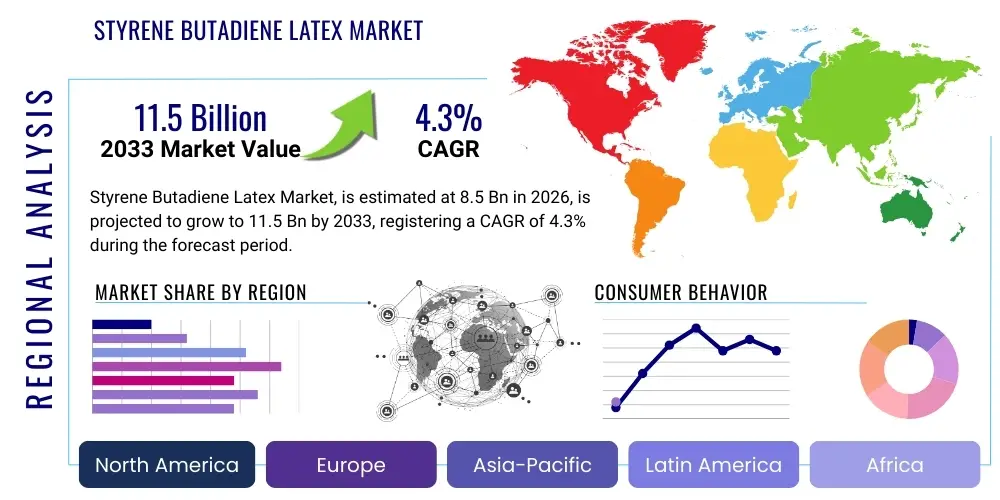

Styrene Butadiene Latex Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440324 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Styrene Butadiene Latex Market Size

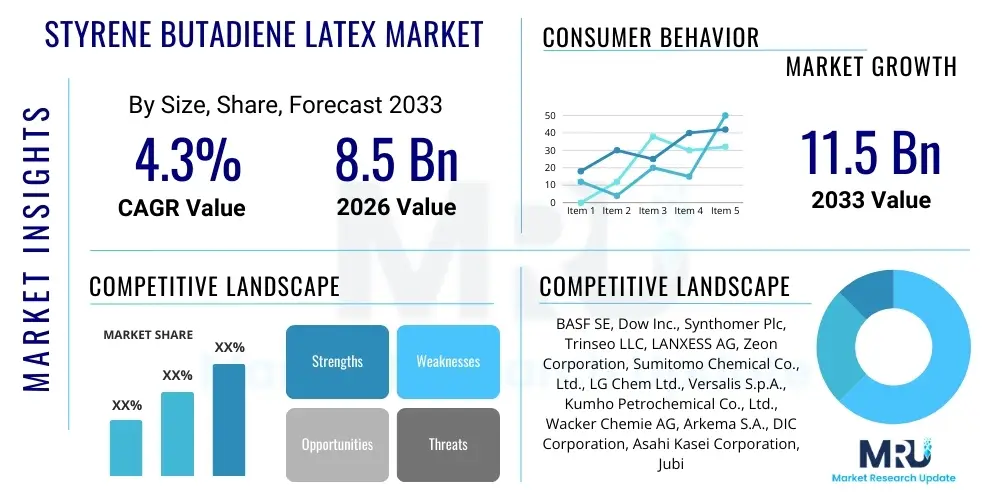

The Styrene Butadiene Latex Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.3% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 11.5 Billion by the end of the forecast period in 2033.

Styrene Butadiene Latex Market introduction

Styrene Butadiene Latex (SBL) is a synthetic rubber latex, an emulsion polymer formed by the copolymerization of styrene and butadiene monomers. Renowned for its versatile properties, SBL offers excellent binding strength, film-forming capabilities, flexibility, and water resistance, making it an indispensable material across numerous industries. Its emulsion form allows for easy handling and application in aqueous systems, contributing to its widespread adoption. This polymer is crucial for enhancing the performance and durability of various end products, serving as a critical ingredient in formulations requiring robust adhesion and coating characteristics.

The major applications of Styrene Butadiene Latex span diverse sectors including paper and board, carpet manufacturing, construction, adhesives, and paints & coatings. In the paper industry, SBL is extensively used as a coating binder to improve printability, gloss, opacity, and stiffness of paper and paperboard, making packaging and graphic papers more appealing and functional. For carpets, SBL provides dimensional stability and tuft lock, preventing fraying and extending product life. Its utility in construction involves enhancing the properties of mortars, concrete, and sealants, improving adhesion, flexibility, and resistance to water and chemicals. Furthermore, it is a key component in a wide array of adhesive formulations and as a binder in water-based paints, contributing to their durability and finish.

The benefits derived from using SBL include its cost-effectiveness, high versatility, and superior adhesion to a broad range of substrates. These attributes are pivotal in driving its market growth. Key driving factors for the Styrene Butadiene Latex market include the robust expansion of the construction industry globally, particularly in emerging economies, increasing demand for high-performance packaging solutions, and the ongoing growth in the automotive sector requiring specialized adhesives and coatings. Additionally, advancements in sustainable SBL formulations and a rising preference for water-based systems over solvent-based alternatives further fuel market expansion, addressing environmental concerns and regulatory pressures.

Styrene Butadiene Latex Market Executive Summary

The Styrene Butadiene Latex market is currently experiencing significant transformative business trends, driven by an increased focus on sustainability, operational efficiency, and product differentiation. Manufacturers are actively investing in research and development to introduce bio-based SBL grades and low-Volatile Organic Compound (VOC) formulations, responding to stringent environmental regulations and growing consumer preference for greener products. Strategic partnerships and mergers and acquisitions are becoming more prevalent as companies seek to consolidate market share, optimize supply chains, and leverage complementary technologies. Furthermore, the market is navigating through dynamic raw material price fluctuations, which necessitates agile supply chain management and diversified sourcing strategies to maintain profitability and ensure supply stability.

From a regional perspective, the market exhibits diverse growth patterns and evolving dynamics. The Asia Pacific region stands as the dominant force, propelled by rapid industrialization, extensive infrastructure development, and a burgeoning construction sector, particularly in countries like China and India. This region is also a hub for paper and packaging manufacturing, further stimulating SBL demand. In contrast, mature markets in North America and Europe are witnessing a shift towards specialty SBL products, emphasizing performance enhancement and sustainable attributes. These regions are characterized by higher regulatory standards and a greater consumer awareness regarding environmental impact, driving innovation in advanced, eco-friendly SBL solutions. Latin America and the Middle East and Africa (MEA) represent emerging markets with considerable growth potential, fueled by increasing urbanization, industrial growth, and government investments in infrastructure projects.

Segmentation trends within the Styrene Butadiene Latex market highlight a notable shift towards specialized applications beyond traditional uses. While paper and board coatings remain a significant segment, the fastest growth is observed in non-paper applications such such as construction chemicals, advanced textiles, and high-performance adhesives. There is an escalating demand for customized SBL grades specifically engineered for specialized adhesive formulations, particularly in the packaging and automotive industries, where lightweighting and improved bonding are critical. Innovation in carpet backing technologies continues to drive demand for SBL with enhanced durability and moisture resistance properties. Furthermore, the increasing adoption of SBL in civil engineering projects, including road construction and repair, underscores its growing versatility and expanding market horizons, diversifying revenue streams for manufacturers.

AI Impact Analysis on Styrene Butadiene Latex Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Styrene Butadiene Latex market frequently revolve around its potential to revolutionize production processes, enhance product quality, and accelerate innovation. Users are keen to understand how AI can optimize manufacturing efficiency, mitigate raw material price volatility through predictive analytics, and contribute to the development of more sustainable and high-performance SBL formulations. Key themes include the role of AI in improving supply chain resilience, enabling predictive maintenance of complex polymerization reactors, and ultimately driving down operational costs while simultaneously improving environmental footprints. Users also express expectations for AI to facilitate data-driven decision-making in market forecasting and customer trend analysis, providing a competitive edge.

Artificial intelligence is set to significantly transform the research and development landscape within the Styrene Butadiene Latex industry. AI-powered computational chemistry and materials informatics can drastically accelerate the discovery and optimization of new SBL formulations by predicting material properties based on monomer ratios and polymerization conditions. This capability minimizes the need for extensive physical experimentation, thereby reducing R&D cycles and associated costs. Furthermore, AI algorithms can identify novel sustainable alternatives for monomers or additives, pushing the industry towards bio-based and environmentally friendly SBL products more rapidly. This data-driven approach allows for precise tailoring of SBL properties to meet specific application requirements, fostering innovation across diverse end-use sectors.

Beyond R&D, AI’s impact on operational efficiencies in SBL manufacturing is profound. Predictive maintenance, powered by machine learning algorithms analyzing sensor data from polymerization reactors and other critical equipment, can foresee potential failures before they occur. This proactive approach minimizes downtime, optimizes resource allocation, and enhances overall production reliability and safety. AI can also optimize energy consumption by adjusting process parameters in real-time, leading to substantial energy savings and a reduced carbon footprint. Real-time quality control systems, utilizing AI and computer vision, can monitor SBL properties during production, ensuring consistent product quality and reducing waste. Moreover, AI can enhance supply chain management through advanced demand forecasting and logistics optimization, ensuring timely delivery of raw materials and finished products, thereby strengthening market responsiveness and resilience against disruptions.

- AI-driven optimization of polymerization processes for improved yield and quality consistency.

- Predictive maintenance for SBL manufacturing equipment, reducing downtime and operational costs.

- Accelerated discovery of new SBL formulations and sustainable materials through computational chemistry.

- Enhanced supply chain resilience via AI-powered demand forecasting and logistics optimization.

- Real-time quality control and anomaly detection in SBL production lines using machine learning.

- Optimization of energy consumption in manufacturing processes, contributing to sustainability goals.

- Data-driven market analysis and trend prediction for strategic business planning.

- Development of intelligent systems for waste reduction and resource efficiency.

DRO & Impact Forces Of Styrene Butadiene Latex Market

The Styrene Butadiene Latex market is shaped by a complex interplay of Drivers, Restraints, Opportunities, and a variety of Impact Forces. Key drivers propelling market growth include the robust global expansion of the construction industry, particularly the rising demand for adhesives, sealants, and concrete admixtures that benefit from SBL's superior binding and waterproofing properties. The burgeoning packaging sector, especially for paper and board applications requiring enhanced printability and durability, also significantly contributes to demand. Furthermore, the increasing consumer preference for sustainable and water-based coatings and adhesives over traditional solvent-based alternatives provides a substantial impetus, aligning with evolving environmental regulations and health consciousness. The versatility and cost-effectiveness of SBL in diverse industrial applications further solidify its market position and growth trajectory.

Conversely, the market faces notable restraints that could temper its expansion. One of the primary challenges is the volatility in raw material prices, specifically styrene and butadiene monomers, which are petrochemical derivatives. Fluctuations in crude oil prices directly impact the cost of these monomers, leading to unpredictable production costs and affecting manufacturers' profit margins. Stringent environmental regulations, particularly in developed regions concerning VOC emissions and the disposal of petrochemical-based products, pose additional hurdles, necessitating significant investment in R&D for compliant and sustainable formulations. The emergence of alternative binders and polymers, especially those derived from bio-based sources, also presents a competitive restraint, potentially diverting market share in certain niche applications. Moreover, the cyclical nature of end-use industries like construction and automotive can lead to intermittent demand fluctuations for SBL products, making market forecasting challenging.

Despite these restraints, the Styrene Butadiene Latex market is abundant with promising opportunities. The continuous innovation in bio-based SBL and low-VOC formulations presents a significant avenue for market penetration and differentiation, catering to the increasing demand for eco-friendly products. Expansion into emerging economies, particularly in Asia Pacific and Latin America, where industrialization and infrastructure development are still in their nascent stages, offers substantial untapped market potential. The development of specialized SBL grades tailored for high-performance applications in advanced textiles, geotextiles, and specialized adhesives for electric vehicles (EVs) creates new lucrative segments. Furthermore, advancements in manufacturing processes, including the adoption of smart manufacturing and AI-driven optimization, promise improved efficiency, reduced costs, and enhanced product quality, providing a competitive edge to forward-thinking market players. The ongoing trend towards urbanization and the increasing need for durable and aesthetic construction materials will continue to open new doors for SBL applications.

The market is also influenced by a range of impact forces. Technological advancements in polymerization techniques, such as living anionic polymerization and emulsion polymerization with controlled radical techniques, enable the production of SBL with precise molecular weights and architectures, leading to enhanced performance characteristics. The competitive landscape, characterized by the presence of both large multinational corporations and specialized regional players, drives innovation and pricing strategies. Economic cycles, trade policies, and geopolitical events can significantly impact supply chains and global demand. Furthermore, shifts in consumer preferences towards specific product attributes, such as enhanced durability, specific tactile properties in carpet backing, or improved print quality in packaging, directly influence product development and market trends for SBL. Regulatory frameworks pertaining to chemical safety and sustainability also exert a strong influence, compelling manufacturers to adapt and innovate constantly.

Segmentation Analysis

The Styrene Butadiene Latex market is broadly segmented based on its diverse applications and the end-use industries it serves, reflecting the wide range of sectors that leverage its unique properties. This segmentation provides a granular understanding of market dynamics, growth drivers, and demand patterns across different verticals. The primary segments typically include applications in paper and paperboard coatings, carpet backing, construction additives, adhesives, and paints & coatings, each representing a significant contribution to the overall market value. Further sub-segmentation within these categories allows for a more detailed analysis of specific product types, performance requirements, and regional consumption trends, enabling stakeholders to identify precise growth opportunities and challenges.

Analyzing these segments reveals varied growth trajectories and market maturity levels. For instance, while paper and board coatings have traditionally been a dominant segment, newer applications in high-performance adhesives and construction chemicals are demonstrating accelerated growth due to increased urbanization and infrastructure development. The demand for SBL in carpet manufacturing remains robust, driven by both residential and commercial construction trends, alongside product innovation aimed at enhancing durability and sustainability. Each segment is influenced by distinct regulatory environments, technological advancements, and consumer preferences, which dictate the specific SBL formulations required. Understanding these nuances is critical for market players to tailor their product offerings, marketing strategies, and distribution channels to effectively capture market share and sustain growth.

- By Application

- Paper & Board

- Carpet Backing

- Construction (Adhesives, Mortars, Concrete, Sealants)

- Adhesives (Labels, Tapes, Packaging, Automotive)

- Paints & Coatings

- Textiles

- Others (Gloves, Asphalt Modification, Batteries)

- By End-Use Industry

- Packaging

- Building & Construction

- Automotive

- Textile & Apparel

- Printing & Publishing

- Consumer Goods

- Others

- By Type

- High Styrene SBL

- Medium Styrene SBL

- Low Styrene SBL

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Styrene Butadiene Latex Market

The value chain for the Styrene Butadiene Latex market is intricate, commencing with the upstream sourcing of raw materials, primarily styrene and butadiene monomers, which are petrochemical derivatives. These monomers are typically produced by large chemical companies and supplied to SBL manufacturers. The quality, purity, and consistent supply of these raw materials are critical factors impacting the final SBL product. Upstream analysis also considers the energy inputs required for monomer production and the overall geopolitical stability affecting crude oil prices, which directly influence monomer costs. Efficient procurement strategies and long-term supply contracts are essential for SBL producers to mitigate price volatility and ensure a stable production process.

Further along the value chain, SBL manufacturers engage in the polymerization process, converting monomers into latex. This involves specialized chemical engineering and significant capital investment in reaction vessels, emulsification systems, and quality control infrastructure. Manufacturers invest heavily in R&D to develop differentiated SBL grades tailored for specific applications, focusing on properties such as solids content, particle size, viscosity, and adhesion characteristics. Post-production, the SBL product moves into distribution. The distribution channel is crucial for delivering the liquid latex product, often in bulk containers or specialized tanks, to various end-users. This involves careful logistics, warehousing, and transportation to maintain product stability and prevent degradation, especially considering its emulsion form.

The downstream analysis of the SBL market focuses on its extensive network of end-users and the applications where it is integrated. This includes paper and board mills, carpet manufacturers, construction chemical formulators, adhesive producers, and paint companies. These end-users act as the primary buyers, incorporating SBL into their finished products to impart desired properties like binding strength, flexibility, and water resistance. Distribution can be direct, where large SBL manufacturers supply directly to major industrial clients, or indirect, involving distributors and agents who cater to smaller-scale users or specialized regional markets. The effectiveness of these distribution channels, coupled with strong technical support and customer service, is paramount for market penetration and customer retention, as product performance and application expertise are highly valued by downstream integrators.

Styrene Butadiene Latex Market Potential Customers

The potential customers for Styrene Butadiene Latex are incredibly diverse, reflecting its broad applicability across numerous industrial sectors due to its superior binding, coating, and adhesive properties. At the forefront are manufacturers within the paper and packaging industry, who utilize SBL extensively as a binder in paper and board coatings to enhance printability, gloss, opacity, and overall durability of products ranging from magazines and brochures to corrugated boxes and liquid packaging boards. These customers prioritize SBL for its ability to improve the aesthetic and functional performance of their paper-based products, making them more competitive in the market.

Another major segment of potential customers includes carpet manufacturers, who rely on SBL for carpet backing applications. Here, SBL provides dimensional stability, tuft lock, and contributes to the overall strength and longevity of carpets and rugs. The construction industry represents a rapidly growing customer base, with companies manufacturing construction chemicals such as concrete admixtures, mortars, tile adhesives, and waterproofing membranes. These customers value SBL for its ability to improve adhesion, flexibility, crack resistance, and water repellency in various building materials, contributing to more durable and resilient structures. The increasing global focus on infrastructure development and renovation projects significantly expands this customer segment.

Beyond these, a significant portion of potential customers are adhesive manufacturers and formulators across various industries, including packaging, automotive, textiles, and consumer goods. SBL serves as a critical component in the production of a wide range of water-based adhesives, offering strong bonding capabilities to diverse substrates. Paint and coatings producers also represent key customers, integrating SBL into their formulations to enhance film formation, adhesion, scrub resistance, and overall paint durability for both interior and exterior applications. Lastly, companies in the textile industry use SBL for textile backings and binders. Each of these end-user segments seeks specific performance attributes from SBL, driving demand for specialized grades and formulations tailored to their unique product requirements and application methods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 11.5 Billion |

| Growth Rate | 4.3% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Dow Inc., Synthomer Plc, Trinseo LLC, LANXESS AG, Zeon Corporation, Sumitomo Chemical Co., Ltd., LG Chem Ltd., Versalis S.p.A., Kumho Petrochemical Co., Ltd., Wacker Chemie AG, Arkema S.A., DIC Corporation, Asahi Kasei Corporation, Jubilant Bhartia Group, Sanyo Chemical Industries, Ltd., The Yokohama Rubber Co., Ltd., Georgia-Pacific Chemicals, Apcotex Industries Limited, Lion Elastomers LLC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Styrene Butadiene Latex Market Key Technology Landscape

The Styrene Butadiene Latex market is characterized by a dynamic and evolving technology landscape, with continuous innovation focused on enhancing product performance, improving manufacturing efficiency, and meeting stringent sustainability goals. At the core of SBL production is emulsion polymerization, a sophisticated chemical process that enables precise control over polymer architecture, particle size distribution, and monomer incorporation. Recent advancements in this area include controlled radical polymerization techniques, which allow for better control over polymer chain length and branching, leading to SBL grades with tailored properties such such as enhanced film formation, improved adhesion, and superior mechanical strength, catering to high-performance applications in construction and specialized adhesives.

Beyond polymerization techniques, significant technological developments are occurring in the formulation and additive technologies for SBL. This includes the development of advanced surfactants and stabilizers that improve latex stability, reduce foaming, and enhance compatibility with other additives in end-use formulations. Innovations in cross-linking agents and rheology modifiers are also crucial, allowing formulators to fine-tune the SBL's performance for specific applications, such as achieving desired stiffness in carpet backing or flexibility in waterproofing membranes. The drive for sustainability has led to technological efforts in developing bio-based monomers or alternative raw materials to replace petrochemical derivatives, as well as processes to reduce energy consumption and minimize waste generation during SBL synthesis, aligning with circular economy principles.

Furthermore, the integration of digital technologies, such as advanced process control systems, real-time analytics, and AI/machine learning, is transforming the manufacturing landscape for Styrene Butadiene Latex. These technologies enable precise monitoring of reaction conditions, predictive maintenance of equipment, and optimization of production parameters, leading to improved yield, consistent quality, and reduced operational costs. Novel characterization techniques, including advanced spectroscopy and microscopy, provide deeper insights into the microstructure and performance of SBL, aiding in rapid product development and quality assurance. These technological advancements collectively contribute to the evolution of SBL from a commodity chemical to a specialized performance material, opening doors to new applications and markets while addressing environmental and regulatory challenges.

Regional Highlights

- Asia Pacific (APAC): Dominates the global Styrene Butadiene Latex market, driven by rapid industrialization, extensive urbanization, and significant investments in infrastructure and construction projects, particularly in China, India, and Southeast Asian countries. The region's robust packaging and paper industries further fuel demand.

- North America: A mature market characterized by a strong focus on specialty SBL grades, high-performance applications, and sustainable solutions. Demand is consistent in construction, automotive, and carpet industries, with increasing emphasis on eco-friendly and low-VOC products.

- Europe: Exhibits steady growth, influenced by stringent environmental regulations and a strong inclination towards sustainable and bio-based SBL products. The region leads in R&D for advanced SBL formulations, with significant demand from the construction, adhesives, and paper & board sectors.

- Latin America: An emerging market with considerable growth potential, spurred by increasing industrial activities, urbanization, and government initiatives in housing and infrastructure development. Brazil and Mexico are key contributors to market expansion in this region.

- Middle East & Africa (MEA): Showing promising growth due to ongoing construction booms, diversification of economies away from oil, and increasing manufacturing capabilities. Demand for SBL is rising in construction, adhesives, and coatings segments across countries like UAE, Saudi Arabia, and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Styrene Butadiene Latex Market.- BASF SE

- Dow Inc.

- Synthomer Plc

- Trinseo LLC

- LANXESS AG

- Zeon Corporation

- Sumitomo Chemical Co., Ltd.

- LG Chem Ltd.

- Versalis S.p.A.

- Kumho Petrochemical Co., Ltd.

- Wacker Chemie AG

- Arkema S.A.

- DIC Corporation

- Asahi Kasei Corporation

- Jubilant Bhartia Group

- Sanyo Chemical Industries, Ltd.

- The Yokohama Rubber Co., Ltd.

- Georgia-Pacific Chemicals

- Apcotex Industries Limited

- Lion Elastomers LLC

Frequently Asked Questions

Analyze common user questions about the Styrene Butadiene Latex market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Styrene Butadiene Latex (SBL) and what are its primary uses?

Styrene Butadiene Latex is a synthetic rubber latex, a polymer emulsion made from styrene and butadiene monomers. It is primarily used as a binder and coating agent in various industries including paper and board (for enhanced printability and strength), carpet backing (for dimensional stability), construction (in adhesives, mortars, and sealants), and in water-based paints and adhesives for improved durability and adhesion.

What are the key factors driving the growth of the SBL market?

The SBL market's growth is largely driven by the expanding global construction sector, increasing demand for high-performance packaging, and the rising preference for water-based, environmentally friendly coatings and adhesives. Its versatility, cost-effectiveness, and superior binding properties across diverse applications further contribute to its market expansion.

What challenges does the Styrene Butadiene Latex market face?

The primary challenges include the volatility of raw material prices (styrene and butadiene, derived from petrochemicals), stringent environmental regulations concerning VOC emissions, and competition from alternative binders. These factors can impact production costs, necessitate significant R&D investments for sustainable solutions, and influence market profitability.

How is sustainability impacting the Styrene Butadiene Latex market?

Sustainability is a significant trend, driving innovation towards bio-based SBL formulations, low-VOC (Volatile Organic Compound) products, and energy-efficient manufacturing processes. This shift addresses environmental concerns, complies with stricter regulations, and meets growing consumer demand for greener products, fostering a more sustainable SBL industry.

Which regions are leading in SBL consumption and market growth?

The Asia Pacific region currently leads in SBL consumption and market growth, propelled by rapid industrialization, infrastructure development, and a booming construction sector in countries like China and India. North America and Europe, while mature, focus on specialty and sustainable SBL grades, while Latin America and MEA show strong emerging market potential.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Butadiene Market Statistics 2025 Analysis By Application (Styrene Butadiene Rubber (SBR), Butadiene Rubber (BR), Styrene Butadiene Latex (SBL), Acrylonitrile Butadiene Styrene (ABS), Adiponitrile), By Type (Extractive Distillation, Oxidative Dehydrogenation), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Butadiene Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Green (Bio-Bde), Black (Fossil-Bde)), By Application (Styrene Butadiene Latex (SBL), Butadiene Rubber (BR), Styrene Butadiene Rubber (SBR), Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Green Butadiene Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Phosphorus-containing all-silica zeolites catalyst type, Silver nitrate powder and zirconyl nitrate catalyst type, Others), By Application (Styrene Butadiene Latex (SBL), Butadiene Rubber (BR), Styrene Butadiene Rubber (SBR), Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Styrene Butadiene Latex Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Solution Styrene Butadiene Latex, Emulsion Styrene Butadiene Latex), By Application (Glass Fiber Processing, Fiber & Carpet Processing, Paper Processing), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Latex Powder Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Styrene Butadiene Latex Powder, Vinyl Acetate Copolymer, Vinyl Acetate Terpolymer), By Application (Concrete Repair Mortars, Ceramic Tile Adhesives, Thermal Insulating Adhesives), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager