Super Glue Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435354 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Super Glue Market Size

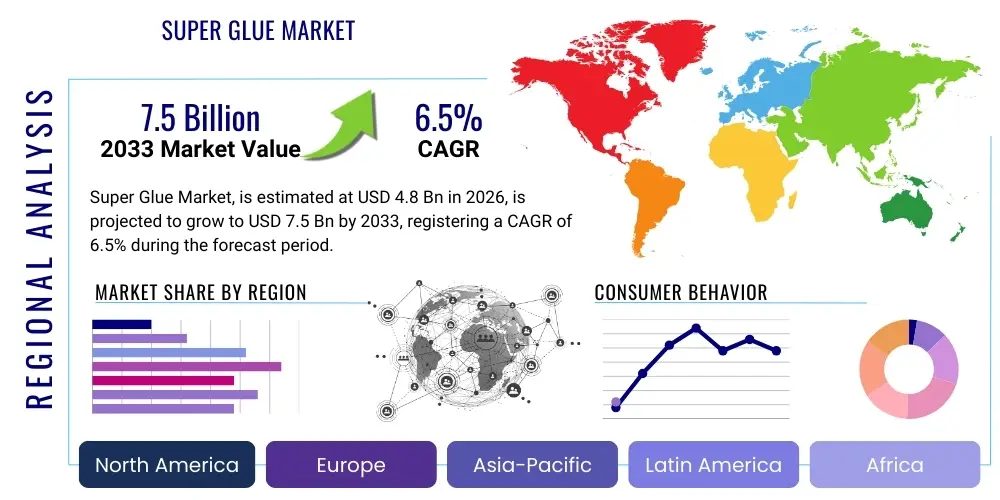

The Super Glue Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033. This consistent growth trajectory is driven primarily by escalating demand from industrial end-users, particularly in the electronics and medical device sectors, where rapid, high-strength bonding solutions are critical for manufacturing efficiency and product miniaturization.

The valuation reflects the increasing adoption of advanced cyanoacrylate formulations, which offer enhanced performance characteristics such as temperature resistance, flexibility, and reduced blooming compared to traditional adhesives. The expansion into new applications, including automotive aftermarket repairs and complex consumer DIY projects, further solidifies the market's upward trend. Investment in research and development focusing on specialized, environmentally friendly, and low-odor formulations is a key factor sustaining the premium pricing and overall market size expansion over the forecast horizon, ensuring the Super Glue market remains a vital component of the global specialty chemicals landscape.

Super Glue Market introduction

The Super Glue market, fundamentally centered around cyanoacrylate adhesives, encompasses a wide range of fast-acting, high-strength bonding agents known for their versatility across numerous material substrates, including plastics, metals, rubber, and ceramics. These adhesives cure rapidly upon contact with moisture, providing an efficient and robust alternative to mechanical fastening or traditional epoxy systems. Product descriptions vary based on viscosity, setting time, and specialized additives designed to meet specific performance requirements, such as enhanced impact resistance or flexibility, catering to both consumer and industrial-grade applications.

Major applications of Super Glue span critical industries such as automotive assembly (for interior components and minor repairs), electronics manufacturing (for securing delicate components and housing assemblies), and the medical sector (for wound closure adhesives and device assembly). Key benefits include extremely fast curing times, excellent bond strength, ease of application, and suitability for miniaturized components where precision is paramount. The primary driving factors for market growth include the proliferation of portable electronic devices requiring compact bonding solutions, the expanding use of lightweight materials in automotive and aerospace industries, and the continuous innovation leading to specialized formulations tailored for demanding environments.

Furthermore, the global shift towards efficient production methods and the increasing complexity of material combinations in modern manufacturing necessitate reliable, instant-bonding solutions. This high demand from original equipment manufacturers (OEMs) for automated dispensing systems and robust technical support fuels continuous product refinement. Consumer awareness regarding the utility and strength of cyanoacrylate products for household repairs and crafts also contributes significantly to the steady growth of the Super Glue market across residential and professional maintenance segments globally.

Super Glue Market Executive Summary

The Super Glue Market is characterized by robust business trends focusing on innovation in formulation chemistry, driven by the need for regulatory compliance and enhanced user safety, particularly the development of low-odor and non-blooming cyanoacrylate variations. Strategic collaborations between adhesive manufacturers and industrial automation providers are common, aimed at integrating high-speed dispensing systems into production lines, thereby boosting efficiency in mass manufacturing environments, especially within the Asia Pacific electronics hub.

Regionally, Asia Pacific (APAC) dominates the market share due to its entrenched position as the global manufacturing center for consumer electronics and automotive components, experiencing rapid urbanization and industrial expansion. North America and Europe, while mature markets, emphasize specialized, high-performance glues for aerospace, medical, and specialized industrial maintenance, prioritizing quality and compliance over volume. Latin America and MEA show nascent but accelerating growth, spurred by increased infrastructure development and localized manufacturing investments.

Segment trends indicate that the industrial segment, particularly the electronics sub-segment, remains the highest value contributor due to the demanding performance requirements of smart devices and circuitry. In terms of product type, modified ethyl cyanoacrylates are seeing strong uptake due to their balanced properties. The consumer segment continues to expand through convenient packaging formats and specialized DIY repair kits, capitalizing on home improvement trends. Overall, the market remains highly competitive, necessitating continuous technological upgrades to maintain a competitive edge and address evolving material science challenges.

AI Impact Analysis on Super Glue Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Super Glue Market predominantly revolve around themes of automated quality control, optimization of dispensing processes, and the development of novel chemistries through computational modeling. Users are keen to understand how AI-driven vision systems can ensure flawless application of tiny glue dots in electronics assembly, minimizing waste and maximizing bond integrity. Furthermore, there is significant interest in how machine learning algorithms can analyze performance data across different substrates and environmental conditions, leading to the rapid formulation of specialized cyanoacrylate products with specific desired characteristics, reducing traditional R&D cycle times. Concerns often center on the initial investment required for AI integration in existing manufacturing setups and the necessity of skilled personnel to manage these advanced systems.

AI's primary influence is seen in optimizing the adhesive manufacturing process itself and revolutionizing application techniques in end-user industries. Predictive maintenance fueled by AI can forecast equipment failures in dispensing machinery, ensuring zero downtime in high-throughput assembly lines. In R&D, generative AI models can simulate molecular interactions, assisting chemists in designing advanced polymers or modifying cyanoacrylate monomers to achieve superior temperature or moisture resistance, characteristics previously difficult to attain quickly through traditional empirical testing methods. This shift towards smart manufacturing processes and data-driven material innovation represents the core impact of AI on the future trajectory of the Super Glue market, ensuring higher quality standards and faster time-to-market for specialized adhesive solutions.

- AI-driven automated quality inspection ensures microscopic precision in adhesive application, reducing defects in electronics assembly.

- Machine Learning optimizes dispensing parameters (flow rate, temperature, pressure) for various viscosities and substrates, minimizing material waste.

- Computational chemistry and Generative AI accelerate the discovery and formulation of new cyanoacrylate variants with enhanced performance characteristics.

- Predictive maintenance algorithms improve the uptime and longevity of complex adhesive dispensing and curing equipment.

- AI analyzes supply chain data to optimize inventory and procurement of critical raw materials, such as ethyl cyanoacrylate monomer.

DRO & Impact Forces Of Super Glue Market

The dynamics of the Super Glue market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively forming significant impact forces. Key drivers include the miniaturization trend across the electronics and medical device industries, which necessitates high-precision, rapid-curing bonding solutions, coupled with the rising global demand for efficient, lightweight composite materials in automotive and aerospace sectors. The simplicity and speed of application inherent to cyanoacrylate adhesives make them indispensable in high-speed manufacturing environments, further bolstering their market penetration.

Conversely, significant restraints hinder market potential. These primarily involve the regulatory scrutiny surrounding volatile organic compounds (VOCs) and the inherent limitations of standard super glues, such as poor resistance to high temperatures, vulnerability to moisture degradation over prolonged periods, and the phenomenon known as "blooming," which leaves a white residue affecting aesthetic quality, especially in consumer products. Furthermore, competition from alternative bonding technologies, such as UV-curing adhesives and high-performance epoxy resins, poses a continuous challenge to market expansion, demanding constant innovation from cyanoacrylate manufacturers.

Opportunities for growth are abundant, particularly in the development of specialized medical-grade adhesives for internal and external applications, and the formulation of flexible and low-odor cyanoacrylates that comply with stringent indoor air quality standards. The increasing popularity of DIY repair culture globally, along with the rising industrial demand in emerging economies for infrastructure and electronic goods manufacturing, provides clear avenues for market penetration. The major impact forces thus include technological substitution risk, regulatory compliance pressure, and the irreversible shift towards smaller, highly complex component assemblies requiring specialized chemical bonding solutions.

Segmentation Analysis

The Super Glue market is rigorously segmented across various parameters including product type, application, end-user industry, and distribution channel, reflecting the diverse and specialized nature of cyanoacrylate usage globally. This segmentation allows manufacturers to target specific performance requirements, such as high-impact resistance for footwear or low viscosity for electronic component fixation. Understanding these distinct segments is crucial for strategic planning, resource allocation, and identifying high-growth niches within the broader adhesive landscape.

The segmentation by product type is foundational, distinguishing between various cyanoacrylate monomers like Ethyl, Methyl, and specialized types such as Methoxy and Alkoxy, each offering distinct advantages in terms of odor, blooming, and suitability for specific plastics or rubbers. End-user segmentation highlights the dominance of industrial applications, particularly in sectors where bond strength and assembly speed are non-negotiable, while the consumer segment thrives on convenience and accessibility for household maintenance and repair tasks.

Furthermore, segmentation based on application, such as general purpose versus specialty medical or automotive structural bonding, determines the regulatory hurdles and performance standards required. The strategic importance of specialty formulations is constantly rising, driven by demanding material compatibility needs in sectors like aerospace and advanced medical diagnostics, requiring higher price points and specialized research and development efforts.

- By Product Type:

- Ethyl Cyanoacrylate

- Methyl Cyanoacrylate

- Butyl Cyanoacrylate

- Octyl Cyanoacrylate

- Other Specialized Formulations (e.g., Alkoxy, Methoxy)

- By Application:

- General Purpose Adhesion

- Structural Bonding (Specific industrial applications)

- Medical Applications (e.g., Tissue Adhesives)

- By End-User Industry:

- Electronics and Electrical

- Automotive and Transportation

- Medical Devices and Healthcare

- Consumer Goods and DIY

- Footwear and Textile

- Aerospace and Defense

- Industrial Maintenance and Repair Operations (MRO)

- By Distribution Channel:

- Direct Industrial Sales

- Retail (Hardware Stores, Supermarkets)

- E-commerce Platforms

Value Chain Analysis For Super Glue Market

The value chain of the Super Glue market commences with the upstream analysis, which is focused on the procurement and processing of key raw materials, primarily formaldehyde and alkyl cyanoacetates, which are synthesized into the foundational cyanoacrylate monomers (e.g., ethyl cyanoacrylate). This stage involves complex chemical manufacturing processes, demanding high purity and consistent quality control to ensure the final adhesive performance. Major chemical suppliers play a crucial role here, and fluctuations in petrochemical prices significantly influence the cost structure of the end product. The efficiency and scale of monomer production directly impact the competitiveness of the downstream adhesive manufacturers.

The midstream of the value chain involves the core manufacturing process where raw monomers are formulated with various additives, including stabilizers, thickeners, accelerators, plasticizers, and colorants, to create specific grades of Super Glue (varying in viscosity, cure speed, and flexibility). Major adhesive companies engage in significant R&D at this stage to develop proprietary formulations that address specific market needs, such as non-blooming or medical-grade products. Packaging and labeling, adhering to stringent safety and regulatory requirements, also form a critical part of this transformation stage before the product moves toward the market.

The downstream analysis focuses on distribution channels, which are bifurcated into direct and indirect routes. Direct industrial sales are vital for large-volume end-users (like automotive OEMs and electronics assembly plants), often involving technical support and bulk dispensing equipment solutions provided directly by the manufacturer. Indirect distribution, crucial for the highly fragmented consumer market, relies on a vast network of distributors, wholesalers, retail hardware chains, and increasingly, specialized e-commerce platforms. The efficiency of the distribution network, especially in logistics and inventory management, determines the final price point and accessibility for both industrial MRO and consumer DIY applications globally.

Super Glue Market Potential Customers

Potential customers for the Super Glue market span a vast array of B2B industrial entities and B2C individual users, driven by the product's universal ability to rapidly bond diverse materials. Within the industrial sphere, the primary end-users are manufacturers engaged in high-volume, precision assembly. The electronics industry, including producers of smartphones, wearables, and PCBs, represents a high-value customer base demanding specialized, fast-curing, low-blooming formulas suitable for automated dispensing in confined spaces. The automotive sector, ranging from OEM assembly of interior components and sensors to aftermarket maintenance and repair operations (MRO), constitutes another crucial customer segment relying on high-strength, vibration-resistant cyanoacrylate variants.

The healthcare and medical device sectors are rapidly growing customer bases, purchasing medical-grade cyanoacrylates for bonding surgical instruments, assembling complex diagnostic equipment, and utilizing specialized formulations as tissue adhesives for non-invasive wound closure. This segment demands the highest regulatory compliance and sterilization compatibility. Furthermore, the aerospace industry utilizes specialized structural cyanoacrylates for non-critical assembly where lightweighting is a priority, and the construction and infrastructure industries use them for fast repairs and sealing applications.

On the consumer front, potential customers include individual homeowners, hobbyists, and professional tradespeople (plumbers, carpenters, electricians) who use Super Glue for household repairs, crafting, and quick fixes. This segment is highly responsive to marketing based on ease of use, durability, and convenience, typically purchasing smaller packaged units through retail and online channels. The diversity of these end-users, ranging from highly automated factories to individual consumers, necessitates a multi-faceted product strategy encompassing bulk industrial solutions and packaged retail items.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Henkel AG & Co. KGaA, 3M Company, H.B. Fuller Company, Bostik (Arkema), Sika AG, Permatex (ITW), MasterBond Inc., Gorilla Glue Inc., Loxeal Engineering Adhesives, Kanto Chemical Co., Inc., LORD Corporation (Parker Hannifin), Dymax Corporation, Chemence, Cyberbond, Franklin International, Gluefast Company, Inc., Devcon (ITW), Super Glue Corporation, KGaA |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Super Glue Market Key Technology Landscape

The technological landscape of the Super Glue market is characterized by ongoing innovation aimed at overcoming the traditional drawbacks of cyanoacrylate adhesives, such as brittleness, limited gap-filling capabilities, and sensitivity to moisture and temperature extremes. A significant technological advancement involves the development of rubber-toughened cyanoacrylates, which incorporate elastomeric particles to dramatically improve shock and impact resistance, making them suitable for dynamic load applications in automotive and industrial assembly. These formulations maintain the rapid curing speed while offering superior flexibility and peel strength, expanding the applicability of super glues into areas traditionally dominated by epoxy and polyurethane adhesives.

Another crucial technological area is the refinement of low-blooming and low-odor cyanoacrylates, typically achieved through the use of Alkoxy or Methoxy cyanoacrylate monomers. Blooming—the white residue formed by the volatilization and subsequent condensation of monomer vapor—is a major concern in aesthetically sensitive industries like electronics and consumer goods. The development of these specialized formulations addresses indoor air quality concerns and enhances product aesthetics, enabling manufacturers to utilize super glue in enclosed or heavily populated assembly areas without adverse effects on workers or the final product appearance. This innovation is critical for regulatory compliance and user acceptance in mature markets.

Furthermore, the technology surrounding dispensing and curing equipment is rapidly evolving. The integration of precision robotic dispensing systems, often incorporating AI-driven vision and quality checks, ensures accurate placement and volume control of micro-dots of adhesive, which is paramount in miniaturized electronics. Coupled with the development of light-curing cyanoacrylates—where a secondary UV light source accelerates the cure mechanism—manufacturers gain greater control over assembly line speed and process automation. These technological refinements in formulation chemistry and application equipment are collectively driving the market toward high-performance, high-reliability bonding solutions.

The development of specialized activators and primers also represents a vital technological component, enabling cyanoacrylates to effectively bond notoriously difficult-to-bond plastics, such as polyolefins (polyethylene and polypropylene). These chemical pretreatments modify the surface energy of the substrate, allowing for robust and instantaneous adhesion where previously only specialized two-part systems could succeed. The focus on single-component, instant-cure systems remains the core driver of R&D, ensuring Super Glue retains its competitive edge over slower-curing alternatives in high-volume manufacturing sectors.

A recent and increasingly important area is the focus on sustainable and bio-based cyanoacrylates. While still nascent, efforts are being made to explore monomers derived from renewable resources, aligning with global corporate sustainability objectives. This technological push addresses environmental concerns related to petroleum-derived chemical components, offering a potential long-term shift in raw material sourcing and manufacturing practices within the Super Glue industry. Such innovations, while costly initially, unlock premium market segments seeking environmentally responsible adhesive solutions.

In summary, the key technological advancements revolve around enhanced resilience (toughening), aesthetic improvement (low blooming/odor), application control (precision dispensing and automation), surface preparation (primers and activators), and long-term sustainability. These innovations solidify cyanoacrylates' position as a dynamic and continuously improving adhesive class, ensuring its relevance in highly demanding industrial applications that require speed, strength, and specialized material compatibility.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market shareholder, primarily driven by China, South Korea, Japan, and India. The region serves as the global manufacturing hub for consumer electronics, automotive components, and general industrial machinery, generating massive demand for industrial-grade cyanoacrylate adhesives. Rapid industrialization, favorable governmental policies supporting manufacturing expansion, and a large consumer base contribute to the unparalleled volume growth. The focus here is on cost-effective, high-speed assembly solutions.

- North America: This region represents a mature, high-value market, characterized by stringent regulatory standards and a strong emphasis on specialized, high-performance glues. Key demand drivers include the aerospace and defense sector, sophisticated medical device manufacturing, and the well-established automotive aftermarket. Innovation is focused on medical-grade, flexible, and chemically resistant formulations, with substantial investment in automated dispensing technologies to maintain high precision manufacturing.

- Europe: Europe exhibits steady growth, driven by the robust automotive sector (especially in Germany and France) and the specialized engineering industry. Regulatory frameworks like REACH influence formulation development, pushing manufacturers towards low-VOC, safe, and environmentally compliant products. The market is highly competitive, emphasizing quality, certification, and tailored solutions for high-end industrial and construction applications.

- Latin America (LAMEA): LAMEA is an emerging market experiencing significant infrastructural development and growing domestic manufacturing capacity, particularly in Brazil and Mexico. Demand is increasing across construction, automotive assembly, and consumer goods production. The market is primarily price-sensitive, though there is a rising trend towards adopting standardized industrial adhesives as manufacturing practices mature.

- Middle East and Africa (MEA): Growth in MEA is moderate but accelerating, primarily fueled by massive infrastructure projects, increasing healthcare spending, and localization of industrial assembly operations, particularly in the UAE and Saudi Arabia. The region relies heavily on imported formulations, though the establishment of local assembly plants creates future opportunities for domestic adhesive production and distribution focused on oil and gas MRO and construction.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Super Glue Market.- Henkel AG & Co. KGaA

- 3M Company

- H.B. Fuller Company

- Bostik (Arkema)

- Sika AG

- Permatex (ITW)

- MasterBond Inc.

- Gorilla Glue Inc.

- Loxeal Engineering Adhesives

- Kanto Chemical Co., Inc.

- LORD Corporation (Parker Hannifin)

- Dymax Corporation

- Chemence

- Cyberbond

- Franklin International

- Gluefast Company, Inc.

- Devcon (ITW)

- Super Glue Corporation

Frequently Asked Questions

Analyze common user questions about the Super Glue market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary chemical component of Super Glue and how does it achieve rapid bonding?

The primary chemical component is cyanoacrylate monomer, typically Ethyl Cyanoacrylate. It achieves rapid bonding through an anionic polymerization reaction initiated by trace amounts of moisture (hydroxide ions) present on the surface of materials or in the surrounding air. This process causes the monomers to instantly link and form a strong plastic polymer chain, resulting in an almost instant cure time and high bond strength, particularly under slight pressure.

Which end-user segment is driving the highest demand for specialized Super Glue formulations?

The Electronics and Electrical industry is the key driver for specialized, high-precision super glue formulations. Demand is high for low-viscosity, low-blooming, and fast-curing cyanoacrylates required for securing microscopic components, connecting flexible circuits, and assembling consumer electronics, where aesthetic quality and automated precision are paramount to the manufacturing process.

What major challenges or restraints are currently affecting the Super Glue market growth?

Major restraints include the inherent performance limitations of standard cyanoacrylates, such as poor resistance to continuous high temperatures and susceptibility to moisture and solvent degradation. Additionally, regulatory pressures concerning volatile organic compounds (VOCs) and the competitive substitution risk posed by advanced structural adhesives and UV-curing technologies continue to challenge market penetration and pricing strategies.

How is the concept of 'blooming' addressed by manufacturers in the Super Glue market?

Blooming, the formation of white residue caused by monomer vaporization, is addressed through the development of specialized low-odor, low-blooming formulations, primarily utilizing Alkoxy or Methoxy cyanoacrylates instead of standard Ethyl Cyanoacrylate. These newer formulations have a lower vapor pressure, minimizing the condensation effect and making them ideal for assembly in enclosed spaces or on products requiring high visual clarity.

Which geographical region is projected to show the most significant growth rate in the Super Glue Market and why?

The Asia Pacific (APAC) region is projected to exhibit the most significant growth rate during the forecast period. This accelerated growth is attributed to the massive scale of manufacturing operations in countries like China and India, the expansion of the electronics and automotive supply chains, and substantial industrial investment driving increased consumption of high-volume industrial adhesives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager