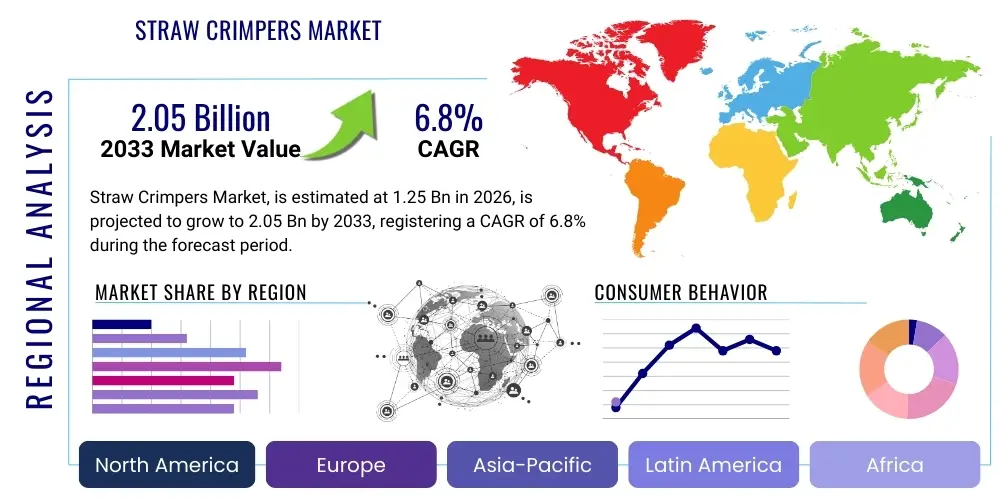

Straw Crimpers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439548 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Straw Crimpers Market Size

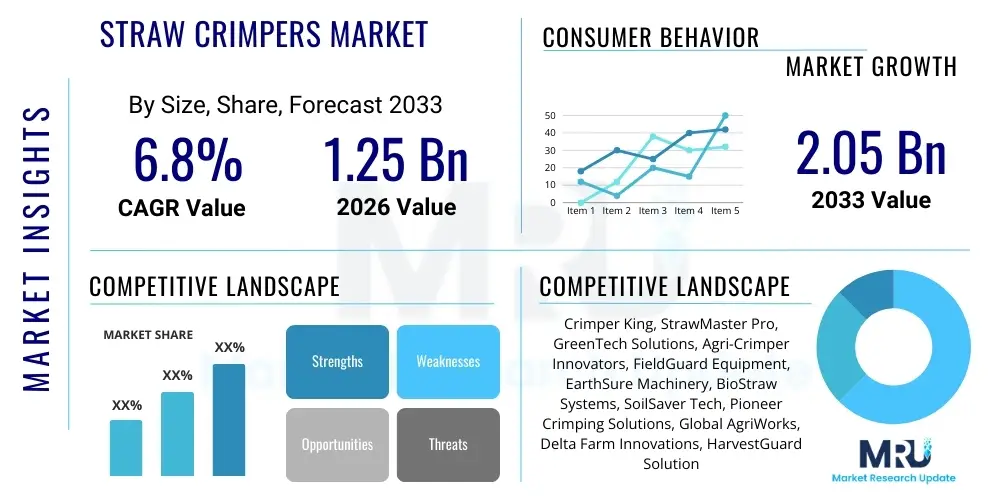

The Straw Crimpers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 2.05 Billion by the end of the forecast period in 2033.

Straw Crimpers Market introduction

The Straw Crimpers Market encompasses the global demand and supply of specialized agricultural machinery designed to process straw by creating crimps or bends. These machines are crucial for enhancing the absorption capabilities of straw, particularly when it is used for erosion control, animal bedding, or as an insulation material. The process of crimping straw involves breaking its natural straightness, which helps it interlock more effectively when spread, improving its stability against wind and water erosion, and increasing its overall surface area for better moisture absorption. This market is intrinsically linked to agricultural practices, land management, and environmental conservation efforts, with innovation focusing on efficiency, versatility, and sustainability. As global agricultural practices evolve towards more sustainable and efficient methods, the role of straw crimpers becomes increasingly significant in optimizing resource utilization and mitigating environmental impacts.

Straw crimpers are agricultural implements that are either tractor-mounted (PTO-driven or hydraulically operated) or self-propelled units, engineered to take straw bales or loose straw and impart a physical crimp. This mechanical alteration is distinct from chopping or shredding, as it maintains the length of the straw fibers while increasing their irregular surface, which is vital for many applications. Key product descriptions include robust construction, adjustable crimping depths, variable working widths, and integration capabilities with other farm machinery such as balers or spreaders. The market offers a range of models, from smaller units suitable for private farm use to large-scale industrial crimpers designed for commercial landscaping or large agricultural operations. The choice of a straw crimper often depends on the scale of operation, the type of straw being processed, and the specific application requirements, demanding a diverse product portfolio from manufacturers.

Major applications for straw crimpers span several critical sectors. In agriculture, crimped straw is highly valued for animal bedding, particularly for livestock, where its increased absorbency helps maintain dryer, cleaner animal environments, reducing the incidence of disease and improving animal welfare. For erosion control, especially on construction sites, new seedbeds, or disturbed land, crimped straw provides superior ground cover, holding soil in place and protecting newly sown seeds from wind and water washout. It is also used as mulch in horticulture and viticulture to conserve soil moisture, regulate soil temperature, and suppress weeds. The benefits of using straw crimpers include significant labor savings compared to manual straw spreading, improved efficacy of straw in its intended applications, reduced material waste due to better interlocking, and enhanced environmental protection through effective erosion mitigation. Driving factors for market growth include the increasing emphasis on sustainable farming, stringent environmental regulations regarding soil erosion, expansion of livestock farming, and the growing demand for efficient land rehabilitation techniques across various industries.

Straw Crimpers Market Executive Summary

The Straw Crimpers Market is currently experiencing robust growth, propelled by several interconnected global trends in agriculture, environmental management, and construction. Business trends indicate a strong move towards mechanization and automation within farming communities, driven by rising labor costs and the continuous pursuit of operational efficiencies. Manufacturers are responding by developing more advanced, durable, and user-friendly crimping solutions that integrate seamlessly with existing farm equipment. There is a notable emphasis on precision agriculture principles, with next-generation crimpers incorporating smart technologies for optimized material application and reduced waste. Furthermore, the market is witnessing increased collaboration between agricultural machinery manufacturers and environmental consulting firms to offer comprehensive solutions for large-scale land remediation and erosion control projects, reflecting a broadening scope beyond traditional farming applications. Investment in research and development is focused on improving machine versatility, fuel efficiency, and reducing maintenance requirements, signaling a mature but innovative market landscape.

Regional trends play a crucial role in shaping the market's dynamics. North America and Europe currently dominate the market due to their advanced agricultural sectors, widespread adoption of modern farming techniques, and strict environmental regulations pertaining to soil conservation and water quality. These regions exhibit high demand for high-capacity, technologically advanced straw crimpers. Asia Pacific, particularly countries like China and India, is emerging as a significant growth hub. This growth is fueled by increasing agricultural mechanization, expanding livestock industries, and governmental initiatives promoting sustainable land management practices. Latin America and the Middle East & Africa regions are also showing considerable potential, albeit at an earlier stage of development, driven by infrastructure development, expanding agricultural frontiers, and a nascent awareness of advanced erosion control methods. The diverse climatic conditions and agricultural scales across these regions necessitate a customized approach to product offerings and market penetration strategies, favoring manufacturers capable of adapting to varied local demands and operational contexts.

Segmentation trends within the Straw Crimpers Market highlight a shift towards specialized solutions catering to distinct application needs and operational scales. By product type, PTO-driven crimpers continue to hold a dominant share due to their cost-effectiveness and versatility, but hydraulic and self-propelled units are gaining traction for large-scale and specialized applications requiring greater precision and autonomy. In terms of end-users, large commercial farms and agricultural contractors represent the largest segment, driven by the need for high-throughput and durable machinery. However, the small and medium-sized farm segment is also expanding, stimulated by the availability of more affordable and compact crimper models. Application-wise, erosion control remains a primary segment, but the demand for crimped straw in animal bedding and specialty mulching is experiencing accelerated growth. This granular segmentation indicates a maturing market where consumers seek tailored solutions, prompting manufacturers to diversify their product lines and offering customized support services to meet specific demands across the diverse agricultural and land management ecosystem.

AI Impact Analysis on Straw Crimpers Market

Common user questions regarding AI's impact on the Straw Crimpers Market often revolve around how artificial intelligence can enhance efficiency, precision, and sustainability within straw crimping operations. Users are keen to understand if AI can automate the crimping process, optimize material distribution, predict maintenance needs for machinery, and ultimately reduce operational costs while improving environmental outcomes. There's a strong interest in AI's potential to integrate crimping with broader smart farming systems, using data from soil sensors, weather forecasts, and satellite imagery to make real-time decisions about where and when crimped straw application would be most effective. Concerns also include the initial investment required for AI-integrated machinery, data privacy, and the technical expertise needed to operate and maintain such advanced systems. Users expect AI to bring a new level of intelligence to a traditionally mechanical process, enabling more dynamic and responsive land management strategies.

- AI-driven Precision Application: AI algorithms can analyze real-time data from drones, satellite imagery, and soil sensors to determine optimal locations and densities for crimped straw application, minimizing waste and maximizing effectiveness for erosion control or mulching. This enhances resource efficiency and environmental protection by avoiding over-application in stable areas and focusing on high-risk zones.

- Predictive Maintenance: AI can monitor the operational parameters of straw crimpers, such as engine performance, blade wear, and hydraulic system health, to predict potential failures before they occur. This enables proactive maintenance scheduling, reduces unexpected downtime, extends the lifespan of machinery, and lowers overall ownership costs for farmers and contractors.

- Automated Operation and Robotics: While full automation of large-scale straw crimping might be nascent, AI can enable semi-autonomous functions like auto-steering, depth control, and variable rate application based on field maps. Future developments could see robotic crimping units operating independently, especially in challenging or expansive terrains, addressing labor shortages and improving consistency.

- Optimization of Straw Sourcing and Logistics: AI can optimize the logistics of straw acquisition and transportation to the crimping site, considering factors like bale availability, storage conditions, and transportation costs. This ensures a consistent supply chain, reduces logistical bottlenecks, and improves the overall efficiency of large-scale crimping projects, enhancing profitability for service providers.

- Enhanced Quality Control and Consistency: AI-powered vision systems could monitor the crimping process in real-time, analyzing the crimp quality and consistency of the straw. This ensures that the processed straw meets specific quality standards required for various applications, such as highly absorbent bedding or robust erosion control, leading to superior outcomes and customer satisfaction.

- Data-driven Decision Making: AI platforms can consolidate and analyze data from crimping operations, weather patterns, soil conditions, and application efficacy to provide actionable insights. This enables farmers and land managers to make more informed decisions about future straw management strategies, improving long-term land health and operational profitability, fostering continuous improvement.

DRO & Impact Forces Of Straw Crimpers Market

The Straw Crimpers Market is significantly influenced by a complex interplay of drivers, restraints, opportunities, and various impact forces that collectively shape its trajectory. Among the primary drivers is the escalating global focus on sustainable agriculture and environmental conservation, which mandates effective soil erosion control on agricultural lands, construction sites, and post-fire rehabilitation zones. Governments and regulatory bodies worldwide are implementing stricter environmental policies that encourage practices like straw mulching and crimping to prevent topsoil loss and maintain water quality. Concurrently, the increasing adoption of mechanization in agriculture, driven by rising labor costs and the demand for operational efficiency, further propels the demand for automated and semi-automated straw crimping solutions. The expanding livestock industry, requiring large volumes of absorbent bedding material, also acts as a substantial driver. Moreover, advancements in agricultural technology, including the development of more durable materials and efficient power systems for machinery, enhance the appeal and utility of modern straw crimpers, making them a more viable investment for diverse users.

Despite these robust drivers, the market faces several restraining factors. The initial capital investment required for purchasing high-quality straw crimping machinery can be substantial, posing a barrier for small and medium-sized farms or contractors with limited budgets. This is particularly true for technologically advanced or large-capacity units. Maintenance costs, including the replacement of wear parts like crimping rollers or blades, can also add to the operational expenses, impacting the total cost of ownership. Another restraint is the seasonal nature of straw availability and the specific window for effective crimping, which can limit the continuous utilization of the machinery throughout the year, affecting return on investment. Furthermore, the variability in straw quality, type, and moisture content across different regions can affect crimper performance and efficiency, requiring operators to make adjustments or invest in versatile models, thereby adding complexity. In some regions, a lack of awareness regarding the benefits of crimped straw for specific applications, or the availability of alternative, less capital-intensive erosion control methods, can also impede market growth.

Opportunities within the Straw Crimpers Market are abundant and diversified. The expansion into emerging economies, particularly in Asia Pacific, Latin America, and Africa, presents significant growth avenues as these regions increasingly adopt modern agricultural practices and invest in infrastructure development that requires advanced erosion control. The growing trend towards smart agriculture and precision farming offers an opportunity for manufacturers to integrate GPS, IoT, and AI technologies into crimpers, enabling more precise, data-driven application and optimized resource utilization. Custom crimping services, targeting specific niche applications such as golf course maintenance, vineyard mulching, or specialized landscaping projects, can create new revenue streams. Additionally, the development of eco-friendly and energy-efficient crimper designs, possibly leveraging electric or hybrid power sources, aligns with global sustainability goals and can attract environmentally conscious buyers. Manufacturers also have an opportunity to offer comprehensive solutions, including machine sales, rental services, maintenance contracts, and training programs, thereby building stronger customer relationships and fostering loyalty within a competitive market landscape. Continuous innovation in material science for machine components can also lead to more durable and efficient crimpers, opening up new market segments and applications.

Segmentation Analysis

The Straw Crimpers Market is extensively segmented to reflect the diverse needs of its end-users and the varied applications of crimped straw, enabling a granular understanding of market dynamics and growth opportunities. This detailed segmentation allows manufacturers to tailor product development, marketing strategies, and distribution channels to specific market niches, ensuring that the right product reaches the right customer with optimal efficiency. The primary segmentation criteria typically include product type, application, end-user, and operational capacity, each offering unique insights into the market's structure. Understanding these segments is critical for stakeholders to identify key growth areas, assess competitive landscapes, and formulate strategic business plans. As the market evolves, the interdependencies between these segments become increasingly pronounced, driving demand for versatile and multi-functional crimping solutions that can cater to a broader spectrum of requirements within the agricultural and environmental sectors. Furthermore, the geographical distribution of these segments highlights regional preferences and market maturity levels, guiding investment decisions and expansion strategies.

- By Product Type:

- PTO-Driven Crimpers: These are tractor-mounted units powered by the tractor's power take-off (PTO) shaft, representing a cost-effective and common solution for various farm sizes. They are valued for their versatility and ease of integration with existing farm machinery, offering a balance of performance and operational flexibility.

- Hydraulic Crimpers: Utilizing a tractor's hydraulic system, these crimpers offer more precise control over crimping depth and pressure, often preferred for specific applications requiring fine adjustments or for larger-scale operations where consistent performance is paramount. They typically allow for easier adjustments from the tractor cab.

- Self-Propelled Crimpers: Standalone units with their own engine and drive system, offering maximum independence and maneuverability. These are usually high-capacity machines designed for large commercial operations, specialized land management projects, or rental fleets where efficiency and continuous operation are critical, providing robust performance without relying on a separate tractor.

- Electric/Battery-Powered Crimpers: An emerging segment focusing on sustainability and reduced emissions. These crimpers are typically smaller, specialized units for urban landscaping, sensitive environmental areas, or niche applications where noise reduction and zero emissions are prioritized, reflecting a growing eco-conscious trend.

- By Application:

- Erosion Control: The largest application segment, where crimped straw is spread on bare soil to prevent wind and water erosion, particularly on construction sites, new road embankments, hillsides, and recently seeded agricultural fields. The interlocking nature of crimped straw significantly enhances its stability and effectiveness in these critical environmental protection roles.

- Animal Bedding: Crimped straw is highly effective as bedding for livestock due to its increased absorbency, which helps keep animal environments drier and cleaner. This application is crucial in dairy, beef, swine, and poultry farming for promoting animal welfare and reducing disease transmission.

- Mulching: Used in horticulture, viticulture, and gardening to conserve soil moisture, regulate soil temperature, suppress weed growth, and enrich soil organic matter as it decomposes. Crimping improves the longevity and coverage of the mulch layer.

- Biofuel & Biomass: While less common, crimped straw can also be processed as a feedstock for biofuel production or as biomass for energy generation, where its altered structure might improve handling and processing efficiency in some systems.

- By End-User:

- Large Commercial Farms: Major consumers requiring high-capacity, durable, and often technologically advanced crimpers for extensive agricultural operations and efficient straw management across vast acreage.

- Small & Medium-Sized Farms: A growing segment driven by the availability of more compact and affordable crimper models, seeking to improve efficiency and adopt sustainable practices without significant capital outlay.

- Agricultural Contractors: Businesses providing specialized crimping services to multiple farms or land management projects, typically investing in versatile and robust machinery capable of handling diverse demands.

- Landscaping & Erosion Control Companies: Firms specializing in environmental restoration, civil engineering, and large-scale landscaping projects, where crimped straw is a primary material for soil stabilization and revegetation efforts.

- Government & Public Sector: Entities involved in park maintenance, highway construction, watershed management, and environmental rehabilitation projects, utilizing crimpers for large-scale land stabilization and restoration, often procuring through tenders.

- By Operational Capacity:

- Low Capacity (Up to 10 acres/hour): Suitable for small farms or specialized, smaller-scale applications, offering maneuverability and lower power requirements, often more affordable.

- Medium Capacity (10-30 acres/hour): A balanced option for mid-sized farms and contractors, providing a good blend of efficiency and operational cost-effectiveness, suitable for a broader range of tasks.

- High Capacity (Above 30 acres/hour): Designed for large commercial farms and extensive land management projects, these units prioritize speed and throughput, minimizing labor and maximizing coverage on vast areas.

Value Chain Analysis For Straw Crimpers Market

The value chain for the Straw Crimpers Market is a comprehensive network encompassing all activities from the raw material sourcing to the final delivery and post-sales support, illustrating how value is added at each stage. This intricate chain begins with the upstream analysis, focusing on the procurement of essential raw materials and components. This involves sourcing high-quality steel for frames and crimping rollers, specialized alloys for wear-resistant blades, hydraulic components, engines (for self-propelled units), power take-off (PTO) shafts, electronic controls, and various other parts. Manufacturers often establish long-term relationships with reputable suppliers to ensure consistent quality and availability of these materials, which directly impacts the durability, performance, and cost-effectiveness of the final crimper product. Research and development activities, including material science innovation and engineering design, are also integral to the upstream segment, continually improving machine efficiency and lifespan. Effective management of this upstream segment is crucial for maintaining competitive pricing and product quality in the market.

Moving downstream, the value chain encompasses the manufacturing, assembly, and distribution phases. Manufacturers transform raw materials and components into finished straw crimpers through precise engineering, fabrication, welding, painting, and assembly processes. Quality control at each manufacturing stage is paramount to ensure the machines meet stringent performance and safety standards. Once manufactured, the products enter the distribution channel, which can be direct or indirect. Direct channels involve manufacturers selling directly to large commercial clients or through their own dedicated sales forces and service centers, fostering strong customer relationships and offering specialized support. Indirect channels, which are more common, utilize a network of independent dealerships, distributors, and agricultural equipment retailers. These intermediaries play a vital role in reaching a broader customer base, particularly small and medium-sized farms and individual contractors, by providing local sales, financing options, inventory management, and accessible parts and service support. The efficiency of these distribution channels significantly impacts market reach, customer satisfaction, and overall sales volume, requiring strategic partnerships and logistical expertise.

The final stages of the value chain involve sales, after-sales service, and the end-user. After direct or indirect sales, manufacturers and their partners provide critical after-sales support, including warranty services, maintenance, spare parts supply, and technical assistance. This ongoing support is essential for ensuring machine longevity, customer loyalty, and repeat business. Training for operators on proper machine usage and maintenance is also a crucial aspect, optimizing performance and safety. The end-users of straw crimpers, ranging from individual farmers and agricultural contractors to landscaping and erosion control companies, utilize these machines for specific applications such as erosion control, animal bedding, or mulching. Their feedback on machine performance, durability, and features is invaluable, often informing future product development and innovation cycles back to the upstream segment. Furthermore, the downstream activities include potential rental services for those who do not wish to invest in direct purchase, and eventually, end-of-life recycling or trade-in programs, contributing to a circular economy model. The effectiveness of the entire value chain hinges on seamless coordination and collaboration among all its participants to deliver maximum value to the end customer.

Straw Crimpers Market Potential Customers

The Straw Crimpers Market serves a diverse and expanding base of potential customers, primarily segmented by their operational scale, specific application needs, and their role within the agricultural and land management sectors. At the forefront are large commercial farms, which represent a significant customer segment. These farms typically manage vast acreages and operate on tight schedules, necessitating high-capacity, durable, and efficient machinery to process large volumes of straw for animal bedding, mulching, or managing crop residues to enhance soil health. Their demand often leans towards sophisticated models, including hydraulic or self-propelled crimpers, that can integrate with their existing fleet of advanced agricultural machinery. The economic benefits derived from improved straw utilization, reduced manual labor, and enhanced environmental compliance are compelling drivers for these large-scale agricultural enterprises, making them key decision-makers in the market, often requiring comprehensive after-sales support and advanced technological features in their purchases.

Another rapidly growing segment of potential customers comprises small and medium-sized farms. While their individual purchasing power might be less than commercial giants, their collective demand for efficient and affordable straw management solutions is substantial. These farms often seek versatile, PTO-driven crimpers that offer a balance between investment cost and operational benefits. Their motivations include reducing labor, improving soil health through better mulching, optimizing animal welfare with superior bedding, and adhering to local environmental regulations for erosion control. Manufacturers are increasingly catering to this segment by offering more compact, user-friendly, and economically viable models, often accessible through dealer networks that provide local support and flexible financing options. The increasing awareness among smaller farmers about sustainable practices and the long-term benefits of crimped straw is a significant factor driving demand from this crucial and expanding customer base, highlighting the need for manufacturers to offer scalable solutions.

Beyond traditional farming, the market extends to specialized service providers and public entities. Agricultural contractors, for instance, form a vital customer group as they offer crimping services to multiple farms and land management projects, thereby requiring robust, multi-functional machines that can handle varying conditions and large throughputs. These contractors are often early adopters of new technologies that enhance efficiency and reliability. Additionally, landscaping companies, erosion control specialists, and civil engineering firms are significant buyers, utilizing straw crimpers for large-scale land stabilization, hydroseeding projects, road construction, and post-disaster land rehabilitation, where effective soil conservation is paramount. Government agencies, including those responsible for highway maintenance, park management, and watershed protection, also represent a segment of potential customers, procuring crimpers for public works projects and environmental restoration initiatives. The diversity of these potential customers underscores the broad utility and growing importance of straw crimping technology across various industries, necessitating a multi-faceted sales and marketing approach from market players.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 2.05 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Crimper King, StrawMaster Pro, GreenTech Solutions, Agri-Crimper Innovators, FieldGuard Equipment, EarthSure Machinery, BioStraw Systems, SoilSaver Tech, Pioneer Crimping Solutions, Global AgriWorks, Delta Farm Innovations, HarvestGuard Solutions, EcoHarvest Machines, TerraProtect Equipment, Maximize Crop Solutions, Superior Farm Tools, Precision Agri-Systems, Integrated Land Solutions, Horizon Agricultural, Modern Farm Machinery |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Straw Crimpers Market Key Technology Landscape

The technological landscape of the Straw Crimpers Market is characterized by continuous innovation aimed at enhancing efficiency, durability, and versatility, driven by the evolving demands of modern agriculture and land management. At its core, the technology involves robust mechanical engineering principles to create effective crimping mechanisms. This includes the development of specialized crimping rollers or discs, often made from high-strength, wear-resistant steel alloys, designed to withstand abrasive straw materials and continuous operation. Innovations in blade design and material science focus on extending the lifespan of these critical components, reducing maintenance downtime and replacement costs for end-users. Beyond the basic mechanical components, the integration of advanced hydraulic systems for precise control over crimping depth and pressure has become standard in many modern units, allowing operators to fine-tune the crimping process for different straw types and application requirements. This mechanical evolution is foundational to the market's progress, ensuring machines can handle diverse operational challenges effectively and reliably.

Beyond fundamental mechanics, the market is increasingly adopting sophisticated electronic and digital technologies. Sensor integration is a growing trend, with sensors monitoring parameters such as crimping pressure, ground speed, and even straw flow, providing real-time feedback to the operator. This data allows for immediate adjustments to optimize performance and material usage. GPS technology is being incorporated into higher-end models, enabling precision agriculture techniques where crimped straw can be applied with variable rates to specific areas of a field based on pre-programmed maps or real-time soil data. This allows for highly targeted application, minimizing waste and maximizing effectiveness, particularly in erosion control. The development of user-friendly control interfaces, often in-cab displays with intuitive graphical representations, simplifies operation and reduces the learning curve for farmers and contractors. These advancements are crucial for driving efficiency and reducing the manual oversight required, making the machinery more appealing to a broader user base seeking automation and precision.

The future of straw crimper technology points towards greater automation, connectivity, and sustainability. Research and development efforts are focused on integrating Internet of Things (IoT) capabilities, allowing for remote monitoring of machine performance, predictive maintenance alerts, and seamless data transfer to farm management systems. This connectivity will enable better fleet management for large contractors and provide valuable operational insights for continuous improvement. Furthermore, the exploration of alternative power sources, such as electric or hybrid drives, is gaining traction, aligning with global efforts to reduce carbon footprints in agriculture. These developments promise quieter operation, lower emissions, and potentially reduced running costs. Robotics and AI also hold potential for future applications, particularly in autonomous crimping operations for vast or difficult-to-access areas, further minimizing human intervention and maximizing operational efficiency. The ongoing blend of robust mechanical engineering with cutting-edge digital and sustainable technologies is set to redefine the capabilities and market appeal of straw crimpers in the coming years, making them indispensable tools for modern land management.

Regional Highlights

- North America: This region, encompassing the United States and Canada, holds a dominant position in the Straw Crimpers Market. Its mature agricultural sector, characterized by large-scale farming operations, high adoption rates of advanced machinery, and significant investment in sustainable land management practices, drives consistent demand. Strict environmental regulations regarding soil erosion and water quality, particularly in states prone to wind and water runoff, further stimulate the market. The presence of leading agricultural equipment manufacturers and a robust distribution network contribute to the region's strong market share. Innovation is focused on high-capacity, precision-oriented crimpers integrating smart farming technologies.

- Europe: Europe is another key market, driven by advanced agricultural practices, strong environmental policies, and a substantial livestock industry. Countries like Germany, France, and the UK are major contributors, demonstrating a high demand for efficient straw management solutions for animal bedding, mulching, and erosion control. The region's emphasis on circular economy principles and sustainable resource use also fuels the adoption of straw crimpers. There is a growing trend towards eco-friendly and energy-efficient models, and a focus on machinery that can adapt to diverse European farm sizes and agricultural landscapes.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate during the forecast period. This growth is primarily attributed to the rapid mechanization of agriculture in countries like China, India, and Australia, alongside increasing government support for sustainable farming practices. Expanding livestock populations, particularly in Southeast Asia, are boosting demand for effective animal bedding solutions. Infrastructure development and a rising awareness of erosion control benefits in emerging economies also contribute significantly to market expansion. Manufacturers are focusing on developing cost-effective, durable, and regionally adaptable crimper models for this diverse and burgeoning market.

- Latin America: This region presents considerable growth potential for the Straw Crimpers Market, driven by the expansion of agricultural frontiers, increasing investments in modern farming technologies, and a growing recognition of the importance of soil conservation. Countries like Brazil, Argentina, and Mexico are key players, with large-scale soybean, corn, and livestock farming operations generating demand. The market is influenced by the need for effective erosion control on vast cultivated lands and the desire to enhance agricultural productivity through sustainable practices. Manufacturers are exploring partnerships and localized production to cater to specific regional needs.

- Middle East and Africa (MEA): The MEA region is at an early stage of market development but holds promising opportunities. Factors such as governmental initiatives to boost agricultural output and ensure food security, coupled with growing infrastructure projects that necessitate erosion control, are stimulating demand. While adoption rates are currently lower compared to other regions, increasing awareness of advanced agricultural techniques and investments in modern farm equipment are expected to drive future growth. Challenges include limited access to financing and a need for robust, simple-to-operate machinery suitable for diverse climatic and soil conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Straw Crimpers Market.- Crimper King

- StrawMaster Pro

- GreenTech Solutions

- Agri-Crimper Innovators

- FieldGuard Equipment

- EarthSure Machinery

- BioStraw Systems

- SoilSaver Tech

- Pioneer Crimping Solutions

- Global AgriWorks

- Delta Farm Innovations

- HarvestGuard Solutions

- EcoHarvest Machines

- TerraProtect Equipment

- Maximize Crop Solutions

- Superior Farm Tools

- Precision Agri-Systems

- Integrated Land Solutions

- Horizon Agricultural

- Modern Farm Machinery

Frequently Asked Questions

Analyze common user questions about the Straw Crimpers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a straw crimper and how does it work to enhance agricultural and environmental applications?

A straw crimper is a specialized agricultural implement designed to mechanically bend or crimp straw, rather than merely chopping or shredding it. This process creates kinks and irregularities in the straw fibers, which significantly improves its ability to interlock with itself and with the ground. In agricultural applications, this enhanced interlocking makes crimped straw an superior material for animal bedding, as it increases absorbency and stability. For environmental uses, particularly erosion control, crimped straw provides better ground cover and adheres more effectively to sloped surfaces, preventing wind and water erosion, protecting newly sown seeds, and improving soil stabilization. The machine typically uses rotating rollers or discs to apply pressure and create the crimps, and can be PTO-driven, hydraulic, or self-propelled, depending on the model and operational scale.

What are the primary benefits of using a straw crimper compared to traditional straw spreading methods for erosion control?

Using a straw crimper offers several significant advantages over traditional, often manual, straw spreading for erosion control. Firstly, crimped straw is far more resistant to displacement by wind and water, meaning it stays in place more effectively on slopes and disturbed ground, providing superior protection against soil erosion. Its interlocking nature creates a cohesive mat that is less likely to blow away or wash out, leading to more durable and effective coverage. Secondly, crimpers ensure a more even and consistent distribution of straw, which optimizes coverage and reduces material waste, making the process more cost-efficient. Thirdly, mechanizing the process with a crimper drastically reduces labor requirements and improves operational efficiency, particularly on large-scale projects. Finally, crimping promotes better seed-to-soil contact by holding the straw in place, which aids in quicker and more uniform seed germination for revegetation efforts, ultimately leading to more successful land restoration outcomes.

What types of straw crimpers are available in the market, and how should an end-user choose the right one for their needs?

The Straw Crimpers Market offers a variety of types, each suited for different operational scales and requirements. The most common are PTO-driven crimpers, which attach to and are powered by a tractor's power take-off, offering versatility and cost-effectiveness for small to medium-sized farms. Hydraulic crimpers, also tractor-mounted but utilizing the tractor's hydraulic system, provide more precise control over crimping depth and pressure, ideal for specialized applications or larger operations needing fine adjustments. For very large-scale commercial applications or extensive land management projects, self-propelled crimpers are standalone units with their own engines, offering maximum independence, high capacity, and maneuverability. Emerging electric/battery-powered models cater to niche applications prioritizing zero emissions and quiet operation. Choosing the right crimper depends on several factors: the size of the area to be covered, the type and volume of straw to be processed, existing farm machinery (e.g., tractor size and hydraulic capacity), budget constraints, and specific application requirements, such as the need for precise variable rate application for erosion control. Consulting with dealers and comparing features like working width, crimping depth adjustability, and durability is essential.

How is artificial intelligence (AI) impacting the functionality and efficiency of modern straw crimpers?

Artificial intelligence is beginning to significantly enhance the functionality and efficiency of modern straw crimpers, transforming them into more intelligent and responsive machines. AI integration primarily focuses on optimizing application, improving maintenance, and enabling smarter decision-making. AI-powered precision application systems can analyze data from GPS, soil sensors, and drone imagery to determine the exact areas requiring crimped straw and the optimal application rate, minimizing waste and maximizing effectiveness for erosion control or mulching. This allows for variable rate application based on real-time field conditions. Furthermore, AI algorithms can enable predictive maintenance by monitoring machine parameters, anticipating potential mechanical failures, and recommending proactive service, thereby reducing costly downtime and extending equipment lifespan. While full autonomy is still developing, AI contributes to semi-autonomous features like auto-steering and adaptive crimping based on straw density. This transition towards AI-driven machinery makes straw crimping more precise, sustainable, and economically viable by optimizing resource utilization and improving operational reliability.

What are the key considerations for maintenance and long-term durability of straw crimping equipment?

Maintaining straw crimping equipment for long-term durability and optimal performance involves several key considerations. Regular cleaning is crucial to prevent straw residue and dirt buildup from impairing moving parts and accelerating wear. Lubrication of all grease points and moving components, as per the manufacturer's recommendations, is essential to reduce friction and extend the lifespan of bearings, chains, and gears. Inspection of critical wear parts, particularly the crimping rollers or blades, for damage, dullness, or excessive wear is paramount, as these components directly impact crimping quality. Worn blades should be promptly replaced to maintain efficiency and avoid unnecessary strain on the machine. Checking hydraulic lines, hoses, and cylinders for leaks or damage, and ensuring proper fluid levels, is vital for hydraulic crimpers. For PTO-driven units, inspecting the PTO shaft for damage and ensuring proper guards are in place is necessary for safety and function. Seasonal storage should involve thorough cleaning, lubrication, and inspection, ideally undercover, to protect the machine from adverse weather elements. Adhering to the manufacturer's maintenance schedule and utilizing genuine spare parts are fundamental practices for ensuring the longevity and reliable operation of straw crimping equipment, thereby maximizing return on investment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager