Stripping Pliers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435651 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Stripping Pliers Market Size

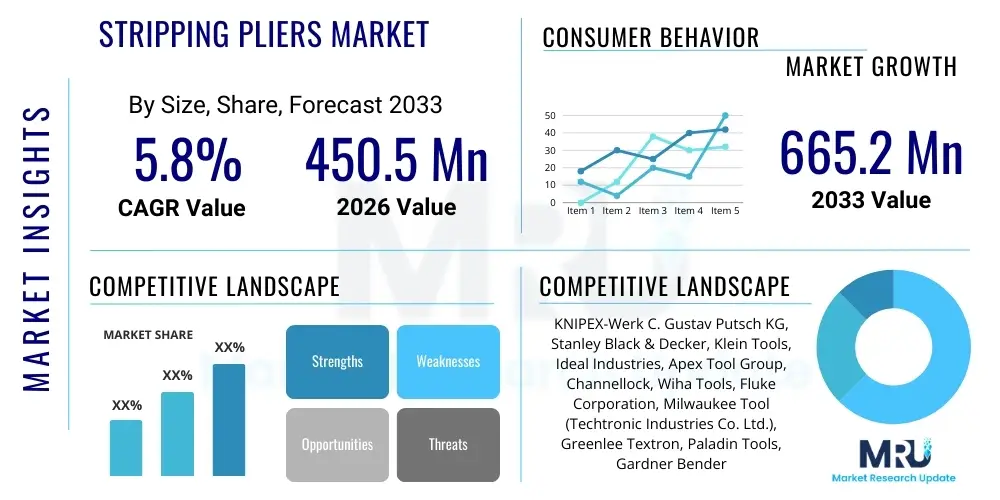

The Stripping Pliers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 665.2 Million by the end of the forecast period in 2033.

Stripping Pliers Market introduction

Stripping pliers, fundamental tools in the electrical and telecommunications industries, are specifically designed to safely and efficiently remove the insulating outer jacket from electrical wires without damaging the underlying metallic conductor. This essential function is critical across various applications, ranging from basic residential wiring to complex industrial machinery installations and large-scale data center infrastructure projects. The efficiency and precision offered by modern stripping pliers directly contribute to the quality and longevity of electrical connections, thereby minimizing potential hazards and ensuring compliance with stringent safety standards globally. Technological advancements have diversified the market, moving beyond simple manual tools to include sophisticated automatic and specialized coaxial cable strippers, catering to varying levels of professional requirement and user volume.

The market growth is intrinsically linked to global trends in urbanization, the expansion of smart infrastructure, and the continuous necessity for maintenance and upgrading of legacy electrical systems. Major applications span construction, automotive manufacturing, aerospace maintenance, and the rapidly growing telecommunications sector, particularly concerning fiber optics and data cabling infrastructure. These tools are indispensable for professional electricians, maintenance technicians, and serious DIY enthusiasts, demanding high durability, ergonomic design, and accuracy across different wire gauges. The core benefits derived from utilizing high-quality stripping pliers include improved operational safety, significant time reduction during installation processes, and ensuring consistent wire integrity, which is paramount in critical power systems.

Key driving factors propelling market expansion include substantial global investments in renewable energy infrastructure, which requires extensive wiring solutions; the proliferation of Internet of Things (IoT) devices necessitating complex low-voltage wiring; and stringent regulatory frameworks mandating professional-grade tools for electrical work. Furthermore, the increasing complexity of wiring harnesses in modern automotive electric vehicles (EVs) and hybrid vehicles provides a robust demand niche for specialized, high-precision stripping solutions. The continuous innovation in materials science, particularly the utilization of durable and lightweight alloys for tool construction, enhances product longevity and user comfort, sustaining the market's positive trajectory through the forecast period.

Stripping Pliers Market Executive Summary

The global Stripping Pliers Market is characterized by a steady migration toward automated and self-adjusting mechanisms, representing a significant business trend focused on enhancing efficiency and minimizing operator fatigue in high-volume electrical assembly tasks. The competitive landscape is intensely driven by intellectual property related to ergonomic design and multi-functionality, with market leaders leveraging robust distribution networks spanning specialized industrial suppliers and mass-market retail channels. Business trends emphasize tools offering adaptability across a broad range of wire types and gauges, particularly in response to the standardization challenges posed by diverse global electrical codes and evolving cable material compositions. Strategic mergers and acquisitions, primarily focused on acquiring niche technological expertise, are observed among major participants aiming to consolidate market share and expand product portfolios into higher-margin specialized tools.

Regionally, the Asia Pacific (APAC) stands out as the primary engine for market growth, underpinned by massive urbanization projects, rapid infrastructure development in emerging economies like India and Southeast Asian nations, and burgeoning electronics manufacturing hubs. North America and Europe, representing mature markets, exhibit stable demand driven by stringent safety regulations and a high propensity for replacement and upgrade cycles involving premium, automated tools. European regional trends emphasize sustainability and tool longevity, often favoring suppliers adhering to strict environmental and social governance (ESG) standards. Conversely, Latin America and the Middle East and Africa (MEA) present burgeoning opportunities, with increasing investments in power grids and telecommunication networks stimulating demand for both foundational manual tools and efficient automatic models for new installations.

In terms of segment trends, the Automatic Stripping Pliers segment is projected to record the highest growth rate, fueled by its inherent productivity advantages in industrial and commercial construction environments where speed and consistency are critical. However, the Manual Stripping Pliers segment retains a dominant share in volume due to its lower cost, reliability, and widespread adoption among residential users and small-scale operations. Within applications, the Industrial segment, encompassing automotive, aerospace, and heavy machinery, maintains the highest value share due to the necessity for high-precision, heavy-duty tools that often integrate specialized features for complex wiring harnesses. The ongoing shift toward modular and pre-fabricated construction techniques further stimulates demand for specialized stripping tools that integrate seamlessly into modern assembly processes.

AI Impact Analysis on Stripping Pliers Market

User queries regarding the impact of Artificial Intelligence (AI) on the stripping pliers domain often revolve around the integration of smart features into traditional tools, the potential for AI-driven automation in high-precision manufacturing, and the use of machine learning algorithms for quality control and predictive maintenance. Users are keen to understand if AI can enhance the accuracy of wire stripping beyond current mechanical limits, especially for sensitive components like fiber optics or specialized shielding. The key themes emerging from this analysis suggest that while AI will not directly replace the handheld tool itself, it will profoundly influence the manufacturing process, supply chain efficiency, and the integration of these tools into sophisticated, automated assembly lines, particularly in aerospace and automotive sectors.

The principal concern for end-users is the cost-benefit ratio of AI-enhanced tools. While systems incorporating visual inspection algorithms (often associated with industrial AI) can verify stripping depth and insulation integrity post-operation, making the process highly repeatable and error-free, the practicality of integrating such complex technology into basic, affordable hand tools remains a commercial hurdle. Expectations center on AI contributing to predictive failure analysis of tool components, optimizing material inventory based on real-time usage patterns in large enterprises, and facilitating the design of ultra-ergonomic tools through biomechanical data analysis driven by machine learning.

The impact is primarily manifested upstream in manufacturing and downstream in high-end industrial environments. AI algorithms optimize the heat treatment and material processing of the stripping jaws, ensuring maximum hardness and longevity. Furthermore, in automated assembly stations where robotic arms handle the stripping pliers, AI governs the force, angle, and consistency of the action, reducing material waste and improving throughput. This integration shifts the value proposition of the tool from a mere mechanical device to a component within a larger, intelligent manufacturing ecosystem, demanding higher connectivity and precision from tool manufacturers.

- AI-driven optimization of manufacturing processes, improving the precision and durability of cutting blades.

- Integration of vision systems in high-volume industrial stripping applications for real-time quality assurance and damage detection.

- Machine learning algorithms optimizing ergonomic tool design based on extensive usage data and human factors engineering.

- Predictive maintenance schedules for industrial-grade stripping equipment facilitated by AI analysis of operational wear patterns.

- Enhanced supply chain efficiency and inventory management for large industrial consumers utilizing AI forecasting models.

DRO & Impact Forces Of Stripping Pliers Market

The Stripping Pliers Market dynamics are shaped by a complex interplay of growth facilitators, market inhibitors, potential opportunities, and external impact forces. A primary driver is the accelerating pace of global infrastructure development, particularly the expansion and modernization of power grids, telecommunication networks (5G rollout), and commercial building construction worldwide. This continuous need for electrical installation and maintenance inherently guarantees consistent demand for wire stripping tools. Coupled with this is the escalating complexity and adoption rate of Electric Vehicles (EVs) and advanced electronic systems, which mandate specialized, high-precision tools for working with fine-gauge, high-voltage wiring harnesses. Furthermore, rising labor costs globally encourage industrial users to invest in faster, more automated stripping tools to enhance productivity per worker.

Restraints primarily revolve around the volatility in raw material prices, particularly specialized alloys (like high-carbon steel and hardened chrome vanadium) necessary for durable cutting components, which directly impacts manufacturing costs and retail pricing stability. Another restraint is the pervasive presence of low-cost, counterfeit, or substandard stripping tools, especially in emerging markets, which poses significant competitive pressure on established brands focusing on quality and safety compliance. These inferior products, while cheaper, often lead to wire damage, compromising safety and demanding repeated replacement, but they still fragment the entry-level market segment. Moreover, the long lifespan of professional-grade tools means replacement cycles are lengthy, potentially dampening volume growth in mature markets once initial equipment saturation is achieved.

Opportunities are abundant in the development and patenting of multi-functional and smart stripping tools that integrate safety features or measurement capabilities, catering to the trend of consolidation in electrician toolkits. The growing focus on high-speed data transmission infrastructure (fiber optics) presents a lucrative niche for specialized optical fiber stripping pliers, demanding extremely high precision and unique material handling capabilities. Impact forces include rapid technological shifts in cable insulation materials (e.g., cross-linked polyethylene) that require continuous refinement in jaw geometry and cutting mechanisms. Global trade disputes and evolving tariffs also constitute significant impact forces, affecting cross-border supply chains and influencing regional manufacturing strategies, thereby altering the final cost structure of the tools for the end consumer. Finally, heightened global safety standards act as an impact force, compelling manufacturers to adhere strictly to certifications like VDE insulation standards for specialized tools, providing an opportunity for premium brands.

Segmentation Analysis

The Stripping Pliers Market undergoes segmentation primarily based on the operational mechanism (Type), the target application environment, and the sales channel utilized for distribution. Understanding these segments is crucial for strategic market positioning, as distinct end-user needs drive specialized product development. The Type segmentation divides the market into Manual, Automatic/Self-Adjusting, and specialized versions (e.g., dedicated coaxial or fiber optic strippers). The preference for Automatic tools is accelerating, especially in high-volume commercial and industrial settings, where efficiency and consistent results across varied wire gauges are paramount, thereby justifying their higher capital cost compared to traditional manual pliers.

Application segmentation categorizes demand into Industrial (including aerospace, automotive, and large-scale manufacturing), Commercial (office buildings, data centers, infrastructure), and Residential/DIY sectors. The Industrial segment dominates in terms of revenue contribution due to the demand for heavy-duty, highly durable, and often customized tools built to handle extreme working conditions and proprietary wiring systems. Conversely, the Residential sector drives volume demand, prioritizing affordability and ease of use, often favoring basic manual or semi-automatic models. The commercial sector exhibits robust growth, fueled by continuous investment in networked infrastructure and high-density cable management systems requiring accurate and damage-free stripping.

Geographic segmentation remains vital, reflecting regional differences in infrastructure maturity, regulatory environments, and labor practices, impacting the adoption rate of high-end automated tools versus fundamental manual devices. The continuous refinement of insulation piercing and cutting technology ensures that manufacturers stay competitive, offering niche tools that address the specific challenges presented by new materials, such as environmentally friendly, halogen-free insulation compounds that are gaining traction across Europe and North America.

- By Type:

- Manual Stripping Pliers

- Automatic Stripping Pliers

- Specialized Strippers (Coaxial, Fiber Optic, Ribbon Cable)

- By Application:

- Industrial (Automotive, Aerospace, Manufacturing)

- Commercial (Construction, Data Centers, Telecom)

- Residential/DIY

- By Distribution Channel:

- Offline (Hardware Stores, Specialized Industrial Suppliers)

- Online (E-commerce Platforms, Direct-to-Consumer)

Value Chain Analysis For Stripping Pliers Market

The value chain for the Stripping Pliers Market commences with upstream activities focused on the procurement of high-quality raw materials, primarily specialized high-carbon steel, alloyed tool steel, and engineering plastics for handles and ergonomic components. The quality and purity of the steel are paramount, directly influencing the durability, sharpness, and longevity of the cutting and stripping jaws. Manufacturers often establish strong, long-term relationships with specialized metal foundries and plastic compound suppliers to ensure consistent material standards. Upstream analysis also involves stringent quality control processes for material hardness testing and corrosion resistance, which are foundational to producing professional-grade tools that meet warranty expectations.

The manufacturing stage involves precision forging, CNC machining, heat treatment processes (critical for achieving the required hardness of the stripping edges), grinding, and assembly. This core stage determines the product's functional excellence, especially for automatic and self-adjusting models that rely on intricate mechanical linkages and calibrated tension springs. Labor productivity and manufacturing efficiency are optimized through lean production methods. Downstream analysis focuses heavily on distribution. The channel strategy is bifurcated: specialized industrial distributors handle bulk sales to large construction firms, automotive factories, and utility companies, often requiring specific certifications and technical support; while large hardware retail chains and e-commerce platforms cater to commercial electricians and the residential market.

Direct distribution, though less common for standardized products, is utilized by high-end manufacturers for large industrial clients or military contracts requiring customized specifications. Indirect channels, primarily through wholesalers and retailers, manage inventory logistics and provide the necessary regional market penetration and accessibility for the broader consumer base. E-commerce platforms have gained significant traction, allowing manufacturers to bypass traditional retail markups and offering extensive product comparison tools and user reviews, thereby accelerating consumer education and purchase decisions. Effective logistics management, ensuring tools are readily available in geographically diverse construction zones, is a continuous challenge and competitive differentiator within the downstream value chain.

Stripping Pliers Market Potential Customers

The diverse nature of electrical installation and maintenance ensures a wide customer base for stripping pliers, spanning highly specialized professionals to casual household users. Professional electricians constitute the largest and most demanding customer segment, requiring tools that offer high precision, durability, multi-functionality, and compliance with strict regulatory standards (e.g., VDE insulation ratings). These professional buyers often prioritize automatic and specialized pliers that significantly reduce labor time on complex projects, focusing on tools with strong ergonomic features to prevent repetitive strain injuries during extended use cycles. Their purchasing decisions are heavily influenced by brand reputation, warranty length, and third-party industry endorsements or certifications, seeking reliability above all else.

Another significant segment is the industrial and manufacturing sector, specifically facility maintenance teams, automotive assembly line technicians, and aerospace engineers. These customers require heavy-duty, often fixed-gauge, strippers designed for specific cable types and high-volume, repetitive operations. In automotive manufacturing, for example, the shift towards increasingly complex wiring harnesses necessitates dedicated tools that can handle multiple layers of insulation without compromising the underlying conductors, driving demand for tailored, industrial-grade solutions. Bulk purchasing and technical integration support are key requirements for this segment, often leading to direct procurement relationships with tool manufacturers.

The residential and do-it-yourself (DIY) market represents a volume-driven segment, seeking easy-to-use, reasonably priced manual or semi-automatic strippers for household repairs, hobby electronics, and basic installations. While price sensitivity is higher in this group, safety features and instructional support are increasingly valued. Finally, the telecommunications sector, including installers working with coaxial, network, and fiber optic cables, forms a highly specialized niche. These technicians require extremely fine, non-damaging stripping tools tailored specifically for delicate optical fibers or heavily shielded data cables, where precision measured in microns is essential for connection integrity. These end-users demand performance optimization for their specific cable infrastructure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 665.2 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | KNIPEX-Werk C. Gustav Putsch KG, Stanley Black & Decker, Klein Tools, Ideal Industries, Apex Tool Group, Channellock, Wiha Tools, Fluke Corporation, Milwaukee Tool (Techtronic Industries Co. Ltd.), Greenlee Textron, Paladin Tools, Gardner Bender, Pro'sKit Industries, Jonard Tools, NWS Germany, Vetus, Facom (Stanley Black & Decker), Heyco, Wera Tools, Tolsen Tools |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Stripping Pliers Market Key Technology Landscape

The technological landscape of the Stripping Pliers Market is characterized by continuous evolution centered on precision engineering, material science, and ergonomic integration aimed at maximizing efficiency and user safety. A primary technological focus is the development of self-adjusting mechanisms, particularly for automatic stripping pliers. These mechanisms utilize complex spring-loaded cams and calibrated cutting depths that automatically detect and adapt to various wire gauges (AWG or metric standards) and insulation thickness without requiring manual calibration. This technology drastically reduces setup time, minimizes the risk of nicking the conductor, and ensures consistent quality across large-scale electrical installations, addressing a critical need for modern electricians handling mixed wiring environments.

Material science innovation is equally critical, concentrating on the composition and treatment of the cutting blades and gripping jaws. Manufacturers employ specialized high-speed tool steels (HSS) and proprietary surface coatings (such as titanium nitride or chrome plating) to enhance the hardness, longevity, and corrosion resistance of the functional components. Furthermore, ergonomic design has transitioned from a simple comfort feature to a sophisticated technological requirement. Modern stripping pliers utilize multi-component handles made from advanced thermoplastic elastomers (TPEs) to provide superior grip, minimize hand fatigue during prolonged use, and often incorporate anti-slip or VDE-certified insulating properties for high-voltage applications, making worker safety central to the tool's technological blueprint.

Emerging technologies include the integration of minimal connectivity features, although primarily focused on high-end industrial maintenance tools rather than standard handheld pliers. This connectivity might involve QR codes or RFID tags embedded in the tool for inventory management and tracking compliance in industrial environments. Precision technology for specialized applications, such as fiber optic strippers, involves sophisticated alignment guides and pre-set cutting depths calibrated to micron tolerances, ensuring the preservation of the delicate glass fiber core. Overall, the technological trajectory points toward smarter, more durable, and highly specialized tools that reduce operational variance and increase overall installation quality across all market segments.

Regional Highlights

- North America: This region represents a mature and technologically advanced market, dominating revenue share primarily due to high labor costs driving the rapid adoption of automated and high-efficiency stripping pliers. Demand is consistently high, fueled by continuous investment in smart grid technology, commercial infrastructure upgrades, and robust residential renovation activity. The U.S. and Canada adhere to stringent safety and quality standards, favoring premium brands like Klein Tools and Ideal Industries. The automotive sector, particularly the rapid growth of EV manufacturing in the U.S., necessitates specialized, high-voltage insulated stripping solutions.

- Europe: Characterized by highly regulated markets and a strong emphasis on worker safety, European demand is concentrated on VDE-certified, insulated stripping pliers. Germany, the UK, and France are key contributors, driven by mandatory maintenance cycles and infrastructure modernization projects aligned with European Union directives on energy efficiency. Environmental regulations also influence tool design, promoting the use of sustainable materials and long-life products. KNIPEX and Wiha, originating from this region, maintain strong market dominance due to their reputation for precision engineering and compliance.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by explosive growth in manufacturing, widespread urbanization, and massive government investment in telecom infrastructure (5G and fiber optics). Countries like China, India, and South Korea present immense volume opportunities. While the market initially relied heavily on basic manual tools, there is a swift transition toward adopting automatic and specialized tools to enhance productivity on large construction and manufacturing sites. The high concentration of electronics assembly plants also stimulates demand for specialized fine-gauge stripping tools.

- Latin America: This region exhibits moderate growth, largely influenced by fluctuating economic conditions and intermittent infrastructure spending. Demand is focused on durable, cost-effective solutions. Brazil and Mexico are the largest markets, benefitting from industrial expansion and investments in power distribution networks. Market adoption tends to favor versatile tools that can handle a wide range of applications, often supplied through global distributors leveraging local partnerships.

- Middle East and Africa (MEA): Growth in MEA is highly localized, concentrated in the Gulf Cooperation Council (GCC) countries due to large-scale construction, oil and gas infrastructure, and ambitious smart city projects. These projects mandate professional-grade tools, driving demand for imported, high-quality automatic strippers. In Africa, market penetration is accelerating, linked to rural electrification initiatives and the expansion of mobile communication networks, creating a rising demand base for foundational stripping tools.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Stripping Pliers Market.- KNIPEX-Werk C. Gustav Putsch KG

- Stanley Black & Decker (includes brands like Facom)

- Klein Tools

- Ideal Industries

- Apex Tool Group

- Channellock, Inc.

- Wiha Tools

- Fluke Corporation

- Milwaukee Tool (Techtronic Industries Co. Ltd.)

- Greenlee Textron

- Paladin Tools

- Gardner Bender

- Pro'sKit Industries

- Jonard Tools

- NWS Germany

- Vetus

- Heyco

- Wera Tools

- Tolsen Tools

- Crescent Tool Company

Frequently Asked Questions

Analyze common user questions about the Stripping Pliers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Automatic Stripping Pliers?

The primary factor driving demand for automatic stripping pliers is the necessity for increased operational efficiency and consistency in high-volume industrial and commercial wiring projects. Automatic tools significantly reduce installation time, minimize conductor damage by self-adjusting to various wire gauges, and mitigate operator fatigue, directly enhancing overall productivity in construction and manufacturing sectors.

How does the adoption of Electric Vehicles (EVs) impact the Stripping Pliers Market?

EV adoption profoundly impacts the market by creating a specialized demand for highly precise and VDE-certified insulated stripping pliers. EV wiring harnesses involve complex, high-voltage cables and delicate sensors, requiring specialized tools that guarantee safety and damage-free preparation, thereby boosting the high-end, safety-compliant segment of the market.

Which geographic region demonstrates the highest growth potential for stripping tools?

The Asia Pacific (APAC) region exhibits the highest growth potential, primarily fueled by extensive government spending on telecommunications infrastructure (5G rollout), rapid urbanization, and massive construction projects across emerging economies like India and Southeast Asia. This growth is driven by the sheer volume of new electrical installations required.

What technological advancements are crucial for maintaining competitiveness in the Stripping Pliers Market?

Crucial technological advancements include the refinement of self-adjusting mechanisms for multi-gauge wires, superior material science utilization (e.g., hardened alloy steel and anti-corrosion coatings) to enhance blade durability, and advanced ergonomic designs incorporating specialized polymers to improve user safety and reduce strain during continuous operation.

What are the key differences between manual, semi-automatic, and automatic stripping pliers?

Manual pliers require physical strength and operator skill to adjust depth and pressure for each wire size. Semi-automatic tools offer fixed-gauge selection with an integrated cutting mechanism. Fully automatic pliers feature internal mechanisms that automatically sense the wire gauge and adjust the cutting depth and stripping force instantaneously, optimizing consistency and speed without manual input.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Stripping Pliers Market Statistics 2025 Analysis By Application (Electrician, Motor Repair, Instrument Repair), By Type (Adjustable End Wire Strippers, Automatic Wire Strippers, Multi-function Wire Strippers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Antimagnetic Stripping Pliers Market Statistics 2025 Analysis By Application (Electrician, Motor Repair, Instrument Repair), By Type (Adjustable End Wire Strippers, Automatic Wire Strippers, Multi-function Wire Strippers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager