary benefits driving the adoption of these actuators include their high positioning accuracy, simplified control architecture that minimizes system complexity, and excellent repeatability crucial for mass production processes. Furthermore, the inherent digital nature of stepper motors allows for easy integration with modern machine control systems (PLCs and microcontrollers). Key driving factors include the rapid expansion of the 3D printing sector demanding reliable Z-axis movement, the continuous miniaturization of electronic components necessitating finer assembly tolerances, and the burgeoning demand for laboratory automation equipment in life sciences research. These trends collectively underscore the stepper motor linear actuator's pivotal role in enabling next-generation precision manufacturing.

Stepper Motor Linear Actuators Market Executive Summary

The Stepper Motor Linear Actuators Market is experiencing dynamic growth, propelled by robust business trends emphasizing digital manufacturing, customization, and efficient energy consumption across industrial automation landscapes. A significant trend involves the increasing preference for closed-loop stepper systems, which incorporate encoders to offer superior torque handling and positional feedback, bridging the performance gap previously held exclusively by servo systems, thereby enhancing reliability in mission-critical applications like automated fluid handling and inspection systems. Furthermore, market competition is driving innovation towards miniaturization and higher power density, allowing these actuators to be integrated into smaller, more compact equipment designs without sacrificing performance, which is vital for portable medical devices and space-constrained factory environments.

Regionally, the Asia Pacific (APAC) stands out as the predominant growth engine, driven by massive investments in domestic semiconductor manufacturing capacity in countries like China, Taiwan, and South Korea, coupled with the exponential growth of the electronics assembly sector. North America and Europe maintain strong market positions, primarily due to their established aerospace, medical device manufacturing, and high-end industrial machinery sectors, which demand customized, high-reliability actuator solutions adhering to stringent regulatory standards. The transition toward localized, automated supply chains post-pandemic has further amplified demand for motion control components across all major geographic zones, focusing on optimizing efficiency and reducing reliance on manual processes.

Segment trends indicate that the lead screw type segment, valued for its simplicity and affordability, remains dominant in high-volume, general industrial applications, while the ball screw segment is showing the fastest growth rate, owing to its superior efficiency, reduced friction, and higher load bearing capabilities required in precision machine tools and advanced automation cells. By application, the semiconductor and electronics segment is the largest consumer, fueled by the relentless demand for microchip production. Meanwhile, the medical and laboratory automation segments are anticipated to exhibit accelerated growth as pharmaceutical companies invest heavily in automated drug discovery and testing platforms, where precise volumetric dosing and positioning are paramount.

AI Impact Analysis on Stepper Motor Linear Actuators Market

User inquiries regarding the impact of Artificial Intelligence on the Stepper Motor Linear Actuators Market frequently revolve around three core themes: predictive maintenance capabilities, enhanced control system optimization, and the integration of AI-driven robotics requiring higher operational speed and precision. Users are keen to understand how AI algorithms can monitor actuator performance in real-time to predict failures, thereby minimizing downtime in continuous manufacturing operations. Furthermore, there is significant expectation that AI will refine complex motion profiles and load compensation, allowing stepper motors to operate closer to their physical limits without compromising positional accuracy or lifespan. The general sentiment is that while AI does not directly replace the hardware, it profoundly optimizes the performance and reliability of these electromechanical systems, particularly in high-throughput, dynamic environments where operational parameters constantly shift.

The integration of machine learning models into actuator control units facilitates advanced diagnostics and anomaly detection, moving beyond simple threshold alerts to pattern recognition that identifies subtle degradations in screw efficiency or motor resonance signatures. This shift towards smart maintenance means end-users can significantly extend the operational lifespan of their machinery and transition from scheduled maintenance routines to condition-based servicing, which maximizes asset utilization. As manufacturing processes become more adaptive and personalized, driven by AI planning systems, the underlying motion components, including stepper motor linear actuators, must offer instantaneous data feedback and highly dynamic response capabilities, compelling manufacturers to incorporate smarter sensors and data processing architectures directly into the actuator design.

Concurrently, AI is driving the demand for actuators with enhanced communication interfaces capable of handling larger streams of operational data required for training sophisticated learning models. This influences the design towards integrated industrial ethernet protocols (like EtherCAT or PROFINET) and edge computing capabilities. The long-term expectation is that AI will enable stepper systems to achieve near-servo performance levels in challenging applications by dynamically compensating for mechanical backlash, thermal expansion, and variable load inertia, unlocking new application areas previously inaccessible to conventional open-loop stepper solutions and cementing their relevance in advanced robotic manipulators.

- AI enables predictive maintenance by analyzing vibration and thermal signatures of the lead or ball screw mechanism.

- Machine learning optimizes complex motion profiles for speed and acceleration, preventing step loss under high load.

- AI-driven control systems facilitate dynamic backlash and compliance compensation, boosting overall system accuracy.

- Enhanced data logging and communication protocols are necessitated by AI for comprehensive operational training datasets.

- AI integration drives demand for closed-loop actuators with integrated high-resolution absolute encoders.

- Optimized energy usage and thermal management in actuators through AI-based workload distribution.

DRO & Impact Forces Of Stepper Motor Linear Actuators Market

The Stepper Motor Linear Actuators Market is driven by the escalating demand for automated precision in manufacturing, coupled with the inherent cost-effectiveness and high-resolution positioning capabilities of stepper-based systems compared to more expensive servo alternatives. Major drivers include the rapid expansion of industrial robotics, the stringent accuracy requirements in diagnostic and surgical instruments within the healthcare sector, and the proliferation of 3D printing and additive manufacturing technologies. The simplicity of digital control and the ability of stepper motors to maintain position without continuous external braking or complex closed-loop control in many low-to-medium dynamic applications further solidifies their market position. However, this growth is partially restrained by limitations such as the inherent risk of step loss under extreme load or acceleration conditions, which necessitates the adoption of more costly closed-loop variants, and their relatively lower speed compared to high-end servo motor solutions.

Opportunities for market expansion are abundant in emerging markets focusing on establishing advanced manufacturing hubs, particularly in Southeast Asia and Latin America, alongside the burgeoning development of specialized small-scale automation devices. The push towards integrating smart components in the Internet of Things (IoT) framework opens up avenues for stepper actuators featuring embedded condition monitoring and network connectivity. Furthermore, the development of advanced materials for lead screws, such as specialized polymers and ceramics, promises reduced friction, enhanced wear resistance, and minimized maintenance requirements, thereby broadening their applicability in harsh or sensitive environments. These technological advancements create significant headroom for market penetration into traditionally underserved segments.

The impact forces shaping this market include technological substitution pressure from advanced brushless DC (BLDC) motor linear actuators, which offer superior speed and efficiency in high-dynamic applications, requiring stepper manufacturers to constantly innovate, particularly in closed-loop control algorithms. Economic instability and fluctuating material costs (especially for precision-machined components like ball screws) act as constraining forces, influencing pricing strategies and supply chain resilience. Conversely, regulatory mandates in the medical and aerospace sectors demanding greater traceability and precision in manufacturing processes exert a powerful positive force, favoring specialized, high-quality stepper linear actuators that meet demanding performance specifications and certification requirements.

Segmentation Analysis

The Stepper Motor Linear Actuators Market is intricately segmented based on core mechanical design, motor control methodology, and end-use application, providing a granular view of market dynamics and tailored customer needs. Understanding these segmentations is critical for manufacturers to align product development with specific industry demands, such as optimizing torque for industrial automation versus ensuring ultra-quiet operation for medical devices. The primary segments revolve around the type of screw mechanism employed, which dictates efficiency and load capacity, and the sophistication of the motor control, differentiating between basic open-loop functionality and advanced closed-loop precision.

The segmentation by screw type includes the highly accurate, low-friction Ball Screw Actuators, which dominate high-end precision machinery, and the simpler, cost-effective Lead Screw Actuators, preferred for lower duty cycles and light-to-moderate load applications where high holding force is essential. Further differentiation occurs based on the power rating and frame size of the stepper motor, directly correlating with the required force output and dimensional constraints of the target application. This allows system integrators to precisely select components that match the required specifications for speed, resolution, and physical footprint, minimizing over-specification and cost.

Application-based segmentation highlights the major consuming industries, with Industrial Automation (including packaging and assembly) being the volume leader, while specialized sectors like Semiconductor Manufacturing and Medical Devices command premium pricing due to stringent cleanliness, reliability, and precision requirements. This diverse application landscape emphasizes the versatility of stepper motor linear actuators as fundamental building blocks in various technological advancements, from large factory production lines to highly specific laboratory instruments.

- Screw Type:

- Ball Screw Linear Actuators

- Lead Screw Linear Actuators

- Motor Control:

- Open-Loop Actuators

- Closed-Loop Actuators (with integrated encoder feedback)

- Force Rating:

- Low Force (up to 500 N)

- Medium Force (500 N to 2,000 N)

- High Force (above 2,000 N)

- Application:

- Industrial Automation (Assembly, Packaging, Material Handling)

- Semiconductor and Electronics Manufacturing (Pick-and-Place, Dispensing)

- Medical and Laboratory Automation (Fluidics, Diagnostic Equipment, Imaging)

- 3D Printing and Additive Manufacturing

- Aerospace and Defense

- Optical Equipment and Photonics

- End-Use Industry:

- Automotive

- Healthcare and Pharmaceuticals

- Consumer Electronics

- Machine Tools

Value Chain Analysis For Stepper Motor Linear Actuators Market

The value chain for the Stepper Motor Linear Actuators Market begins with the upstream suppliers of critical raw materials and specialized components, including magnetic materials (for stepper motors), high-grade stainless steel or engineered plastics for screws and nuts, and precision bearings. Upstream analysis focuses heavily on the procurement of rare earth magnets (Neodymium) essential for high-torque motors and the specialized grinding and finishing processes required for achieving the micro-level tolerances of ball screws. Efficiency and cost control at this stage are paramount, as material scarcity or price volatility directly impacts the final product cost. Component suppliers, such such as those providing specialized encoders for closed-loop systems, represent a critical upstream input determining the technological capability of the finished actuator unit.

The middle segment of the value chain involves the design, assembly, and integration of the stepper motor with the linear mechanism. This stage includes core manufacturing activities like precision machining, coil winding, and rigorous quality control testing (e.g., measuring positional repeatability and lifespan). Manufacturers either specialize in the complete integrated unit or source standardized components (like motors) and focus on actuator mechanism development. Distribution channels are varied: direct sales often handle large industrial original equipment manufacturers (OEMs) requiring extensive customization and technical support, while indirect channels utilize specialized industrial distributors and component retailers to serve small and medium enterprises (SMEs) and maintenance/repair/operations (MRO) markets.

Downstream analysis centers on end-users and post-sales services. The demand is driven by system integrators who incorporate these actuators into complex machinery, and by end-use industries such as medical device manufacturers or semiconductor foundries. Customer satisfaction is heavily influenced by technical support, availability of replacement parts, and the robustness of the actuator in long-term, high-duty cycle applications. The increasing complexity of integrated automation solutions mandates strong collaboration between actuator manufacturers and system integration partners to ensure seamless compatibility and optimal performance, especially when utilizing advanced networking and control architectures.

Stepper Motor Linear Actuators Market Potential Customers

The primary potential customers and end-users of Stepper Motor Linear Actuators are organizations that require high-resolution, reliable, and digitally controllable linear motion in a cost-effective package. This segment is dominated by Original Equipment Manufacturers (OEMs) specializing in automated machinery, ranging from small desktop equipment to large-scale industrial robotic cells. Key buyers include manufacturers of Computer Numerical Control (CNC) machinery, specialized 3D printing equipment builders focused on high-accuracy industrial materials, and producers of analytical instrumentation used in laboratory settings where precise fluid dispensing or sample manipulation is mandatory.

A rapidly growing segment of potential customers resides in the medical device and pharmaceutical industries. These buyers utilize stepper linear actuators extensively in automated drug discovery systems, precision liquid handlers, diagnostic imaging equipment (where focusing mechanisms require fine adjustment), and robotic surgical assistants. For these customers, factors like reliability, low particulate generation, and compliance with strict regulatory standards (such as ISO 13485) are prioritized over pure cost, driving demand for premium, often closed-loop, stainless steel or ceramic components suitable for sterile environments.

Furthermore, semiconductor manufacturing facilities and electronics assembly houses are crucial potential customers. They deploy these actuators in high-speed pick-and-place robots, wafer inspection stages, and component dispensing machines, where positional accuracy down to the sub-micron level is critical for yield rates. The ongoing global expansion of microchip production guarantees sustained, high-volume demand from this highly demanding sector, constantly seeking faster and more reliable motion solutions to keep pace with Moore’s Law.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.8 Billion |

| Market Forecast in 2033 | USD 4.6 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Danaher Corporation (Thomson Industries), Haydon Kerk Pittman (AMETEK), Oriental Motor, Parker Hannifin, Schneider Electric, Helix Linear Technologies, PBC Linear, Tusk Direct, Nippon Pulse America, Ewellix, IAI America, Lin Engineering, Haff-Elektro, Applied Motion Products, Bishop-Wisecarver, Venture Mfg. Co., Aerotech, HIWIN Technologies, MOONS' Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stepper Motor Linear Actuators Market Key Technology Landscape

The technological landscape of the Stepper Motor Linear Actuators Market is defined by continuous innovation aimed at enhancing precision, increasing speed, and improving energy efficiency while maintaining cost competitiveness. A pivotal development is the widespread adoption of integrated closed-loop control systems, which utilize high-resolution rotary or linear encoders to monitor the rotor position in real-time. This technology eliminates the risk of step loss, a traditional weakness of stepper motors, thereby allowing them to handle higher dynamic loads and accelerations, significantly expanding their application scope into areas previously dominated by servo motors. Furthermore, closed-loop systems allow for dynamic adjustment of current based on load requirements, leading to reduced heat generation and improved energy efficiency, a crucial factor in modern factory automation.

Another significant technological advancement centers on the mechanical interface, specifically the design and manufacturing precision of the lead screw and ball screw mechanisms. Manufacturers are increasingly utilizing precision-rolled and ground screws with specialized coatings (like PTFE or proprietary anti-friction treatments) to minimize wear, reduce stick-slip effects, and maximize service life, especially in high-duty cycle applications. The integration of anti-backlash nut technologies, often involving preloaded split nuts or spring-loaded designs, ensures minimal play and maximum repeatability, critical for applications like high-resolution focusing systems and micro-dosing pumps where even minute errors are unacceptable. Material science also plays a role, with lightweight and durable composite materials being explored for certain components to reduce inertia.

Control electronics are rapidly evolving, integrating advanced features such as micro-stepping, which electronically subdivides the motor’s basic step angle, dramatically increasing resolution and resulting in smoother, quieter motion profiles. Newer driver technologies incorporate resonance suppression and ripple control algorithms, optimizing motor performance across a wider speed range and reducing operational noise, which is vital for medical and laboratory settings. The trend toward digital integration also includes the incorporation of industrial communication protocols (e.g., EtherCAT, CANopen) directly into the motor drive, enabling decentralized control architectures and seamless communication within the broader Industry 4.0 framework.

Regional Highlights

The Stepper Motor Linear Actuators Market exhibits distinct regional consumption patterns, reflecting varying levels of industrialization, technological maturity, and government investment in key manufacturing sectors.

- Asia Pacific (APAC): APAC is the fastest-growing and largest regional market, primarily fueled by the exponential growth of electronics assembly, consumer goods manufacturing, and massive infrastructure investments in semiconductor fabrication plants (especially in China, Taiwan, and South Korea). The region benefits from lower manufacturing costs, making stepper actuators a highly attractive solution for high-volume automation lines. Countries like India and Southeast Asian nations are rapidly adopting automation to enhance competitive edge, ensuring sustained demand for essential motion components.

- North America: Characterized by early adoption of advanced automation and stringent quality requirements, North America remains a lucrative market, dominated by demand from specialized high-tech industries, including aerospace, defense, and sophisticated medical device manufacturing. The focus here is often on closed-loop, high-reliability actuators that meet specific certifications (e.g., FDA clearance for medical applications), often commanding premium pricing.

- Europe: Europe is a mature market driven by the robust machine tool industry (Germany, Italy) and the automotive sector's shift towards electric vehicle production lines, requiring precise, reliable assembly automation. Strong emphasis is placed on efficiency, energy consumption standards, and compliance with EU machinery directives, favoring suppliers who offer highly efficient, durable linear motion solutions integrated into decentralized control networks.

- Latin America (LATAM): The LATAM market is emerging, driven by modernization efforts in packaging, food and beverage processing, and specialized machinery manufacturing. While price sensitivity is generally higher, increasing foreign direct investment in manufacturing is gradually raising the adoption rate of advanced automation components, particularly in Brazil and Mexico.

- Middle East and Africa (MEA): MEA is the smallest market, though growth is visible, primarily linked to infrastructure projects, oil and gas processing modernization, and nascent pharmaceutical manufacturing initiatives in countries like Saudi Arabia and the UAE. Demand is project-based and concentrated in sectors requiring robust, high-force actuators capable of operating in challenging environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stepper Motor Linear Actuators Market.- Danaher Corporation (Thomson Industries)

- Haydon Kerk Pittman (AMETEK)

- Oriental Motor Co., Ltd.

- Parker Hannifin Corporation

- Schneider Electric SE

- Helix Linear Technologies

- PBC Linear (Pacific Bearing Company)

- Tusk Direct, Inc.

- Nippon Pulse America, Inc.

- Ewellix AB

- IAI America, Inc.

- Lin Engineering (A Curtiss-Wright Company)

- Haff-Elektro AG

- Applied Motion Products, Inc.

- Bishop-Wisecarver Corporation

- Venture Mfg. Co.

- Aerotech, Inc.

- HIWIN Technologies Corp.

- MOONS' Industries (America) Inc.

- New Scale Technologies, Inc.

Frequently Asked Questions

Analyze common user questions about the Stepper Motor Linear Actuators market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of closed-loop stepper motor linear actuators over traditional open-loop systems?

Closed-loop stepper linear actuators incorporate high-resolution encoders, eliminating the risk of step loss under high load or acceleration. This provides improved positional accuracy, higher dynamic response, and the ability to operate at maximum torque, making them suitable for critical, high-precision applications like surgical robotics and advanced dispensing systems.

How does the choice between ball screw and lead screw mechanisms affect actuator performance?

Ball screw actuators offer superior efficiency, higher speed, and larger load capacity due to lower friction, making them ideal for continuous, high-duty cycle industrial automation. Lead screw actuators are simpler, more cost-effective, and provide superior holding torque (non-back-driving capability) suitable for low-to-moderate duty cycles and vertical positioning where self-locking is required.

Which industry accounts for the largest demand for stepper motor linear actuators globally?

The Industrial Automation sector, encompassing general assembly, packaging, and material handling, represents the largest consumer segment. However, the Semiconductor and Electronics Manufacturing industry, driven by the need for ultra-precision positioning in wafer handling and micro-assembly, is the fastest-growing segment in terms of technological advancement and revenue per unit.

What role does micro-stepping play in optimizing the performance of these linear actuators?

Micro-stepping is an electronic technique that increases the effective resolution of the actuator by subdividing the motor's full step angle. This results in significantly smoother motion, reduced mechanical vibration and noise, and enhanced positional accuracy, which is essential for scanning applications and instruments sensitive to motion quality.

Are stepper motor linear actuators suitable for vacuum or cleanroom environments?

Yes, specialized stepper motor linear actuators are widely designed for vacuum and cleanroom use, particularly those utilized in semiconductor fabrication. These models often feature specialized materials, low outgassing lubricants, and are built to stringent cleanroom standards (e.g., ISO Class 1 or higher) to minimize particle generation and ensure contamination control.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager