Strain Amplifier Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434199 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Strain Amplifier Market Size

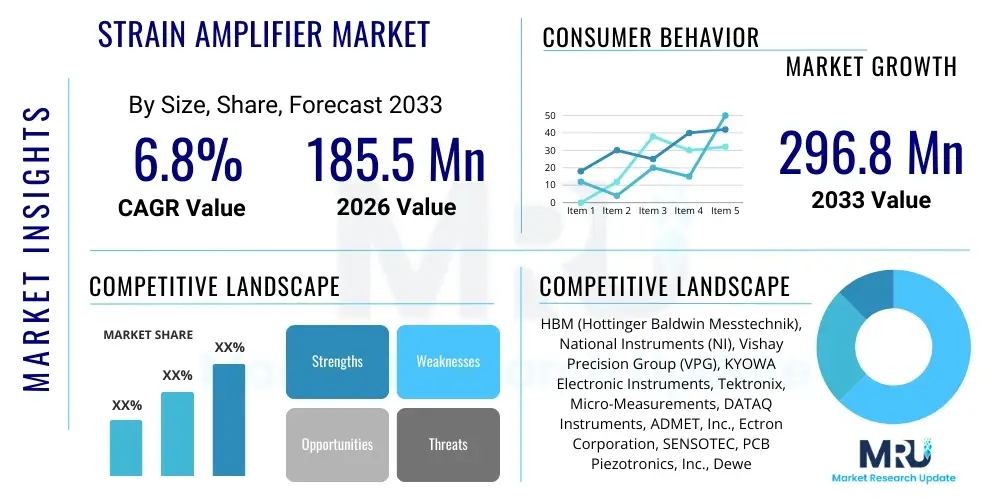

The Strain Amplifier Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 185.5 Million in 2026 and is projected to reach USD 296.8 Million by the end of the forecast period in 2033.

Strain Amplifier Market introduction

Strain amplifiers are specialized electronic instruments designed to condition, amplify, and linearize the minute electrical signals generated by strain gauges, load cells, and pressure sensors. These devices are critical components in measurement systems used across diverse industries, transforming micro-volt level changes indicative of physical deformation into usable, high-level voltage or current signals compatible with data acquisition systems (DAQ), controllers, and monitoring equipment. The primary function involves bridge excitation, signal conditioning (filtering and noise reduction), and precise amplification, ensuring accuracy and stability in quantitative physical measurement applications.

The core product description centers on high-precision instrumentation amplifiers, often featuring low noise, high common-mode rejection ratio (CMRR), and adjustable gain settings to accommodate various sensor types and sensitivity requirements. Modern strain amplifiers increasingly incorporate digital features, such as integrated analog-to-digital converters (ADCs), linearization algorithms, and digital interfaces (like Ethernet or USB), moving beyond simple analog signal processing. Major applications span structural health monitoring, quality control in manufacturing, material testing, aerodynamic research, and force/torque measurement in robotics and automation systems.

Key benefits driving market demand include improved measurement resolution, enhanced system reliability, robust performance in harsh industrial environments, and simplified integration into complex testing setups. The primary driving factors are the stringent regulatory requirements for structural integrity in civil engineering and aerospace, the proliferation of automation and smart manufacturing (Industry 4.0), and the continuous demand for high-accuracy sensor data in research and development. The necessity for precise feedback in automated production lines where force and pressure are critical variables solidifies the market's positive trajectory.

Strain Amplifier Market Executive Summary

The Strain Amplifier Market is characterized by robust growth, primarily fueled by the accelerating adoption of IoT and industrial automation solutions across developed and emerging economies. Business trends indicate a strong shift towards modular, distributed, and wireless strain amplifier systems, facilitating easier integration into large-scale monitoring projects such as bridges, wind turbines, and long-span infrastructure. Manufacturers are focusing on miniaturization and enhancing the power efficiency of standalone units, responding to the demand for portable testing equipment and sensorized infrastructure. Competition remains focused on product accuracy, calibration services, and providing comprehensive software platforms for data analysis, ensuring vendor stickiness through specialized ecosystem support.

Geographically, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, driven by massive investments in infrastructure development, rapid industrialization, and the expansion of the automotive and electronics manufacturing sectors in countries like China, India, and South Korea. North America and Europe retain market leadership in terms of technology adoption, primarily due to established aerospace, defense, and advanced medical device industries that demand ultra-high precision measurement tools. Regional trends emphasize compliance with local safety standards and the development of regional service centers to support complex installations and rapid recalibration needs.

Segmentation trends highlight the dominance of the benchtop/rack-mounted segment by revenue, catering to laboratory and heavy industrial testing, while the modular/in-line segment shows the fastest growth rate, aligning with the rise of embedded systems and smart machine design. Technology wise, digital strain amplifiers are rapidly gaining market share over purely analog counterparts, offering superior noise immunity and data processing capabilities. End-user trends confirm the increasing importance of the automotive and aerospace sectors, particularly due to the mandatory stress testing required for lightweight composite materials and new battery structures in electric vehicles and aircraft.

AI Impact Analysis on Strain Amplifier Market

User queries regarding the impact of Artificial Intelligence (AI) on the Strain Amplifier Market frequently revolve around predictive maintenance, automated data interpretation, and the enhancement of measurement accuracy. Users are concerned with how AI integration might obsolete current signal processing techniques or, conversely, how AI can optimize calibration processes and detect incipient sensor failures before critical data loss occurs. A significant thematic concern is the integration of high-volume strain data (streaming from thousands of gauges in large structures) into machine learning models for real-time structural prognosis, moving measurement systems from reactive recording tools to proactive predictive instruments.

The primary influence of AI lies in its ability to manage and analyze the complex, high-frequency data generated by modern strain amplifier systems, particularly in dynamic testing environments. AI algorithms, specifically deep learning models, are being deployed for advanced noise filtering and signal decomposition, allowing researchers and engineers to extract meaningful patterns from noisy signals that traditional filtering methods often fail to isolate. This leads to higher precision in calculating critical metrics like fatigue life and material yield strength, directly improving the value proposition of the advanced strain amplifiers capable of transmitting raw, high-bandwidth data streams.

Furthermore, AI is pivotal in enabling true Condition-Based Monitoring (CBM) by correlating subtle changes in strain data with environmental factors (temperature, humidity, vibration) and operational loads. This fusion of data allows for the creation of digital twins of physical assets, where strain data provides the 'health heartbeat.' AI-driven software integrated with amplifier hardware assists in optimizing the gain settings dynamically, performing real-time self-diagnostics, and drastically reducing the human effort required for continuous system monitoring and scheduled recalibration.

- AI enhances predictive maintenance by identifying anomalous strain patterns indicative of structural degradation.

- Machine learning optimizes dynamic calibration routines, reducing setup time and minimizing environmental drift errors.

- Deep learning algorithms enable advanced noise cancellation, increasing the signal-to-noise ratio (SNR) of amplified signals.

- AI facilitates high-throughput data analysis for structural health monitoring (SHM) systems using massive sensor arrays.

- Integration of AI in smart amplifiers supports automated fault detection and real-time self-correction of measurement offsets.

DRO & Impact Forces Of Strain Amplifier Market

The Strain Amplifier Market is driven by the global imperative for enhanced safety and quality assurance across critical industries, counterbalanced by inherent challenges related to system complexity and high initial investment costs. Opportunities arise from technological advancements, particularly the integration of wireless communication and advanced digital processing capabilities, while the competitive impact forces necessitate continuous innovation in precision and cost-efficiency. The overall market momentum is strong, driven by regulatory compliance and the accelerating shift towards smart infrastructure worldwide.

Drivers: Growing adoption of smart monitoring systems (Industry 4.0) requiring high-fidelity feedback; increasing R&D activities in material science and composite structure testing (especially in aerospace and automotive); stringent governmental regulations mandating structural integrity testing in civil infrastructure; and the demand for automated quality control systems in high-volume manufacturing environments. These factors necessitate the deployment of reliable, high-accuracy strain sensing solutions amplified by specialized instrumentation. Restraints: The primary constraints include the high cost associated with high-precision amplifiers and complex sensor installations, particularly for large-scale, distributed measurements. Additionally, challenges related to electromagnetic interference (EMI) in industrial settings and the need for frequent, expert calibration services act as dampening factors, especially for smaller enterprises with limited technical resources.

Opportunities: Significant growth pathways exist in the development of low-power, wireless strain amplification modules for long-term monitoring in remote locations; the incorporation of field-programmable gate arrays (FPGAs) for ultra-fast data acquisition and signal processing; and market expansion into emerging applications such as bio-instrumentation and precise force feedback in surgical robotics. The continuous development of novel strain gauge materials and sensor geometries also creates demand for amplifiers tailored to handle their specific electrical characteristics. Impact Forces: The bargaining power of buyers is moderate to high, as standardization is limited and purchasing decisions are heavily influenced by vendor reputation, precision specifications, and post-sale support. The threat of substitutes is low, as specialized strain amplifiers are essential for converting resistive strain measurements, making generic data acquisition units inadequate for high-fidelity applications. Competitive intensity remains high, focusing on feature differentiation, miniaturization, and software ecosystem compatibility.

Segmentation Analysis

The Strain Amplifier Market is comprehensively segmented based on the type of technology employed, the physical format/mounting, the number of channels supported, and the final end-user application. This multi-dimensional segmentation reflects the diverse requirements inherent in precision measurement across research, manufacturing, and structural monitoring domains. Understanding these segments is crucial for manufacturers to tailor product specifications, pricing strategies, and distribution channels to maximize market penetration and address specific industrial pain points, such as signal integrity in noisy environments or portability for field testing.

The segmentation by format, encompassing benchtop, modular, and in-line systems, clearly delineates the market split between controlled laboratory settings (benchtop) and robust industrial or embedded applications (modular/in-line). The increasing demand for embedded sensing within smart machines and infrastructure is pushing the modular segment to the forefront of growth, favoring small form factor and high integration capabilities. Conversely, segmentation by channel count demonstrates the bifurcation between complex testing requiring high-density multi-channel systems (often exceeding 64 channels for aerospace testing) and simple single-channel solutions used for dedicated machine feedback.

Application-based segmentation provides the clearest view of revenue drivers, with material testing and structural health monitoring being the two most dominant segments. The evolution of materials (e.g., carbon fiber composites) requires more sophisticated, high-speed strain measurement, directly driving demand for advanced digital strain amplifiers with integrated high-resolution ADCs. This analytical framework allows market participants to identify lucrative niches, such as specialized amplifiers optimized for high-temperature or cryogenic environments prevalent in certain research fields.

- By Type/Technology:

- Analog Strain Amplifiers

- Digital Strain Amplifiers (Integrated ADC/DSP)

- Wireless Strain Amplifiers

- By Format/Mounting:

- Benchtop/Rack-Mounted Amplifiers

- Modular/DIN Rail Amplifiers

- In-line/Embedded Amplifiers

- By Channel Count:

- Single-Channel Amplifiers

- Multi-Channel Amplifiers (2 to 16 Channels)

- High-Density Systems (16+ Channels)

- By End-User Application:

- Automotive Testing (Vehicle dynamics, crash testing)

- Aerospace and Defense (Fatigue testing, structural monitoring)

- Civil Engineering (Structural Health Monitoring - Bridges, Dams)

- Material Testing Laboratories

- Industrial Automation and Robotics

- Medical Devices and Bio-instrumentation

Value Chain Analysis For Strain Amplifier Market

The value chain for the Strain Amplifier Market begins with the upstream suppliers providing essential electronic components, specifically high-precision operational amplifiers, low-noise power management ICs, high-resolution analog-to-digital converters (ADCs), and specialized communication chips. The quality and stability of these core components directly dictate the final accuracy and noise performance of the strain amplifier system. Manufacturers rely on specialized semiconductor vendors to provide components that meet stringent specifications regarding thermal drift and long-term stability, which is crucial for instrumentation-grade electronics. Procurement strategies focus heavily on reliability and redundancy in the supply of high-end integrated circuits.

Midstream activities involve the design, assembly, and testing of the final amplifier units. This stage includes complex engineering processes such as circuit board layout optimization to minimize noise (EMI/RFI), firmware development for digital amplifiers, and rigorous calibration procedures. Manufacturing efficiency, particularly in modular systems, depends on advanced automated surface-mount technology (SMT) lines and subsequent quality control testing. Certification and compliance (e.g., CE, FCC, ISO standards) are critical barriers to entry at this stage, establishing product reliability and suitability for regulated industries like aerospace and medical devices.

Downstream activities involve distribution channels, installation, integration, and post-sale services. Direct sales channels are often preferred for highly customized, complex multi-channel systems, allowing manufacturers to provide specialized technical consultation and integration support directly to research institutes and large engineering firms. Indirect channels, utilizing specialized distributors, system integrators, and value-added resellers (VARs), are crucial for reaching smaller end-users and providing localized stock and rapid field support globally. The final step involves sophisticated post-installation services, including periodic recalibration, software updates, and expert training on complex data analysis software packages, reinforcing the long-term relationship between the supplier and the end-user.

Strain Amplifier Market Potential Customers

The primary end-users of strain amplifiers are entities involved in measuring physical forces, testing material properties, and ensuring the structural integrity of critical assets. This includes large-scale manufacturing enterprises that utilize automated quality control to verify product specifications, particularly in sectors where failure carries high economic or safety costs. Potential customers are deeply embedded in environments requiring precision measurements under static, dynamic, or highly transient loading conditions, making data fidelity a non-negotiable requirement for their operational success.

One major segment comprises the aerospace and defense industries, including OEMs and third-party testing facilities, which use strain amplifiers extensively for fatigue testing of airframes, engine components, and composite structures. In this context, strain amplifiers are essential tools for validating simulation models and demonstrating regulatory compliance regarding safety factors and expected service life. Similarly, the automotive industry relies on these devices for crash testing, monitoring suspension dynamics, validating chassis stiffness, and precisely measuring torque and force within powertrain components, particularly with the rapid shift towards electric vehicle (EV) development.

Another significant customer base includes civil engineering firms, government agencies responsible for infrastructure, and specialized structural health monitoring (SHM) companies. These customers deploy modular and often wireless strain amplifier systems to continuously monitor the long-term behavior of bridges, tunnels, pipelines, and dams, allowing for proactive maintenance and minimizing catastrophic failures. Additionally, academic institutions and independent material testing laboratories are perpetual customers, needing flexible, high-accuracy benchtop systems for fundamental research into material properties, stress analysis, and product development validation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.5 Million |

| Market Forecast in 2033 | USD 296.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | HBM (Hottinger Baldwin Messtechnik), National Instruments (NI), Vishay Precision Group (VPG), KYOWA Electronic Instruments, Tektronix, Micro-Measurements, DATAQ Instruments, ADMET, Inc., Ectron Corporation, SENSOTEC, PCB Piezotronics, Inc., Dewesoft, OMEGA Engineering, Futek Advanced Sensor Technology, Inc., Loadpoint Bearings, Measurement Specialties, Sensata Technologies, Mettler Toledo, Kistler Group, Spectris plc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Strain Amplifier Market Key Technology Landscape

The modern Strain Amplifier Market is rapidly evolving, driven by advancements in integrated circuit design, digital signal processing (DSP), and connectivity protocols. A central technological shift involves the transition from purely analog amplification systems to high-performance digital strain amplifiers, which incorporate embedded ADCs with resolutions often exceeding 24 bits and high sampling rates (up to several hundred kHz per channel). This digital integration provides superior immunity to electrical noise, allows for precise digital linearization and compensation for thermal drift in the strain gauges, and facilitates direct communication via industrial protocols like Ethernet/IP or EtherCAT, crucial for distributed monitoring networks.

Another significant technological focus is on enhancing wireless capabilities. Wireless strain amplifier modules, powered by low-energy protocols such as Bluetooth Low Energy (BLE) or specialized industrial wireless standards, are enabling monitoring in previously inaccessible or highly dynamic environments, such as rotating machinery or remote civil structures. These systems integrate power management features to support long-term, battery-operated deployment while maintaining required data sampling rates. The challenge remains in balancing battery life with data throughput, leading manufacturers to develop smart sampling techniques and edge processing capabilities within the modules themselves.

Furthermore, the incorporation of advanced filtering techniques, including Kalman filters and bespoke algorithms implemented on Field-Programmable Gate Arrays (FPGAs), allows for real-time processing of high-frequency dynamic strain data, which is essential for vibration analysis and high-speed impact testing. The trend toward modular and scalable systems, often utilizing standardized rack architectures (e.g., PXI or proprietary modular platforms), ensures that end-users can easily expand their measurement systems and integrate strain amplifiers alongside other sensor conditioning units, providing flexible solutions for complex, multi-physics testing scenarios.

Regional Highlights

The global distribution of the Strain Amplifier Market reflects the concentration of high-tech manufacturing, advanced research institutions, and large-scale infrastructure projects. Regional market strength is intrinsically linked to industrial activity in aerospace, automotive, and civil engineering sectors, as these are the heaviest users of high-precision strain measurement technology. Developed regions typically lead in adopting the latest digital and wireless amplification technologies, while emerging markets often focus on mass deployment of robust, cost-effective analog or entry-level digital systems for rapid industrial expansion.

North America holds a substantial share of the market, primarily driven by the massive presence of aerospace and defense contractors, stringent safety standards for infrastructure, and a robust research and development ecosystem. The demand is particularly high for sophisticated, multi-channel dynamic testing systems used in military and commercial aircraft certification, coupled with substantial investments in next-generation material science testing. Regulatory emphasis on structural integrity and product reliability ensures a continuous, high-value demand for certified, precision strain amplifiers and associated services.

Asia Pacific (APAC) is projected to be the fastest-growing region over the forecast period. This growth is underpinned by unprecedented government spending on new transportation infrastructure (high-speed rail, bridges, ports) and the rapid expansion of domestic automotive and electronics manufacturing bases, particularly in China and India. While initial market entry often involves price-sensitive solutions, there is an increasing shift toward high-quality digital systems as local industries mature and prioritize quality control and international certification standards. Europe maintains a strong market position, characterized by established automotive excellence (Germany, France) and specialized material research capabilities, driving demand for precise, customizable laboratory-grade and modular industrial strain amplifiers.

- North America (US & Canada): Dominant in high-precision aerospace and defense testing; significant adoption of digital and wireless amplification for large infrastructure monitoring (SHM).

- Europe (Germany, UK, France): High demand from established automotive and specialized industrial manufacturing; strong focus on R&D for advanced material fatigue testing.

- Asia Pacific (China, India, Japan): Fastest growing region due to vast infrastructure development and expansion of mass manufacturing; increasing investment in localized high-density testing facilities.

- Latin America (Brazil, Mexico): Emerging market driven by oil & gas pipeline monitoring and localized automotive manufacturing; focus on robust, reliable industrial instrumentation.

- Middle East & Africa (MEA): Growth driven by large-scale construction projects, including megacities and energy sector development (oil & gas infrastructure monitoring).

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Strain Amplifier Market.- HBM (Hottinger Baldwin Messtechnik)

- National Instruments (NI)

- Vishay Precision Group (VPG)

- KYOWA Electronic Instruments

- Tektronix

- Micro-Measurements

- DATAQ Instruments

- ADMET, Inc.

- Ectron Corporation

- SENSOTEC

- PCB Piezotronics, Inc.

- Dewesoft

- OMEGA Engineering

- Futek Advanced Sensor Technology, Inc.

- Loadpoint Bearings

- Measurement Specialties

- Sensata Technologies

- Mettler Toledo

- Kistler Group

- Spectris plc

Frequently Asked Questions

Analyze common user questions about the Strain Amplifier market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the fundamental difference between analog and digital strain amplifiers?

Analog strain amplifiers process signals purely using hardware components, offering high bandwidth but susceptibility to noise and drift. Digital strain amplifiers incorporate an Analog-to-Digital Converter (ADC) and often a Digital Signal Processor (DSP), providing superior noise immunity, integrated linearization, and direct digital output for improved accuracy and easier integration into modern networked data acquisition systems.

Why is temperature compensation critical for strain amplifier performance?

Temperature compensation is critical because the resistance of strain gauges and their lead wires, as well as the amplifier's internal electronics, change significantly with temperature, introducing measurement errors (thermal drift). High-quality strain amplifiers utilize advanced circuitry, often involving internal reference gauges (like Wheatstone bridge completion) and digital algorithms, to nullify these temperature-induced offsets, ensuring stable and accurate measurements.

Which end-user segment is driving the highest demand for multi-channel strain amplifiers?

The aerospace and civil engineering sectors are driving the highest demand for multi-channel strain amplifiers. Aerospace testing requires simultaneous monitoring of hundreds of strain points on airframes and components during fatigue and static load tests, while civil structural health monitoring (SHM) necessitates large, distributed sensor arrays to track structural behavior over extended periods.

How does Industry 4.0 adoption influence the technological development of strain amplifiers?

Industry 4.0 drives demand for strain amplifiers to be modular, miniaturized, and network-enabled (e.g., supporting EtherCAT or PROFINET). This integration allows for real-time force and stress data feedback directly into manufacturing control systems and AI platforms, facilitating predictive maintenance, automated quality control, and the creation of digital twins for critical production assets.

What major challenges restrict the widespread adoption of wireless strain amplification systems?

The major challenges include maintaining reliable data integrity over wireless links in noisy industrial environments, balancing required high sampling rates with battery longevity for long-term deployments, and managing the complexity of synchronizing data streams from numerous distributed wireless nodes for dynamic measurements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager