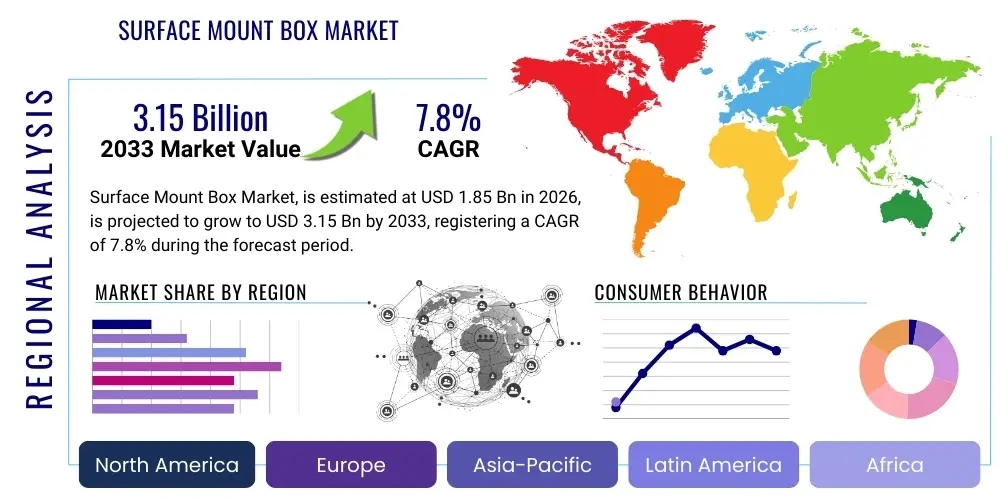

Surface Mount Box Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436221 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Surface Mount Box Market Size

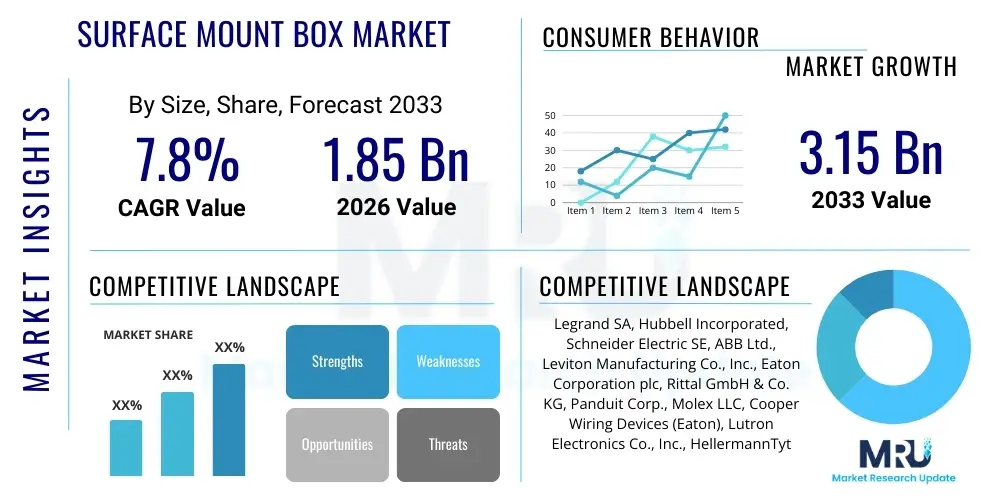

The Surface Mount Box Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.15 Billion by the end of the forecast period in 2033.

Surface Mount Box Market introduction

The Surface Mount Box Market encompasses the production and distribution of enclosures designed to mount electrical outlets, network connectivity points, or multimedia interfaces directly onto the surface of a wall, ceiling, or structure, eliminating the need for invasive in-wall installation. These devices are fundamental components in structured cabling systems, providing necessary strain relief, protection for delicate connections, and accessibility for maintenance. They are particularly crucial in retrofit projects, historical buildings where concealed wiring is restricted, and commercial environments requiring flexible and adaptable network infrastructure expansion.

Surface mount boxes, often fabricated from materials such as high-impact ABS plastic, PVC, or various metals, are differentiated by the number of ports or gangs they support (single-gang, double-gang, or multi-port). The increasing demand for seamless data connectivity, particularly driven by the proliferation of IoT devices, smart home automation, and 5G network deployment, significantly bolsters the market. These boxes facilitate orderly cable management and adherence to safety standards, ensuring reliable power and data transmission in diverse settings ranging from residential homes to large industrial complexes and institutional facilities. The continuous advancement in construction standards and the growing emphasis on aesthetics and minimal installation downtime further drive innovation in product design, focusing on sleeker profiles and enhanced durability.

Major applications include integrating Ethernet cables (Cat5e, Cat6, Cat6A), fiber optics, and traditional electrical wiring. The primary benefits of using surface mount boxes include installation speed, cost-effectiveness compared to running new conduit inside walls, and superior flexibility for relocation or reconfiguration of network drops. Key driving factors include the rapid global urbanization necessitating new commercial infrastructure, the rise of industrial automation (Industry 4.0), and stringent regulations requiring easily accessible termination points for inspection and repair. Furthermore, the expansion of data centers and server farms, which rely on modular and scalable connectivity solutions, provides a consistent demand base for robust surface mount enclosures.

Surface Mount Box Market Executive Summary

The Surface Mount Box Market is characterized by robust growth, primarily fueled by the global transition towards smart infrastructure and expanded digital connectivity across commercial and residential sectors. Business trends indicate a strong move toward modular and tool-less installation systems, favoring materials that offer high fire ratings and resistance to environmental stressors, especially in industrial environments. Leading manufacturers are focusing on integrating features that support higher data transfer speeds, such as improved shielding within the box structure to mitigate electromagnetic interference, catering specifically to Cat6A and Cat8 cabling requirements. Strategic partnerships between box manufacturers and providers of complete structured cabling systems are becoming essential to offer integrated, end-to-end solutions, enhancing market penetration and value proposition.

Regional trends reveal Asia Pacific (APAC) as the fastest-growing market, driven by massive investments in telecom infrastructure, large-scale construction projects in developing economies like India and China, and the rapid adoption of smart city initiatives. North America and Europe maintain significant market shares, characterized by strong replacement cycles for legacy systems and high uptake of premium, aesthetically superior products tailored for modern office and residential designs. Conversely, market maturity in some Western regions necessitates innovation focusing on niche applications, such as specialized weather-resistant enclosures for outdoor IoT installations or high-security metal boxes for governmental facilities.

Segmentation trends highlight the dominance of plastic (ABS/PVC) boxes due to their cost-effectiveness and ease of manufacturing, though metal surface mount boxes are seeing increased adoption in high-security and industrial settings where superior durability and EMI shielding are required. By application, the commercial sector remains the largest segment, driven by office buildings, retail, and hospitality upgrades. The residential segment, however, is demonstrating the highest growth trajectory, supported by the mandatory inclusion of structured wiring in new home construction and the consumer drive for whole-home smart connectivity integration. Manufacturers are increasingly tailoring products to meet specific industry standards, such as those related to healthcare environments, which demand anti-microbial coatings and precise installation guidelines.

AI Impact Analysis on Surface Mount Box Market

Common user questions regarding AI's impact on the Surface Mount Box Market often revolve around two key areas: the optimization of manufacturing processes and the role of surface mount boxes within AI-driven infrastructure. Users inquire about how AI can predict material defects during molding, automate quality control inspections for compliance with fire and safety standards, and optimize supply chain logistics to minimize inventory costs and delivery times. Furthermore, there is significant interest in understanding how the physical components, specifically surface mount boxes, will adapt to house the increasing density of sensors and edge computing devices required for decentralized AI processing, demanding better thermal management and tighter integration capabilities within the box structure itself.

The introduction of AI is fundamentally influencing the operational efficiency of the Surface Mount Box industry, rather than the product's core function. AI-powered Computer Vision systems are being implemented on assembly lines to instantly detect molding flaws or incorrect component assembly, ensuring consistent quality across high-volume production runs, which is crucial for maintaining safety certifications. Predictive maintenance algorithms are also optimizing machinery uptime, reducing unexpected production stoppages, and lowering overall manufacturing costs. This precision in production, driven by AI, allows manufacturers to meet stringent specifications required for high-performance networking standards (e.g., Cat8), thereby increasing competitive advantage.

In terms of application, surface mount boxes are critical enabling components for AI deployment. As edge computing and industrial IoT gain traction, surface mount enclosures provide the protected housing for gateways, micro-servers, and specialized AI processing hardware installed close to the data source (e.g., factory floor, traffic junction). The physical dimensions, thermal dissipation properties, and ingress protection (IP) ratings of these boxes must evolve to support high-power, heat-generating AI hardware, pushing manufacturers towards designing modular, ventilation-optimized, and environmentally sealed surface mount solutions. AI is thus indirectly shaping the required technical specifications of future surface mount box designs.

- AI-driven optimization of manufacturing processes for zero-defect production.

- Predictive analytics for raw material procurement and supply chain efficiency.

- Surface mount boxes serve as protected enclosures for AI edge computing hardware and IoT sensors.

- AI vision systems automate quality assurance, verifying compliance with fire safety and dimensional standards.

- Demand for thermally managed surface mount boxes to house high-density AI components.

DRO & Impact Forces Of Surface Mount Box Market

The Surface Mount Box Market is propelled by significant global drivers, primarily the aggressive expansion of data and telecommunications infrastructure, coupled with the mandatory upgrade of aging electrical systems worldwide. The relentless rollout of high-speed networking standards (Cat6A, Cat8, and fiber-to-the-home (FTTH)) necessitates high-quality, standardized termination points, which surface mount boxes reliably provide. Conversely, the market faces restraints, chiefly the aesthetic preference for concealed wiring in modern high-end architectural design, leading to a bias towards recessed or in-wall installations. Furthermore, volatility in the cost of key raw materials, particularly plastics like ABS and specialized metal alloys, can impact manufacturing profitability and pricing stability, posing a challenge for small and mid-sized enterprises.

Significant opportunities are emerging from the smart building and industrial IoT sectors. The requirement for flexible and dense connectivity points in commercial environments undergoing digital transformation creates a consistent need for modular surface mount solutions that can accommodate varied data, power, and multimedia connections simultaneously. The rapid growth of data centers and server farms that utilize raised floors and structured cabling systems heavily relies on accessible and durable surface mount accessories for managing complex cable routing. Impact forces, such as government regulatory pressure requiring standardized electrical and network installations for safety, along with the growing consumer expectation for reliable, high-speed internet access in every room, profoundly influence product design and market demand.

The market’s competitive landscape is further impacted by innovation, specifically the shift toward pre-wired and pre-configured box assemblies that reduce on-site installation time, making them highly attractive to large-scale construction contractors. Another powerful force is the environmental, social, and governance (ESG) movement, which pushes manufacturers to adopt recycled or sustainable materials, demanding certifications that confirm the environmental friendliness and long-term recyclability of the plastic components used in surface mount boxes. Manufacturers who can effectively navigate the rising material costs while simultaneously meeting the demand for superior aesthetic integration and high-performance specifications are positioned for market leadership.

Segmentation Analysis

The Surface Mount Box Market is comprehensively segmented based on material type, product type, number of gangs, and end-user application, allowing for a detailed understanding of market dynamics and specialized demand patterns across different sectors. Material segmentation distinguishes between cost-effective plastics (ABS, PVC), highly durable metals (aluminum, galvanized steel), and composite materials, each serving distinct functional requirements related to fire safety, EMI shielding, and environmental resistance. Product type often focuses on the specific connector type the box is designed to house, such as data-only (RJ45), power-only, or combined multimedia boxes that integrate fiber and coaxial connections alongside standard data ports.

The segmentation by end-user application provides critical insights into the primary sources of demand. The commercial segment, encompassing offices, retail spaces, and educational institutions, demands large volumes of standardized, multi-gang boxes for extensive networking infrastructure. In contrast, the industrial segment (factories, warehouses) focuses on rugged, highly protected boxes (high IP ratings) capable of withstanding harsh environmental conditions like moisture, dust, and temperature extremes. The residential sector, while smaller in volume per project, is growing rapidly, driven by smart home installations and the need for aesthetically pleasing boxes that blend into interior designs, often prioritizing sleek, low-profile designs.

Segmentation by number of gangs (single, double, triple, and four-gang) directly correlates with the density of connectivity required at a specific termination point. Single-gang boxes are typical for basic power outlets or single data drops, whereas multi-gang boxes are essential for consolidated workstations or network hubs requiring multiple simultaneous connections (e.g., data, phone, power, and multimedia). Understanding these granular segmentations is vital for manufacturers to tailor product specifications, ensuring compliance with diverse national wiring standards (e.g., North American, European, and Asian standards, which differ in physical dimensions and mounting specifications).

- By Material:

- Plastic (ABS, PVC, Polycarbonate)

- Metal (Steel, Aluminum, Galvanized)

- Composites

- By Product Type:

- Data/Communication Boxes

- Electrical/Power Boxes

- Multimedia/Combined Boxes

- Fiber Optic Boxes

- By Number of Gangs:

- Single Gang

- Double Gang

- Multi-Gang (3 or 4 ports)

- By Application:

- Residential

- Commercial (Offices, Retail, Hospitality)

- Industrial (Factories, Warehouses, Utilities)

- Data Centers & Telecom

- By Standards Compliance:

- NEMA

- IEC/IP Rated

- UL Listed

Value Chain Analysis For Surface Mount Box Market

The value chain for the Surface Mount Box Market begins with the upstream sourcing of raw materials, primarily specialized polymers such as high-impact ABS and PVC, alongside various grades of steel and aluminum required for metal enclosures. Suppliers in this segment face pressure related to price volatility and adherence to strict material specifications, particularly non-flammability and high dielectric strength. Manufacturing constitutes the core value-add process, involving injection molding for plastics, stamping and fabrication for metals, and subsequent assembly. Efficiency in manufacturing is paramount, utilizing large-scale automation and precision tooling to maintain low unit costs while complying with complex international standards (e.g., UL, CE marking, RoHS compliance).

The midstream involves logistics and distribution channels, which are critical due to the commodity nature and high volume of the product. The market utilizes both direct and indirect channels. Direct sales often cater to large infrastructure projects, Original Equipment Manufacturers (OEMs) who integrate the boxes into larger cabling systems, and government/utility tenders. This channel emphasizes relationship management and technical support. The dominant indirect channel involves distribution through large electrical wholesalers, building material suppliers, and specialized telecom distributors, who manage inventory and provide quick access for smaller contractors and DIY markets. E-commerce platforms are increasingly serving as a significant distribution pathway, especially for standard residential and small commercial projects, demanding robust inventory management and fast fulfillment capabilities.

The downstream activities involve the installation and end-use application by certified electricians, low-voltage technicians, and construction contractors. Value is added at this stage through professional installation, system integration, and adherence to local building codes. End-users (commercial building owners, homeowners, industrial facilities) ultimately derive value from the boxes by ensuring reliable, protected, and accessible termination points for their electrical and data networks. Continuous feedback from professional installers regarding ease of use, mounting flexibility, and durability significantly influences future product development and design iterations, completing the loop of the value chain.

Surface Mount Box Market Potential Customers

The potential customers for Surface Mount Boxes are highly diversified, spanning nearly every sector that relies on organized electrical power and data communication. Key buyers include large-scale construction and infrastructure development companies responsible for building new commercial office towers, residential complexes, and public facilities like hospitals and schools. These customers require bulk quantities of certified, high-standard boxes for initial wiring installations and prioritize logistical efficiency and product compatibility with established conduit systems.

Another major customer segment comprises telecommunication and network service providers, including carriers and dedicated system integrators. These entities procure specialized surface mount boxes, particularly those designed for fiber optic termination and high-density data drops (Cat6A and beyond), as they expand network coverage and upgrade existing infrastructure to support higher bandwidth demands for 5G and FTTH deployment. Their purchasing decisions are highly influenced by performance metrics, shielding effectiveness, and compliance with specific telecom industry specifications.

Furthermore, a substantial portion of the market is driven by the maintenance, repair, and operations (MRO) segment, including facility managers of existing commercial and industrial properties, and electrical contractors performing retrofit or renovation work. For these customers, surface mount boxes offer a flexible, non-invasive solution for adding new power outlets or data points without extensive structural modifications. The growing consumer segment, driven by DIY enthusiasts and smart home installers, represents a rapidly expanding customer base seeking user-friendly, aesthetically pleasing plastic boxes available through retail hardware stores and online marketplaces.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.15 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Legrand SA, Hubbell Incorporated, Schneider Electric SE, ABB Ltd., Leviton Manufacturing Co., Inc., Eaton Corporation plc, Rittal GmbH & Co. KG, Panduit Corp., Molex LLC, Cooper Wiring Devices (Eaton), Lutron Electronics Co., Inc., HellermannTyton, Connectix Ltd., BG Electrical, D-Link Corporation, Nexans S.A., Southwire Company, LLC, Belden Inc., OBO Bettermann Holding GmbH & Co. KG, Siemens AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Surface Mount Box Market Key Technology Landscape

The technology landscape of the Surface Mount Box Market is primarily driven by material science innovation, focusing on enhancing fire resistance, durability, and electromagnetic shielding capabilities. Manufacturers are increasingly utilizing advanced polymers, such as fire-retardant polycarbonate and specialized ABS blends, to meet stringent safety standards like UL 94 V-0, which is mandatory in many commercial and institutional settings. This technological evolution extends to metal boxes, where lightweight aluminum alloys treated with corrosion-resistant coatings are being developed to offer robust protection in industrial and outdoor environments while minimizing installation burden. The incorporation of specialized internal geometry, such as integrated separation walls and grounding mechanisms, is also a technological advancement critical for supporting high-frequency data cables (e.g., Cat8), ensuring signal integrity by minimizing crosstalk and EMI.

Installation technology represents another crucial area of innovation, particularly the move towards modular and tool-less designs optimized for rapid deployment and flexibility. Modern surface mount boxes feature snap-fit lids, integrated cable management features (like strain relief anchors), and universal mounting hole patterns that simplify the attachment of various connectivity modules (keystone jacks, couplers, etc.). Rapid prototyping techniques, enabled by 3D printing, are allowing manufacturers to accelerate the development cycle for application-specific boxes, especially those requiring precise interfaces for specialized industrial control systems or proprietary communication hardware. This focus on rapid configurability is essential to cater to the bespoke needs of large-scale system integrators and telecom infrastructure projects.

Furthermore, technology related to ingress protection (IP) ratings and environmental sealing is highly relevant, especially for boxes utilized in critical infrastructure or outdoor installations. High-performance surface mount boxes now routinely feature IP66 or IP67 ratings, incorporating specialized gaskets and UV-resistant materials to ensure protection against dust, water, and extreme weather conditions. The integration of smart features, such as embedded sensors for temperature monitoring within industrial control boxes or compatibility with Radio Frequency Identification (RFID) tags for asset tracking and maintenance logging, signifies the increasing sophistication of what were traditionally simple passive components. These advancements collectively ensure that surface mount boxes remain relevant in highly demanding, digitally interconnected environments.

Regional Highlights

- Asia Pacific (APAC): The APAC region stands as the fastest-growing market globally, driven by unprecedented levels of investment in smart infrastructure, widespread urbanization, and aggressive rollout of 5G networks and Fiber-to-the-Home (FTTH) projects across countries like China, India, and Southeast Asia. The sheer volume of new construction—both commercial and residential—provides a massive market for surface mount solutions. Furthermore, government initiatives promoting industrial automation (Industry 4.0) in manufacturing hubs significantly increase the demand for high-durability, IP-rated surface mount enclosures on factory floors. Market growth here is also characterized by a high demand for cost-effective, yet reliably certified, plastic boxes due to budget constraints in mass housing projects.

- North America: North America holds a substantial share of the market, driven by stringent regulatory environments (NEC and local electrical codes) that necessitate high-quality, UL-listed products, ensuring safety and performance. The primary market drivers include the continuous replacement and upgrade cycles of aging commercial infrastructure and the massive expenditure on data center expansion. The region exhibits high demand for premium products, including metal boxes for enhanced security and sophisticated multi-gang boxes integrating data, power, and charging ports (e.g., USB-C) into a single aesthetic unit, catering to modern office environments and advanced residential smart homes.

- Europe: The European market is mature but highly focused on energy efficiency, sustainability, and aesthetic integration, driven by EU directives and high construction standards. Germany, the UK, and France are key contributors, emphasizing products compliant with IEC standards and RoHS regulations (Restriction of Hazardous Substances). The renovation and retrofit market is particularly strong, as older buildings require modern networking capabilities without major structural changes, favoring easy-to-install surface mount solutions. There is also a distinct focus on modular systems to support flexible workspace design and compliance with fire safety norms in public buildings.

- Latin America, Middle East, and Africa (LAMEA): This region is characterized by fragmented growth but high potential, especially in the Middle Eastern Gulf Cooperation Council (GCC) countries, which are undertaking mega-infrastructure projects (e.g., smart cities in Saudi Arabia and UAE). These projects drive demand for high-specification, weather-resistant boxes suitable for extreme climates. In Latin America and Africa, market expansion is tied to improving telecommunications access and basic electrification projects, favoring robust, entry-level to mid-range products. Regulatory standardization and supply chain stability remain key challenges and opportunities in this diverse region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Surface Mount Box Market.- Legrand SA

- Hubbell Incorporated

- Schneider Electric SE

- ABB Ltd.

- Leviton Manufacturing Co., Inc.

- Eaton Corporation plc

- Rittal GmbH & Co. KG

- Panduit Corp.

- Molex LLC

- Cooper Wiring Devices (Eaton)

- Lutron Electronics Co., Inc.

- HellermannTyton

- Connectix Ltd.

- BG Electrical

- D-Link Corporation

- Nexans S.A.

- Southwire Company, LLC

- Belden Inc.

- OBO Bettermann Holding GmbH & Co. KG

- Siemens AG

Frequently Asked Questions

Analyze common user questions about the Surface Mount Box market and generate a concise list of summarized FAQs reflecting key topics and concerns.What materials are most commonly used for Surface Mount Boxes and why?

The most common materials are high-impact plastics, specifically ABS (Acrylonitrile Butadiene Styrene) and PVC (Polyvinyl Chloride), due to their cost-effectiveness, ease of molding, non-conductivity, and good fire-retardant properties. Metal options, such as galvanized steel or aluminum, are used where superior durability, security, and electromagnetic interference (EMI) shielding are required, typically in industrial or high-security commercial installations.

How does the growth of IoT and smart buildings influence the demand for Surface Mount Boxes?

The proliferation of IoT devices and smart building technologies drives increased demand for surface mount boxes by requiring a higher density of localized power and data termination points. These boxes provide the necessary protected enclosures for sensors, edge computing gateways, and network access points, especially in retrofit scenarios where minimal structural intrusion is preferred, enabling rapid and flexible smart technology integration.

What is the key difference between single-gang and multi-gang surface mount boxes?

The distinction lies in the capacity and physical size; a single-gang box accommodates one standard outlet or module, while multi-gang boxes (double, triple, or four-gang) provide space for multiple devices, allowing for the consolidation of power, data, and multimedia connections at a single location. Multi-gang boxes are essential for dense workstation environments and commercial applications requiring diverse connectivity options.

Which geographical region exhibits the fastest growth rate for the Surface Mount Box Market?

The Asia Pacific (APAC) region is projected to register the fastest growth rate. This acceleration is attributed to massive governmental and private investments in telecommunications infrastructure, rapid urbanization, large-scale residential and commercial construction booms, and the widespread adoption of modern networking standards across emerging economies in the region.

What is Answer Engine Optimization (AEO) and how is it relevant to this report?

Answer Engine Optimization (AEO) is a content strategy focused on structuring information to directly and concisely answer user queries, making it easily consumable by AI assistants and generative search engines (like Google's SGE or Microsoft Copilot). In this report, AEO is achieved through the use of specific headings, structured lists, and direct, summarized responses within sections like the FAQ and Executive Summary to maximize visibility in rich search snippets and generative answers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager