Surface Mount Technology (SMT) Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439923 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Surface Mount Technology (SMT) Equipment Market Size

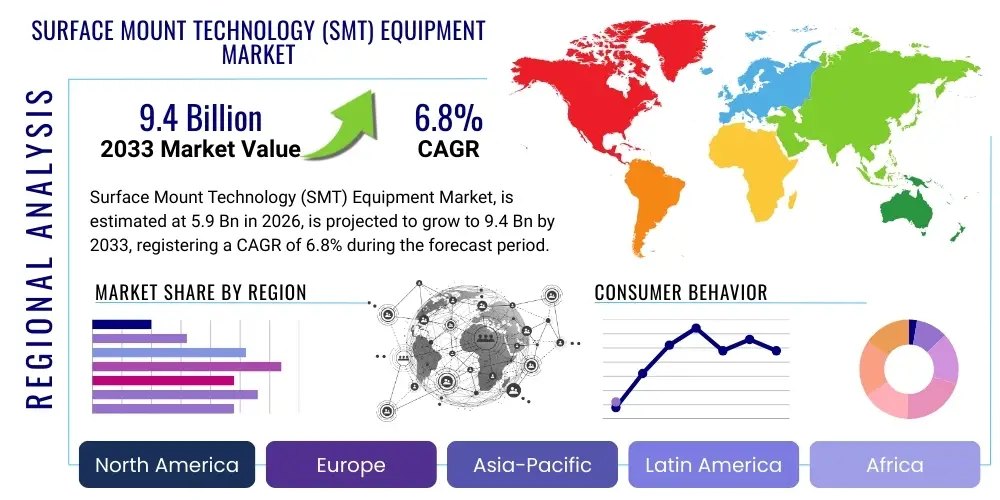

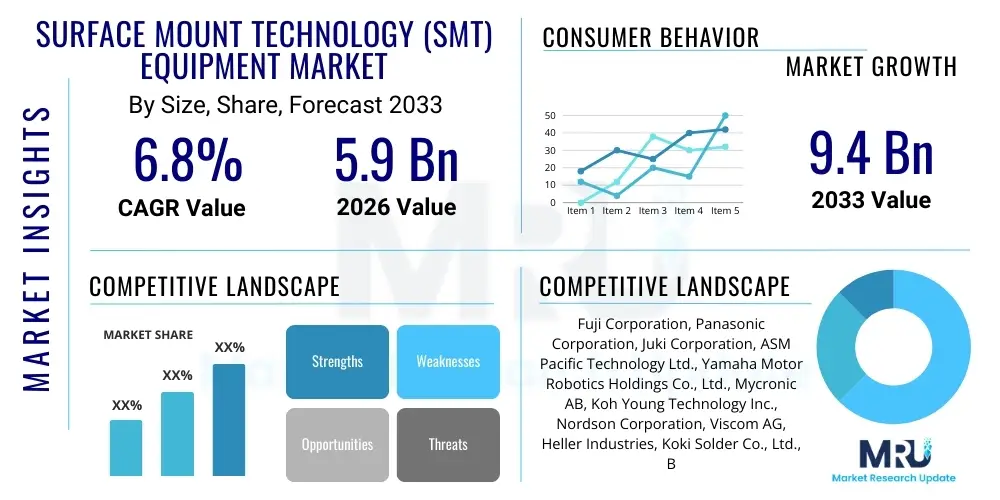

The Surface Mount Technology (SMT) Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 5.9 Billion in 2026 and is projected to reach USD 9.4 Billion by the end of the forecast period in 2033.

Surface Mount Technology (SMT) Equipment Market introduction

The Surface Mount Technology (SMT) Equipment Market is a critical and dynamic segment within the electronics manufacturing industry, providing the essential machinery for the automated assembly of electronic components onto printed circuit boards (PCBs) using surface mount techniques. This advanced manufacturing process, known as Surface Mount Technology, has largely superseded traditional through-hole technology due to its ability to facilitate greater component density, enhance electrical performance, and significantly reduce the physical footprint of electronic devices. The equipment suite typically includes highly specialized machines such as precision pick-and-place robots, sophisticated screen printers for solder paste deposition, meticulously controlled reflow ovens for soldering, and advanced inspection systems like Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) to ensure quality and reliability.

The widespread adoption of SMT is driven by its inherent benefits, which translate directly into improved manufacturing efficiency and cost-effectiveness. These advantages include faster production cycles, reduced material costs through smaller component usage, and superior reliability of electronic assemblies. Consequently, SMT equipment finds extensive application across a broad spectrum of industries. From the ubiquitous consumer electronics sector, encompassing smartphones, tablets, and smart wearables, to the rapidly advancing automotive electronics industry for infotainment, safety systems, and electric vehicle components, SMT is indispensable. It is also crucial for telecommunications infrastructure, including 5G base stations, high-performance computing, complex medical devices, industrial automation systems, and specialized aerospace and defense electronics.

The market's sustained growth trajectory is underpinned by several powerful driving forces. Foremost among these is the incessant demand for smaller, lighter, and more powerful electronic devices, which mandates high-precision and high-speed assembly. The global proliferation of the Internet of Things (IoT), requiring billions of interconnected smart devices, alongside the expansive rollout of 5G networks and the increasing sophistication of vehicle electrification and autonomous driving technologies, all contribute to a surging demand for state-of-the-art SMT solutions. These trends collectively underscore the continuous need for innovative, automated, and highly efficient SMT equipment capable of meeting the stringent requirements of next-generation electronic manufacturing.

Surface Mount Technology (SMT) Equipment Market Executive Summary

The SMT Equipment Market is currently experiencing a period of robust expansion, shaped by a confluence of evolving business trends that underscore the industry's commitment to efficiency, precision, and advanced automation. A significant trend observed is the accelerated integration of Industry 4.0 principles, including comprehensive connectivity, real-time data analytics, and cyber-physical systems, into SMT lines. Manufacturers are heavily investing in equipment that offers higher speeds, greater placement accuracy, and enhanced flexibility, enabling them to adapt quickly to diverse production demands, ranging from high-volume consumer electronics to specialized, high-mix products for industrial and medical applications. The drive towards lean manufacturing and total quality management further propels the adoption of sophisticated monitoring and control solutions within the SMT ecosystem.

Regional dynamics play a crucial role in the market's global landscape. Asia Pacific continues to assert its dominance as the leading market for SMT equipment, primarily due to the presence of a colossal electronics manufacturing base, particularly in countries like China, Taiwan, and South Korea, which serve as global production hubs. This region benefits from both high-volume manufacturing for global consumption and burgeoning domestic demand for electronic products. Meanwhile, North America and Europe are witnessing steady, strategic growth, characterized by significant investments in advanced manufacturing technologies, smart factory initiatives, and a focus on high-reliability, high-value product segments such as aerospace, defense, and medical electronics, where precision and stringent quality standards are paramount.

From a segmentation perspective, the market is seeing sustained demand across all equipment types, with particular emphasis on certain categories. Pick-and-place machines, being central to the SMT assembly process, maintain a substantial market share, constantly evolving to handle smaller, more complex components at ever-increasing speeds. Concurrently, there is a rapidly expanding demand for advanced inspection equipment, specifically Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) systems, which are critical for ensuring defect-free production in increasingly dense and intricate PCB designs. Furthermore, the emergence of advanced packaging techniques and heterogeneous integration is driving demand for highly specialized SMT equipment capable of handling novel component types and complex assembly challenges, indicating a continuous technological advancement across the board.

AI Impact Analysis on Surface Mount Technology (SMT) Equipment Market

Users frequently inquire about how Artificial Intelligence (AI) will revolutionize the efficiency, precision, and automation capabilities within SMT manufacturing. Common questions revolve around AI's role in predictive maintenance, real-time quality control, process optimization, and intelligent decision-making for equipment operation and resource allocation. There's significant interest in how AI can reduce defects, enhance throughput, and enable more adaptive and autonomous SMT lines, ultimately impacting operational costs and product time-to-market. The industry anticipates AI to be a critical enabler for smart factories, allowing SMT equipment to learn, adapt, and self-optimize assembly processes, minimizing human intervention and maximizing production quality.

The integration of AI transforms traditional SMT operations by fostering a data-driven approach to manufacturing. Through sophisticated algorithms, AI systems can analyze vast amounts of production data, identifying subtle patterns and anomalies that human operators might miss. This leads to proactive problem-solving, improved process stability, and a significant reduction in waste. The enhanced decision-making capabilities provided by AI also facilitate dynamic adjustments to production schedules and equipment parameters, optimizing resource utilization and ensuring responsiveness to market changes. Ultimately, AI's influence extends beyond mere automation, enabling a paradigm shift towards truly intelligent, self-optimizing, and resilient SMT manufacturing environments.

- Enhanced predictive maintenance through machine learning algorithms analyzing equipment performance data, preventing downtime.

- Real-time defect detection and classification using AI-powered Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) systems, improving quality control.

- Optimized process parameters and adaptive control for pick-and-place machines and reflow ovens, leading to higher yield and efficiency.

- Automated material handling and inventory management through AI-driven robotics and logistics systems within SMT lines.

- Intelligent scheduling and production planning, allowing SMT lines to dynamically adapt to production changes and material availability.

- Advanced data analytics for identifying root causes of defects and process inefficiencies, driving continuous improvement.

- Automated root cause analysis for assembly defects, significantly speeding up problem resolution.

- Self-calibration and self-correction capabilities for SMT equipment, reducing manual intervention and setup times.

- Simulation and digital twin technology powered by AI for virtual testing and optimization of SMT line configurations.

DRO & Impact Forces Of Surface Mount Technology (SMT) Equipment Market

The SMT Equipment Market is primarily propelled by a robust set of drivers rooted in the global demand for advanced electronics. The relentless push for miniaturization and enhanced performance in electronic devices, from consumer gadgets to industrial controls, necessitates highly precise and efficient assembly solutions. This intrinsic requirement for compact yet powerful electronics directly fuels the demand for sophisticated SMT equipment. Furthermore, the burgeoning growth in specific high-tech sectors significantly contributes to market expansion. This includes the rapid development of automotive electronics, particularly in electric vehicles (EVs) and autonomous driving systems, the extensive rollout of 5G communication infrastructure, and the exponential proliferation of Internet of Things (IoT) devices, all of which rely heavily on advanced SMT for their complex PCB assemblies.

Despite these powerful drivers, the market faces notable restraints that can impede its growth trajectory. The most significant barrier is the substantial initial capital investment required for acquiring state-of-the-art SMT equipment, which can be prohibitive for smaller manufacturers or those in developing regions. The inherent technological complexity of modern SMT lines, demanding specialized expertise for operation, maintenance, and troubleshooting, also presents a challenge, exacerbated by a persistent global shortage of skilled labor in electronics manufacturing. Additionally, the cyclical nature of demand in the consumer electronics sector, which often experiences fluctuating market trends, can lead to periods of unpredictable investment and production capacity adjustments within the SMT equipment market.

Opportunities within the SMT Equipment Market are abundant and largely revolve around technological innovation and strategic market penetration. A major avenue for growth lies in the deeper integration of Industry 4.0 technologies, such as Artificial Intelligence (AI), Machine Learning (ML), and the Industrial Internet of Things (IIoT), which promise to revolutionize SMT lines through enhanced automation, predictive maintenance, and real-time process optimization. The development of modular and flexible SMT solutions that can easily adapt to varying production requirements and product changes presents another significant opportunity. Moreover, the increasing demand for advanced packaging techniques, such as System-in-Package (SiP) and heterogeneous integration, requires new generations of SMT equipment, opening new market segments. Emerging economies, driven by industrialization and rising consumer disposable incomes, represent untapped potential for market expansion, particularly for cost-effective and scalable SMT solutions. These impact forces collectively define a competitive landscape shaped by technological progression, economic imperatives, and evolving manufacturing paradigms.

Segmentation Analysis

The SMT Equipment Market is meticulously segmented to provide a granular understanding of its diverse operational environment, reflecting the varied technological demands, application specificities, and end-user requirements that characterize the global electronics manufacturing landscape. This comprehensive segmentation is instrumental for market participants, investors, and policymakers to identify precise growth vectors, anticipate market shifts, and formulate targeted strategic initiatives. By dissecting the market along distinct dimensions, it becomes possible to discern nuanced trends and opportunities that might otherwise be overlooked in a broader market analysis. Each segment provides unique insights into where capital is being invested, what technological advancements are most critical, and which sectors are driving demand for specific types of SMT solutions.

The primary axes of segmentation within this market typically include the classification of equipment by type, which ranges from fundamental component placement machines to sophisticated inspection and rework systems. This categorization highlights the technological diversity and functional specialization inherent in SMT lines. Concurrently, segmentation by application delineates the distinct industries and product categories that utilize SMT equipment, such as consumer electronics, automotive, telecommunications, medical, and industrial sectors. Each application area presents unique demands on SMT equipment concerning precision, speed, reliability, and capability to handle specific component types or environmental conditions. Understanding these application-specific needs is crucial for equipment manufacturers to tailor their product offerings and R&D efforts.

Furthermore, the market is segmented by end-user, differentiating between large-scale Electronics Manufacturing Services (EMS) providers, who serve multiple clients with diverse product portfolios, and Original Equipment Manufacturers (OEMs), who integrate SMT processes into their in-house production for their proprietary products. This distinction sheds light on differing procurement strategies, investment cycles, and service requirements. Finally, geographical segmentation provides a regional perspective, identifying leading markets and emerging growth hotspots across continents. These multifaceted segmentation dimensions collectively offer a detailed framework for analyzing market dynamics, competitive positioning, and future growth prospects across the entire value chain of the Surface Mount Technology Equipment industry.

- By Equipment Type

- Pick and Place Machines

- Screen Printers

- Reflow Ovens

- Inspection Equipment

- Automated Optical Inspection (AOI)

- Solder Paste Inspection (SPI)

- Automated X-ray Inspection (AXI)

- Dispensing Equipment

- Rework and Repair Equipment

- Cleaning Equipment

- Conveyors and Handling Equipment

- By Application

- Consumer Electronics

- Automotive Electronics

- Telecommunications

- Industrial Electronics

- Medical Devices

- Aerospace and Defense

- Others (e.g., Lighting, Security Systems)

- By End User

- Electronics Manufacturing Services (EMS) Providers

- Original Equipment Manufacturers (OEMs)

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Surface Mount Technology (SMT) Equipment Market

The value chain for the Surface Mount Technology (SMT) Equipment Market is a complex and highly integrated network, commencing with the crucial upstream activities. This initial phase involves a diverse array of suppliers providing fundamental raw materials such as various metals, specialized polymers, and advanced electronic components that form the building blocks of SMT machinery. Beyond basic materials, the upstream segment also encompasses highly specialized component manufacturers who supply precision mechanics, sophisticated optical systems, advanced sensor technologies, and intricate software solutions essential for the precise control and operation of SMT equipment. These specialized inputs are critical, as the performance and accuracy of the final SMT machines heavily depend on the quality and innovation embedded at this foundational stage.

Moving further along the value chain, the core SMT equipment manufacturers take these diverse inputs and engage in the design, engineering, assembly, and rigorous testing of the complex machinery. This stage is characterized by intensive research and development (R&D) efforts aimed at continually improving machine speed, placement accuracy, flexibility, and overall automation capabilities. Manufacturers invest heavily in software development for machine vision, process control, and data analytics, ensuring their equipment can integrate seamlessly into modern smart factory environments. Quality assurance and compliance with international manufacturing standards are paramount at this stage, as the reliability of SMT equipment directly impacts the efficiency and quality of electronic product assembly for end-users.

The downstream segment of the value chain focuses on distribution and post-sales support. For large-scale clients such as major Electronics Manufacturing Services (EMS) providers and Original Equipment Manufacturers (OEMs), distribution is predominantly direct, allowing manufacturers to forge strong relationships and provide tailored solutions. This often includes comprehensive installation services, extensive operator training programs, and ongoing maintenance contracts, which are vital for maximizing equipment uptime and operational efficiency. While direct sales dominate, indirect channels, involving authorized distributors or specialized system integrators, cater to smaller enterprises or specific regional markets, providing localized support and access. This intricate value chain emphasizes innovation, precision, and sustained customer support, reflecting the high-stakes nature of electronic manufacturing where downtime and defects can have significant financial repercussions.

Surface Mount Technology (SMT) Equipment Market Potential Customers

The Surface Mount Technology (SMT) Equipment Market caters to a diverse and expanding base of potential customers, all of whom are fundamentally involved in the manufacturing, assembly, or development of electronic products. The largest segment of these customers comprises vast Electronics Manufacturing Services (EMS) providers. These companies operate on a contract basis, offering comprehensive PCB assembly and manufacturing services to a multitude of clients across various industries. EMS providers require highly flexible, high-speed, and robust SMT lines capable of handling a wide range of component types and production volumes, making them key purchasers of advanced SMT equipment.

Another significant customer segment includes Original Equipment Manufacturers (OEMs). These are companies that design and produce electronic devices under their own brand, choosing to integrate SMT processes directly into their in-house manufacturing operations. OEMs often have very specific requirements tailored to their proprietary product lines, focusing on customization, process control, and the ability to maintain intellectual property within their own facilities. As such, they seek SMT equipment that offers specialized capabilities, scalability, and seamless integration with their existing production infrastructure. The automotive, telecommunications, and industrial electronics sectors, in particular, represent a large portion of the OEM customer base.

Beyond these core manufacturing entities, the SMT equipment market also serves a niche but critical customer group encompassing research and development institutions, academic facilities, and specialized prototyping firms. These organizations require SMT capabilities for innovation, new product development, process experimentation, and low-volume, high-complexity assembly. The ongoing global trends towards smart manufacturing, personalized electronics, and industry-specific automation continue to broaden this customer base. As new applications for electronics emerge, the demand for adaptable, high-performance, and efficient SMT solutions will grow, continually attracting new buyers seeking to establish or enhance their electronic assembly capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.9 Billion |

| Market Forecast in 2033 | USD 9.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fuji Corporation, Panasonic Corporation, Juki Corporation, ASM Pacific Technology Ltd., Yamaha Motor Robotics Holdings Co., Ltd., Mycronic AB, Koh Young Technology Inc., Nordson Corporation, Viscom AG, Heller Industries, Koki Solder Co., Ltd., BTU International, Mirtec Co. Ltd., Orbotech Ltd. (KLA Corporation), CyberOptics Corporation (Nordson), Rehm Thermal Systems, ITW EAE (MPM, Vitronics Soltec, Camalot), Ascentek, Essemtec AG, Europlacer (Blakell Europlacer Ltd.), Asscon Systemtechnik-Elektronik GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Surface Mount Technology (SMT) Equipment Market Key Technology Landscape

The technological landscape of the SMT Equipment market is a vibrant arena of continuous innovation, fundamentally driven by the electronics industry's unrelenting pursuit of enhanced precision, unprecedented speed, operational flexibility, and comprehensive automation. At the core of this evolution are sophisticated vision systems that are integral to nearly every piece of SMT equipment, from advanced optical inspection (AOI) machines ensuring defect-free solder joints to pick-and-place robots precisely aligning minuscule components. These vision systems, often powered by high-resolution cameras and advanced image processing algorithms, enable ultra-fine pitch placement and meticulous quality control. Concurrently, sophisticated motion control systems, employing linear motors and high-accuracy encoders, ensure that pick-and-place operations achieve unparalleled speed and repeatability, critical for high-volume manufacturing of complex PCBs.

A significant trend defining the current technological paradigm is the profound integration of Artificial Intelligence (AI) and Machine Learning (ML) across the entire SMT production line. AI algorithms are deployed for real-time defect detection and classification, moving beyond simple anomaly identification to predicting potential failures and identifying root causes. ML models optimize process parameters for reflow ovens and screen printers, adapting to material variations and environmental conditions to achieve higher yields and energy efficiency. Furthermore, the advent of Industry 4.0 principles, including the Industrial Internet of Things (IIoT), has transformed SMT factories into intelligent, interconnected ecosystems. This involves ubiquitous sensor integration, cloud-based data management platforms, and cyber-physical systems that enable remote monitoring, predictive maintenance, and seamless data exchange between different machines and production stages, fostering a truly smart manufacturing environment.

Beyond these overarching trends, specific technological advancements continue to shape individual equipment categories. In dispensing technology, miniaturization and multi-functionality allow for precise application of solder paste, adhesives, or underfill materials on increasingly dense boards. Reflow ovens are evolving with advanced thermal profiles and vacuum capabilities to handle sensitive components and minimize voids. Robotics is playing an expanding role, not just in pick-and-place, but also in automated material handling, component loading, and end-of-line packaging, further reducing manual labor and enhancing throughput. The collective evolution of these technologies ensures that SMT equipment can meet the stringent demands of next-generation electronic assemblies, characterized by smaller components, higher densities, and more complex functionalities, driving the industry towards greater efficiency and innovation.

Regional Highlights

- Asia Pacific (APAC): Positioned as the undisputed global leader in the SMT Equipment Market, primarily due to its expansive and mature electronics manufacturing ecosystem. Countries such as China, Taiwan, South Korea, Japan, and Vietnam serve as major production hubs for a vast array of electronic devices, driving immense demand for high-volume, high-precision SMT machinery. Significant governmental and private sector investments in smart factory initiatives, coupled with a burgeoning domestic consumer base for electronics, further solidify APAC's market dominance and continuous growth trajectory. The region is also at the forefront of adopting advanced SMT technologies to handle increasingly complex and miniaturized components.

- North America: This region exhibits a strong focus on high-value, high-mix, and often lower-volume production, emphasizing advanced research and development in areas like advanced packaging and specialized electronics. North American manufacturers are keen adopters of Industry 4.0 technologies, seeking to enhance automation, efficiency, and traceability within their SMT lines. Significant growth is observed in critical sectors such as aerospace, defense, medical devices, and high-performance computing, where stringent quality standards and technological sophistication drive demand for cutting-edge SMT solutions.

- Europe: The European market is characterized by a strong emphasis on precision engineering, advanced automation, and sustainable manufacturing practices within its SMT sector. Countries like Germany, France, and other Western European nations lead in the production of industrial electronics, automotive components, and high-reliability systems. There is a consistent push for integrating sophisticated software solutions, robotics, and advanced inspection technologies to optimize production processes and ensure superior product quality. Investments are increasingly directed towards flexible SMT lines that can accommodate diverse product portfolios and smaller batch sizes efficiently.

- Latin America: Representing an emerging yet steadily growing market for SMT equipment, Latin America is witnessing increased manufacturing capabilities, particularly in countries such as Mexico and Brazil. This growth is spurred by foreign direct investments in electronics assembly plants, aiming to serve both regional markets and provide cost-effective manufacturing for North American companies. As industrialization progresses and local demand for consumer electronics rises, the region presents significant opportunities for SMT equipment providers, particularly those offering scalable and cost-efficient solutions.

- Middle East and Africa (MEA): While a nascent market, the MEA region is demonstrating nascent growth in the SMT equipment sector. This is driven by ongoing governmental initiatives focused on economic diversification, which includes building indigenous manufacturing capabilities in electronics. Investments in telecommunications infrastructure, consumer electronics assembly, and specialized industrial applications are slowly gaining traction. As local expertise develops and regulatory frameworks mature, the region is expected to present long-term growth opportunities for SMT equipment suppliers, albeit from a lower base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Surface Mount Technology (SMT) Equipment Market.- Fuji Corporation

- Panasonic Corporation

- Juki Corporation

- ASM Pacific Technology Ltd.

- Yamaha Motor Robotics Holdings Co., Ltd.

- Mycronic AB

- Koh Young Technology Inc.

- Nordson Corporation

- Viscom AG

- Heller Industries

- Koki Solder Co., Ltd.

- BTU International

- Mirtec Co. Ltd.

- Orbotech Ltd. (KLA Corporation)

- CyberOptics Corporation (Nordson)

- Rehm Thermal Systems

- ITW EAE (MPM, Vitronics Soltec, Camalot)

- Essemtec AG

- Europlacer (Blakell Europlacer Ltd.)

- Asscon Systemtechnik-Elektronik GmbH

Frequently Asked Questions

Analyze common user questions about the Surface Mount Technology (SMT) Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Surface Mount Technology (SMT) equipment?

SMT equipment refers to specialized machinery used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This includes devices like pick-and-place machines, screen printers, reflow ovens, and inspection systems, enabling high-density and automated electronic assembly crucial for modern electronics manufacturing.

What are the primary drivers of growth in the SMT Equipment Market?

Key growth drivers include the continuous demand for miniaturized and high-performance electronic devices, rapid expansion of automotive electronics, 5G technology deployment, and the proliferation of IoT devices, all requiring advanced, efficient, and precise PCB assembly solutions.

How does AI impact SMT equipment manufacturing?

AI significantly enhances SMT manufacturing by enabling predictive maintenance, real-time quality control through advanced inspection, optimized process parameters, and intelligent automation of material handling, leading to higher efficiency, reduced defects, and smarter factory operations.

Which region dominates the SMT Equipment Market?

Asia Pacific (APAC) currently dominates the SMT Equipment Market. This is attributed to its extensive electronics manufacturing base, high production volumes in countries like China, Taiwan, and South Korea, and strong domestic demand for electronic products across various sectors.

What are the main types of SMT equipment?

The main types include pick-and-place machines for component mounting, screen printers for solder paste application, reflow ovens for soldering, and inspection equipment such as Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) for quality assurance. Other types include dispensing, rework, and cleaning equipment.

What role does automation play in the SMT equipment market?

Automation is fundamental in the SMT equipment market, enabling high-speed, high-precision component placement and assembly. It minimizes human error, increases throughput, and ensures consistency. Advanced automation includes robotics for material handling, automated inspection systems, and software-driven process control, crucial for modern, efficient electronics manufacturing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager