Strain Gage Meters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439126 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Strain Gage Meters Market Size

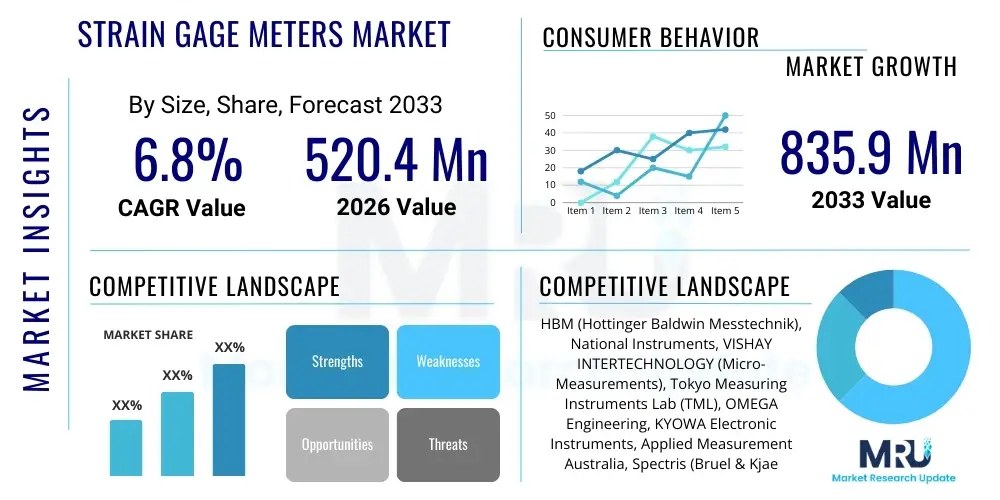

The Strain Gage Meters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 520.4 million in 2026 and is projected to reach USD 835.9 million by the end of the forecast period in 2033.

Strain Gage Meters Market introduction

Strain Gage Meters are crucial instruments used for accurately measuring mechanical strain, which is a key parameter in determining stress, force, and displacement within materials and structures. These meters primarily operate by receiving and conditioning the electrical signal output from a strain gauge sensor, typically configured in a Wheatstone bridge circuit. The high precision and reliability offered by these measurement systems make them indispensable across various high-stakes industries, ensuring structural integrity and optimizing performance in critical applications.

The core product technology centers around sophisticated data acquisition and processing capabilities, transforming minute changes in resistance—caused by physical strain—into usable digital or analog measurements. Major applications span structural health monitoring in civil engineering, rigorous fatigue testing in automotive and aerospace sectors, quality control in material science, and load monitoring in industrial machinery. These meters often integrate features like high sampling rates, multi-channel inputs, and advanced filtering to handle dynamic testing environments and deliver accurate results under diverse operating conditions.

Driving factors for the market expansion include the global increase in infrastructure development requiring continuous health monitoring, the escalating demand for lightweight yet robust materials in manufacturing, and the stringent regulatory standards mandating detailed safety and longevity testing of components. The integration of Strain Gage Meters into larger Industrial Internet of Things (IIoT) ecosystems further enhances their utility, enabling remote monitoring and predictive maintenance strategies that significantly reduce operational downtime and costs for end-users worldwide.

Strain Gage Meters Market Executive Summary

The Strain Gage Meters Market is experiencing robust growth driven by accelerating technological convergence, particularly the integration of wireless communication and advanced digital processing capabilities into sensing solutions. Business trends indicate a strong shift towards modular and portable testing equipment, allowing for greater flexibility in fieldwork and remote diagnostics, thereby appealing to sectors like civil engineering and field automotive testing. Key market players are investing heavily in software solutions that enhance data visualization, automated calibration, and integration with cloud platforms, moving beyond mere measurement tools to comprehensive data analysis systems.

Regional trends highlight the Asia Pacific (APAC) region as the fastest-growing market, primarily fueled by massive infrastructural projects in countries like China and India, coupled with rapid expansion in domestic automotive and electronics manufacturing. North America and Europe, while mature, maintain leadership in high-end applications, focusing on aerospace defense and sophisticated materials testing, where demand for extreme accuracy and reliability is paramount. The increasing adoption of advanced materials such as composites necessitates specialized strain measurement tools, driving innovation in meter sensitivity and temperature compensation algorithms across all major geographies.

Segment trends emphasize the proliferation of digital strain gage meters over traditional analog counterparts, attributed to superior noise immunity, simplified data logging, and seamless integration with computerized analysis systems. Furthermore, the specialized application segment focusing on high-temperature and harsh environment testing is witnessing substantial growth, pushing manufacturers to develop ruggedized meters and associated sensors capable of maintaining accuracy under extreme operational duress. This shift towards application-specific, high-performance metering solutions defines the competitive trajectory for the forecast period.

AI Impact Analysis on Strain Gage Meters Market

Common user questions regarding AI's impact on the Strain Gage Meters Market typically revolve around automated data interpretation, predictive failure analysis, and the optimization of testing cycles. Users frequently inquire about how AI can filter out noise and drift to provide cleaner strain data, whether machine learning algorithms can automate complex sensor calibration, and if integrating AI models can lead to real-time structural health diagnosis rather than just raw data collection. These concerns highlight the desire for Strain Gage Meters to transition from passive data recorders to intelligent, proactive monitoring systems capable of extracting actionable insights immediately at the edge or via cloud-based analytics, fundamentally altering how stress testing and structural integrity management are executed in the field.

- AI enhances predictive maintenance protocols by analyzing historical strain data patterns, enabling early detection of material fatigue or structural anomalies before catastrophic failure occurs.

- Machine learning algorithms significantly improve signal processing capabilities, filtering environmental noise and temperature-induced drift from strain measurements, leading to higher data fidelity and precision.

- Automated Test Script Generation (ATSG) powered by AI optimizes the efficiency of large-scale testing campaigns, reducing the time required for setup, execution, and post-processing of strain measurement data.

- AI facilitates sensor fusion, integrating strain gage meter data with inputs from accelerometers, temperature sensors, and displacement transducers to provide a holistic and context-aware understanding of structural performance.

- Generative AI tools assist design engineers by simulating optimal sensor placement and configuration for complex geometries, maximizing the effectiveness of the strain measurement layout prior to physical installation.

- AI-driven automated calibration routines reduce downtime and cost associated with manual meter verification, ensuring sustained measurement accuracy throughout the instrument's operational lifecycle.

DRO & Impact Forces Of Strain Gage Meters Market

The market dynamics for Strain Gage Meters are predominantly shaped by robust drivers such as the escalating investment in critical national infrastructure—including bridges, dams, and railways—which necessitates continuous, high-precision structural health monitoring systems. Concurrently, the rigorous testing standards within the automotive sector, driven by the shift towards electric vehicles (EVs) and lightweight body designs, require advanced strain mapping for safety and performance validation. However, the market faces restraints, chiefly the inherent sensitivity of strain gauges to environmental factors like temperature and humidity, which necessitates costly and complex compensation hardware and software, adding to the total cost of ownership. The intense demand for highly skilled technicians for proper sensor installation and calibration also poses a restraint on widespread adoption in less developed regions. Opportunities abound in the development of fully integrated wireless sensor networks (WSNs) that simplify deployment and maintenance, particularly leveraging low-power wide-area network (LPWAN) technologies to transmit strain data over vast distances efficiently.

Segmentation Analysis

The Strain Gage Meters market is segmented based on the instrument type, the core technology employed, the specific end-user industry, and the application area. Segmentation provides critical insights into specialized demand pockets, showing preference differences between laboratory-grade, high-channel-count systems used in R&D and robust, compact meters utilized for field measurements. The differentiation between analog and digital output meters is crucial, with digital solutions increasingly dominating due to superior integration capabilities and data integrity. Analyzing these segments helps manufacturers tailor product development towards specific industry requirements, such as high-frequency dynamic testing demanded by the aerospace industry versus long-term, static monitoring prevalent in civil infrastructure projects.

- By Type:

- Analog Strain Gage Meters

- Digital Strain Gage Meters (including high-speed and low-speed DAC units)

- Portable/Handheld Meters

- Benchtop/Modular Systems

- By Application:

- Stress and Fatigue Testing

- Structural Health Monitoring (SHM)

- Load and Force Measurement

- Torque Measurement

- Material Testing

- By End-User Industry:

- Automotive and Transportation

- Aerospace and Defense

- Civil Engineering and Construction

- Industrial Machinery and Robotics

- Oil and Gas

- Research and Development (R&D)

- By Technology:

- Resistance-Based Strain Gage Meters

- Fiber Optic Strain Sensing Meters

- MEMS-Based Strain Sensing Systems

Value Chain Analysis For Strain Gage Meters Market

The value chain for Strain Gage Meters begins upstream with the sourcing of highly specialized raw materials, including thin resistive foil materials (Constantan, Karma alloys), high-purity semiconductor materials for transducer manufacturing, and robust housing polymers. Upstream activities also involve the design and production of high-precision electronic components, such as Analog-to-Digital Converters (ADCs), microprocessors, and sophisticated signal conditioning chips, where supplier stability and quality control are paramount to the final instrument's accuracy. Key challenges in this phase include maintaining consistent quality of resistive elements and ensuring the stability of bonding agents used in sensor attachment.

The midstream focuses on manufacturing and assembly, encompassing the calibration and certification of the meters. This stage requires significant investment in cleanroom environments and advanced metrology equipment to achieve traceable measurement standards. Manufacturers differentiate themselves through proprietary signal conditioning techniques, software development for data analysis, and adherence to international quality standards (e.g., ISO/IEC 17025). The efficiency of manufacturing processes, particularly in modular and multi-channel systems, directly influences market competitiveness and profitability.

Downstream distribution channels are bifurcated into direct sales to large institutional clients (Aerospace, major R&D labs) requiring complex integration support, and indirect channels relying on specialized distributors and system integrators who provide localized technical support and often combine the meters with custom testing rigs. Post-sales services, including mandatory periodic calibration, maintenance contracts, and technical training, constitute a significant portion of the downstream value. The role of specialized integrators is growing, especially in complex Structural Health Monitoring projects where the meters must be seamlessly interfaced with IT infrastructure and visualization platforms.

Strain Gage Meters Market Potential Customers

Potential customers for Strain Gage Meters are highly diversified, spanning multiple industries where the accurate measurement of physical integrity and load bearing is critical for safety, regulatory compliance, and performance optimization. Major end-users include original equipment manufacturers (OEMs) in the transportation sector, particularly automotive companies that utilize meters for crash testing, chassis stress analysis, and optimizing battery housing structures in electric vehicles to ensure compliance with stringent safety regulations. Aerospace and Defense organizations represent a premium customer base, requiring ultra-high-accuracy meters for flight safety critical applications, including wing fatigue analysis and testing of composite materials under extreme thermal and mechanical loads.

Furthermore, civil engineering firms and government bodies responsible for infrastructure maintenance are significant buyers, utilizing these meters for long-term structural health monitoring (SHM) of bridges, tunnels, and large buildings to prevent catastrophic failure and schedule predictive maintenance. Industrial machinery manufacturers, including those producing heavy equipment, robotics, and complex tooling, rely on strain gage meters embedded within their quality control processes to validate design parameters and ensure the durability and reliability of their products under heavy operational stress. The continuous expansion of global construction and manufacturing activities ensures a steady and increasing demand across these diverse customer segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 520.4 million |

| Market Forecast in 2033 | USD 835.9 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | HBM (Hottinger Baldwin Messtechnik), National Instruments, VISHAY INTERTECHNOLOGY (Micro-Measurements), Tokyo Measuring Instruments Lab (TML), OMEGA Engineering, KYOWA Electronic Instruments, Applied Measurement Australia, Spectris (Bruel & Kjaer), GE Measurement & Control, Siemens, ADLINK Technology, Dataforth Corporation, Campbell Scientific, Futek Advanced Sensor Technology, PCB Piezotronics, Instron, Ectron Corporation, SENSYS Calibration. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Strain Gage Meters Market Key Technology Landscape

The technological landscape of the Strain Gage Meters Market is rapidly evolving, moving away from purely analog signal processing towards highly integrated digital systems that offer enhanced accuracy and data management capabilities. A key technology advancement is the proliferation of high-resolution Analog-to-Digital Converters (ADCs) embedded directly within the meters, enabling high-fidelity data capture at rapid sampling rates, crucial for dynamic testing scenarios like impact analysis and vibrational testing. Furthermore, Digital Signal Processing (DSP) techniques are increasingly utilized to condition and analyze the signal in real-time, effectively mitigating common issues such as thermal drift, electromagnetic interference, and creep, thereby maintaining measurement integrity under diverse operational stresses.

Another significant technological driver is the adoption of wireless connectivity standards, including Bluetooth Low Energy (BLE) and various Wi-Fi protocols, transforming previously cumbersome wired test setups into flexible, distributed sensor networks. This wireless integration is fundamental to the growth of Structural Health Monitoring (SHM) systems, allowing meters to be deployed in remote or difficult-to-access locations without extensive cabling infrastructure. Moreover, miniaturization enabled by advancements in microelectronics and MEMS (Micro-Electro-Mechanical Systems) based strain sensing technologies is producing compact, low-power meters suitable for embedding directly into components, offering localized and highly efficient strain mapping capabilities.

The future technology trajectory points toward greater integration with edge computing and cloud platforms. Smart Strain Gage Meters are being developed with onboard processing power capable of executing machine learning algorithms locally. This capability allows for immediate anomaly detection and data compression before transmission, significantly reducing bandwidth requirements and latency. Materials science also plays a vital role, with ongoing research focusing on developing more stable and less temperature-sensitive resistive elements and advanced bonding agents that ensure long-term stability and high reliability, particularly in harsh environments found in the oil and gas or extreme temperature testing sectors.

Regional Highlights

- North America: This region holds a significant market share, characterized by high spending on advanced research and development, particularly in the aerospace, defense, and automotive R&D sectors. The stringent regulatory environment, especially concerning structural safety and material performance, necessitates the use of premium, high-accuracy strain measurement systems. The presence of major technology hubs and leading aerospace manufacturers drives continuous innovation in multi-channel data acquisition systems and real-time structural health monitoring solutions.

- Europe: Europe is a mature market distinguished by strong industrial automation and high engineering standards, particularly in Germany (automotive) and the UK/France (aerospace). The region prioritizes quality and traceability, leading to high demand for certified, laboratory-grade benchtop and modular strain gage systems. Furthermore, European Union initiatives promoting sustainable and resilient infrastructure heavily influence the adoption of advanced long-term monitoring equipment for existing structures and new construction projects.

- Asia Pacific (APAC): APAC is projected to exhibit the highest CAGR during the forecast period, primarily driven by massive government investments in infrastructure development (e.g., high-speed rail, smart cities) across China, India, and Southeast Asia. The rapid expansion of manufacturing capabilities, coupled with increasing domestic demand for higher quality assurance in consumer electronics and electric vehicles, fuels the demand for cost-effective yet reliable digital strain gage meters for quality control and fatigue testing.

- Latin America: This region demonstrates steady growth, concentrated mainly in Brazil and Mexico, fueled by manufacturing output and localized resource extraction industries (mining, oil and gas). The market is often cost-sensitive, driving demand for robust and simple-to-use portable meters suitable for field testing and routine maintenance checks in remote industrial settings.

- Middle East and Africa (MEA): Growth in MEA is highly dependent on large-scale infrastructure projects (e.g., mega-city developments in the UAE and Saudi Arabia) and the oil and gas industry. Strain gage meters are critical for monitoring pipeline integrity, platform stress levels, and ensuring the structural soundness of new, ambitious construction projects, requiring devices capable of withstanding extreme desert temperatures and salinity.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Strain Gage Meters Market.- HBM (Hottinger Baldwin Messtechnik)

- National Instruments

- VISHAY INTERTECHNOLOGY (Micro-Measurements)

- Tokyo Measuring Instruments Lab (TML)

- OMEGA Engineering

- KYOWA Electronic Instruments

- Applied Measurement Australia

- Spectris (Bruel & Kjaer)

- GE Measurement & Control

- Siemens

- ADLINK Technology

- Dataforth Corporation

- Campbell Scientific

- Futek Advanced Sensor Technology

- PCB Piezotronics

- Instron

- Ectron Corporation

- SENSYS Calibration

- Dewesoft

- Hi-Techniques

Frequently Asked Questions

Analyze common user questions about the Strain Gage Meters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between analog and digital strain gage meters?

Analog meters typically output a voltage signal proportional to the strain, requiring external data acquisition hardware. Digital meters integrate the Analog-to-Digital Converter (ADC) internally, providing conditioned, high-resolution digital data directly, which enhances noise immunity and simplifies integration with modern computing systems.

How is temperature compensation achieved in strain gage measurement systems?

Temperature compensation is primarily achieved through the use of self-temperature-compensated strain gauges designed to match the thermal expansion coefficient of the test material, or more commonly, through the use of a Wheatstone bridge configuration with a dummy gauge positioned on an unstressed piece of the same material to nullify thermal effects.

What role does Structural Health Monitoring (SHM) play in driving the Strain Gage Meters Market?

SHM systems rely heavily on continuously collecting high-fidelity strain data to assess the real-time integrity and longevity of critical civil and mechanical structures. The mandatory need for predictive maintenance and safety compliance in aging infrastructure globally is the principal factor driving demand for robust, long-term deployable strain gage meters, often featuring wireless capabilities.

Which industry accounts for the largest application segment of strain gage meters?

The Automotive and Transportation industry segment currently accounts for a substantial share due to the intensive requirement for component validation, crash testing, fatigue analysis of new materials, and optimization of vehicle designs, particularly with the transition toward electric vehicle (EV) platforms and lightweighting strategies.

What are the benefits of integrating AI/Machine Learning with strain measurement?

AI/ML integration improves data quality by automatically filtering noise and compensating for environmental drift. It also enables automated anomaly detection and advanced predictive analysis, allowing users to move beyond raw data collection to actionable insights regarding component life expectancy and real-time structural safety assessments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager