Super Fine Talc Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437535 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Super Fine Talc Powder Market Size

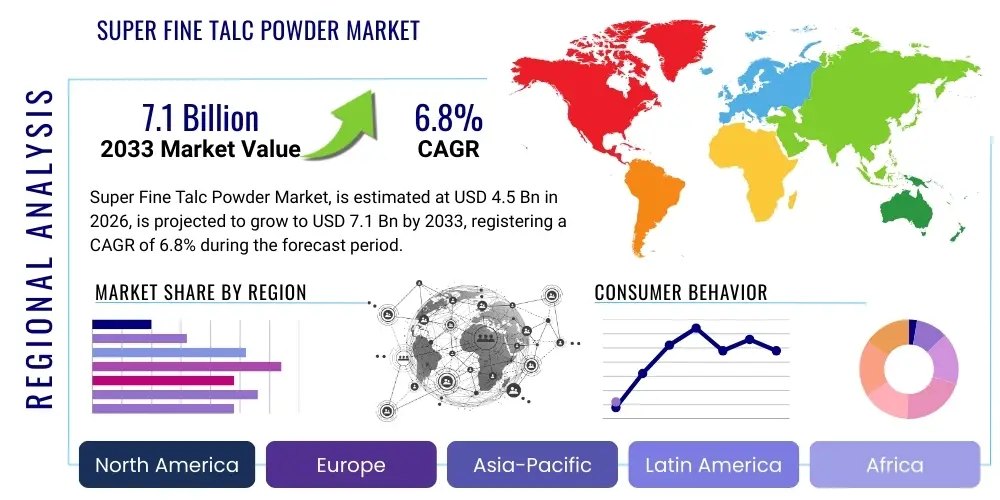

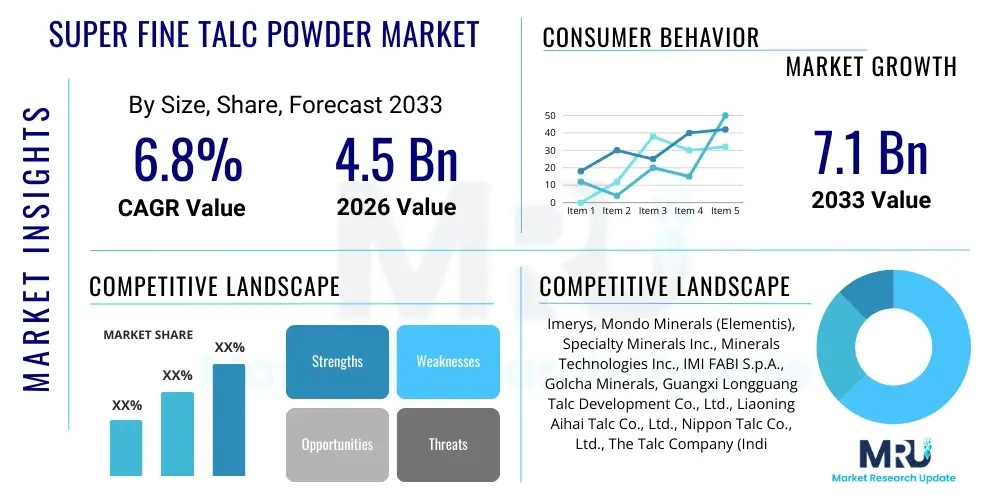

The Super Fine Talc Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 billion in 2026 and is projected to reach USD 7.1 billion by the end of the forecast period in 2033.

Super Fine Talc Powder Market introduction

The Super Fine Talc Powder Market encompasses the production and distribution of high-purity, micronized talc characterized by extremely small particle sizes, often below 10 micrometers (µm), and frequently reaching sub-micron levels (D90 less than 5 µm). This classification ensures superior performance in applications requiring exceptional reinforcement, smooth surface finish, barrier properties, and rheological control. The material is chemically inert hydrous magnesium silicate, renowned for its platy structure, softness, and high thermal stability, making it indispensable across various high-specification industries.

The primary applications driving demand for super fine talc powder include high-performance plastics (polypropylene, nylon), where it acts as a nucleation agent and improves mechanical strength, stiffness, and dimensional stability. Furthermore, it is critical in specialized coatings and paints for anti-corrosion properties and matte finishes, in high-quality paper manufacturing for improved opacity and smoothness, and within the cosmetics and pharmaceuticals sectors for its smooth texture and absorbent properties. The differentiation of super fine talc from standard grades lies fundamentally in its consistent particle size distribution (PSD) and high brightness index, which justifies its premium pricing and usage in sensitive applications.

Market growth is predominantly fueled by the increasing global emphasis on lightweight materials in the automotive and aerospace industries, necessitating advanced fillers that enhance plastic performance without significantly increasing density. Regulatory pressures promoting sustainable packaging solutions and the robust expansion of infrastructure projects, requiring high-durability coatings and construction materials, further accelerate adoption. The inherent benefits of super fine talc, such as reduced coefficient of friction and superior electrical insulation, position it as a critical additive for modern industrial requirements.

- Product Description: High-purity, micronized hydrous magnesium silicate with particle sizes typically below 10 µm.

- Major Applications: Automotive plastics, specialty coatings, cosmetics, pharmaceuticals, and high-quality paper.

- Key Benefits: Enhanced stiffness, dimensional stability, improved barrier properties, superior surface finish, and thermal stability.

- Driving Factors: Lightweighting trends in automotive, stringent material performance standards, and growth in the cosmetics sector.

Super Fine Talc Powder Market Executive Summary

The Super Fine Talc Powder Market is poised for substantial expansion, driven by accelerating demand from advanced materials and specialty chemical sectors globally. Key business trends indicate a strong focus on supply chain resilience, purity standardization, and technological investment in dry grinding and classification techniques to achieve tighter particle size specifications required by end-users. Strategic alliances between miners and micronization specialists are becoming common to control quality from mine to market, ensuring consistency necessary for high-volume automotive and medical applications. The competitive landscape is characterized by established players maintaining vertical integration to leverage high-quality raw material sources, alongside specialized processors focusing solely on value-added ultra-fine grades.

Regionally, Asia Pacific continues to dominate market consumption due to rapid industrialization, particularly the massive growth in automotive production and manufacturing of consumer goods in China, India, and Southeast Asia. North America and Europe, while mature markets, exhibit steady demand, focusing intensely on high-end, customized talc grades for advanced polymer compounding and pharmaceutical use, driven by stringent quality and regulatory frameworks. Emerging regional trends involve significant investment in sustainable mining and processing techniques, particularly in Europe, addressing environmental concerns related to mineral extraction and processing waste.

Segmentation analysis reveals that the polymer and plastic segment maintains the largest market share, predominantly utilizing super fine talc for lightweighting solutions in vehicle construction. However, the coatings and paints segment is projected to exhibit the fastest growth rate, fueled by the demand for environmentally friendly, low-VOC coatings that rely on fine talc for enhanced viscosity control, UV resistance, and matting effects. Furthermore, the cosmetic grade segment, demanding the highest level of purity (often pharmaceutical grade) and ultra-fine particles (D90 < 5 µm), showcases robust stability, indicating consumer willingness to pay a premium for high-quality personal care products.

- Business Trends: Increased vertical integration, focus on consistent PSD, and specialized toll processing agreements.

- Regional Trends: Dominance of APAC in consumption; high-value customization and stringent regulatory compliance in North America and Europe.

- Segment Trends: Polymer/Plastic remains the largest consumer; Coatings/Paints segment demonstrates the fastest expansion trajectory.

AI Impact Analysis on Super Fine Talc Powder Market

User queries regarding AI's influence in the Super Fine Talc Powder Market frequently center on optimizing mining operations, enhancing processing efficiency, and automating quality control, particularly in achieving precise particle size distribution (PSD). Common themes include concerns about the high initial investment required for implementing AI-driven sensors and analytical tools, and expectations surrounding predictive maintenance capabilities that can minimize downtime in specialized micronization plants. Users are keen to understand how AI algorithms can rapidly analyze X-ray diffraction and particle analysis data to ensure consistent material purity, especially crucial for pharmaceutical and cosmetic grades where contamination risks must be zero. The consensus suggests that AI integration will primarily affect operational expenditures and material specification consistency rather than radically altering the fundamental chemistry of talc processing.

The application of Artificial Intelligence (AI) and machine learning (ML) is beginning to revolutionize the upstream and midstream segments of the talc value chain. In mining, AI algorithms analyze geological data derived from drones and satellite imagery to identify optimal drilling locations, improving extraction efficiency and reducing environmental impact associated with unnecessary excavation. Furthermore, AI-powered systems are utilized in ore sorting processes, employing computer vision and spectral analysis to distinguish high-purity talc from gangue minerals, thereby significantly boosting the quality of the feedstock entering the micronization stage. This precise sorting reduces energy consumption during subsequent grinding processes.

In the processing phase, which is critical for producing super fine talc, AI models optimize the complex parameters of jet mills and mechanical classifiers. Achieving a sub-micron particle size distribution consistently is challenging and highly energy-intensive. ML models continuously monitor variables such as air flow, feed rate, rotor speed, and internal temperatures, making real-time adjustments to maximize throughput while minimizing energy usage and maintaining tight PSD specifications. This predictive control dramatically reduces waste material and ensures that the final product meets the increasingly stringent technical specifications required by advanced polymer compounders and specialty chemical manufacturers.

- Enhanced Ore Sorting: AI uses spectral analysis to improve feedstock purity before processing.

- Optimized Grinding: Machine learning controls jet mill parameters for consistent sub-micron particle size distribution (PSD).

- Predictive Maintenance: AI algorithms forecast equipment failures in high-wear micronization machinery, reducing costly downtime.

- Automated Quality Control: Computer vision systems rapidly verify particle shape, aspect ratio, and color/whiteness index for high-grade products.

- Supply Chain Forecasting: AI models predict demand fluctuations across specialized end-use sectors (e.g., medical devices, specialized coatings), optimizing inventory levels.

DRO & Impact Forces Of Super Fine Talc Powder Market

The market for Super Fine Talc Powder is characterized by a complex interplay of strong demand drivers, significant constraints related to quality control and regulatory hurdles, and emerging opportunities in niche, high-value applications. The primary drivers revolve around the global push for enhanced material performance, particularly in automotive lightweighting and demanding industrial coatings, which necessitate fillers with extremely consistent particle metrics and high aspect ratios. These factors are further amplified by the growth in urbanization and infrastructure development, which drives demand for robust, durable construction materials and protective coatings that utilize fine talc for rheological modification and barrier enhancement. The material’s ability to replace less effective or more expensive fillers in various systems maintains its competitive edge.

However, the market faces considerable restraints, primarily centered on the high processing costs associated with achieving the "super fine" classification. Micronization and classification of talc to sub-10 µm, and especially sub-5 µm, require substantial energy input and specialized, high-capital equipment (such as jet mills), limiting the number of producers capable of consistently supplying high-quality product. Furthermore, regulatory scrutiny regarding impurities, particularly the necessity of ensuring zero asbestos contamination, imposes strict quality control protocols that increase operational expenses and constrain supply sources. The volatile nature of energy prices also directly impacts production costs, given the energy intensity of ultra-fine grinding.

Opportunities for market expansion are significant, particularly in the realm of sustainable and specialized materials. The development of talc-based additives for biodegradable plastics and biopolymers presents a substantial growth avenue, aligning with global environmental policy shifts. Additionally, the increasing sophistication of the electronics and semiconductor industry requires ultra-high purity talc grades for specialized electronic encapsulation and thermal management compounds, offering premium pricing potential. The expansion into developing pharmaceutical excipients and high-performance friction materials further diversifies the application portfolio, providing resilience against potential slowdowns in traditional end-use sectors like standard plastics or paper. These forces—Drivers, Restraints, and Opportunities (DRO)—collectively define the velocity and direction of market evolution.

- Drivers: Automotive lightweighting trends; demand for high-performance specialty coatings; expansion of the cosmetics and pharmaceutical industries requiring high purity.

- Restraints: High energy consumption and capital costs associated with ultra-fine grinding; stringent regulatory requirements concerning asbestos contamination; variability in raw material quality.

- Opportunities: Growing adoption in bio-plastics and compostable materials; expansion into high-purity electronic and medical applications; technological advancements in processing efficiency.

- Impact Forces: Technological innovation in micronization (high); regulatory compliance pressure (high); raw material purity dependence (moderate to high).

Segmentation Analysis

The Super Fine Talc Powder market is structurally segmented based on crucial metrics including particle size, end-use application, and grade purity, each addressing distinct industrial requirements and value propositions. Particle size is perhaps the most defining characteristic, differentiating standard talc from super fine grades (typically D90 < 10 µm) and ultra-fine grades (D90 < 5 µm), which command the highest premiums due to the processing difficulty and performance superiority they offer in niche applications. The purity of the talc, categorized into industrial, cosmetic, and pharmaceutical grades, determines suitability for consumption in regulated industries, with pharmaceutical grades being the most rigorously tested and consequently the most expensive.

Application segmentation reveals the dominance of the polymers and plastics sector, which utilizes super fine talc to enhance material stiffness, impact strength, and dimensional stability, particularly in engineering thermoplastics like polypropylene. The coatings segment is critical, using fine talc for viscosity modification, anti-settling, and improving the barrier properties against moisture and chemicals, thereby extending the durability of protective coatings. Other significant segments include paper, for enhanced opacity and printability, and the high-growth cosmetics and personal care sector, where the silky texture and oil absorption capacity of super fine talc are highly valued.

Geographic segmentation underscores the regional disparities in manufacturing capabilities and consumption patterns. Asia Pacific leads both in terms of production capacity and consumption volume, driven by large-scale manufacturing output. Conversely, North America and Europe focus heavily on specialized, high-purity grades for complex applications in medical and automotive safety systems. This multi-dimensional segmentation allows market participants to tailor product offerings and strategic investments toward specific, high-potential segments characterized by stringent technical specifications and less price sensitivity.

- By Grade:

- Industrial Grade

- Cosmetic Grade

- Pharmaceutical Grade

- By Particle Size:

- D90 5 µm – 10 µm (Fine)

- D90 < 5 µm (Ultra Fine)

- D90 < 2 µm (Sub-micron)

- By Application:

- Polymers and Plastics (e.g., PP, PE, Nylon)

- Paints and Coatings

- Paper and Pulp

- Ceramics

- Cosmetics and Personal Care

- Pharmaceuticals

- Rubber

Value Chain Analysis For Super Fine Talc Powder Market

The value chain for Super Fine Talc Powder is intensive and highly specialized, beginning with upstream mining and concluding with specialized downstream application integration. Upstream activities involve the exploration, extraction, and initial crushing of crude talc ore. The quality of the ore, particularly its whiteness and the absence of deleterious minerals like dolomite, chlorite, and, critically, asbestos, determines the ultimate value of the refined product. Controlling feedstock quality at this initial stage is paramount, as impurity removal becomes significantly harder and more costly after micronization. Large, integrated miners often possess proprietary high-purity deposits, providing a key competitive advantage.

The midstream processing stage is the most value-intensive component, involving complex dry or wet grinding and classification techniques, such as jet milling, ball milling, and air classification, to achieve the super fine particle size distribution (PSD). Companies operating in this segment invest heavily in sophisticated equipment and process control technologies to ensure consistent, tight PSD tolerances and high whiteness/brightness levels, which are non-negotiable for cosmetic and pharmaceutical grades. Distribution channels are bifurcated: direct sales channels dominate for large-volume industrial consumers (e.g., major polymer compounders) who require highly technical support and customized specifications, while indirect channels utilizing specialized distributors serve smaller buyers or those in geographically challenging markets.

Downstream activities involve the final end-user, such as automotive component manufacturers, specialty paint formulators, and cosmetic producers. The successful integration of super fine talc requires specialized knowledge from the buyer regarding dosing, dispersion, and compounding techniques to realize the material’s full performance benefits, such as enhanced modulus or superior anti-blocking capabilities. The technical relationship between the talc producer and the downstream user is often symbiotic, with joint development agreements common, particularly when integrating new talc grades into complex systems like advanced engineering plastics or highly regulated medical device components.

- Upstream Analysis: Mineral exploration, extraction (mining), and preliminary crushing and sorting of high-purity ore.

- Midstream Analysis: Specialized processing (micronization via jet or ball mills), classification (air separators), and quality testing (PSD and purity analysis).

- Distribution Channel: Direct sales to large industrial consumers (polymers, automotive); indirect sales through chemical distributors for regional or smaller specialized markets (coatings, ceramics).

Super Fine Talc Powder Market Potential Customers

The potential customer base for Super Fine Talc Powder is diverse, spanning highly regulated industries that prioritize material performance and quality consistency over cost. Primary buyers include major polymer compounding firms, especially those focusing on producing lightweight engineering plastics for the automotive sector. These companies utilize super fine talc to achieve significant increases in flexural modulus and heat distortion temperature in polypropylene and polyamide compounds, critical for engine components and structural interior parts. The consistency of particle morphology ensures predictable shrinkage rates and surface finish quality, which are non-negotiable for tier-one automotive suppliers.

Another major segment consists of specialty chemical and coatings manufacturers. These customers purchase super fine talc primarily for its ability to enhance rheology, reduce sagging, and act as a functional extender that improves the UV stability and corrosion resistance of exterior architectural and industrial protective coatings. Furthermore, the paper industry, specifically producers of high-quality coated papers, constitutes a steady customer base, leveraging the talc's platy structure to improve surface smoothness, reduce pitch accumulation, and enhance ink absorption characteristics, catering to premium packaging and publication markets.

The highest purity grades of super fine talc are exclusively targeted at the cosmetics and pharmaceutical industries. Cosmetic formulators are critical buyers, utilizing talc as a bulking agent, anti-caking agent, and for imparting a characteristic soft feel in powder foundations, blushes, and deodorants, demanding strict compliance with safety regulations (like EU and FDA standards). Similarly, pharmaceutical manufacturers procure ultra-high purity talc as an excipient, filler, or anti-adherent in tablet manufacturing, where traceability and rigorous testing for microbial and asbestos contaminants are paramount, making these customers the highest value per volume segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 billion |

| Market Forecast in 2033 | USD 7.1 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Imerys, Mondo Minerals (Elementis), Specialty Minerals Inc., Minerals Technologies Inc., IMI FABI S.p.A., Golcha Minerals, Guangxi Longguang Talc Development Co., Ltd., Liaoning Aihai Talc Co., Ltd., Nippon Talc Co., Ltd., The Talc Company (India), Jilin Province Huayuan Talc, Pangea Talc International, Xilolites, Haicheng Jinghua Mineral, Pingdu Talc Mine Industrial Co. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Super Fine Talc Powder Market Key Technology Landscape

The technological landscape of the Super Fine Talc Powder market is dominated by advancements in particle size reduction and classification systems, which are critical for achieving the specified micronization levels. The transition from traditional mechanical grinding (like roller mills) to advanced fluid energy mills, such as jet mills, represents the core technological shift. Jet mills utilize high-velocity compressed air or steam to cause particle collisions, resulting in ultra-fine particle sizes with a tight and controllable particle size distribution (PSD), essential for high-performance applications like those in automotive paints and thin-film plastics. The optimization of these energy-intensive milling processes is a continuous focus area, incorporating advanced sensors and automated control loops to minimize specific energy consumption (SEC) per ton of finished product.

Beyond size reduction, classification technology, particularly high-efficiency air classifiers (such as dynamic classifiers), plays an equally vital role. These systems separate the fine particles from coarser materials with extreme precision, allowing producers to achieve the desired D90 or D50 particle cut points consistently, thereby guaranteeing product quality across different batches. Recent innovations include the integration of artificial intelligence (AI) and machine learning (ML) into classifier operation, enabling real-time adjustments based on laser diffraction particle size analysis feedback. This closed-loop optimization ensures maximum yield of the super fine fraction while maintaining the rigorous purity and PSD required by the high-value market segments.

Furthermore, technology related to impurity detection and removal is crucial, particularly concerning asbestos contamination. Advanced mineralogical analysis techniques, including automated mineralogy via scanning electron microscopy (SEM) and Raman spectroscopy, are used to provide rapid, certified verification that the super fine talc meets zero-tolerance standards, particularly for cosmetic and pharmaceutical grades. Processors are also investing in surface treatment technologies, where super fine talc particles are coated with silanes or other coupling agents to enhance compatibility and dispersion within hydrophobic polymer matrices, further boosting its functional performance as a reinforcement agent.

- Micronization Technology: High-efficiency jet mills (fluid energy mills) for ultra-fine grinding (sub-5 µm).

- Classification Systems: Dynamic air classifiers integrated with real-time laser diffraction analysis for tight PSD control.

- Purity Verification: Automated mineralogy using SEM and X-ray Diffraction (XRD) for asbestos and impurity detection.

- Surface Modification: Chemical surface treatment (e.g., silane coating) to improve compatibility with polymer resins.

Regional Highlights

The global Super Fine Talc Powder market exhibits distinct consumption patterns and operational characteristics across its major geographic regions, namely Asia Pacific (APAC), North America, Europe, Latin America, and the Middle East & Africa (MEA).Asia Pacific (APAC)

APAC stands as the undisputed leader in both production capacity and consumption volume for super fine talc powder. This dominance is primarily attributed to the rapid expansion of industrial manufacturing, particularly in China and India, which are major hubs for automotive production, electronics, and construction activities. The substantial consumer base and supportive governmental policies favoring industrial growth ensure consistent, high-volume demand from the polymers and coatings sectors. Furthermore, APAC houses significant natural talc deposits, particularly in China (Liaoning and Guangxi provinces), enabling large-scale, cost-effective processing operations. The region focuses heavily on industrial-grade super fine talc for high-volume plastic compounding, although demand for cosmetic and pharmaceutical grades is also escalating due to rising disposable incomes and stricter regional quality standards.

The competitive environment in APAC is intense, marked by the presence of numerous local players alongside international majors. While cost efficiency is a major determinant, the shift towards electric vehicles and advanced infrastructure projects is driving a significant qualitative change. Manufacturers are increasingly seeking talc grades that offer superior thermal conductivity and electrical insulation properties for use in battery casings and specialized electronic components. This region's growth trajectory is projected to remain the steepest throughout the forecast period, cementing its role as the global manufacturing engine for talc-consuming products.

- Key Countries: China, India, Japan, South Korea.

- Market Relevance: Largest market share by volume; highest growth rate driven by automotive and construction sectors.

North America

North America is characterized by a mature market focused on high-specification, premium talc grades. Consumption is dominated by demanding sectors such as aerospace, medical devices, and high-end automotive applications (e.g., specialized plastics for safety features). Unlike APAC, the North American market emphasizes quality, consistency, and regulatory compliance, particularly regarding purity and the rigorous absence of asbestos, especially for cosmetic and pharmaceutical applications where FDA standards are strictly enforced. The trend toward lightweighting in the U.S. automotive industry continues to drive sustained demand for highly specialized fine talc used in compounded resins.

Technological innovation is a major factor, with North American producers investing significantly in advanced processing technologies, including specialized dry grinding and chemical surface treatment capabilities, to enhance the performance of talc in polymer matrices. The region maintains a high technical barrier to entry, requiring suppliers to provide extensive application support and certification. The market exhibits stable, consistent growth tied directly to the recovery and expansion of complex manufacturing sectors and continued investment in infrastructure improvements requiring high-durability coatings.

- Key Countries: United States, Canada.

- Market Relevance: High-value, specialty-grade consumption; emphasis on regulatory compliance (FDA/TSCA) and technical performance in medical and automotive safety applications.

Europe

The European market for Super Fine Talc Powder is characterized by stringent environmental regulations, a strong commitment to sustainability, and high demand from the premium automotive and industrial coating segments. Europe has historically been a key innovator in the industrial talc sector, holding significant high-purity reserves in countries like France, Italy, and Finland. The focus is heavily on green materials, driving interest in super fine talc as a functional filler that can reduce overall material usage and weight in end products, aligning with European Union (EU) sustainability directives.

The coatings and paints sector in Europe is a vital consumer, demanding fine talc for low-VOC (Volatile Organic Compound) formulations, where it enhances barrier protection and matting properties without compromising environmental standards. The automotive sector, particularly the manufacturers of luxury and high-performance vehicles, relies on consistent, high-aspect ratio talc to achieve precise mechanical properties in vehicle interiors and exteriors. The market growth is moderately paced, highly dependent on industrial output and continued investment in high-end manufacturing and renovation projects.

- Key Countries: Germany, France, Italy, Finland.

- Market Relevance: Driven by strict environmental regulations and low-VOC coating demand; strong adoption in high-performance polymer compounding and luxury automotive components.

Latin America (LATAM)

The LATAM market is considered an emerging but rapidly growing region for super fine talc, primarily concentrated in Brazil and Mexico due to their substantial automotive manufacturing bases and expanding construction sectors. Market growth is closely tied to economic stability and foreign investment in manufacturing infrastructure. The primary demand currently stems from industrial applications, specifically standard polymer compounding and construction chemicals. Although the market size is smaller compared to APAC or North America, its potential for volume growth is high as regional standards of living and regulatory scrutiny gradually increase, driving demand for higher quality products.

Challenges in LATAM include logistical complexities and price sensitivity, often leading to a preference for locally available, sometimes lower-grade, materials. However, multinational corporations operating assembly plants in the region increasingly require global specification compliance, necessitating the import or local production of certified super fine talc grades. This demand for compliance creates a niche for specialized international suppliers capable of maintaining high-quality standards.

- Key Countries: Brazil, Mexico, Argentina.

- Market Relevance: Emerging market with high potential growth; primarily driven by regional automotive assembly and infrastructure investment.

Middle East and Africa (MEA)

The MEA region, particularly the Gulf Cooperation Council (GCC) countries, exhibits demand linked strongly to massive infrastructure projects and the expansion of oil and gas processing facilities. Super fine talc is crucial here for specialized industrial coatings used in protective applications against harsh desert environments and corrosive chemical exposure. The cosmetics and personal care sector, particularly in the UAE and Saudi Arabia, is also a significant consumer, reflecting the region’s high consumption of luxury goods and personal grooming products. South Africa remains the primary industrial hub in the African continent.

Supply in MEA is largely dependent on imports from Europe and Asia, resulting in higher landed costs compared to other regions. Opportunities exist in the development of local manufacturing capabilities for specialty chemicals and plastics, which would stabilize demand and potentially encourage regional processing investment. The market requires high-performance materials capable of withstanding extreme temperature variations and high UV radiation, making the specific properties of super fine talc highly valued in protective formulations.

- Key Countries: UAE, Saudi Arabia, South Africa.

- Market Relevance: Demand driven by large-scale infrastructure, protective industrial coatings for energy assets, and a growing high-end cosmetics segment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Super Fine Talc Powder Market.- Imerys

- Mondo Minerals (Elementis)

- Specialty Minerals Inc.

- Minerals Technologies Inc.

- IMI FABI S.p.A.

- Golcha Minerals

- Guangxi Longguang Talc Development Co., Ltd.

- Liaoning Aihai Talc Co., Ltd.

- Nippon Talc Co., Ltd.

- The Talc Company (India)

- Jilin Province Huayuan Talc

- Pangea Talc International

- Xilolites

- Haicheng Jinghua Mineral

- Pingdu Talc Mine Industrial Co.

Frequently Asked Questions

Analyze common user questions about the Super Fine Talc Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What defines Super Fine Talc Powder, and how does it differ from standard talc grades?

Super Fine Talc Powder is primarily defined by its extremely small particle size, typically having a D90 (90% of particles) less than 10 micrometers (µm), often reaching sub-micron levels (D90 < 5 µm). Standard talc features significantly coarser particle size distributions. The ultra-fine nature of the super fine grade provides superior surface area, enhanced stiffness/reinforcement in polymers, better barrier performance in coatings, and a smoother texture in cosmetic applications, justifying its higher processing cost and premium pricing. Its specialized nature necessitates advanced jet milling and air classification techniques.

Which industry applications drive the highest demand for high-purity super fine talc?

The highest demand for high-purity super fine talc is predominantly driven by two distinct sectors: the automotive industry, where it is critical for producing lightweight, high-performance engineering plastics (especially reinforced polypropylene) that enhance fuel efficiency and structural integrity, and the highly regulated cosmetics and pharmaceutical sectors. These sensitive applications require talc grades certified to be completely free of asbestos and other heavy metal contaminants, necessitating rigorous quality control and specialized, segregated processing lines.

What are the primary technological challenges in producing super fine talc powder consistently?

The primary technological challenges lie in the energy-intensive process of micronization and maintaining a tight, consistent particle size distribution (PSD). Achieving particle sizes below 5 µm demands advanced equipment like jet mills, which consume substantial power. Consistency requires sophisticated closed-loop control systems, often incorporating AI, to manage parameters like air flow and feed rate. Ensuring zero contamination, especially asbestos traceability from the mine source, represents a non-negotiable operational challenge that requires specialized mineralogical analysis technology.

How do global regulatory trends regarding asbestos contamination affect the market supply chain?

Global regulatory trends, particularly in North America and Europe, impose zero-tolerance standards for asbestos contamination in talc, particularly for cosmetic and pharmaceutical grades. This has forced producers to invest heavily in advanced geological sourcing, rigorous screening, and certified testing protocols (like XRD and SEM) across the entire supply chain. These regulations restrict the usable raw material sources globally and significantly increase the operational complexity and cost for suppliers, favoring those with proprietary, proven asbestos-free deposits and integrated quality control systems.

What is the regional market outlook for Super Fine Talc Powder, and where is growth concentrated?

The regional market outlook shows that growth is predominantly concentrated in the Asia Pacific (APAC) region, driven by continuous expansion in industrial output, particularly automotive manufacturing and urban development projects in China and India. While North America and Europe maintain stable demand for premium, high-specification grades for niche applications (e.g., aerospace, medical), APAC's rapid industrialization and sheer scale of manufacturing ensure it remains the dominant consumer and the fastest-growing market in terms of volume throughout the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager