Stone Gypsum Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439644 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Stone Gypsum Market Size

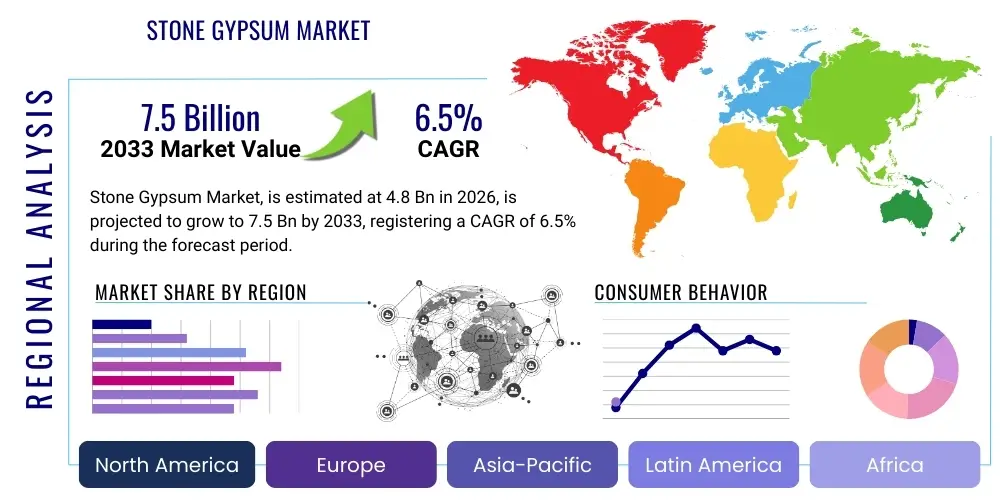

The Stone Gypsum Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 billion in 2026 and is projected to reach USD 7.5 billion by the end of the forecast period in 2033.

Stone Gypsum Market introduction

Stone gypsum, scientifically classified as hydrated calcium sulfate (CaSO4·2H2O), is a ubiquitous naturally occurring mineral that has served as a cornerstone material across construction and various industrial sectors for thousands of years. Its unique crystalline structure and chemical composition endow it with an exceptional array of advantageous properties, fundamentally including inherent fire resistance, superior sound absorption capabilities, effective thermal insulation, and remarkable ease of workability. These collective characteristics position gypsum as a foundational material in contemporary building practices, significantly contributing to the safety, comfort, energy efficiency, and overall structural integrity of modern edifices. Gypsum is typically found in extensive sedimentary deposits, formed through the geological evaporation of ancient seas, making it an abundantly available natural resource distributed globally.

The market for stone gypsum encompasses a diverse and expanding portfolio of products, predominantly including plaster, plasterboard (commonly known as drywall), and specialized gypsum-based building blocks. These applications ingeniously leverage gypsum's ability to undergo calcination, where controlled heating transforms it into plaster of Paris (a hemihydrate form), which subsequently rehydrates and sets to create a rigid, durable, and highly versatile material. Beyond its pervasive role in conventional construction, stone gypsum finds critical applications in the cement manufacturing industry, where it acts as an essential retarder to precisely control the setting time of Portland cement mixes, thereby improving workability and preventing undesirable flash setting. Furthermore, in the vital agricultural sector, it serves as a highly effective soil amendment, demonstrably enhancing soil structure, mitigating salinity, and supplying crucial nutrients such as calcium and sulfur, which are paramount for promoting robust crop yields and fostering overall soil health. Its multifaceted benefits, encompassing both profound functional performance and compelling environmental advantages through the increasing adoption of synthetic alternatives, continue to propel its pervasive demand across multiple key economic sectors worldwide.

Several pivotal factors are concurrently driving the sustained and robust growth of the global stone gypsum market. Foremost among these is the unrelenting pace of global urbanization, coupled with significant public and private sector investments in infrastructure development, and the burgeoning demand for residential and commercial spaces globally, particularly across rapidly industrializing emerging economies. The escalating need for vast quantities of high-performance building materials is met efficiently by gypsum, which offers a cost-effective, versatile, and high-performance solution. Moreover, a heightened global emphasis on sustainable construction practices and increasingly stringent building codes pertaining to fire safety, energy efficiency, and indoor air quality further bolsters market expansion. The rising adoption of synthetic gypsum, meticulously derived from industrial processes such as flue gas desulfurization, offers an environmentally friendly alternative, directly addressing resource conservation concerns and actively contributing to circular economy initiatives. This powerful confluence of demand drivers, coupled with continuous technological advancements in processing and product formulation, emphatically underscores the market's dynamic and robust growth trajectory.

Stone Gypsum Market Executive Summary

The Stone Gypsum Market is strategically positioned for sustained expansion, propelled by an intricate interplay of global construction booms, continuous technological advancements, and a heightened, pervasive focus on sustainability across industries. Current business trends indicate a significant and systemic shift towards optimizing operational efficiency, frequently facilitated by advanced automation and comprehensive digital integration across manufacturing processes. There is a palpable movement towards relentless product innovation, with leading manufacturers substantially investing in intensive research and development to engineer advanced gypsum-based materials that offer superior performance characteristics. These include enhanced moisture resistance for wet environments, increased structural strength-to-weight ratios, and improved thermal and acoustic insulation values, catering to evolving architectural and engineering demands. Furthermore, strategic market consolidation through meticulously planned mergers, astute acquisitions, and collaborative partnerships remains a key competitive tactic for companies aiming to expand their geographical footprint, diversify product portfolios, and achieve substantial economies of scale within an increasingly competitive global landscape. The market's inherent resilience is further bolstered by consistent demand from dynamic renovation and remodeling sectors, complementing the vigorous pace of new construction.

From a comprehensive regional perspective, the market exhibits highly varied dynamics, accurately reflecting differing stages of economic development, specific construction trends, and distinct regulatory environments. The Asia Pacific region undeniably stands out as the primary growth engine, fueled by unprecedented rates of urbanization, extensive government-backed infrastructure projects, and a booming residential construction sector, with economic powerhouses like China, India, and Indonesia leading this robust expansion. North America and Europe, while representing more mature and established markets, demonstrate stable and consistent demand, largely propelled by ongoing renovation and remodeling activities, a strong societal focus on stringent green building certifications, and the widespread adoption of high-performance, specialized gypsum products compliant with advanced building codes. Conversely, the Middle East and Africa (MEA) region is experiencing an accelerated growth trajectory, invigorated by ambitious mega-projects and concerted economic diversification efforts away from traditional oil-dependent economies, while Latin America is witnessing consistent growth spurred by economic recovery, increasing foreign investment, and ongoing national housing initiatives.

Segmentation trends within the stone gypsum market comprehensively underscore the overwhelming dominance of the building and construction sector, which collectively consumes the vast majority of global gypsum production for essential applications such as plasterboard, drywall, and various plaster finishes. Within this critical segment, the residential and commercial sub-segments are firmly projected to maintain their leading positions, driven by continuous global demand for new housing units and modern business infrastructure development. A particularly notable and impactful trend is the rapidly increasing market penetration of synthetic gypsum, which is steadily gaining significant traction over its natural counterpart owing to evolving environmental regulations, cost-effectiveness in certain regional contexts, and its superior, consistent purity profile. The industrial segment, encompassing diverse uses in cement manufacturing and specialized plasters, along with the burgeoning agricultural sector for crucial soil amendment purposes, are also expected to exhibit steady, albeit comparatively slower, growth. This intricate and comprehensive segmentation reflects a market that is inherently diversified in its applications and increasingly responsive to pivotal environmental sustainability imperatives, cutting-edge technological advancements, and shifting global economic paradigms.

AI Impact Analysis on Stone Gypsum Market

The strategic integration of Artificial Intelligence (AI) into the Stone Gypsum Market is profoundly poised to revolutionize traditional operational paradigms, meticulously addressing critical concerns such as efficiency, granular cost management, innovative product development, and overarching environmental sustainability. Industry stakeholders are actively querying and exploring how AI can be most effectively deployed to optimize complex resource allocation, automate intricate manufacturing processes, and provide highly predictive insights into dynamic market demand fluctuations and potential supply chain vulnerabilities. There is a strong and pervasive user interest in thoroughly understanding AI's multifaceted capabilities for advanced geological data analysis to identify new gypsum deposits more efficiently, optimize precise blast patterns in mining operations, and significantly enhance real-time quality control during calcination and subsequent plasterboard production. Users are also keenly interested in AI-driven solutions explicitly tailored for minimizing waste generation, improving energy consumption profiles in notoriously high-energy processes like drying, and robustly fostering circular economy practices by refining the sophisticated processing of recycled gypsum and synthetic alternatives, thereby maximizing resource utilization and minimizing ecological footprint.

Beyond the immediate and tangible operational improvements, the market is aggressively exploring AI's transformative potential in pioneering product development and bespoke customization. Enquiries frequently focus on how advanced AI algorithms can accurately simulate and rigorously predict the performance characteristics of novel gypsum composites, enabling the precise design of materials with substantially improved fire resistance, superior acoustic properties, and enhanced structural integrity without the need for extensive and costly physical prototyping. Furthermore, the pivotal role of AI in creating smarter, more responsive building materials that possess the inherent capability to adapt dynamically to environmental changes or intelligently monitor structural health is a burgeoning and highly promising area of interest for future market growth. The overarching expectation is that AI will unequivocally serve as a transformative tool, not only streamlining and optimizing current industrial processes but also unlocking unprecedented new avenues for innovation, significantly reducing the industry's environmental footprint, and substantially bolstering the competitive edge of market players through sophisticated data-driven decision-making and advanced levels of automation across the entire value chain, ushering in a new era of efficiency and sustainability.

- AI-powered predictive maintenance programs can significantly optimize the operational lifespan of heavy machinery utilized in gypsum mining and processing operations, thereby minimizing unscheduled downtime, substantially reducing maintenance costs, and ensuring a continuous and uninterrupted production flow. This allows for a highly proactive rather than merely reactive approach to comprehensive equipment management and asset utilization.

- Advanced AI algorithms are being strategically deployed to dramatically enhance demand forecasting accuracy, meticulously integrating multiple disparate data points such as construction permits issued, macroeconomic indicators, and nuanced seasonal trends to optimize inventory levels and precisely align production schedules. This effectively reduces instances of overproduction, minimizes substantial storage costs, and proactively prevents critical supply shortages.

- The meticulous development of next-generation gypsum-based materials profoundly benefits from AI-assisted design and sophisticated simulation tools, enabling researchers to accurately predict material properties and performance characteristics under a wide array of operational conditions. This significantly accelerates the innovation cycle for products boasting improved strength, superior thermal insulation capabilities, and enhanced fire resistance.

- AI-driven process control systems are critically important for optimizing energy consumption in energy-intensive stages such as gypsum calcination and drying processes. These intelligent systems continuously monitor key parameters like temperature, humidity, and pressure, making real-time adjustments to operations to achieve maximum energy efficiency and substantially reduce carbon emissions, aligning with global sustainability goals.

- AI-enabled quality control systems ingeniously utilize machine vision and a sophisticated array of sensor data to detect minute defects, impurities, and inconsistencies in gypsum boards and plasters with remarkable precision and speed. This ensures that product quality standards are consistently met or exceeded, significantly reducing material waste and invariably improving overall customer satisfaction and brand loyalty.

- Leveraging AI for comprehensive geological surveying and meticulous resource exploration profoundly facilitates the more efficient identification of new gypsum deposits. AI analyzes vast and complex datasets encompassing seismic, satellite, and geological information, precisely pinpointing promising locations and optimizing drilling strategies, thereby substantially reducing exploration costs and accelerating discovery timelines.

- The strategic integration of robotics and AI in the intricate handling, precise stacking, and efficient packaging of gypsum products automates numerous labor-intensive tasks on the factory floor. This not only significantly enhances operational efficiency and throughput but also dramatically improves workplace safety by minimizing human exposure to hazardous heavy lifting and repetitive manual tasks.

- AI applications are increasingly pivotal in advancing comprehensive circular economy initiatives within the gypsum market, particularly in the highly effective recycling of construction and demolition waste containing gypsum. AI can optimize complex sorting, advanced purification, and sophisticated reprocessing techniques, ensuring that high-quality recycled gypsum can be seamlessly reintroduced into the production cycle, thus significantly reducing landfill waste and actively conserving valuable natural resources.

DRO & Impact Forces Of Stone Gypsum Market

The Stone Gypsum Market is dynamically shaped by a complex and ever-evolving interplay of Drivers, Restraints, and Opportunities, which collectively constitute its pivotal Impact Forces. Significant drivers propelling robust market growth include the relentless and escalating pace of global construction activities, particularly pronounced in the burgeoning residential, expansive commercial, and critical infrastructure sectors across both rapidly industrializing emerging economies and established developed nations. Prevailing urbanization trends, coupled with sustained global population growth and substantial governmental and private sector investments in extensive public works and housing development schemes, collectively generate an insatiable demand for essential building materials like gypsum. Furthermore, the inherent superior properties of gypsum, such as its exceptional fire-resistant qualities, highly effective soundproofing capabilities, and notable thermal insulation benefits, emphatically position it as a preferred material for achieving enhanced safety, superior comfort, and optimal energy efficiency in contemporary buildings. These advantages align perfectly with increasingly stringent global building codes and growing consumer preferences for highly sustainable and resilient structures. The rising adoption of advanced prefabricated gypsum components and streamlined modular construction techniques also contributes significantly to demand, accelerating construction processes and substantially reducing overall project timelines and labor costs.

However, the market's expansive growth trajectory is not without its inherent challenges, primarily manifested as significant Restraints. Environmental concerns intrinsically associated with the traditional mining of natural gypsum, including potential habitat disruption, complex land reclamation issues, and the considerable energy consumption involved in extraction and initial processing, are leading to heightened regulatory scrutiny and increased public opposition. These mounting pressures compel manufacturers to actively seek more sustainable sourcing options, frequently at higher initial capital expenditures. Furthermore, unpredictable fluctuations in the global prices of key raw materials, particularly energy and transportation logistics, can considerably impact production expenses and logistical operations, directly affecting profitability margins for manufacturers. Moreover, the increasing availability and growing competitiveness of alternative building materials, such as engineered wood products, fiber cement boards, magnesium oxide boards, and various types of specialized insulation, pose a continuous threat to gypsum's established market share, necessitating relentless innovation and strategic differentiation to maintain its competitive edge. Stringent and continuously evolving environmental and safety regulations across diverse geographical regions also contribute significantly to operational complexities and augment compliance costs for market participants.

Despite these discernible challenges, the Stone Gypsum Market presents substantial and promising Opportunities for accelerated growth and groundbreaking innovation. Foremost among these is the escalating global demand for sustainable and certified green building materials, which emphatically favors the increased adoption and continuous technological advancement of synthetic gypsum. This material is meticulously derived from industrial byproducts like flue gas desulfurization (FGD) and phosphogypsum, offering not only an eco-friendly alternative to natural mining but also presenting significant opportunities for industrial waste valorization and robust circular economy initiatives. Technological advancements in gypsum product development, leading to enhanced performance characteristics such as improved moisture resistance for humid environments, higher compressive strength for structural applications, better acoustic dampening for sound control, and enhanced mold resistance, can unlock entirely new application areas and cater to highly specialized construction needs. The global trend towards extensive renovation, comprehensive remodeling, and critical refurbishment projects, particularly prominent in mature economies, provides a continuous and steady demand stream for gypsum products. Furthermore, the strategic diversification of gypsum applications beyond traditional construction, expanding into specialized industrial uses such as medical plasters, advanced dental molds, and sophisticated agricultural amendments, offers compelling avenues for market players to broaden their revenue streams and mitigate reliance on a single sector, thereby fostering long-term market resilience, sustained growth, and enhanced profitability.

Segmentation Analysis

The Stone Gypsum Market is meticulously segmented based on a comprehensive set of critical parameters, including product type, application, and end-use, to provide an unparalleled, granular understanding of its multifaceted dynamics and future growth prospects. This detailed segmentation is absolutely crucial for market participants, enabling them to precisely identify lucrative niches, formulate highly targeted and effective strategies, and proactively adapt to evolving consumer preferences and increasingly stringent industry standards. The analysis facilitates a comprehensive assessment of how distinct market components contribute to the overall industry structure and forecast future growth trajectories, accurately reflecting both the inherent versatility of gypsum and the varied demands across its diverse use cases. The market's structural integrity and dynamic evolution are heavily influenced by the intricate interplay between these segments, highlighting areas of rapid expansion versus those exhibiting stable but comparatively slower growth, thereby guiding strategic investment and development decisions.

A profound understanding of these detailed segments allows for precise strategic forecasting, optimized resource allocation, and a sharper competitive edge. For instance, analyzing the differential growth rates between synthetic gypsum and natural gypsum effectively reflects prevailing sustainability trends, evolving environmental regulations, and resource availability pressures. Similarly, the comprehensive breakdown by application vividly illustrates the pervasive and critical role of gypsum across a multitude of sectors, with a predominant focus on the construction industry. Furthermore, the end-use segmentation provides invaluable insights into distinct demand patterns originating from residential, commercial, industrial, and extensive infrastructure developments, helping businesses to optimally align their production capacities, supply chain logistics, and marketing efforts with specific and evolving market needs. This structured and analytical approach to market segmentation ensures that all critical dimensions influencing the stone gypsum industry are thoroughly examined, providing a robust, data-driven foundation for informed decision-making and strategic planning for all stakeholders, ranging from raw material suppliers to advanced end-product manufacturers, fostering innovation and sustainable growth.

- By Product Type: This segment fundamentally differentiates the source and form of gypsum utilized across various applications, reflecting distinct origins and processing requirements.

- Natural Gypsum: Mined directly from geological deposits found across the globe, representing the traditional and historically dominant source of gypsum. Its availability, purity, and mineral composition can vary significantly by regional deposit.

- Synthetic Gypsum: A high-quality, sustainable alternative derived as a byproduct from various industrial chemical processes, addressing environmental concerns and resource scarcity.

- FGD Gypsum: Derived from Flue Gas Desulfurization processes in coal-fired power plants, it represents the largest source of synthetic gypsum globally, driven by environmental regulations to capture sulfur dioxide emissions.

- Phosphogypsum: A byproduct of phosphoric acid production, though its use is often subject to strict regulatory oversight and may be restricted in certain regions due to potential radioactivity concerns and impurity levels.

- Citric Acid Gypsum: Produced during the manufacturing of citric acid, this type of synthetic gypsum is typically characterized by its remarkably high purity and consistent chemical composition, making it suitable for specialized applications.

- Other Synthetic Gypsum: Encompasses gypsum generated from various other industrial processes, including titanium dioxide production, nickel refining, and certain chemical reactions, each possessing unique characteristics.

- By Application: This segment highlights the diverse and extensive end-uses of gypsum across a broad spectrum of industries, showcasing its versatility and indispensability.

- Building & Construction: The largest and most critical application segment, foundational for modern infrastructure and interior finishing.

- Plaster: Primarily used for interior wall and ceiling finishes, known for creating smooth, aesthetically pleasing surfaces, and providing essential fire resistance and sound insulation.

- Plasterboard/Drywall: The most common and widely utilized gypsum product globally, essential for constructing interior walls and ceilings in both residential and commercial buildings due to its ease of installation and performance benefits.

- Ceiling Tiles: Offers crucial acoustic and thermal insulation properties, alongside fire protection, and aesthetic versatility in various institutional, commercial, and residential settings.

- Blocks & Bricks: Utilized for constructing lightweight, non-load-bearing partition walls and interior structures, offering quick installation and design flexibility.

- Other Building Materials: Includes a range of specialized products such as gypsum fiberboards, cornices, decorative moldings, and architectural elements used for aesthetic enhancements and functional performance.

- Cement Manufacturing: Gypsum serves as a vital setting retarder in Portland cement, which is added during the clinker grinding process to control hydration rates and improve the workability of concrete mixes.

- Agriculture (Soil Amendment): Extensively used to improve soil structure, enhance water penetration and drainage, mitigate soil salinity, and supply essential plant nutrients like calcium and sulfur, thereby boosting crop yields and soil health.

- Industrial (Fillers, Medical Plaster, Art & Craft): Encompasses diverse industrial uses, ranging from fillers in plastics, paints, and pharmaceuticals, to rapid-setting medical casts for orthopedic applications, and precise molds for pottery, ceramics, and artistic endeavors.

- Decoration & Interior Design: Specifically utilized for intricate ornamental features, elaborate cornices, custom ceiling designs, and other decorative elements, leveraging gypsum's exceptional moldability and smooth finish capabilities.

- Building & Construction: The largest and most critical application segment, foundational for modern infrastructure and interior finishing.

- By End-Use: This segment categorizes gypsum consumers based on the specific type of projects or sectors in which the material is deployed, providing insight into demand drivers.

- Residential: Includes single-family homes, multi-family dwellings, apartments, and large-scale housing complexes, with demand primarily driven by population growth, urbanization, and evolving housing preferences.

- Commercial: Covers offices, retail spaces, hotels, hospitals, educational institutions, and public buildings, heavily influenced by economic activity, business expansion, and public sector investments.

- Industrial: Pertains to factories, warehouses, manufacturing facilities, and specialized industrial complexes, often requiring gypsum for durability, fire safety, and specific structural applications.

- Infrastructure: Encompasses large-scale public works projects like roads, bridges, tunnels, airports, and public transportation hubs, where gypsum is used in various capacities including ground stabilization, finishing, and sound attenuation.

Value Chain Analysis For Stone Gypsum Market

The value chain of the Stone Gypsum Market is a sophisticated, multi-tiered process commencing with highly specialized upstream activities focused on the meticulous sourcing and extraction of raw materials. This initial and crucial phase primarily involves either the precise mining of natural gypsum from geological quarries, where critical factors such as geographical location, deposit purity, and extraction efficiency are paramount considerations, or the strategic procurement of synthetic gypsum. Synthetic gypsum is predominantly sourced from significant industrial byproduct streams, such as flue gas desulfurization (FGD) plants associated with large-scale coal-fired power generation, or from complex processes in the chemical industry like phosphoric acid and citric acid manufacturing. Key suppliers at this foundational stage invariably include large-scale mining operations and utility companies or chemical manufacturers that produce gypsum as a carefully controlled byproduct. The quality, intrinsic purity, and consistent chemical composition of this raw gypsum directly dictate the suitability, performance, and ultimate market value of all subsequent gypsum-based products, thereby necessitating rigorous quality assurance protocols and comprehensive environmental impact assessments during the sourcing and initial processing stages. The efficient and notably cost-effective transportation of these bulk raw materials from extraction sites or industrial plants to primary processing facilities constitutes a critical logistical challenge, frequently representing a substantial portion of the overall upstream expenditure due to the material's inherent weight and considerable volume.

Midstream activities within the stone gypsum value chain meticulously encompass the sophisticated processing and advanced manufacturing of a diverse range of gypsum-based products. This crucial and technologically intensive stage involves several complex industrial processes, including the initial crushing of raw gypsum into smaller, manageable pieces, precise grinding to achieve specific particle size distributions essential for product performance, and the highly controlled calcination process. Calcination, which involves heating the gypsum to carefully regulated temperatures, precisely removes a specific amount of water, fundamentally transforming it into plaster of Paris (hemihydrate gypsum), which serves as the foundational base for a multitude of finished products. Following calcination, various specialized additives, binders, and reinforcing agents are meticulously blended to impart specific performance characteristics. These tailored attributes include enhanced structural strength, faster or slower setting times, improved moisture resistance, superior fire-retardant properties, or better acoustic performance. Manufacturers leverage cutting-edge machinery, advanced automation, and sophisticated process control systems to ensure unparalleled efficiency, consistent product quality, and strict adherence to stringent international industry standards. The technological capabilities and innovation at this midstream stage profoundly influence the innovation potential, competitive differentiation, and market penetration of the final products, ranging from standard plasterboards to highly specialized acoustic panels and advanced high-strength gypsum blocks.

Stone Gypsum Market Potential Customers

Potential customers for stone gypsum and its vast array of derived products span an extensive and remarkably diverse range of industries and end-user segments, unequivocally reflecting the material's indispensable utility in modern economic development and construction. The most prominent and substantial segment of end-users comprises the global construction industry. This broad category includes major construction conglomerates undertaking large-scale commercial developments such as expansive office complexes, bustling shopping malls, and luxurious hospitality establishments; residential builders rigorously focused on constructing single-family homes, multi-story apartment buildings, and sprawling housing communities; and adept civil engineering firms engaged in critical infrastructure projects like public buildings, sophisticated transportation hubs, and comprehensive urban regeneration schemes. These entities primarily procure gypsum for its widespread use in plasterboard (drywall), interior plasters for wall and ceiling finishes, ceiling tiles, and lightweight partition blocks, highly valuing its inherent fire-resistant properties, excellent sound insulation capabilities, and the significant ease of installation that contributes profoundly to faster project completion times and reduced labor costs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 billion |

| Market Forecast in 2033 | USD 7.5 billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Knauf Gips KG, Saint-Gobain (Gyproc), USG Corporation, Etex Group (Siniat), Georgia-Pacific LLC, National Gypsum Company, Continental Building Products, PABCO Gypsum, American Gypsum, Boral Limited, Kingspan Group (Celotex), Yoshino Gypsum Co., Ltd., LafargeHolcim Ltd., Refratechnik Cement GmbH, Gypsum Management and Supply (GMS) Inc., Armstrong World Industries, Inc., Beijing New Building Material (BNBM) Public Limited Company, Arabian Gypsum Co., Global Gypsum Co., British Gypsum (part of Saint-Gobain), Volma Group, US Gypsum (part of USG Corporation), Ayas Minerals Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stone Gypsum Market Key Technology Landscape

The Stone Gypsum Market's technological landscape is under constant evolution, driven by relentless imperatives for enhanced operational efficiency, superior product performance, and robust environmental sustainability throughout the entire value chain. At the very heart of gypsum processing lies advanced calcination technology, which prominently includes state-of-the-art rotary kilns, highly efficient flash calciners, and fluid bed calciners. These sophisticated systems allow for unprecedented precise control over the complex dehydration process of raw gypsum, enabling manufacturers to produce various types of gypsum plaster—such as both alpha-hemihydrate and beta-hemihydrate—with highly tailored properties like specific setting times, superior mechanical strengths, enhanced surface hardness, and optimized densities. This versatility is crucial for meeting the diverse requirements across a spectrum of applications, ranging from quick-setting dental plasters to slow-setting construction plasters, while simultaneously prioritizing energy efficiency and minimizing greenhouse gas emissions. Furthermore, innovative grinding and milling techniques, encompassing advanced roller mills and highly efficient ball mills, are critically important for achieving the desired particle size distribution and purity, which directly influence the workability, finish quality, and overall performance characteristics of gypsum-based products.

Regional Highlights

- North America: This region represents a mature and highly stable market for stone gypsum, characterized by consistent demand propelled by robust residential and commercial construction sectors, alongside significant and ongoing investments in renovation, remodeling, and extensive repair activities. Stringent building codes, particularly concerning fire safety, energy efficiency, and indoor air quality, strongly favor the widespread adoption of high-performance gypsum products and advanced drywall systems. The market is also a prominent and early adopter of synthetic gypsum, reflecting a strong commitment to sustainable building practices and efficient resource conservation. Continuous innovation in moisture-resistant, mold-resistant, and sound-attenuating gypsum boards represents a key trend, catering to evolving consumer expectations for enhanced indoor air quality, comfort, and long-term durability in both new constructions and extensive retrofits.

- Europe: The European market for stone gypsum is distinctly defined by its strong emphasis on pioneering green building initiatives, robust circular economy principles, and increasingly stringent environmental regulations. This comprehensive regulatory framework, coupled with a high level of environmental awareness among consumers and industry players, drives the accelerating adoption of synthetic gypsum and recycled gypsum in construction projects across the continent. Key contributing countries such as Germany, France, and the UK demonstrate sustained demand, actively focusing on energy-efficient, lightweight, and prefabricated gypsum solutions for both new build constructions and extensive refurbishment projects. The market is also experiencing notable growth in specialized gypsum products meticulously designed for improved acoustic performance, enhanced structural integrity, and superior aesthetic finishes, aligning with the region's high standards for building quality and sustainability targets.

- Asia Pacific (APAC): Positioned as the largest and fastest-growing market globally for stone gypsum, the APAC region's remarkable expansion is primarily fueled by unprecedented rates of urbanization, monumental infrastructure development projects, and a booming residential construction sector. Countries like China, India, Indonesia, and Vietnam are at the forefront of this vigorous growth, driven by rapidly expanding populations, steadily rising disposable incomes, and substantial governmental investments in urban and rural development initiatives. The abundant availability of raw materials, coupled with relatively competitive labor costs, makes the region a highly attractive manufacturing hub for gypsum products. The escalating demand for affordable, yet high-performance, building materials to support rapid and extensive development continues to propel the market forward significantly, creating vast opportunities for market participants.

- Latin America: This region is progressively emerging as a significant growth frontier for the stone gypsum market, propelled by ongoing economic development, increasing foreign direct investment in critical infrastructure, and a rising demand for modern, high-quality housing solutions. Countries such as Brazil, Mexico, Argentina, and Chile are witnessing a steady uptick in construction activities across residential, commercial, and public sectors, indicative of economic recovery and expansion. The market is characterized by a growing awareness and appreciation for the benefits of gypsum products, including their cost-effectiveness, construction efficiency, and inherent safety features. While natural gypsum remains a primary source, there is a gradual but noticeable increase in the adoption of synthetic gypsum and imported specialized products to meet evolving building standards, advanced design preferences, and sustainability goals within the region.

- Middle East & Africa (MEA): The MEA region is experiencing an impressive surge in stone gypsum demand, largely attributed to ambitious mega-construction projects and rapid urbanization initiatives, particularly prominent in Gulf Cooperation Council (GCC) countries like Saudi Arabia, UAE, and Qatar. These nations are heavily investing in diversifying their economies away from oil dependence, leading to massive developments in real estate, tourism infrastructure, and extensive commercial hubs. The demand for fire-resistant, moisture-resistant, and aesthetically versatile building materials is exceptionally high to meet modern architectural standards in often harsh climates. In Africa, growing populations, improving economic conditions, and increasing foreign investment in infrastructure and housing are also contributing to steady market expansion, though regulatory environments and supply chain efficiencies continue to vary considerably across the vast continent.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stone Gypsum Market.- Knauf Gips KG

- Saint-Gobain (Gyproc)

- USG Corporation (now a subsidiary of Knauf)

- Etex Group (Siniat)

- Georgia-Pacific LLC

- National Gypsum Company

- Continental Building Products (now part of CertainTeed, a Saint-Gobain company)

- PABCO Gypsum

- American Gypsum

- Boral Limited

- Kingspan Group (Celotex)

- Yoshino Gypsum Co., Ltd.

- LafargeHolcim Ltd.

- Refratechnik Cement GmbH

- Gypsum Management and Supply (GMS) Inc.

- Armstrong World Industries, Inc.

- Beijing New Building Material (BNBM) Public Limited Company

- Arabian Gypsum Co.

- Global Gypsum Co.

- British Gypsum (part of Saint-Gobain)

- Volma Group

- US Gypsum (part of USG Corporation)

- Ayas Minerals Group

Frequently Asked Questions

What is Stone Gypsum and what are its primary applications in construction?

Stone gypsum is a naturally occurring mineral, hydrated calcium sulfate (CaSO4·2H2O), extensively utilized in the construction industry due to its inherent fire-resistant, sound-insulating, and thermal-insulating properties. Its primary applications encompass the manufacturing of plasterboard (drywall), interior plasters for wall and ceiling finishes, ceiling tiles, and gypsum blocks, all contributing significantly to building safety, comfort, and aesthetics. Beyond construction, it is also a vital setting retarder in cement production and serves as an effective soil amendment in agriculture to improve soil structure and nutrient availability for crops.

How do natural and synthetic gypsum differ, and why is synthetic gypsum gaining importance?

Natural gypsum is extracted directly from geological deposits through traditional mining operations, representing the conventional source. Synthetic gypsum, conversely, is a valuable byproduct of various industrial processes, most notably flue gas desulfurization (FGD) in coal-fired power plants. Synthetic gypsum is rapidly gaining importance due to its alignment with environmental sustainability goals, as it effectively provides a valuable use for industrial waste, significantly reduces the environmental impact associated with extensive mining, and often exhibits higher purity and consistent quality, thereby aligning perfectly with green building standards and robust circular economy initiatives.

What are the key market drivers propelling the growth of the Stone Gypsum Market?

The Stone Gypsum Market's growth is predominantly propelled by the rapid pace of global urbanization and substantial infrastructure development worldwide, leading to an increasing demand for residential, commercial, and public construction. Other pivotal drivers include the inherent fire-resistant, sound-insulating, and thermal-efficient properties of gypsum, making it a highly preferred building material. Furthermore, the growing emphasis on sustainable construction practices and increasingly stringent building codes that favor environmentally friendly and high-performance materials, particularly synthetic gypsum, significantly contribute to market expansion and innovation.

What are the primary challenges or restraints affecting the Stone Gypsum Market?

The market faces several significant challenges. These include environmental concerns intrinsically associated with the mining of natural gypsum, which often leads to stricter regulatory pressures and public scrutiny regarding land use and ecological impact. Additionally, volatility in raw material and energy prices directly impacts production costs and logistics, posing a considerable restraint on profitability. Competition from alternative building materials and the complex, varying regulatory frameworks across different regions also contribute to market challenges, requiring continuous adaptation, technological innovation, and strategic resilience from industry players.

Which geographical region exhibits the most significant growth in the Stone Gypsum Market?

The Asia Pacific (APAC) region currently demonstrates the most significant growth and holds the largest market share in the Stone Gypsum Market. This robust expansion is primarily attributed to accelerated urbanization, massive government investments in critical infrastructure projects, and a booming residential construction sector across key economies like China, India, and Southeast Asian nations. The region's large and rapidly growing population, coupled with increasing disposable incomes and extensive industrial development, consistently fuels the substantial demand for gypsum-based building materials, making it a dominant force in the global market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager