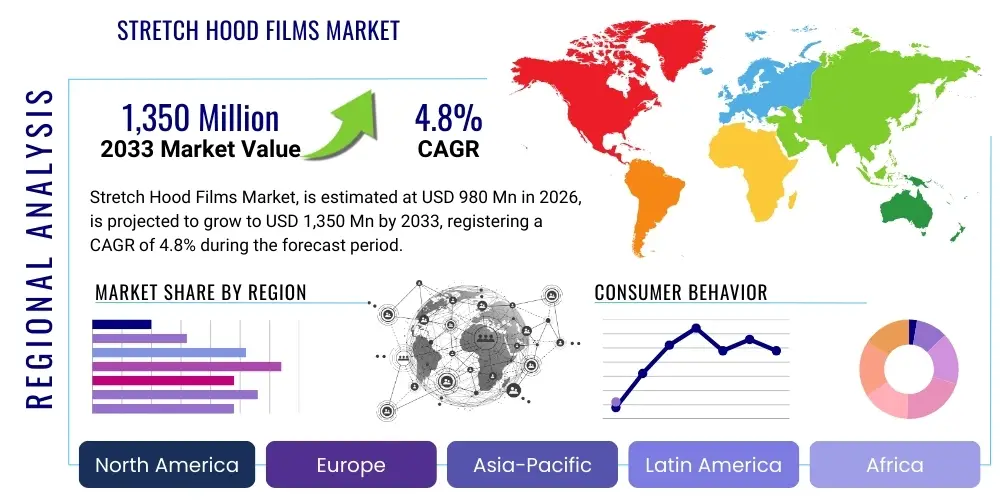

Stretch Hood Films Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435682 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Stretch Hood Films Market Size

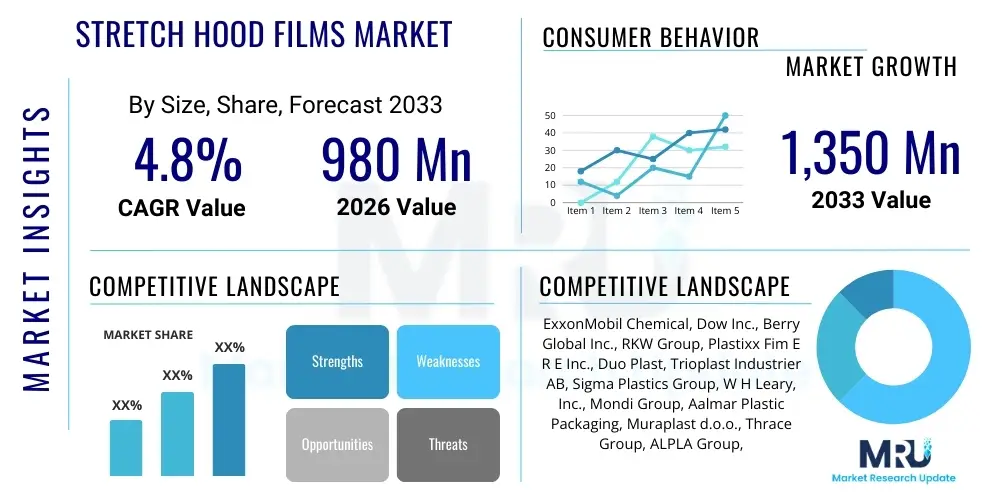

The Stretch Hood Films Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 980 Million in 2026 and is projected to reach USD 1,350 Million by the end of the forecast period in 2033.

Stretch Hood Films Market introduction

The Stretch Hood Films Market encompasses the manufacturing and distribution of specialized elastic films used primarily for packaging and securing palletized goods. These advanced polymeric films, typically composed of linear low-density polyethylene (LLDPE) or metallocene polyethylene (mPE), offer superior load containment, weather protection, and visual clarity compared to traditional shrink wrap or stretch wrap methods. The films are applied using automated stretch hooding machinery, pulling the pre-stretched film over the pallet and then allowing it to retract and tightly conform to the product shape, thereby ensuring stability during transit and storage. This methodology is gaining traction across numerous industries due to its cost-efficiency, speed of application, and environmental benefits stemming from reduced material usage and easier recyclability.

Major applications of stretch hood films are concentrated in sectors requiring high throughput and stringent load security, such as cement and building materials, chemicals and fertilizers, food and beverage, and consumer packaged goods (CPG). In the logistics chain, ensuring that bulk goods arrive intact is paramount, making stretch hood technology an essential component of modern warehousing and distribution centers. The superior tear and puncture resistance of high-quality stretch hood films minimizes product damage, translating directly into reduced operational losses for end-users. Furthermore, the capacity of these films to maintain shape even under high vibrations or extreme temperatures differentiates them from conventional pallet securing solutions.

The market growth is fundamentally driven by the escalating demand for automated packaging solutions globally, catalyzed by rising labor costs and the necessity for increased operational efficiency. Key benefits include excellent water and dust resistance, UV protection (critical for outdoor storage of building materials), and enhanced branding opportunities through high-definition printing on the film surface. The shift towards sustainable packaging practices also serves as a major driver, as newer film formulations offer reduced gauge thickness while maintaining performance, leading to source reduction and a lower carbon footprint throughout the supply chain. Manufacturers are continuously investing in innovative polymer blends to improve elasticity and holding force, reinforcing the position of stretch hood technology as the preferred method for high-volume pallet unitization.

Stretch Hood Films Market Executive Summary

The Stretch Hood Films Market is undergoing robust expansion, characterized by significant shifts towards automation, material innovation, and sustainable practices. Business trends indicate a strong focus among manufacturers on developing multilayer co-extrusion technologies, allowing for the creation of films that combine toughness, clarity, and stretch recovery optimization. The competitive landscape is defined by the necessity for advanced machinery integration, as the effectiveness of the film is highly dependent on the speed and precision of the stretch hooding equipment. Key stakeholders are forming strategic alliances with automation providers to offer comprehensive, integrated palletizing and packaging systems, thereby capturing greater market share and enhancing customer retention by providing turnkey solutions for high-volume industrial operations. Furthermore, the increasing adoption of Industry 4.0 principles in manufacturing facilities necessitates packaging solutions like stretch hood films that support rapid throughput and automated quality checks.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, primarily fueled by the massive expansion of manufacturing and infrastructure projects, particularly in countries like China and India, leading to substantial demand from the cement, petrochemical, and fertilizer industries. North America and Europe, while mature, demonstrate strong adoption driven by strict regulatory requirements for load stability and a pronounced consumer preference for recyclable packaging. European growth is additionally bolstered by mandatory waste reduction targets, prompting the rapid substitution of less efficient packaging methods with stretch hood films. Companies are increasingly optimizing regional supply chains to reduce logistics costs and provide specialized film grades tailored to local climatic conditions and specific industry standards.

Segment trends reveal that the LLDPE material segment maintains dominance due to its favorable cost-to-performance ratio, although the metallocene PE segment is rapidly increasing its market penetration, valued for its superior elasticity and enhanced sealing properties at thinner gauges, which aligns perfectly with sustainability goals. The industrial segment, encompassing construction and chemicals, remains the largest application area, demanding extreme puncture resistance and UV stabilization. However, the food and beverage sector is showing accelerated adoption, driven by the need for hygienic, weather-resistant pallet protection, especially for fragile goods and temperature-sensitive products. Innovations in bio-based and recycled content polymers are defining segment diversification, enabling suppliers to meet demanding corporate sustainability mandates from large multinational corporations.

AI Impact Analysis on Stretch Hood Films Market

User queries regarding AI's impact on the Stretch Hood Films Market typically revolve around operational efficiency, quality control, and predictive maintenance of packaging lines. Users are keenly interested in how Artificial Intelligence can optimize film usage, thereby reducing waste and cost. Specific concerns center on whether AI-powered vision systems can accurately detect minor film flaws or load shifts in real-time before transit, ensuring superior load security. Furthermore, there is significant interest in predictive analytics—how AI algorithms can forecast maintenance needs for high-speed stretch hooding machinery and optimize material flow, ensuring zero downtime in 24/7 manufacturing environments. The overarching expectation is that AI integration will transform the film manufacturing process, making formulations smarter, production faster, and quality assurance fully automated, moving away from subjective human inspection to data-driven decision-making processes.

The introduction of AI is fundamentally transforming both the manufacturing of the films and their application within end-user facilities. In manufacturing, AI algorithms analyze polymer characteristics, extruder performance, and cooling rates in real-time, allowing for micro-adjustments that ensure consistent film thickness, stretch ratio, and tear resistance across massive production runs. This level of precision is unattainable through traditional statistical process control (SPC) methods. By optimizing machine parameters based on multivariate datasets, AI significantly reduces material scrap rates and energy consumption during the extrusion process, leading to substantial cost savings and improving overall environmental performance metrics for film producers.

In the application phase, AI-driven machine vision systems are integrated into stretch hooding equipment to monitor the palletizing and wrapping sequence. These systems can instantly identify minor imperfections in the pallet configuration, such as slight load misalignment or inconsistent stretch tension distribution, and either autonomously correct the issue or flag it for operator intervention. This prevents costly transit damage before the pallet leaves the dock. Moreover, AI models use historical operational data—including machine temperature, vibration, and film consumption rates—to predict equipment failure with high accuracy, enabling scheduled maintenance rather than reactive repairs, maximizing throughput and operational stability for major industrial clients.

- AI-powered vision systems enable real-time detection of film defects and load stability issues during the application process, ensuring enhanced quality control.

- Predictive maintenance algorithms analyze data from stretch hooding machinery sensors to forecast component failures, drastically reducing unexpected downtime and maintenance costs.

- Optimized film usage achieved through AI-driven material consumption monitoring, leading to reduced gauge thickness requirements and lower material waste.

- AI facilitates the development of smarter film formulations by analyzing correlation between polymer characteristics, extruder variables, and final film performance metrics (e.g., holding force and puncture resistance).

- Automated inventory management and supply chain forecasting for film manufacturers, improving responsiveness to dynamic market demand shifts.

- Enhanced energy efficiency in film extrusion by using machine learning models to fine-tune heating and cooling processes based on material properties and ambient conditions.

- Autonomous process optimization in end-user facilities, allowing stretch hood equipment to adapt tension and stretch ratios based on real-time load dimensions and weight distribution.

DRO & Impact Forces Of Stretch Hood Films Market

The Stretch Hood Films Market is propelled by strong Drivers related to industrial automation and operational efficiency, while facing specific Restraints such as high initial investment costs for machinery and fluctuations in raw material prices. Significant Opportunities arise from the development of sustainable, bio-based polymers and penetration into emerging economies with rapidly expanding logistics infrastructure. These factors interact as Impact Forces, dictating the strategic direction of market players. The overarching force is the global imperative to minimize product damage during transport, which solidifies the demand for high-performance containment systems like stretch hood technology. Furthermore, the stringent regulatory environment regarding load stability in regions like Europe mandates the use of highly secure pallet wrapping solutions, thereby acting as a powerful external driver for market adoption.

Key drivers include the pervasive trend of automation across manufacturing and warehousing sectors, where high-speed packaging is essential to keep pace with production volume, a requirement perfectly met by stretch hooding systems capable of handling over 100 pallets per hour. The superior load containment provided by stretch hood films, which wraps the load on five sides (including the top), offers excellent protection against moisture, dust, and UV radiation—a critical feature for industries like chemicals and construction materials that often store inventory outdoors. The cost benefits over traditional shrink hood technology, primarily due to lower energy consumption (no heat tunnel required) and reduced material weight, strongly influence procurement decisions in favor of stretch hood solutions. These economic and efficiency factors collectively drive sustained demand globally.

However, market expansion faces notable constraints, primarily concerning the substantial capital expenditure required to install high-speed stretch hooding machinery, which poses a barrier to entry for smaller manufacturers or those operating on thin margins. Furthermore, the market relies heavily on petrochemical derivatives (polyethylene resins), making it susceptible to the volatility of crude oil and natural gas prices, directly affecting the cost of film production and end-user pricing. Opportunities for future growth are rooted in innovation, particularly the successful commercialization of recycled and compostable stretch hood films, addressing the growing consumer and regulatory pressure for environmentally friendly packaging. Expanding infrastructure development and growth in e-commerce necessitating robust packaging in developing regions represent substantial untapped markets for stretch hood film manufacturers and system integrators.

- Drivers:

- Increasing global demand for high-speed automated pallet unitization systems in manufacturing and logistics.

- Superior load stability, moisture protection, and UV resistance offered by stretch hood films compared to conventional wraps.

- Energy efficiency advantages of stretch hooding technology (no heat tunnel required), lowering operational costs for end-users.

- Regulatory mandates in key regions demanding enhanced security and stability for palletized goods during transit.

- Restraints:

- High initial capital investment required for purchasing and integrating advanced stretch hooding machinery.

- Volatility and dependence on fluctuating prices of crude oil and petrochemical raw materials (polyethylene resins).

- Technical requirements concerning precise film formulation and machinery calibration, necessitating specialized expertise.

- Opportunities:

- Development and commercialization of sustainable film options, including bio-based, recycled content (PCR), and biodegradable stretch hood films.

- Market penetration in emerging economies characterized by rapid industrialization and expansion of logistics networks.

- Technological integration with Industry 4.0 solutions, utilizing sensors and IoT for smart packaging monitoring.

- Impact Forces:

- The imperative for supply chain optimization driving adoption for damage reduction.

- Environmental regulations forcing product innovation toward reduced gauge and enhanced recyclability.

- Automation trends significantly accelerating replacement cycles for older, less efficient packaging equipment.

Segmentation Analysis

The Stretch Hood Films Market is primarily segmented based on material type, film layers, application, and end-use industry. Material segmentation is crucial as it dictates the film's elasticity, puncture resistance, and cost profile, with Linear Low-Density Polyethylene (LLDPE) and Metallocene Polyethylene (mPE) dominating the landscape. Segmentation by film layers addresses performance requirements; monolayer films are cost-effective but multilayer co-extruded films offer customized properties, combining tear resistance, high stretch recovery, and UV protection in specialized structures. This granular segmentation allows manufacturers to precisely target niche markets, offering tailored solutions that meet stringent industry standards for hygiene, chemical resistance, or load dynamics.

Application-based segmentation distinguishes between the type of palletized goods, covering everything from bulk bags of chemicals to stacked beverage cans. The film’s specifications, such as coefficient of friction and cling properties, are adjusted depending on whether the application requires intense load containment (e.g., concrete blocks) or gentle protection (e.g., paper rolls). Furthermore, the segmentation by end-use industry highlights demand variations, with the chemical and fertilizer sector demanding high chemical resistance and durability, while the food and beverage industry prioritizes food-grade safety compliance and superior optical clarity for product visibility. The strategic importance of these segmentations lies in mapping the diverse needs of industrial consumers and aligning product development efforts with the highest growth potential sectors.

The ongoing trend toward high-performance, thin-gauge films is profoundly impacting segmentation strategies. While traditional thicker films still serve heavy-duty industrial applications, the rapid growth in the retail and CPG sectors favors advanced multilayer films that offer maximum load stability at significantly reduced thicknesses, thereby lowering material costs and improving sustainability metrics. This shift necessitates complex co-extrusion capabilities and sophisticated R&D, segmenting the market between commodity film providers and specialized high-performance film innovators. Understanding this dynamic ensures that market players allocate resources efficiently, focusing on segments where superior technology yields the highest competitive advantage and margin return.

- By Material Type:

- Linear Low-Density Polyethylene (LLDPE)

- Metallocene Polyethylene (mPE)

- Ethylene Vinyl Acetate (EVA)

- Others (e.g., Recycled Content Polymers, Bio-based Films)

- By Film Layers:

- Monolayer Films

- Multilayer Films (3-layer, 5-layer, 7-layer co-extrusion)

- By Application:

- Standard Pallet Wrapping

- Heavy Duty/High Puncture Resistance Applications

- UV Stabilized Applications (Outdoor Storage)

- Food Contact Applications

- By End-Use Industry:

- Chemicals and Fertilizers

- Building and Construction Materials (Cement, Concrete, Bricks)

- Food and Beverage (Bottles, Cans, Bagged Products)

- Consumer Packaged Goods (CPG)

- Paper, Pulp, and Textile

- Logistics and Warehousing

Value Chain Analysis For Stretch Hood Films Market

The value chain of the Stretch Hood Films Market is characterized by a high degree of integration between upstream raw material suppliers, film converters, equipment manufacturers, and downstream end-users. Upstream analysis focuses on the petrochemical industry, which supplies the necessary polymer resins, predominantly LLDPE and mPE. The cost and quality of these resins are crucial determinants of the final film's performance and market price. Film manufacturers (converters) utilize advanced multi-layer co-extrusion technology to transform these resins into high-performance stretch hood films, requiring specialized machinery and technical expertise in polymer blending to achieve desired stretch recovery, clarity, and resistance characteristics. Successful navigation of the upstream segment requires secure, long-term supply contracts and effective risk management against petrochemical price volatility.

The midstream involves the transformation process and includes equipment manufacturers who produce the specialized high-speed stretch hooding machines. While film converters and machine providers are often separate entities, there is a strong symbiotic relationship, as the film must be perfectly calibrated to the machinery’s specifications for optimal performance. Distribution channels for both the films and the machinery vary significantly. Films, being consumables, are primarily distributed indirectly through specialized industrial packaging distributors, who manage localized inventory and provide technical support to end-users. These distributors are critical in bridging the gap between large-scale manufacturers and diverse industrial customers, offering services such as inventory management and technical consultations on machine settings.

Downstream analysis centers on the vast array of end-users across the building, chemical, and food sectors. Direct sales channels are often employed for large volume customers or those requiring customized film formulations and integrated system solutions (film + machinery package), especially by leading market players. However, indirect channels through packaging wholesalers and regional distributors dominate general market supply. The final stage involves the consumption of the film, where performance metrics—such as load stability percentage and film usage per pallet—are measured by the buyer. Customer feedback loops are essential for continuous product improvement, particularly regarding sustainability features like film recyclability and down-gauging potential, completing the cyclical nature of the value chain.

Stretch Hood Films Market Potential Customers

Potential customers for Stretch Hood Films are industrial entities that engage in large-volume manufacturing, requiring efficient, secure, and weatherproof methods for unitizing palletized loads for storage and distribution. The typical profile of a buyer is a large-scale manufacturing plant or a high-throughput logistics center that palletizes thousands of goods daily. Key purchasing criteria for these customers include reliability (minimizing transit damage), speed (compatibility with high-speed production lines), and cost-effectiveness over the product lifecycle, favoring films that offer superior performance at reduced gauges. Furthermore, regulatory compliance, especially regarding load security and environmental standards, heavily influences purchasing decisions, positioning high-performance, recyclable films favorably.

The heaviest adopters of stretch hood technology are concentrated in industries dealing with dense, often weatherproof-sensitive materials or products requiring extreme stability. For instance, manufacturers of cement, concrete aggregates, fertilizers, and petrochemicals rely on stretch hood films for five-sided protection against moisture and dust during outdoor storage and lengthy sea shipments. Similarly, the beverage industry, characterized by high volume and fragile loads (e.g., glass bottles or beverage cartons), demands films with excellent vertical holding force and anti-slip properties to prevent shifting or collapse during high-speed sorting and transportation. These end-users typically enter into long-term contracts for film supply, often bundling film procurement with maintenance and technical support for their stretch hooding machinery.

- Chemical and Petrochemical Producers: Requiring moisture and chemical resistance for bagged polymers, resins, and fertilizers.

- Building Materials Manufacturers: Companies producing cement, roofing tiles, pre-cast concrete blocks, and bricks needing UV protection for outdoor storage.

- Food and Beverage Companies: High-speed packaging lines for canned goods, bottled beverages, dairy, and bulk food ingredients prioritizing hygiene and load stability.

- Pulp and Paper Mills: Securing heavy paper rolls, cut sheets, and cardboard components requiring tear resistance and dust protection.

- Logistics and Distribution Centers: Large 3PL (Third-Party Logistics) providers utilizing automated warehouses demanding consistent, rapid pallet wrapping solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 980 Million |

| Market Forecast in 2033 | USD 1,350 Million |

| Growth Rate | CAGR 4.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ExxonMobil Chemical, Dow Inc., Berry Global Inc., RKW Group, Plastixx Fim E R E Inc., Duo Plast, Trioplast Industrier AB, Sigma Plastics Group, W H Leary, Inc., Mondi Group, Aalmar Plastic Packaging, Muraplast d.o.o., Thrace Group, ALPLA Group, Coveris Holdings SA, Eurofilm Extrusion, AEP Industries (Amcor), HIPAC S.p.A., Silvalac, Polifilm Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stretch Hood Films Market Key Technology Landscape

The technology landscape for stretch hood films is defined by advancements in polymer science and sophisticated co-extrusion processes, crucial for achieving the required elastic memory and mechanical strength. The foundational technology involves multi-layer blown film extrusion, where 3, 5, or 7 layers of different polyethylene resins are simultaneously extruded to create a composite film. This process allows engineers to strategically place specialty additives, such as metallocene catalysts (mPE) for enhanced stretchability in the core, UV stabilizers on the outer layer for weather resistance, and cling agents on the inner layer for secure contact with the load. The drive for technical superiority pushes manufacturers toward developing proprietary polymer blends that minimize gauge thickness while maximizing holding force, contributing directly to sustainability targets and material cost reduction for end-users.

A significant technological focus is placed on enhancing the elastic recovery properties of the film. Superior stretch hood films possess excellent "elastic memory," meaning they tightly return to their original, smaller dimensions after being highly stretched over the pallet by the hooding machine. This provides the containment force necessary to secure heavy, vibrating, or shifting loads. Innovations in this area often utilize high-grade mPE resins, which offer greater toughness and stress retention compared to traditional LLDPE. Furthermore, surface treatment technologies, including specialized coatings or additives, are being developed to control the coefficient of friction (COF), ensuring stacked pallets do not slip against each other during transport while still facilitating smooth application by high-speed machinery. Technology providers are also integrating sensor technology into production lines to monitor film quality in real-time.

The supporting machinery technology is equally vital, focusing on integration, speed, and efficiency. Advanced stretch hooding machines now feature precise servo-motor controlled stretching systems and automated pallet height sensors, allowing for customized film application based on load geometry. Recent technological advancements include the capability for machines to switch between multiple film widths or gauges automatically, minimizing changeover time and maximizing production flexibility. Furthermore, connectivity through IoT platforms is becoming standard, enabling remote monitoring, data logging of wrapping parameters (e.g., tension and film consumption), and predictive diagnostics, which aligns with the global shift towards smart manufacturing and automated logistics management systems for optimizing packaging operations.

Regional Highlights

Regional dynamics play a crucial role in shaping the Stretch Hood Films Market, primarily driven by industrialization rates, logistics infrastructure development, and stringent regional regulatory frameworks governing load security and waste management. North America and Europe currently represent the highest consumption markets in terms of value, characterized by mature manufacturing sectors and high adoption rates of automated packaging technologies. In Europe, the focus is heavily skewed toward sustainability, driven by the Circular Economy Action Plan, which mandates high recycling rates and promotes material reduction. This regulatory push accelerates the demand for advanced, thin-gauge multilayer stretch hood films that qualify as source reduction solutions and are easily recyclable through existing PE streams.

Asia Pacific (APAC) is recognized as the fastest-growing market by volume, fueled by unprecedented infrastructure investment and exponential growth in domestic manufacturing across diverse sectors, including cement, steel, chemicals, and FMCG. Countries like China, India, and Southeast Asian nations are rapidly replacing manual or older shrink-wrapping processes with modern, automated stretch hooding solutions to handle surging production outputs. The region's growth is also characterized by a lower initial base for automation, providing significant opportunities for suppliers of integrated film and machinery solutions. Competitive pricing and local manufacturing capabilities are key success factors in the highly decentralized APAC market landscape, where economic efficiency often supersedes premium sustainability features.

The Latin America and Middle East & Africa (MEA) regions exhibit strong potential, albeit from a smaller market base. Latin America's demand is spurred by the growth of its industrial food processing and beverage sectors, which require secure, hygienic palletizing. In the MEA, particularly the GCC countries, high demand originates from large-scale petrochemical facilities and construction projects, necessitating films that offer superior UV stabilization and robustness due to harsh climatic conditions and complex global supply chains. Investment in new manufacturing facilities and the modernization of existing logistics hubs are primary drivers in these developing regions, making them strategic targets for long-term capacity expansion by global stretch hood film providers focusing on regional supply chain optimization and technical support availability.

- North America (US, Canada): Mature market driven by high labor costs necessitating automation and robust supply chains. Strong demand from CPG and chemical industries. Focus on reliability and high-speed operation.

- Europe (Germany, UK, France, Italy): Leading the market in terms of sustainability adoption. Demand is centered on high-performance, thin-gauge films, driven by EU waste reduction and recycling targets. High penetration in construction and industrial sectors.

- Asia Pacific (China, India, Japan, Southeast Asia): Fastest growing region due to massive industrialization, infrastructure development, and increasing automation adoption in emerging economies. Significant growth in chemical, cement, and fertilizer application segments.

- Latin America (Brazil, Mexico): Growing industrial and food/beverage sectors driving demand for secure palletization. Market expansion is correlated with foreign investment in manufacturing facilities.

- Middle East and Africa (GCC Countries, South Africa): High demand for UV-stabilized and extreme-weather resistant films, primarily serving the petrochemical, construction, and export-oriented commodity sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stretch Hood Films Market. These companies are pivotal in driving technological advancements, defining market standards, and dominating global production capacity. Their strategies often involve backward integration (securing raw material supply), forward integration (offering complete hooding system solutions), and significant R&D investment in sustainable and high-performance film formulations.- ExxonMobil Chemical

- Dow Inc.

- Berry Global Inc.

- RKW Group

- Plastixx Fim E R E Inc.

- Duo Plast

- Trioplast Industrier AB

- Sigma Plastics Group

- W H Leary, Inc.

- Mondi Group

- Aalmar Plastic Packaging

- Muraplast d.o.o.

- Thrace Group

- ALPLA Group

- Coveris Holdings SA

- Eurofilm Extrusion

- AEP Industries (Amcor)

- HIPAC S.p.A.

- Silvalac

- Polifilm Group

- M.J. Maillis Group

- Bischof + Klein SE & Co. KG

- Intertape Polymer Group (IPG)

- Novolex Holdings LLC

Frequently Asked Questions

Analyze common user questions about the Stretch Hood Films market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Stretch Hood Film and traditional Shrink Film?

The primary difference lies in the application process and material properties. Stretch Hood Film is pre-stretched and applied cold, using its elastic memory (recoil force) to secure the load, offering superior water protection and energy savings (no heat tunnel required). Shrink Film requires heat application (via a heat tunnel) to shrink and conform tightly to the pallet. Stretch hooding is typically faster and more energy-efficient for high-volume, uniform loads.

Which industry applications drive the highest demand for UV-stabilized Stretch Hood Films?

The Building and Construction materials industry (e.g., cement, concrete bags, roofing materials) and the Chemical and Petrochemical sector (fertilizers, polymer resins) generate the highest demand for UV-stabilized films. These materials are frequently stored outdoors for extended periods, necessitating robust UV protection to prevent material degradation and maintain load integrity under direct sunlight exposure during storage and distribution.

How do sustainable stretch hood films, such as PCR (Post-Consumer Recycled) content films, impact market growth?

Sustainable films significantly boost market growth by addressing corporate mandates for environmental responsibility and adhering to strict governmental regulations (especially in Europe). PCR and bio-based films reduce the reliance on virgin fossil fuels and lower the carbon footprint of packaging. This allows large multinational customers to meet their waste reduction targets, making sustainability a crucial competitive differentiator and a key driver of innovation and adoption in mature markets.

What role does Metallocene Polyethylene (mPE) play in enhancing film performance?

Metallocene Polyethylene (mPE) is a premium resin used to enhance the performance of stretch hood films, particularly in multilayer structures. mPE provides superior toughness, higher puncture resistance, and significantly improved holding force and elastic recovery compared to conventional LLDPE. This allows manufacturers to drastically reduce the gauge (thickness) of the film while maintaining, or even exceeding, the necessary load stability, leading to source reduction and cost savings.

What is the typical return on investment (ROI) timeframe for industrial companies adopting automated Stretch Hooding systems?

The ROI timeframe for investing in automated stretch hooding systems typically ranges from 18 to 36 months, depending heavily on the prior packaging method, production volume, and energy costs. The savings are realized through reduced labor requirements, substantial decreases in energy consumption (by eliminating heat tunnels), minimized film consumption via optimized thin-gauge use, and significant reduction in product damage during transit due to superior load containment security.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager