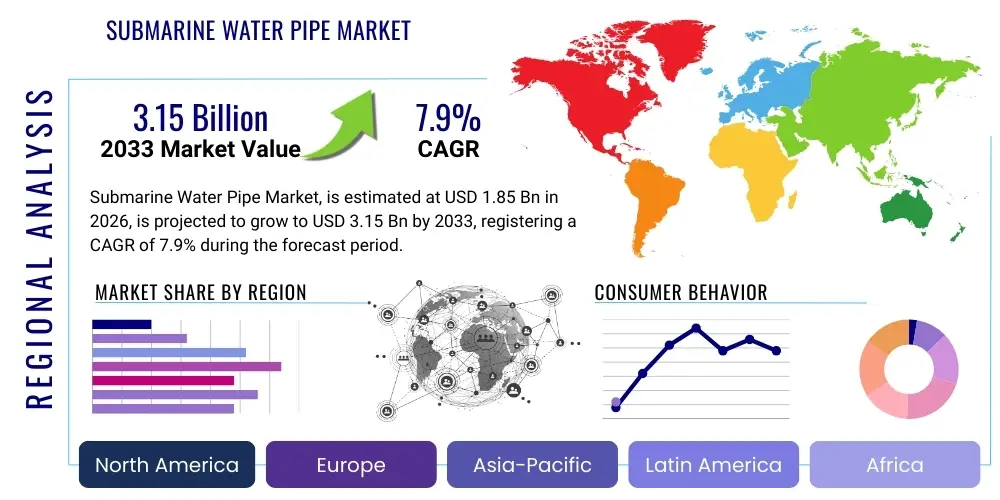

Submarine Water Pipe Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438765 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Submarine Water Pipe Market Size

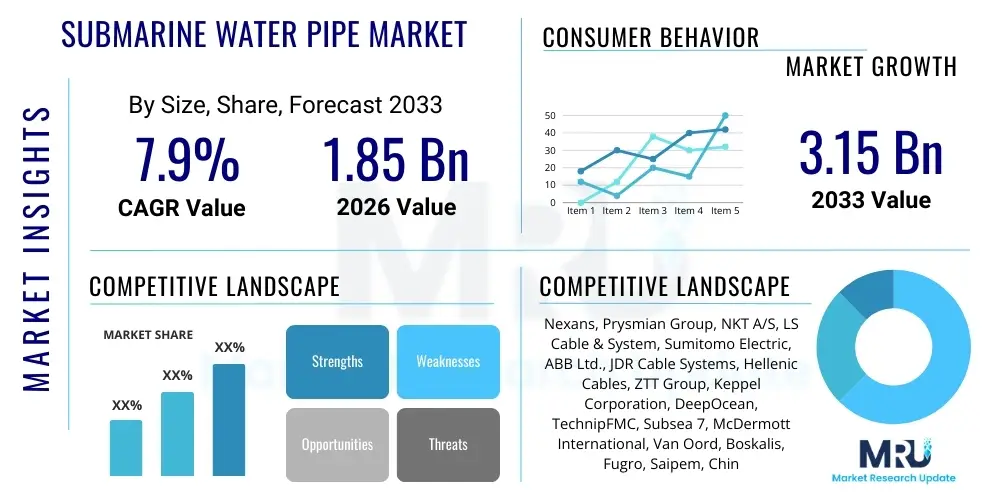

The Submarine Water Pipe Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.9% between 2026 and 2033. The market is estimated at $1.85 Billion in 2026 and is projected to reach $3.15 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally driven by the escalating global need for potable water security and the necessity to transport large volumes of fresh or desalinated water across maritime boundaries, linking islands to mainlands or serving coastal industrial hubs.

Submarine Water Pipe Market introduction

The Submarine Water Pipe Market encompasses the manufacturing, installation, and maintenance of pipelines designed to transport water beneath the surface of seas, lakes, and rivers. These specialized infrastructure assets are crucial for managing water scarcity, supporting cross-border water sharing agreements, and ensuring reliable supply to communities located on islands or along arid coastlines. The pipelines are constructed using highly durable materials such as High-Density Polyethylene (HDPE), steel, and composite materials, engineered to withstand immense hydrostatic pressures, corrosive marine environments, and dynamic seabed conditions.

Major applications of these pipes include large-scale water transmission projects connecting reservoirs to metropolitan areas, effluent discharge lines from wastewater treatment plants located offshore, and crucial intake/outtake lines for coastal desalination facilities. The primary benefits derived from these systems are enhanced water supply resilience, reduced reliance on expensive land-based transport alternatives, and the ability to access vast offshore water sources or connect geographically separated infrastructure nodes efficiently. Key driving factors include rapid global urbanization, increased investments in sustainable water management solutions, and technological advancements in marine pipe installation techniques, such as horizontal directional drilling (HDD) and deep-sea trenching, which reduce environmental impact and deployment risks.

Submarine Water Pipe Market Executive Summary

The global Submarine Water Pipe Market demonstrates robust expansion driven by critical infrastructure investments aimed at securing water resources against climate change effects. Business trends indicate a strong shift towards prefabricated pipe segments and the use of flexible materials like HDPE, which significantly lowers installation costs and improves resilience against seismic activity compared to traditional steel structures. Furthermore, the market is characterized by long-term contractual agreements between governments, utility providers, and specialized marine engineering firms, emphasizing reliability and longevity over initial capital outlay. Regulatory landscapes, particularly in Europe and parts of Asia, are promoting stringent environmental standards, thereby accelerating the adoption of advanced installation methods that minimize disturbance to marine ecosystems.

Regional trends highlight the Asia Pacific (APAC) region as the fastest-growing market, largely due to high population density, rapid industrial development, and subsequent strain on existing water resources, necessitating large-scale desalination and cross-sea pipeline projects, notably in nations like China, India, and island nations. North America and Europe, while mature, focus heavily on replacement and modernization of aging infrastructure, utilizing smart monitoring systems integrated into new installations. Segment trends show that the desalination application segment is expected to exhibit the highest CAGR, propelled by the increasing global prevalence of water stress, particularly in the Middle East and Africa (MEA), where coastal countries are heavily dependent on seawater purification technologies, requiring robust intake and brine discharge systems.

AI Impact Analysis on Submarine Water Pipe Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) can enhance the longevity, operational efficiency, and predictive maintenance of complex submarine infrastructure. Key themes revolve around the potential for AI-driven anomaly detection within pipeline networks, optimization of installation logistics, and real-time assessment of pipeline integrity against dynamic environmental stressors such as strong currents or seabed movement. Concerns often focus on the cybersecurity risks associated with integrating smart sensors and AI control systems into critical national infrastructure. Expectations are high regarding the deployment of autonomous underwater vehicles (AUVs) guided by ML algorithms for precise inspection, reducing the need for expensive and risky human intervention, thereby significantly lowering operational expenditure (OPEX) over the system's projected lifespan.

AI's primary influence is moving the industry from reactive maintenance schedules to predictive models, analyzing vast datasets generated by smart pigs, fiber optic sensors (FOS), and remote monitoring stations. This shift allows operators to anticipate failure points caused by corrosion, external impact, or material fatigue long before a critical incident occurs, dramatically improving system uptime and reducing catastrophic leakage risks. Furthermore, in the planning and engineering phase, sophisticated AI algorithms are utilized to optimize pipe routing, factoring in complex bathymetric data, geological hazards, and environmental sensitivities to determine the most cost-effective and resilient deployment path. This optimization reduces construction duration and minimizes exposure to marine risks.

- AI-enhanced Predictive Maintenance: Utilizing sensor data and ML algorithms to forecast material degradation and schedule repairs proactively.

- Installation Route Optimization: Employing AI to analyze geophysical data for identifying the safest and most efficient pipeline laying paths.

- Real-time Leak Detection: Integrating deep learning models to process acoustic and pressure sensor data for rapid identification of minor leaks.

- Autonomous Inspection Systems: ML-guided Autonomous Underwater Vehicles (AUVs) for detailed, efficient, and frequent pipeline surveillance.

- Operational Energy Efficiency: Optimizing pumping station cycles based on real-time demand and pipe friction modeling.

DRO & Impact Forces Of Submarine Water Pipe Market

The Submarine Water Pipe Market is influenced by a dynamic interplay of growth drivers stemming from demographic shifts and environmental pressures, tempered by significant financial and technical restraints inherent to underwater engineering, while capitalizing on emerging opportunities linked to sustainable resource management and novel material science. The dominant driver remains the increasing global water scarcity and the subsequent rise in government mandates for water security projects. However, the high capital expenditure required for laying pipelines in deep water, coupled with the long regulatory approval processes, acts as a primary restraint. The emergence of modular construction techniques and advanced composite materials presents significant opportunities for reducing project timelines and improving pipe durability, ultimately shaping market competitiveness and investment decisions.

Drivers: Intensifying global water stress and the subsequent boom in desalination plant construction globally necessitate reliable submarine pipelines for both intake and brine discharge. Rapid coastal population growth requires robust infrastructure to support municipal water supply systems, often extending supply lines offshore or connecting distant fresh water sources. Additionally, advancements in trenching, burial, and corrosion protection technologies have made previously infeasible long-distance submarine water transfer projects economically viable and technically sound, encouraging governments and utility companies to invest in these large-scale interconnector projects.

Restraints: The market faces significant hurdles related to the extremely high initial investment costs associated with deep-sea installation vessels, specialized pipe-laying equipment, and extensive marine surveys. Regulatory complexities and the necessity for multi-jurisdictional approvals, especially for cross-border projects, often cause substantial project delays. Furthermore, the inherent technical risks associated with external factors, such as anchoring damage from shipping traffic, seismic activity, and biofouling, demand specialized maintenance protocols and robust protective measures, adding complexity and operational expenditure.

Opportunities: Opportunities lie primarily in developing modular and prefabricated piping solutions that accelerate deployment and reduce vessel time. The increasing focus on inter-regional water transfer schemes, particularly linking areas of surplus water to arid regions, opens up vast new markets for ultra-long distance pipelines. Furthermore, the integration of smart monitoring technologies, including fiber optic sensing and integrated data analytics, offers utility providers the chance to enhance asset management, extend operational lifespan, and minimize environmental risks associated with leaks or failures, creating a substantial aftermarket services segment.

- Market Driver: Global Escalation of Water Scarcity and Desalination Investments.

- Market Restraint: Extremely High Capital Costs and Complex Marine Regulatory Environment.

- Market Opportunity: Development of Modular Pipeline Systems and Cross-Border Water Interconnection Projects.

- Impact Force: Climate Change effects driving immediate need for resilient infrastructure solutions.

- Impact Force: Technological advances in material science increasing pipeline flexibility and corrosion resistance.

Segmentation Analysis

The Submarine Water Pipe Market is systematically segmented based on Material Type, application, and End-Use sector, providing a granular view of investment patterns and technological preferences across various utility environments. The Material Type segment is critical, as the choice of pipe material directly influences installation technique, resilience, longevity, and overall project cost. HDPE pipes are increasingly gaining dominance due to their flexibility, ease of deployment, and exceptional resistance to corrosion, making them highly suitable for shallow to medium water depths, particularly in municipal applications where long-term low maintenance is prioritized.

The Application segment highlights key demand drivers, with Water Transmission pipelines, encompassing long-distance connections between sources and treatment plants, representing the largest market share. However, the fastest growth is observed in the Desalination Plants segment, where rapid commissioning of new facilities, especially in water-stressed coastal regions, generates consistent demand for high-capacity intake and discharge lines. Understanding these segment dynamics is crucial for manufacturers and engineering firms to tailor their product offerings and specialized marine services to areas exhibiting peak demand and unique project specifications, such as extremely large diameters or high-pressure requirements.

- By Material Type:

- High-Density Polyethylene (HDPE)

- Steel (Carbon Steel, Stainless Steel)

- Concrete (Concrete Weight Coating, Concrete Lined)

- Composites and Others (e.g., Fiberglass Reinforced Plastic)

- By Application:

- Water Transmission (Long-distance bulk transport)

- Desalination Plant Intake/Outfall Lines

- Wastewater Discharge (Effluent Outfalls)

- Cross-Border/Inter-Island Supply

- Industrial Cooling/Process Water

- By End-Use:

- Municipal and Public Utility

- Industrial (Power Generation, Manufacturing)

- Agricultural (Large-scale irrigation transfer)

Value Chain Analysis For Submarine Water Pipe Market

The value chain for the Submarine Water Pipe Market is extensive, starting from the specialized upstream manufacturing of corrosion-resistant materials and large-diameter pipes, extending through complex logistical and specialized installation phases, and concluding with long-term maintenance and monitoring services. Upstream analysis focuses heavily on raw material suppliers (steel, polymers, coating materials) and the highly specialized pipe manufacturing sector, which requires significant capital investment in extrusion or welding facilities capable of producing segments that meet stringent marine and environmental specifications. The quality control at this stage is paramount, dictating the ultimate lifespan and performance of the submarine asset under harsh conditions.

Downstream activities are dominated by specialized marine engineering, procurement, and construction (EPC) contractors, who manage complex project logistics, marine vessel operations, trenching, installation, and commissioning. This segment is characterized by high barriers to entry due to the necessity for owning or chartering highly specialized pipe-laying barges, remotely operated vehicles (ROVs), and deepwater trenching equipment. Distribution channels are predominantly direct, involving direct contractual relationships between the pipe manufacturer or EPC consortium and the end-user utility or government agency. Given the customized and project-specific nature of submarine pipes, indirect distribution through generalized wholesalers is negligible, reinforcing the importance of strong, direct client relationships and technical consulting throughout the project lifecycle.

Submarine Water Pipe Market Potential Customers

Potential customers in the Submarine Water Pipe Market are primarily large entities requiring high-volume, reliable, and secure water transport solutions over challenging geographical features. The largest segment of end-users are Municipal and Public Utility Authorities globally, specifically those serving rapidly growing coastal populations or island communities dependent on external water sources or desalination facilities. These entities prioritize long-term asset reliability, adherence to stringent quality standards for potable water, and minimized maintenance complexity to ensure continuous public service delivery.

Another significant customer segment includes governments and state-owned enterprises (SOEs) driving national or regional water security agendas, often funding complex, multi-billion-dollar cross-border water interconnector projects aimed at mitigating drought risks or sharing resources between nations. Furthermore, major industrial consumers, particularly coastal power generation facilities (for cooling water intake/outfall) and large-scale manufacturing operations requiring vast volumes of process water, represent crucial buyers, seeking robust and high-capacity piping solutions tailored to extreme operational environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion |

| Market Forecast in 2033 | $3.15 Billion |

| Growth Rate | 7.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nexans, Prysmian Group, NKT A/S, LS Cable & System, Sumitomo Electric, ABB Ltd., JDR Cable Systems, Hellenic Cables, ZTT Group, Keppel Corporation, DeepOcean, TechnipFMC, Subsea 7, McDermott International, Van Oord, Boskalis, Fugro, Saipem, China Ocean Engineering Construction, CTC Marine Projects |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Submarine Water Pipe Market Key Technology Landscape

The technological landscape of the Submarine Water Pipe Market is centered on enhancing installation speed, maximizing pipe integrity under aggressive environmental loads, and enabling continuous, remote monitoring. Key technologies involve advanced pipe material composites, such as high-strength polyethylene reinforced with non-metallic fibers, which offer superior fatigue resistance and lighter weight compared to traditional steel, simplifying transportation and deployment logistics. Furthermore, specialized anticorrosion and antifouling coatings, utilizing nanotechnologies and bio-resistant materials, are critical for extending the operational lifespan of pipelines in bio-active and high-salinity marine environments, particularly relevant for effluent outfalls.

Installation technology represents another major area of innovation. Horizontal Directional Drilling (HDD) is increasingly utilized to transition pipelines from the land entry point to the subsea burial site, minimizing disruption to coastal zones and sensitive habitats. For deepwater projects, advanced pipe-laying methods, including controlled depth tow and reel-lay techniques, ensure precise placement and minimized stress on the pipeline during deployment. Crucially, the integration of Fiber Optic Sensing (FOS) technology embedded within the pipe wall or surrounding protective layers allows for real-time monitoring of strain, temperature, and acoustic anomalies, providing essential data for integrity management and early leak detection, transitioning infrastructure management into the domain of Industrial Internet of Things (IIoT).

Regional Highlights

Regional dynamics play a crucial role in shaping the demand and technological deployment within the Submarine Water Pipe Market, largely reflective of local water stress levels, economic development, and existing infrastructure maturity. The Asia Pacific (APAC) region is forecasted to exhibit the highest growth rate, driven primarily by unprecedented urbanization along coastal areas and the corresponding need for massive water treatment and transmission infrastructure, particularly in emerging economies. Countries like China, Australia, and South Korea are heavily investing in long-distance inter-island water links and large-scale desalination projects to secure their metropolitan water supplies, favoring durable solutions like large-diameter HDPE and steel pipes.

North America and Europe represent mature markets characterized by stringent regulatory environments and a focus on replacing aging assets and enhancing resilience against extreme weather events. In Europe, the emphasis is on connecting island territories and securing cross-sea supply routes, often utilizing deep-water installation expertise derived from the oil and gas sector. The shift in these regions is toward highly monitored, smarter pipelines incorporating advanced sensors and requiring minimal environmental impact during installation, often favoring specialized EPC contractors capable of undertaking complex rehabilitation projects without significant service interruption.

The Middle East and Africa (MEA) region remains a critical area, especially for applications related to desalination. Gulf Cooperation Council (GCC) countries, heavily reliant on desalinated water, are continuously commissioning new plants, requiring expansive and resilient submarine intake and brine discharge systems. The technical requirements in this region often include extremely high-capacity pipes capable of handling high-salinity water and resisting high temperatures, driving demand for specialized coated steel and high-grade composite materials, ensuring that infrastructure investments align with ambitious long-term national water strategies.

- Asia Pacific (APAC): Dominating growth due to rapid urbanization, increased desalination capacity deployment in coastal cities, and vital infrastructure links to island nations (e.g., Singapore, Indonesia, Philippines).

- Europe: High demand driven by infrastructure replacement, adherence to strict environmental regulations (WFD), and cross-border water grid connectivity projects within the Mediterranean and Nordic regions.

- North America: Stable market focusing on resilience, integrating advanced monitoring systems, and addressing the modernization of critical coastal municipal water intake structures, primarily in California and the Eastern Seaboard.

- Middle East & Africa (MEA): Crucial market anchored by massive investments in desalination infrastructure, particularly in Saudi Arabia, UAE, and Qatar, demanding robust, high-capacity steel and composite pipelines.

- Latin America: Emerging potential driven by industrial water demands and addressing water scarcity challenges in densely populated coastal regions of Brazil, Chile, and Peru.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Submarine Water Pipe Market.- Nexans

- Prysmian Group

- NKT A/S

- LS Cable & System

- Sumitomo Electric Industries, Ltd.

- ABB Ltd.

- JDR Cable Systems (TFKable Group)

- Hellenic Cables

- ZTT Group

- Keppel Corporation

- DeepOcean

- TechnipFMC

- Subsea 7 S.A.

- McDermott International, Ltd.

- Van Oord B.V.

- Royal Boskalis Westminster N.V.

- Fugro N.V.

- Saipem S.p.A.

- China Ocean Engineering Construction General Company (COEC)

- CTC Marine Projects (part of Offshore Marine Contractors)

Frequently Asked Questions

Analyze common user questions about the Submarine Water Pipe market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Submarine Water Pipe Market?

The market growth is primarily driven by escalating global water scarcity, substantial governmental investment in desalination facilities, rapid coastal urbanization increasing demand for municipal water supply, and the imperative to secure resilient water infrastructure against climate change impacts. Technological advancements in pipe materials and installation techniques also reduce project risks and costs, stimulating new investments.

Which material type dominates the Submarine Water Pipe Market segmentation?

While steel pipes remain vital for ultra-deep or very high-pressure applications, High-Density Polyethylene (HDPE) is increasingly dominating the market, especially in shallow to medium depths and municipal applications. HDPE is favored for its superior corrosion resistance, flexibility, lighter weight, and significantly reduced deployment complexity and cost compared to traditional rigid materials.

What are the main risks associated with submarine pipeline operations?

Key operational risks include mechanical damage from external forces, primarily caused by ship anchors or fishing trawlers, along with material degradation due to corrosion, biofouling, and stress fatigue from dynamic seabed movement or seismic events. These risks necessitate robust burial strategies, protective concrete coatings, and continuous integrity monitoring using smart sensors.

How does the integration of AI impact the long-term maintenance of submarine water pipes?

AI significantly shifts maintenance from reactive to predictive models. By analyzing real-time sensor data (pressure, strain, acoustics), AI algorithms forecast potential failure points, identify minor anomalies early, optimize inspection schedules using AUVs, and dramatically reduce system downtime, thereby lowering overall operational expenditure (OPEX) and enhancing water supply reliability.

Which geographic region exhibits the fastest growth potential for submarine water pipe installation?

The Asia Pacific (APAC) region is projected to show the fastest market growth. This is attributed to high population growth, extensive infrastructure development in coastal areas, particularly for securing potable water for megacities, and significant governmental investment in large-scale inter-island and cross-sea water transmission projects necessary for regional water security.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager