Strain Gauge Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432265 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Strain Gauge Market Size

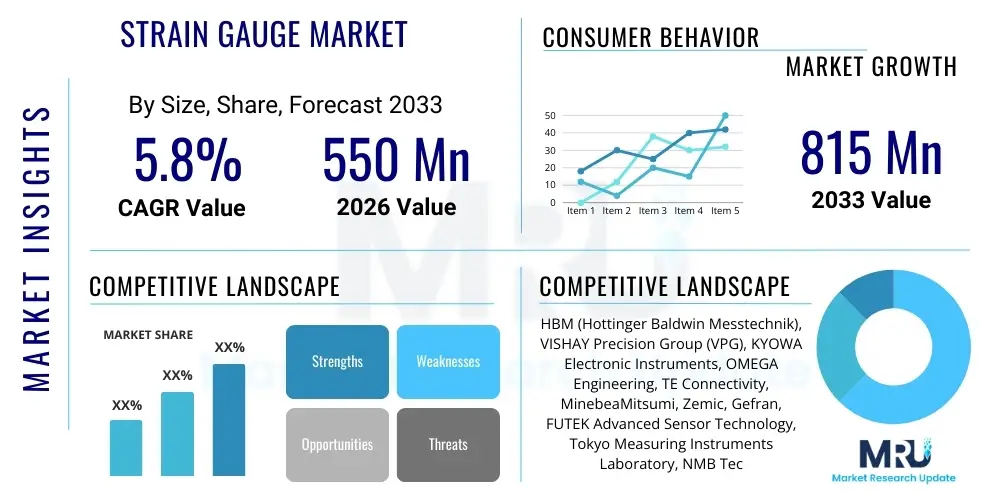

The Strain Gauge Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $550 million in 2026 and is projected to reach $815 million by the end of the forecast period in 2033.

Strain Gauge Market introduction

The Strain Gauge Market focuses on the design, manufacturing, and distribution of sensors utilized for measuring strain, stress, torque, pressure, and displacement in materials and structures. These fundamental measurement devices operate on the principle of piezoresistivity, where the electrical resistance of the gauge material changes proportionally to the mechanical strain applied. Strain gauges are not only crucial standalone sensors but also form the core component of various transducers, including load cells, pressure sensors, and torque transducers, making them indispensable across virtually all engineering disciplines requiring precise physical measurements. The core product definition involves highly sensitive resistance elements mounted onto a substrate, encapsulated for protection, and wired into a Wheatstone bridge circuit for output signal generation. Their ability to deliver high-fidelity, linear responses to minute deformations distinguishes them in the sensor market.

Major applications for strain gauges are intensely focused on safety-critical and performance-driven sectors. In the Aerospace and Defense industry, they are used extensively for structural health monitoring (SHM) of aircraft wings, fuselage joints, and engine components, ensuring compliance with rigorous flight safety standards and lifespan prediction models. The Automotive sector leverages strain gauges for optimizing chassis design, testing crashworthiness, monitoring engine performance, and developing advanced suspension systems. Furthermore, in Civil Engineering, these devices are essential for long-term monitoring of infrastructure like bridges, dams, and tunnels, providing early warnings about potential structural degradation. The primary benefits include precise structural analysis, validation of Finite Element Method (FEM) simulations, material property determination, and effective quality control in manufacturing processes, ultimately leading to enhanced product reliability and optimized material costs across industrial operations.

The market growth trajectory is significantly propelled by several driving factors, including the global push toward Industry 4.0 and the massive deployment of connected devices (IoT) in industrial environments, necessitating constant, accurate monitoring of mechanical processes. Increased investment in infrastructure projects, particularly in developing nations, coupled with stringent government regulations concerning the structural integrity of public assets, mandate the wider adoption of sensor-based monitoring systems. Additionally, continuous technological advancements focusing on miniaturization, enhanced sensitivity, and the development of fiber optic and wireless strain gauge variants are broadening their applicability into harsh environments and difficult-to-access locations, further stimulating market expansion and replacing older, less precise mechanical testing methods with real-time digital solutions.

Strain Gauge Market Executive Summary

The Strain Gauge Market is characterized by robust growth driven by high-precision demands in critical industries like aerospace and automotive, alongside the pervasive influence of smart factory initiatives. Current business trends indicate a strong shift towards digital integration, with manufacturers prioritizing the development of gauges offering wireless connectivity, integrated data logging capabilities, and advanced temperature compensation techniques to maintain accuracy in fluctuating environments. Consolidation and strategic partnerships among technology providers and specialized sensor manufacturers are prevalent, aiming to create comprehensive measurement ecosystems that encompass the entire signal chain, from sensor to analysis software. Furthermore, the rising cost of raw materials and the need for high-purity specialized foils present moderate challenges, pushing companies toward optimized manufacturing processes and higher value-added product lines.

Regionally, Asia Pacific (APAC) stands out as the primary engine for market growth, attributed to monumental investments in infrastructural development in countries like China and India, coupled with rapid expansion in domestic automotive manufacturing and electronics production. North America and Europe, while being mature markets, maintain high demand due to stringent safety regulations and intensive R&D activities, particularly in defense and medical device sectors, focusing on cutting-edge, high-temperature, and ultra-high-precision gauges. Latin America and the Middle East and Africa (MEA) are emerging as high-potential markets, driven by oil and gas infrastructure expansion and increasing mining activities, which require robust strain and pressure monitoring solutions adapted to harsh operating conditions and remote deployment scenarios.

In terms of segmentation, the Foil Strain Gauge segment currently dominates the market due to its high accuracy, stability, and cost-effectiveness, making it the preferred choice for general-purpose industrial applications. However, the Semiconductor Strain Gauge segment is projected to exhibit the fastest growth rate, fueled by its extremely high gauge factor, which is critical for measuring minute strains in specialized medical and consumer electronics applications where sensitivity is paramount. The Application segment is heavily tilted towards the Test & Measurement category, but the Original Equipment Manufacturer (OEM) integration into transducers (load cells, pressure sensors) represents a foundational and steadily growing revenue stream, integral to long-term market stability and diversification across various end-user product manufacturing processes.

AI Impact Analysis on Strain Gauge Market

Common user questions regarding AI's impact on the Strain Gauge Market revolve around automation potential, predictive maintenance capabilities, and the integration of machine learning for advanced data interpretation. Users frequently inquire about how AI can enhance the accuracy and reliability of measurements, specifically addressing issues like sensor drift, noise reduction, and compensating for environmental variables without human intervention. Key concerns center on whether AI-driven analysis tools will require specialized training or hardware integration, and how effectively AI can identify subtle structural anomalies before they lead to critical failure, moving beyond simple threshold alerts. The general expectation is that AI will transform raw strain data into actionable, predictive insights, significantly lowering operational risks and maintenance costs across large monitoring networks.

- AI algorithms enable sophisticated anomaly detection in continuous strain monitoring data, identifying deviations indicative of fatigue or structural damage far earlier than traditional methods.

- Integration of machine learning models optimizes the calibration and compensation processes for strain gauges, automatically correcting for non-linearities caused by temperature variations and material creep.

- AI facilitates predictive maintenance schedules by analyzing long-term strain trends, allowing operators to prioritize inspection and repair activities based on calculated remaining useful life (RUL) estimates for infrastructure.

- Automated sensor network management utilizes AI to diagnose faulty gauges, optimize power consumption in wireless networks, and ensure data integrity across thousands of measurement points simultaneously.

- Generative AI models assist in designing optimal strain gauge placement and configuration on complex geometries by simulating stress distributions and validating theoretical sensor requirements, reducing physical prototyping cycles.

DRO & Impact Forces Of Strain Gauge Market

The dynamics of the Strain Gauge Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively determine the market's trajectory and competitive landscape. The primary drivers include rapid industrialization and escalating investments in infrastructure across emerging economies, coupled with stringent global regulatory standards demanding precise structural safety monitoring in sectors like aerospace, automotive, and civil engineering. Opportunities arise from technological advancements, particularly the development of high-performance, non-contact, and wireless sensing solutions, alongside the integration of strain data into comprehensive IoT ecosystems and predictive maintenance platforms. Conversely, the high sensitivity of gauges to temperature fluctuations, the requirement for complex installation and calibration procedures, and the availability of alternative sensing technologies (e.g., optical fibers, laser interferometers) pose significant restraints to uniform market adoption and expansion. These forces create a nuanced market environment prioritizing specialized, integrated solutions over generalized components.

The impact forces influencing the market are multifaceted, spanning technological shifts and economic pressures. Technological impact is high, driven by the shift towards miniaturization and the need for gauges capable of operating reliably in extreme conditions, such as high vacuum or cryogenics, which demands intensive materials science R&D. Economic forces, including fluctuating raw material costs (e.g., specialized nickel-chromium alloys) and varying degrees of industrial spending across regions, directly affect profitability and production scaling. Furthermore, the competitive intensity is increasing as global players seek to differentiate through specialized service offerings, including full system integration, advanced signal conditioning, and proprietary data analysis software, moving beyond mere hardware supply and emphasizing the total cost of ownership (TCO) for end-users.

Regulatory frameworks also exert a critical impact, particularly in highly regulated industries. For instance, aerospace certifications mandate specific quality and traceability standards for every component, ensuring that strain gauges used in flight-critical applications adhere to exceptionally high standards, which limits market entry for non-compliant suppliers. Geopolitical stability and global trade policies influence the supply chain of specialized sensor materials and electronic components, affecting lead times and pricing. Overall, the market remains moderately consolidated but highly competitive in niche high-precision segments, necessitating continuous innovation in gauge design and system integration capabilities to maintain relevance and capture growth opportunities.

Segmentation Analysis

The Strain Gauge Market is fundamentally segmented based on factors such as type, material, application, and operating temperature, reflecting the diverse requirements across various end-user industries. This detailed segmentation allows manufacturers to tailor their product offerings to specific operational demands, optimizing gauge sensitivity, stability, and durability for particular environments, whether they involve high static loads in civil engineering or high-frequency dynamic measurements in aerospace testing. Understanding these segments is crucial for strategic market positioning, enabling companies to focus R&D efforts on emerging high-growth areas, such as fiber optic sensors for hazardous or electromagnetic interference-prone environments, which represent a premium opportunity within the Type segmentation.

- By Type:

- Foil Strain Gauges

- Wire Strain Gauges

- Semiconductor Strain Gauges

- Thin-Film Strain Gauges

- Fiber Optic Strain Gauges

- By Operating Temperature:

- Standard Temperature Gauges (-30°C to 150°C)

- High Temperature Gauges (Above 150°C)

- Cryogenic Gauges (Below -150°C)

- By Application:

- Industrial Measurement & Control

- Test & Measurement (R&D)

- OEM Integration (Load Cells, Transducers)

- Structural Health Monitoring (SHM)

- By End-Use Industry:

- Aerospace & Defense

- Automotive

- Civil Engineering

- Medical

- Consumer Electronics

- Oil & Gas and Energy

Value Chain Analysis For Strain Gauge Market

The Strain Gauge market value chain begins with the upstream suppliers responsible for highly specialized raw materials. This includes providers of high-purity metal alloys (such as Constantan or Karma), semiconductor wafers (silicon), and specialized polymer substrates and adhesives. The quality and consistency of these materials directly dictate the performance characteristics, such as the gauge factor and temperature stability, of the final product. Procurement activities at this stage focus heavily on securing long-term contracts and ensuring material traceability, given the precision requirements of the end-use applications. Suppliers specializing in photolithography and etching equipment are also critical upstream partners, enabling the precise geometric patterns required for foil and thin-film gauge manufacturing, which emphasizes the need for high capital expenditure and specialized process control at the manufacturing stage.

The core manufacturing and processing stage involves highly technical steps: pattern generation, bonding to the substrate, encapsulation, and lead wire attachment. This stage is dominated by specialized gauge manufacturers who possess proprietary know-how regarding thermal treatments and encapsulation techniques necessary to ensure long-term stability and resilience against environmental factors. Distribution channels play a vital role, often categorized into direct sales and indirect sales via specialized distributors. Direct channels are typically utilized for large-volume OEM contracts or complex custom projects requiring deep technical consultancy, such as major aerospace R&D programs. Indirect channels, involving authorized dealers and system integrators, handle standard product lines and serve a broader base of small to medium-sized enterprises (SMEs) requiring off-the-shelf solutions and local technical support.

The downstream segment primarily consists of system integrators, test labs, and end-users. System integrators combine strain gauges with signal conditioners, data acquisition systems (DAQ), and analytical software to provide a complete measurement solution, adding significant value through calibration and installation services. The ultimate end-users are spread across the diverse industrial landscape, utilizing the gauges for critical measurement tasks. The relationship with downstream players is crucial for feedback on product performance and defining requirements for future product development, particularly concerning ruggedness and ease of integration into existing industrial setups. Effective value capture occurs through proprietary sensing technology and specialized system integration services, positioning manufacturers who offer holistic solutions favorably in the competitive market landscape.

Strain Gauge Market Potential Customers

Potential customers for strain gauges span the full spectrum of industries that prioritize structural integrity, material testing, and precise force measurement. The primary consumer base includes major Original Equipment Manufacturers (OEMs) who integrate strain gauges into their own products, such as manufacturers of industrial machinery, specialized medical diagnostic equipment, and automotive component suppliers who embed these sensors into vehicle chassis or engine monitoring systems. Furthermore, independent commercial and governmental testing laboratories constitute a significant customer segment, relying on strain gauges for material characterization, fatigue testing, and quality assurance processes essential for certification and compliance verification across multiple product lines and engineering projects.

A second major category of potential customers includes large-scale infrastructure owners and operators, such as utility companies, railway authorities, and civil engineering firms. These entities utilize strain gauges extensively for Structural Health Monitoring (SHM) of critical assets like bridges, power plants, wind turbines, and pipelines. The demand here is often for highly durable, long-life gauges that can be networked for continuous, remote monitoring, often necessitating wireless or fiber optic variants to withstand harsh outdoor conditions and prolonged exposure to environmental stressors, thereby moving the purchasing decision towards specialized, robust systems rather than simple, disposable sensors.

Finally, the academic and research community represents a constantly growing customer base. Universities and private R&D centers globally require precision strain gauges for advanced material science research, development of new composites, biomechanical studies, and experimental validation of theoretical models. These customers frequently require small volumes of highly specialized gauges—such as miniature semiconductor gauges or custom-designed thin-film sensors—to measure strains in unique and challenging experimental conditions. The purchasing drivers for this segment are centered on extreme accuracy, sensitivity, and the availability of specialized technical support from the manufacturer to facilitate complex research setups.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 million |

| Market Forecast in 2033 | $815 million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | HBM (Hottinger Baldwin Messtechnik), VISHAY Precision Group (VPG), KYOWA Electronic Instruments, OMEGA Engineering, TE Connectivity, MinebeaMitsumi, Zemic, Gefran, FUTEK Advanced Sensor Technology, Tokyo Measuring Instruments Laboratory, NMB Technologies, Sichuan Hengchuang Technology, Interface Inc., Shenzhen Sensor Technology, Micro-Measurements (VPG brand), Althen Sensors, G. V. Das & Sons, Sensing Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Strain Gauge Market Key Technology Landscape

The technological landscape of the Strain Gauge Market is undergoing continuous innovation focused on enhancing accuracy, durability, and integration capabilities. The established technology, metal foil gauges, remains dominant, relying on advanced photolithography to achieve precise grid patterns and high gauge factors. However, significant R&D effort is directed toward improving the temperature compensation mechanisms, moving beyond simple self-temperature compensation (STC) alloys to integrated digital compensation achieved via software and embedded temperature sensors (thermistors) within the gauge assembly. This hybrid approach significantly improves performance stability in fluctuating thermal environments, a perennial challenge for traditional resistive sensors, thereby enhancing measurement reliability in demanding industrial applications.

A crucial emerging technology involves the miniaturization of semiconductor strain gauges and the advancement of thin-film deposition techniques. Semiconductor gauges, often based on doped silicon, offer vastly higher gauge factors (up to 100 times greater than foil), making them ideal for extremely sensitive measurements in small or micro-electro-mechanical systems (MEMS). Thin-film gauges are gaining traction for applications requiring integration directly onto components, such as jet engine blades or surgical instruments, utilizing sputtering or vacuum deposition processes to create highly durable and contamination-resistant sensors that do not significantly alter the mechanical properties of the structure being monitored. This direct integration capability is opening up new markets in sophisticated OEM sensor manufacturing and biomedical sensing.

Furthermore, wireless and fiber optic sensing technologies represent high-growth niches. Wireless strain gauge systems, often employing low-power wide-area networks (LPWAN) or Bluetooth Low Energy (BLE), address the significant challenge of wiring infrastructure in large-scale monitoring projects like bridges or pipelines, drastically reducing installation costs and complexity. Fiber optic strain gauges, based on Bragg grating technology, are entirely immune to electromagnetic interference (EMI) and are explosion-proof, positioning them as the preferred solution for environments characterized by high EMI, radio frequency noise, or explosive atmospheres, such as high-voltage electrical installations, MRI facilities, and oil & gas drilling operations. These advanced technologies are driving the market's evolution towards remote, autonomous, and intrinsically safe monitoring systems, creating higher value propositions for end-users seeking enhanced operational safety and efficiency.

Regional Highlights

- Asia Pacific (APAC): This region is forecast to exhibit the highest growth rate due to massive investments in infrastructure development, rapid urbanization, and the expansion of the automotive manufacturing sector, particularly in economies such as China, India, Japan, and South Korea. APAC's growing focus on renewable energy projects (wind farms, solar installations) mandates rigorous testing and structural health monitoring, substantially driving the demand for high-reliability strain gauges and load cells used in quality control and ongoing operational efficiency assessment.

- North America: Representing a mature but innovation-driven market, North America maintains strong demand, primarily fueled by the massive aerospace and defense industries, which require highly specialized, high-temperature, and fatigue-resistant strain gauges for critical applications. Stringent safety regulations governing oil and gas infrastructure and aging civil infrastructure maintenance programs further stabilize market demand, focusing purchasing towards high-specification, certified monitoring systems and integrated data analysis solutions.

- Europe: The European market is characterized by a strong presence in advanced manufacturing, particularly the high-end automotive sector (Germany, Italy) and precision engineering. Demand is robust due to strict environmental and safety standards (e.g., Euro NCAP crash testing) and significant R&D investment in materials science and structural engineering, driving the adoption of highly accurate measurement tools for design validation and continuous quality control across production lines.

- Latin America (LATAM): Growth in LATAM is driven by regional investments in energy infrastructure, mining operations, and burgeoning civil construction projects. Countries like Brazil and Mexico are increasing their adoption of advanced sensing technologies to modernize industrial plants and comply with international operational efficiency benchmarks, although market penetration is still hindered by economic volatility and reliance on imported sophisticated sensing equipment.

- Middle East and Africa (MEA): This region shows specialized growth linked heavily to the expansive oil and gas industry, requiring rugged, explosion-proof, and high-temperature strain gauges for pipeline monitoring, drilling equipment, and refinery process control. Government-led diversification efforts and smart city initiatives in the Gulf Cooperation Council (GCC) countries are also generating new pockets of demand for structural monitoring solutions in large-scale building and transit projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Strain Gauge Market.- HBM (Hottinger Baldwin Messtechnik)

- VISHAY Precision Group (VPG)

- KYOWA Electronic Instruments

- OMEGA Engineering

- TE Connectivity

- MinebeaMitsumi

- Zemic

- Gefran

- FUTEK Advanced Sensor Technology

- Tokyo Measuring Instruments Laboratory

- NMB Technologies

- Sichuan Hengchuang Technology

- Interface Inc.

- Shenzhen Sensor Technology

- Micro-Measurements (VPG brand)

- Althen Sensors

- Sensing Systems

- A.A. Lab Systems

- DAQ System Technologies

- Weldon Sensors

Frequently Asked Questions

Analyze common user questions about the Strain Gauge market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the fundamental working principle of a foil strain gauge?

A foil strain gauge operates based on the principle of piezoresistivity. When mechanical stress is applied to the object, the gauge deforms, causing a proportional change in the electrical resistance of the metallic foil grid, which is then measured using a Wheatstone bridge circuit to quantify the strain.

How does temperature affect strain gauge measurements and how is compensation achieved?

Temperature variations cause thermal expansion in both the gauge material and the test specimen, leading to resistance changes unrelated to mechanical strain (thermal output). Compensation is primarily achieved through self-temperature compensating (STC) alloys, bridge completion using dummy gauges mounted on similar material, or through software correction using integrated thermistors.

What are the key advantages of using semiconductor strain gauges over traditional foil gauges?

Semiconductor strain gauges offer a significantly higher gauge factor (up to 100 times greater), providing enhanced sensitivity for measuring extremely minute strains. They are often smaller and are preferred for highly sensitive applications in medical devices, high-frequency measurements, and where space constraints are critical, despite being more temperature sensitive.

In which industry is Structural Health Monitoring (SHM) using strain gauges most critical?

SHM utilizing strain gauges is most critical in Civil Engineering, where it is essential for the long-term safety and maintenance assessment of large public assets such as bridges, dams, tunnels, and skyscrapers. Continuous monitoring provides real-time data on structural degradation, fatigue, and load distribution, enabling predictive maintenance.

What role does wireless technology play in the modern strain gauge market?

Wireless technology enables the deployment of strain gauges in remote, difficult-to-access locations without requiring extensive and costly wiring infrastructure. Wireless systems are critical for large-scale, distributed monitoring networks, reducing installation time and providing flexibility, particularly for temporary testing or monitoring in vast infrastructure projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Strain Gauge Sensors Market Size Report By Type (Metal strain gauge Sensors, Semiconductor strain gauge Sensors), By Application (Weighing Equipment, Aerospace, Cranes, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Torsion Load Cell Market Statistics 2025 Analysis By Application (Motor Torque Measurement, Internal Combustion Engine Torque Measurement, Water Pump Torque Measurement, Automobile Torque Measurement, Ship Torque Measurement), By Type (Non-Contact Torsion Load Cell, Strain Gauge Torsion Load Cell), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Resistance Strain Gauge Market Statistics 2025 Analysis By Application (Load Cells, Pressure Transducer, Torque Transducer), By Type (Foil Strain Gauge, Wire Strain Gauge, Semiconductor Strain Gauge), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Torsion Load Cell Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Non-Contact Torsion Load Cell, Strain Gauge Torsion Load Cell), By Application (Motor Torque Measurement, Internal Combustion Engine Torque Measurement, Water Pump Torque Measurement, Automobile Torque Measurement, Ship Torque Measurement, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager