Straight Air Screwdriver Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439596 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Straight Air Screwdriver Market Size

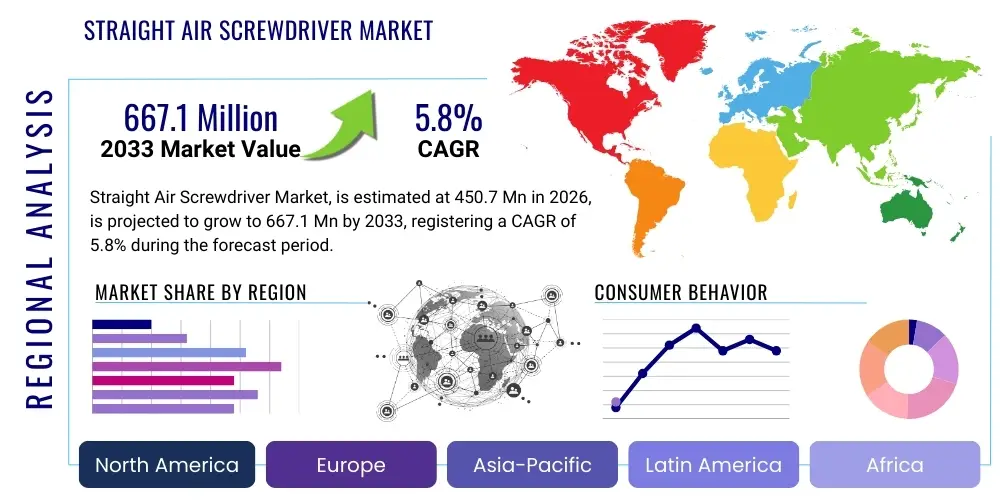

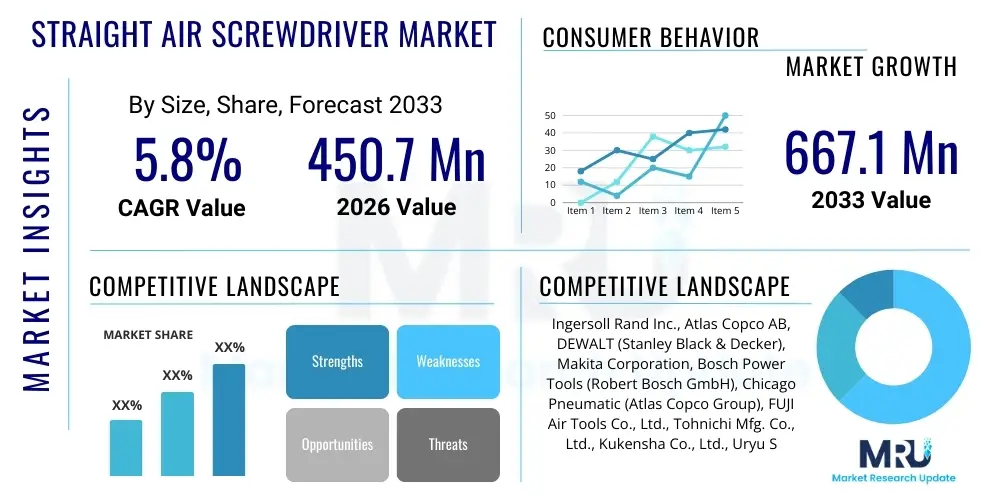

The Straight Air Screwdriver Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.7 Million in 2026 and is projected to reach USD 667.1 Million by the end of the forecast period in 2033.

Straight Air Screwdriver Market introduction

The Straight Air Screwdriver Market encompasses the global manufacturing, distribution, and sales of pneumatic fastening tools designed for precision assembly tasks across various industrial sectors. These tools utilize compressed air to drive a rotary motion, enabling efficient and controlled fastening and unfastening of screws, bolts, and other threaded components. Characterized by their lightweight design, high power-to-weight ratio, and exceptional durability, straight air screwdrivers offer significant advantages in applications requiring consistent torque accuracy, reduced operator fatigue, and enhanced productivity. Major applications span critical manufacturing environments such as automotive assembly, aerospace component fabrication, electronics manufacturing, general industrial assembly, and woodworking. The inherent benefits of these tools include superior torque control, leading to fewer rework incidents and improved product quality, prolonged operational life compared to electric counterparts due to robust pneumatic motors, and enhanced safety features in hazardous environments where sparks from electric tools are a concern. Driving factors for market growth are primarily linked to the global trend towards industrial automation, the increasing demand for precision fastening in high-value manufacturing, and the continuous focus on ergonomic solutions to improve worker comfort and efficiency in production lines. Furthermore, their suitability for continuous operation in demanding environments without overheating issues positions them as indispensable tools in modern manufacturing processes, supporting the acceleration of assembly lines and contributing to overall operational excellence.

Straight Air Screwdriver Market Executive Summary

The Straight Air Screwdriver Market is experiencing robust growth driven by accelerating industrial automation and the expanding manufacturing sectors worldwide. Key business trends indicate a strong emphasis on smart factory integration, where these pneumatic tools are increasingly equipped with advanced sensor technology for real-time data collection, enhancing predictive maintenance capabilities and optimizing assembly line performance. Manufacturers are also focusing on developing ergonomic designs and lightweight materials to improve user comfort and productivity, addressing a critical need in labor-intensive industries. Regionally, the Asia Pacific continues to emerge as the dominant market, propelled by rapid industrialization, significant investments in automotive and electronics manufacturing, and a burgeoning labor force. North America and Europe demonstrate stable growth, characterized by demand for high-precision, technologically advanced tools for sophisticated manufacturing operations, while emerging economies in Latin America and the Middle East & Africa show promising potential due to infrastructure development and diversifying industrial bases. Segmentation trends highlight a growing preference for tools offering precise torque control and those designed for specialized applications, such as micro-assembly in electronics or high-torque fastening in heavy machinery. The demand for various drive types, including Phillips, Torx, and hex, tailored to specific fasteners, also remains a significant driver. This holistic market evolution underscores the straight air screwdriver's enduring role as a foundational tool in modern industrial assembly, continuously adapting to technological advancements and evolving operational requirements across the global manufacturing landscape.

AI Impact Analysis on Straight Air Screwdriver Market

The integration of Artificial Intelligence (AI) is set to significantly revolutionize the Straight Air Screwdriver Market, moving beyond simple automation to introduce unprecedented levels of precision, efficiency, and predictive capabilities. User inquiries frequently revolve around how AI can enhance the accuracy of torque application, minimize errors, and optimize the overall fastening process. There is considerable interest in AI's potential for real-time monitoring of tool performance, predicting maintenance needs, and integrating seamlessly into larger, interconnected smart factory ecosystems. Concerns often include the initial cost of AI-enabled systems, data security implications, and the necessity for skilled personnel to manage and interpret AI-generated insights. The overarching expectation is that AI will elevate straight air screwdrivers from standalone tools to intelligent components of sophisticated assembly lines, contributing to higher quality outputs, reduced downtime, and more agile manufacturing operations. This shift promises to empower manufacturers with actionable data, enabling them to make proactive decisions regarding tool calibration, operator training, and workflow optimization, ultimately leading to substantial improvements in production efficiency and cost-effectiveness.

Specifically, AI is poised to transform several critical aspects of straight air screwdriver usage and management. By analyzing vast datasets of fastening operations, AI algorithms can identify optimal torque settings for various materials and fastener types, dynamically adjusting tool parameters in real-time to ensure consistent, defect-free assembly. This capability dramatically reduces instances of under- or over-tightening, which are common causes of product defects and costly rework. Furthermore, AI-powered systems can monitor the vibrational patterns, air pressure, and operational cycles of screwdrivers to predict potential mechanical failures before they occur. This predictive maintenance approach shifts from reactive repairs to proactive servicing, minimizing unexpected downtime and extending the lifespan of valuable equipment. The ability of AI to learn from operational data also allows for continuous process improvement, fine-tuning the entire assembly sequence for maximum throughput and quality control.

Beyond individual tool performance, AI’s impact extends to broader manufacturing system integration. In robotic assembly lines utilizing straight air screwdrivers, AI enables more adaptive and precise robotic movements, optimizing the sequence and angle of fastening for complex components. This level of intelligent automation reduces the need for constant human supervision and allows robots to handle a wider array of tasks with greater dexterity. Moreover, AI can facilitate operator training by providing personalized feedback based on performance data, helping new users quickly master the nuances of precision fastening. The overarching trend is towards a more intelligent, interconnected, and self-optimizing manufacturing environment where straight air screwdrivers, augmented by AI, play a pivotal role in achieving the highest standards of production quality and operational efficiency.

- AI enables dynamic torque optimization, ensuring precise fastening by adjusting tool settings based on real-time material properties and fastener specifications, significantly reducing errors and improving product quality.

- Predictive maintenance analytics, powered by AI, monitor tool performance parameters such as vibration, air consumption, and operational cycles to anticipate potential failures, thereby minimizing unplanned downtime and extending equipment longevity.

- Seamless integration into robotic assembly systems, allowing AI to guide robotic arms for optimal straight air screwdriver positioning and operation, enhancing speed, accuracy, and versatility in automated manufacturing environments.

- Enhanced quality control through AI-driven anomaly detection, where systems can identify and flag inconsistencies in fastening processes, preventing defective products from moving further down the production line.

- Operator training and feedback systems leverage AI to analyze user performance, providing personalized recommendations and immediate corrections to improve skill acquisition and operational efficiency.

- Process optimization algorithms utilize AI to analyze entire assembly workflows, identifying bottlenecks and inefficiencies related to fastening tasks, and suggesting improvements for enhanced throughput and resource utilization.

- Data-driven decision-making becomes more robust as AI compiles and interprets operational data from straight air screwdrivers, offering insights into tool utilization, common failure modes, and opportunities for continuous improvement in manufacturing processes.

DRO & Impact Forces Of Straight Air Screwdriver Market

The Straight Air Screwdriver Market is shaped by a complex interplay of drivers, restraints, and opportunities, collectively forming the impact forces that dictate its trajectory. Key drivers propelling market growth include the relentless global expansion of industrial automation across sectors like automotive, aerospace, and electronics, which inherently demands high-speed, high-precision fastening tools. The increasing focus on ergonomic design to reduce operator fatigue and improve workplace safety further fuels adoption, as air screwdrivers are typically lighter and produce less vibration than their electric counterparts. Restraints on market expansion primarily involve the relatively high initial investment required for pneumatic systems, including compressors and air lines, which can be a barrier for smaller enterprises. Moreover, the emergence and continuous advancement of cordless electric screwdrivers, offering enhanced portability and reduced setup complexity, pose a significant competitive threat, challenging the traditional dominance of air-powered tools. Opportunities for growth are abundant in emerging economies undergoing rapid industrialization, where new manufacturing facilities necessitate efficient assembly solutions. The development of smart factory technologies, integrating air screwdrivers with IoT sensors for data collection and predictive maintenance, also presents a substantial avenue for innovation and market penetration, offering manufacturers enhanced control and optimization capabilities. Furthermore, specialized applications requiring intrinsically safe tools in volatile environments, where electric sparks are a risk, continue to reinforce the unique value proposition of air screwdrivers, ensuring their sustained relevance in a diverse industrial landscape.

Segmentation Analysis

The Straight Air Screwdriver Market is thoroughly analyzed across various strategic segments to provide a granular understanding of its structure and dynamics. These segmentations allow for detailed insights into market preferences, application-specific demands, and regional consumption patterns, essential for stakeholders to formulate targeted business strategies. The primary segmentation categories encompass different aspects of the product, including its torque range, type of drive, application areas, and the end-user industries it serves, each revealing distinct growth trajectories and competitive landscapes. Understanding these segments is crucial for identifying niche opportunities, forecasting demand, and developing products that precisely meet the evolving needs of modern manufacturing and assembly operations.

- By Torque Range:

- Low Torque Straight Air Screwdrivers: These tools are designed for delicate and precise fastening tasks, typically providing torque outputs ranging from 0.1 Nm to 5 Nm. They are primarily utilized in industries such as electronics manufacturing, where small components and sensitive materials require controlled force to prevent damage. Applications include assembling smartphones, circuit boards, small appliances, and precision instruments. Their compact size and lightweight nature make them ideal for intricate work, significantly reducing operator fatigue during prolonged use in repetitive assembly lines.

- Medium Torque Straight Air Screwdrivers: Catering to a broader range of general assembly tasks, medium torque screwdrivers typically offer torque outputs between 5 Nm and 30 Nm. This segment is highly versatile and finds extensive application in automotive interior assembly, white goods manufacturing, furniture production, and general light industrial assembly. They strike an optimal balance between power and precision, enabling efficient fastening of medium-sized screws and bolts without compromising material integrity. The robust design of these tools ensures durability and consistent performance in demanding production environments.

- High Torque Straight Air Screwdrivers: Engineered for heavy-duty fastening applications, these tools deliver substantial torque, often exceeding 30 Nm and going up to 100 Nm or more. They are indispensable in sectors such as heavy automotive assembly, aerospace component manufacturing, construction, and machinery fabrication where large fasteners require significant force for secure tightening. High torque models are built for resilience and continuous operation, often incorporating advanced clutch mechanisms for precise torque control even at higher settings. Their contribution is critical in ensuring structural integrity and safety in large-scale constructions and heavy-duty equipment.

- By Drive Type:

- Phillips Drive: Straight air screwdrivers equipped with Phillips drive bits are among the most common and widely used, suitable for a vast array of screws found in consumer electronics, domestic appliances, and general manufacturing. The cross-head design allows for easy engagement and provides adequate grip for most standard fastening tasks.

- Torx Drive: Offering superior torque transfer and reduced cam-out compared to Phillips, Torx drive screwdrivers are preferred in applications requiring high torque without damaging the screw head, such as in automotive components, electronics, and aerospace. The six-point star design provides excellent engagement and extends bit life.

- Hex Drive: Hex drive screwdrivers are essential for fastening hex head screws and bolts, commonly found in machinery assembly, furniture construction, and automotive engine components. They provide robust engagement for high-torque applications and are less prone to stripping.

- Slotted Drive: While less common in high-volume industrial settings due to cam-out tendencies, slotted drive air screwdrivers are still used for specific legacy applications or where a simple, flat-blade fastener is preferred.

- Pozidriv Drive: An improvement on the Phillips head, Pozidriv offers even greater cam-out resistance and torque transmission due to additional small ribs. It is popular in European manufacturing, particularly in woodworking and construction.

- Other Drives: This category includes specialized drive types such as Square (Robertson), Tri-Wing, Spanner, and various proprietary designs used in niche applications requiring tamper-resistance or unique assembly requirements, ensuring versatility across diverse industrial needs.

- By Application:

- Automotive Assembly: Straight air screwdrivers are critical in various stages of automotive manufacturing, from interior panel fastening and engine component assembly to chassis and trim installation. Their precision, speed, and consistent torque control are vital for ensuring vehicle safety and quality standards.

- Electronics Manufacturing: In the assembly of consumer electronics, computers, and telecommunications equipment, low-torque straight air screwdrivers are indispensable for fastening delicate components without causing damage, ensuring product functionality and reliability.

- Aerospace Component Assembly: Precision and reliability are paramount in aerospace. Straight air screwdrivers are used for assembling critical components, where strict torque specifications and flawless fastening are non-negotiable for aircraft safety and performance.

- General Industrial Assembly: This broad category includes the manufacturing of appliances, machinery, tools, and equipment where efficient and accurate fastening is required across diverse production lines, making straight air screwdrivers a versatile choice.

- Woodworking and Furniture Manufacturing: From assembling cabinets and chairs to intricate joinery, air screwdrivers provide the necessary power and control for efficient and consistent fastening in the woodworking industry, improving production speed and finish quality.

- Medical Device Assembly: The precise and controlled fastening capabilities of straight air screwdrivers are crucial in the manufacturing of medical devices, where even minor discrepancies can have significant consequences. These tools help ensure the reliability and safety of life-saving equipment.

- By End-User Industry:

- Manufacturing Sector: The largest end-user, encompassing a wide range of industries including automotive, electronics, aerospace, and general machinery production, where straight air screwdrivers are integral to assembly lines.

- Construction Sector: Used in light construction tasks, such as drywall installation, decking, and framework assembly, where speed and consistent fastening are beneficial.

- Maintenance, Repair, and Overhaul (MRO): These tools are essential for servicing and repairing existing machinery, vehicles, and equipment in various industrial and commercial settings, offering durability and ease of use for maintenance technicians.

- Aerospace & Defense: A specialized segment demanding the highest levels of precision and reliability, utilizing straight air screwdrivers for assembling aircraft structures, military vehicles, and complex weapon systems.

- Energy Sector: Used in the assembly and maintenance of power generation equipment, including components for wind turbines, solar panels, and traditional power plants, where robust and reliable fastening is critical.

Value Chain Analysis For Straight Air Screwdriver Market

The value chain for the Straight Air Screwdriver Market is a multi-tiered system encompassing raw material suppliers, component manufacturers, tool assemblers, distributors, and ultimately, the end-users. The upstream segment of the value chain is critical, involving suppliers of high-grade raw materials such as specialized steels, aluminum alloys, and engineering plastics that are essential for the durability and performance of pneumatic tools. These materials must meet stringent quality standards to withstand the rigorous demands of industrial use. Additionally, component manufacturers provide specialized parts like pneumatic motors, gears, clutches, and housing components, which are often produced by companies with deep expertise in precision machining and material science. The quality and innovation at this upstream stage directly influence the final product's performance characteristics, including torque accuracy, lifespan, and ergonomic properties. Collaboration with these specialized suppliers is crucial for tool manufacturers to maintain competitive advantages and incorporate advanced features, ensuring a steady supply of high-quality inputs that comply with industry standards and regulations.

Moving downstream, the value chain encompasses the manufacturing and assembly of straight air screwdrivers, followed by their distribution to end-users. Tool manufacturers integrate components from various suppliers, employing advanced assembly techniques and quality control measures to produce the final pneumatic screwdrivers. This stage often involves significant investment in R&D to innovate new designs, improve ergonomics, and enhance torque control mechanisms. After manufacturing, distribution channels play a pivotal role in reaching the diverse global customer base. These channels can be broadly categorized into direct and indirect sales. Direct distribution involves manufacturers selling directly to large industrial clients, often automotive OEMs or aerospace companies, through their own sales teams or dedicated project channels. This approach allows for direct communication, customization, and comprehensive after-sales support, fostering strong long-term relationships and facilitating tailored solutions for specific assembly line requirements.

Indirect distribution, on the other hand, relies heavily on a network of industrial distributors, wholesalers, retailers, and online platforms. Industrial distributors, often specializing in pneumatic tools or general industrial supplies, serve a wide array of small and medium-sized enterprises (SMEs) that may not have the capacity for direct procurement. These distributors provide localized stock, technical support, and rapid delivery services, making tools accessible to a broader market. Online platforms and e-commerce channels are gaining increasing importance, offering convenience, competitive pricing, and extensive product information to both commercial and individual buyers. The effectiveness of these distribution channels is vital for market penetration and ensuring that straight air screwdrivers reach various end-user industries efficiently, from large-scale manufacturing plants to independent workshops. Maintaining strong relationships across all segments of this complex value chain, from raw material providers to the final point of sale, is essential for sustained growth and responsiveness to market demands.

Straight Air Screwdriver Market Potential Customers

The Straight Air Screwdriver Market caters to a diverse range of potential customers, primarily encompassing industries and businesses that rely heavily on precision fastening and efficient assembly processes. The largest segment of end-users originates from the manufacturing sector, which includes major players in the automotive industry, where these tools are indispensable for assembling vehicle components such as interior panels, engine parts, and chassis elements. The electronics manufacturing sector also represents a significant customer base, utilizing low-torque air screwdrivers for the delicate assembly of circuit boards, smartphones, and various electronic devices where precision and damage prevention are paramount. Furthermore, the aerospace industry is a critical customer segment, demanding the highest levels of accuracy and reliability for assembling aircraft structures and sensitive aerospace components, making straight air screwdrivers a preferred choice due to their consistent torque output and robustness. These core manufacturing industries continuously seek tools that enhance productivity, reduce rework, and ensure the highest quality standards for their complex products.

Beyond the core manufacturing giants, the market also serves a broad spectrum of other industrial and commercial end-users. General industrial assembly plants, which produce a wide array of goods from white goods and machinery to furniture and general equipment, constitute a substantial customer segment. These facilities value the durability, speed, and ergonomic benefits that straight air screwdrivers offer in high-volume, repetitive tasks. The construction sector, particularly for light-duty assembly and finishing work, also utilizes these tools for applications like drywall installation, decking, and securing fixtures, appreciating their consistent performance and ease of use. Additionally, the maintenance, repair, and overhaul (MRO) sector across various industries relies on straight air screwdrivers for disassembling and reassembling equipment during servicing, valuing their reliability and efficiency in demanding maintenance environments.

Emerging markets and specialized applications further expand the customer base for straight air screwdrivers. As developing economies industrialize, new manufacturing facilities for consumer goods, automotive parts, and infrastructure components drive fresh demand for efficient assembly tools. Industries requiring intrinsically safe tools in hazardous or volatile environments, such as certain chemical plants or oil and gas facilities, also turn to pneumatic screwdrivers due to their absence of electrical sparks, which is a critical safety advantage. Small and medium-sized enterprises (SMEs) across these sectors also represent a growing customer group, often purchasing through industrial distributors. The continuous evolution in product design, offering enhanced ergonomics, greater torque accuracy, and smart capabilities, helps maintain and expand this diverse customer base by meeting increasingly sophisticated and specific operational requirements across the global industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.7 Million |

| Market Forecast in 2033 | USD 667.1 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ingersoll Rand Inc., Atlas Copco AB, DEWALT (Stanley Black & Decker), Makita Corporation, Bosch Power Tools (Robert Bosch GmbH), Chicago Pneumatic (Atlas Copco Group), FUJI Air Tools Co., Ltd., Tohnichi Mfg. Co., Ltd., Kukensha Co., Ltd., Uryu Seisaku, Ltd., SP Air Corporation, AIMCO Global, Desoutter Industrial Tools (Atlas Copco Group), FIAM Utensili Pneumatici S.p.A., SUMAKE Industrial Co., Ltd., CPT Tools (Chicago Pneumatic Tool Company), Cleco Production Tools (Apex Tool Group), Dynabrade, Inc., NITTO KOHKI Co., Ltd., Shinano Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Straight Air Screwdriver Market Key Technology Landscape

The technological landscape of the Straight Air Screwdriver Market is continually evolving, driven by the persistent demand for higher precision, improved ergonomics, and greater operational efficiency in industrial assembly. A primary technological focus is on advanced torque control mechanisms, moving beyond simple clutch systems to incorporate sophisticated pneumatic logic and electronic feedback loops. These innovations allow for extremely accurate and repeatable torque settings, which are critical in industries like aerospace and electronics where consistent fastening prevents material damage and ensures product reliability. Manufacturers are increasingly integrating microprocessors and sensors into straight air screwdrivers, enabling real-time monitoring of torque, speed, and angle, which can then be transmitted wirelessly to central control systems for quality assurance and process optimization. This integration is vital for achieving zero-defect manufacturing goals and complying with stringent industry standards, ensuring that every fastener is tightened to the exact specification required.

Another significant area of technological advancement lies in ergonomic design and material science. To combat operator fatigue and enhance productivity, manufacturers are investing in lightweight yet robust materials such as advanced aluminum alloys and composite polymers, significantly reducing the tool's weight without compromising its durability or power. Coupled with ergonomic handle designs, improved vibration dampening systems, and reduced noise levels, these advancements contribute to a more comfortable and safer working environment for operators during prolonged shifts. Furthermore, innovations in pneumatic motor design are leading to more efficient air consumption, which translates into lower operational costs and a reduced carbon footprint for manufacturing facilities. The focus on making these tools more user-friendly and less physically demanding is a key driver for adoption in industries grappling with labor shortages and an increased emphasis on worker well-being.

The integration of Straight Air Screwdrivers into smart factory ecosystems represents a transformative technological trend. This involves equipping tools with IoT capabilities for connectivity and data exchange, allowing them to communicate with other machines, robots, and central manufacturing execution systems (MES). Such connectivity facilitates predictive maintenance by monitoring tool health and usage patterns, enabling proactive servicing before failures occur. It also supports adaptive assembly processes, where tools can receive dynamic instructions based on real-time production needs, optimizing workflows and improving overall line efficiency. Moreover, advancements in air filtration and lubrication systems ensure cleaner air supply to the tools, extending their lifespan and reducing contamination risks in sensitive environments. These technological strides not only enhance the performance and longevity of straight air screwdrivers but also solidify their position as essential components in the smart, interconnected, and highly efficient manufacturing plants of the future.

Regional Highlights

- North America: The North American market for straight air screwdrivers is characterized by its maturity and a strong emphasis on technological innovation and high-quality industrial solutions. The region's robust automotive, aerospace, and general manufacturing sectors consistently drive demand for precision fastening tools. Manufacturers here prioritize tools with advanced torque control, ergonomic designs, and data integration capabilities to support automation and industry 4.0 initiatives. There is a significant focus on enhancing productivity and ensuring product reliability, leading to continuous investment in sophisticated pneumatic systems. The presence of major global players and a well-established distribution network further solidifies its position as a key market.

- Europe: Europe represents a highly advanced market, with countries like Germany, Italy, and the UK leading in precision manufacturing and industrial automation. The demand for straight air screwdrivers is particularly high in the automotive, machinery, and electronics industries, driven by strict quality standards and a strong commitment to ergonomic workplaces. European manufacturers often seek tools that offer exceptional durability, precise repeatable torque, and low noise levels, reflecting the region's emphasis on both product quality and occupational health and safety. The ongoing shift towards smart factories and sustainable production practices also influences tool selection and technological advancements within the region.

- Asia Pacific (APAC): The Asia Pacific region is the largest and fastest-growing market for straight air screwdrivers, primarily fueled by the rapid industrialization and expansion of manufacturing bases in countries such as China, India, Japan, South Korea, and Southeast Asian nations. This region is a global hub for automotive production, electronics manufacturing, and general consumer goods assembly, leading to immense demand for efficient and cost-effective fastening solutions. Investments in new production facilities, coupled with a large and growing workforce, are key drivers. While cost-effectiveness remains important, there is also an increasing adoption of advanced, high-precision tools to meet rising quality expectations and support export-oriented manufacturing.

- Latin America: The Latin American market is an emerging region with growing potential for straight air screwdrivers. Countries like Brazil, Mexico, and Argentina are experiencing significant investments in automotive, aerospace, and infrastructure development, which in turn drives the demand for industrial assembly tools. While still developing, the market is gradually shifting towards adopting more advanced and efficient pneumatic tools to improve manufacturing output and quality. Economic stability and foreign direct investment in manufacturing are key factors influencing the growth trajectory of this region, as local industries aim to compete on a global scale.

- Middle East and Africa (MEA): The MEA region presents a developing market for straight air screwdrivers, primarily influenced by investments in oil and gas, infrastructure, and diversification into manufacturing sectors. Countries in the Gulf Cooperation Council (GCC) are investing heavily in industrialization and urban development, creating a demand for robust and reliable assembly tools. The construction and energy sectors are significant end-users, requiring durable tools for heavy-duty applications. As the region continues its efforts to diversify economies away from traditional resources, the manufacturing footprint is expected to grow, consequently increasing the adoption of advanced pneumatic tools.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Straight Air Screwdriver Market.- Ingersoll Rand Inc.

- Atlas Copco AB

- DEWALT (Stanley Black & Decker)

- Makita Corporation

- Bosch Power Tools (Robert Bosch GmbH)

- Chicago Pneumatic (Atlas Copco Group)

- FUJI Air Tools Co., Ltd.

- Tohnichi Mfg. Co., Ltd.

- Kukensha Co., Ltd.

- Uryu Seisaku, Ltd.

- SP Air Corporation

- AIMCO Global

- Desoutter Industrial Tools (Atlas Copco Group)

- FIAM Utensili Pneumatici S.p.A.

- SUMAKE Industrial Co., Ltd.

- CPT Tools (Chicago Pneumatic Tool Company)

- Cleco Production Tools (Apex Tool Group)

- Dynabrade, Inc.

- NITTO KOHKI Co., Ltd.

- Shinano Inc.

Frequently Asked Questions

What are the primary advantages of using a straight air screwdriver over an electric one?

Straight air screwdrivers offer several key advantages, particularly in industrial settings. They typically provide a higher power-to-weight ratio, leading to reduced operator fatigue during prolonged use. Their pneumatic motors are more durable and generate less heat, making them suitable for continuous, high-volume operations without overheating. Air tools are also intrinsically safer in hazardous environments as they do not produce electrical sparks, reducing the risk of fires or explosions. Furthermore, they often deliver more consistent and precise torque control, crucial for maintaining product quality in critical assembly tasks, and tend to have a longer overall operational lifespan due to fewer complex electronic components.

How does torque control function in a straight air screwdriver and why is it important?

Torque control in a straight air screwdriver is typically managed by a clutch mechanism that disengages once a preset torque level is achieved, preventing over-tightening or under-tightening of fasteners. More advanced models may incorporate pneumatic logic or electronic feedback for even finer adjustments and consistency. This precise control is critically important because it ensures uniform fastening across all components, preventing material damage, improving product reliability, and meeting stringent quality standards in industries like automotive, aerospace, and electronics. Consistent torque directly impacts the structural integrity and long-term performance of assembled products.

What industries are the primary consumers of straight air screwdrivers?

The primary consumers of straight air screwdrivers are industries that require high-volume, precision fastening in their assembly processes. This includes the automotive industry for vehicle assembly, electronics manufacturing for delicate component fastening, aerospace for critical aircraft part assembly, and general industrial manufacturing for various machinery, appliances, and consumer goods. Additionally, the woodworking and furniture manufacturing sectors also utilize these tools for efficient and consistent fastening. Their robust performance and precision make them indispensable in environments where quality, speed, and reliability are paramount.

What maintenance is typically required for straight air screwdrivers?

Proper maintenance for straight air screwdrivers is essential for ensuring their longevity and optimal performance. Key maintenance tasks include regular lubrication with pneumatic tool oil, which helps to keep internal components moving smoothly and prevents rust. It's also crucial to ensure a clean and dry air supply, as moisture and contaminants can damage the motor and seals; thus, proper air filtration and water separators are necessary. Periodic inspection of hoses, fittings, and the tool's housing for wear and tear, along with cleaning air inlets and exhausts, is also recommended. Adhering to manufacturer-recommended service intervals for clutch calibration and component replacement will prevent breakdowns and maintain torque accuracy.

How do advancements in AI and IoT impact the future of straight air screwdrivers?

Advancements in AI and IoT are profoundly transforming the future of straight air screwdrivers by integrating them into smart factory ecosystems. IoT connectivity allows these tools to transmit real-time data on torque, speed, and usage patterns to central systems, enabling predictive maintenance, optimizing production workflows, and enhancing overall quality control. AI algorithms can analyze this data to dynamically adjust tool settings for optimal performance, identify potential issues before they cause downtime, and even guide robotic arms in automated assembly. This intelligent integration boosts productivity, reduces errors, minimizes operational costs, and positions straight air screwdrivers as integral components of highly efficient and adaptive manufacturing environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager