Surfboard Skeg Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440112 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Surfboard Skeg Market Size

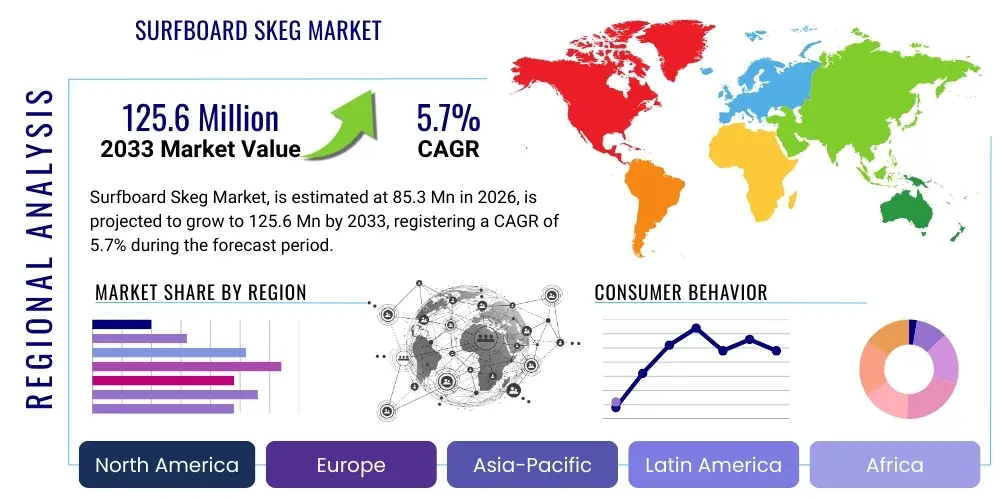

The Surfboard Skeg Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.7% between 2026 and 2033. The market is estimated at USD 85.3 Million in 2026 and is projected to reach USD 125.6 Million by the end of the forecast period in 2033. This growth is primarily driven by the increasing global popularity of surfing as a recreational activity and a competitive sport, coupled with continuous advancements in material science and manufacturing technologies that enhance skeg performance and durability. The market also benefits from a rising demand for customized surfing equipment, allowing riders to fine-tune their boards for specific wave conditions and riding styles, thereby fostering innovation and consumer interest.

Surfboard Skeg Market introduction

The Surfboard Skeg Market encompasses the design, manufacturing, and distribution of fins, which are crucial components attached to the underside of a surfboard to provide stability, drive, and maneuverability. These hydrodynamic foils dictate how a surfboard interacts with water, influencing speed, control, and turning ability. A wide array of skeg types exists, from single fins providing stability for longboards, to multi-fin setups like twin fins, thrusters (three fins), quad fins (four fins), and five-fin configurations, each designed for distinct performance characteristics tailored to different board types, wave conditions, and rider preferences.

Major applications of surfboard skegs span across various surfing disciplines, including recreational surfing, professional competitive surfing, and surf schools. They are essential for all types of surfboards, including shortboards, longboards, funboards, stand-up paddleboards (SUPs), and specialty boards. The primary benefits of high-quality skegs include enhanced board control, increased speed down the line, improved turning response, and greater stability, which collectively elevate the surfing experience for both novices and seasoned professionals. Driving factors for market growth include the global expansion of surfing tourism, increased investment in surf-related infrastructure, continuous innovation in composite materials such as fiberglass, carbon fiber, and specialized plastics, and a growing consumer interest in customizing their equipment for optimal performance and aesthetics.

Surfboard Skeg Market Executive Summary

The Surfboard Skeg Market is characterized by robust business trends focusing on innovation, customization, and sustainability. Manufacturers are increasingly investing in research and development to introduce lighter, stronger, and more aerodynamically efficient skegs utilizing advanced composite materials and sophisticated design software. The trend towards personalization is strong, with modular fin systems and customizable fin templates gaining traction, allowing surfers to easily swap and tune their setups. Furthermore, there is a noticeable shift towards eco-friendly manufacturing processes and the use of sustainable materials, driven by increasing environmental awareness among consumers and industry stakeholders alike. Companies are exploring bio-resins, recycled plastics, and wood alternatives to minimize ecological footprint while maintaining performance.

Regional trends indicate significant market growth in established surfing regions such as North America and Europe, supported by a large installed base of surfers and robust distribution networks. However, the Asia Pacific region, particularly countries like Australia, Indonesia, and Japan, is emerging as a critical growth engine due to rising disposable incomes, expanding surf tourism, and increasing local participation. Latin America also presents substantial opportunities, with countries like Brazil experiencing a surge in surfing popularity. These regional dynamics are influencing supply chain optimizations and targeted marketing strategies by leading market players. Segments trends highlight a strong demand for performance-oriented thruster and quad fin setups for shortboards, while single fins and 2+1 configurations remain popular for longboards and SUPs, reflecting diverse consumer needs and evolving surfing styles.

AI Impact Analysis on Surfboard Skeg Market

Common user questions regarding AI's impact on the Surfboard Skeg Market often revolve around its potential to revolutionize design, material selection, and personalized performance. Users frequently inquire if AI can design a "perfect" skeg, predict optimal fin setups for specific surfers and conditions, suggest new high-performance materials, or even enable real-time adaptive fin systems. There's also curiosity about AI's role in manufacturing efficiency and quality control. Based on this analysis, users anticipate AI will drive significant advancements in hydrodynamics, material science, and personalized recommendations, enhancing both the functionality and user experience of surfboard skegs, leading to a new era of performance customization.

- Computational Fluid Dynamics (CFD) simulations powered by AI will optimize hydrodynamic profiles, enabling designers to predict and refine skeg performance with unprecedented accuracy, leading to more efficient water flow and reduced drag.

- Generative design algorithms will allow for the creation of intricate, lightweight, and strong skeg structures, leveraging material properties to their fullest potential while minimizing material usage and waste.

- Predictive analytics will be used to identify the best material compositions for specific performance characteristics, such as flex, stiffness, and durability, by analyzing vast datasets of material properties and real-world testing results.

- AI-driven personalization engines could recommend optimal skeg setups based on a surfer's skill level, weight, preferred wave types, board dimensions, and even historical performance data, offering highly tailored equipment advice.

- Automated quality control systems integrating computer vision and machine learning will enhance manufacturing precision, ensuring consistency in skeg production and identifying defects faster than traditional methods, thereby improving product reliability.

- AI could facilitate the development of "smart skegs" equipped with sensors to collect real-time data on speed, angle, and pressure, feeding information back to surfers or coaches for performance analysis and further optimization.

DRO & Impact Forces Of Surfboard Skeg Market

The Surfboard Skeg Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include the escalating global participation in surfing activities, fueled by rising leisure spending, increased media coverage of surf sports, and the accessibility of surf tourism destinations. Technological advancements in material science, particularly the development of high-strength, lightweight composites like carbon fiber and advanced resins, allow manufacturers to create skegs with superior performance characteristics and durability. Furthermore, the growing demand for customized surfing equipment, where surfers seek to fine-tune their boards for specific conditions and riding styles, directly propels innovation and product diversification within the skeg market. The continuous evolution of fin systems, offering easier interchangeability and precise adjustments, also contributes to market expansion.

However, several restraints challenge market growth. The relatively high cost associated with premium, performance-oriented skegs made from advanced materials can be a barrier for budget-conscious consumers, especially in developing regions. Limited access to suitable surfing locations globally also naturally caps the potential market size, as the product's utility is tied directly to the availability of waves. Environmental concerns surrounding the manufacturing processes of composite materials, which often involve non-biodegradable plastics and resins, represent another restraint, pushing the industry towards costly research and development into sustainable alternatives. The cyclical nature of tourism and discretionary spending can also impact demand, particularly during economic downturns or global crises.

Opportunities for growth are abundant, particularly in emerging markets where surfing is gaining traction, opening new avenues for distribution and localized product offerings. The ongoing development of sustainable and eco-friendly skeg materials and manufacturing practices presents a significant opportunity for brands to differentiate themselves and appeal to environmentally conscious consumers. Furthermore, the expansion of e-commerce platforms and direct-to-consumer sales channels allows manufacturers to reach a broader global audience more efficiently, reducing reliance on traditional retail infrastructures. The integration of smart technologies, such as embedded sensors for real-time performance tracking and AI-driven design, offers a futuristic pathway for product innovation and market expansion. Impact forces, as analyzed through Porter's Five Forces, include a moderate threat of new entrants due to specialized manufacturing knowledge, significant bargaining power of buyers driven by product differentiation and customization options, and varying bargaining power of suppliers depending on the uniqueness of raw materials. The threat of substitutes is low, as skegs are integral to surfboard functionality, and industry rivalry is high due to numerous established and niche players competing on performance, price, and brand reputation.

Segmentation Analysis

The Surfboard Skeg Market is comprehensively segmented based on various critical attributes, including the type of fin setup, the materials used in construction, the specific fin system employed, the application or type of surfboard, and the distribution channel through which these products reach consumers. This segmentation provides a granular view of market dynamics, revealing preferences, growth patterns, and competitive landscapes within each category. Understanding these segments is crucial for manufacturers to tailor their product offerings, marketing strategies, and R&D efforts to meet the diverse needs of the global surfing community.

- By Type:

- Single Fin

- Twin Fin

- Thruster (Tri-Fin)

- Quad Fin

- 5-Fin Set (Convertible)

- Specialty Fins (e.g., Keels, Canards)

- By Material:

- Fiberglass

- Plastic (Nylon, PC, PVC)

- Carbon Fiber

- Composite Materials (e.g., Glass & Carbon blends, Basalt)

- Wood (e.g., Balsa, Bamboo)

- Other Sustainable Materials

- By Fin System:

- FCS (Fin Control System)

- Futures Fins

- US Box (Longboard Box)

- Glass-on Fins

- Lokbox

- Others (e.g., Flow, Powerbase)

- By Application/Surfboard Type:

- Shortboards

- Longboards

- Funboards/Mid-lengths

- Stand-Up Paddleboards (SUPs)

- Wakeboards/Wakesurfers (specific skegs)

- Kiteboards/Windsurfers (specific skegs)

- By Distribution Channel:

- Online Retail (E-commerce Websites, Marketplaces)

- Specialty Surf Shops

- Sporting Goods Stores

- Direct-to-Consumer (Manufacturer Websites)

- Rental Services/Surf Schools

Value Chain Analysis For Surfboard Skeg Market

The value chain for the Surfboard Skeg Market encompasses a series of interconnected stages, beginning with the sourcing of raw materials and culminating in the final delivery of the product to the end-user. The upstream segment involves the procurement of essential raw materials, including specialized resins (epoxy, polyester), various types of fiberglass cloth, carbon fiber sheets, high-grade plastic pellets (for molded fins), and sustainably sourced wood for certain niche products. Key suppliers in this stage are chemical companies, composite material manufacturers, and specialized timber suppliers, whose quality and cost directly influence the final product. Precision tooling and machinery for manufacturing are also critical upstream components.

Midstream activities primarily involve the design, manufacturing, and assembly of the skegs. This phase includes extensive research and development for new hydrodynamic shapes and material combinations, CAD/CAM design, precision molding (injection molding, compression molding, resin transfer molding), CNC machining for fin foils, and intricate hand-foiling for premium fins. Quality control and rigorous testing are integral at this stage to ensure performance specifications and durability. Manufacturers may specialize in a particular fin system or material, or offer a broad range of products, with intellectual property around fin profiles and attachment systems being highly valuable assets.

Downstream activities focus on the distribution and sale of surfboard skegs. This involves a complex network of wholesalers, regional distributors, and various retail channels. Direct distribution involves manufacturers selling directly to consumers through their own e-commerce platforms, offering greater control over branding and customer relationships. Indirect channels include specialty surf shops, which provide expert advice and a tactile purchasing experience, larger sporting goods retailers, and a wide array of online marketplaces. The choice of distribution channel often depends on the manufacturer's scale, target audience, and brand positioning, with online retail increasingly dominating due to its reach and convenience. The efficiency and reach of these distribution channels are paramount for market penetration and customer accessibility.

Surfboard Skeg Market Potential Customers

The Surfboard Skeg Market caters to a diverse spectrum of end-users and buyers, each with unique needs and purchasing motivations. At the core, individual surfers constitute the largest customer segment, ranging from enthusiastic beginners seeking reliable and forgiving setups to advanced and professional surfers demanding high-performance, precision-engineered fins that can optimize their board for competitive surfing or specific wave conditions. This segment often invests in multiple fin sets to adapt to varying board types, wave sizes, and personal riding styles, demonstrating a strong interest in customization and performance enhancement.

Beyond individual consumers, several institutional and commercial entities represent significant potential customers. Surf schools and rental shops frequently purchase durable and versatile skegs in bulk, prioritizing robustness and ease of maintenance for their fleet of rental boards. These establishments often opt for standard, resilient plastic or molded composite fins that can withstand frequent use and beginner-level wear and tear. Furthermore, surfboard manufacturers are key OEM (Original Equipment Manufacturer) customers, purchasing skegs directly from fin producers to bundle with new boards, or sometimes producing proprietary integrated fin systems. Specialized surf travel companies and resorts that offer surfing packages also represent a growing customer base, ensuring their equipment is up-to-date and tailored to their client base, further diversifying the market's reach.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 85.3 Million |

| Market Forecast in 2033 | USD 125.6 Million |

| Growth Rate | 5.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | FCS (Fin Control Systems), Futures Fins, Shapers Fins, True Ames, Captain Fin Co., Manta Fins, Seabase, DaKine, Kinetik Racing, Machados Fins, Alkali Fins, Rainbow Fin Co., Island Fin Design, 3DFins, Glide Fins, Powerblade, Solite, Naked Viking Surf, Boardworks, Black Project Fins |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Surfboard Skeg Market Key Technology Landscape

The Surfboard Skeg Market is continuously evolving, driven by advancements in materials science, manufacturing processes, and design methodologies. A foundational technology involves the use of advanced composite materials, primarily fiberglass, carbon fiber, and various blends of high-performance resins (epoxy, polyester). These materials are meticulously chosen for their optimal strength-to-weight ratio, flex properties, and durability, enabling the creation of lightweight yet robust skegs that directly impact a board's performance. Innovations in composite layups, such as specific weaving patterns and resin infusion techniques, allow manufacturers to finely tune the flex characteristics of a fin, providing precise control and responsiveness to the surfer.

Modern manufacturing relies heavily on precision engineering techniques like Computer Numerical Control (CNC) machining and advanced molding processes. CNC machines are used to precisely foil and cut fin templates, ensuring consistent hydrodynamic profiles and exact dimensions, which are critical for performance. Injection molding and resin transfer molding (RTM) are employed for mass production of composite and plastic fins, offering cost-effectiveness and scalability while maintaining quality. Beyond traditional manufacturing, additive manufacturing, specifically 3D printing, is gaining traction for rapid prototyping and the creation of highly customized or geometrically complex fin designs that might be challenging or impossible to produce with conventional methods. This technology supports iterative design and allows for personalized performance enhancements based on individual surfer preferences and specific board requirements.

Furthermore, the integration of computational tools and simulation software is transforming skeg design. Computational Fluid Dynamics (CFD) software enables designers to model and analyze water flow around fin profiles, predicting drag, lift, and maneuverability characteristics before physical prototypes are even created. This iterative virtual testing significantly reduces development time and costs while optimizing performance. Emerging technologies include the exploration of bio-based resins and recycled materials for more sustainable production, alongside the potential integration of smart sensors into skegs to collect real-time data on speed, angle, and pressure, which can then be analyzed to further optimize performance and provide valuable feedback to surfers. These technological advancements collectively contribute to a market focused on delivering higher performance, greater customization, and increased sustainability.

Regional Highlights

- North America: A mature market with a strong surfing culture, particularly in coastal regions like California and Hawaii. Characterized by high consumer spending on premium equipment, a significant presence of established brands, and a strong demand for performance-oriented and customizable skegs. The region benefits from a large recreational surfing population and a robust infrastructure for retail and distribution.

- Europe: Experiencing steady growth driven by increasing participation in surfing in countries such as France, Portugal, Spain, and the UK. The market is influenced by surf tourism and a growing awareness of sustainable and eco-friendly products. Demand spans across various segments, from beginner-friendly plastic fins to high-end composite setups for competitive surfers.

- Asia Pacific (APAC): The fastest-growing region, propelled by the rising popularity of surfing in Australia, Indonesia, Japan, and emerging markets like the Philippines and Vietnam. Increased disposable incomes, development of surf resorts, and a burgeoning middle class contribute to market expansion. This region is also a key manufacturing hub for many global brands, influencing supply chain dynamics.

- Latin America: Presents significant growth potential, with Brazil leading the market due to its extensive coastline and passionate surfing community. Other countries like Mexico, Costa Rica, and Peru also show promising growth. The market here is characterized by a mix of local manufacturers and international brands, with a growing demand for both affordable and mid-range performance fins.

- Middle East and Africa (MEA): A niche but developing market, with increasing interest in surfing in regions like South Africa, Morocco, and parts of the UAE. Growth is primarily driven by tourism and expatriate communities, with a rising emphasis on accessible and durable equipment. Infrastructure development for surf tourism is a key factor influencing future market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Surfboard Skeg Market.- FCS (Fin Control Systems)

- Futures Fins

- Shapers Fins

- True Ames

- Captain Fin Co.

- Manta Fins

- Seabase

- DaKine

- Kinetik Racing

- Machados Fins

- Alkali Fins

- Rainbow Fin Co.

- Island Fin Design

- 3DFins

- Glide Fins

- Powerblade

- Solite

- Naked Viking Surf

- Boardworks

- Black Project Fins

Frequently Asked Questions

Analyze common user questions about the Surfboard Skeg market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary types of surfboard skegs?

Surfboard skegs are primarily categorized by the number of fins: single fins for classic stability, twin fins for looseness and speed, thrusters (three fins) for a balance of drive and maneuverability, quad fins for speed and hold, and 5-fin sets offering versatile configurations. Each type is designed to optimize performance for specific board types, wave conditions, and surfing styles.

How do different skeg materials impact performance?

Skeg materials significantly affect performance. Fiberglass offers a balanced flex, ideal for all-around surfing. Carbon fiber provides increased stiffness and responsiveness for high-performance maneuvers. Plastic fins are durable and cost-effective, suitable for beginners. Composite materials blend properties for specific flex patterns, optimizing drive and feel. The material choice influences a fin's flex, weight, and durability, directly impacting speed, control, and turning response.

What is the best fin setup for a beginner surfer?

For beginner surfers, a thruster (three-fin) setup is generally recommended due to its excellent balance of stability, control, and maneuverability. This configuration provides a predictable and forgiving ride, making it easier to learn turning techniques and maintain balance on the wave. Often, molded plastic or composite fins are preferred for their durability and affordability, as beginners are more prone to impacts.

How do I choose the right fin system for my surfboard?

Choosing the right fin system depends on your surfboard's fin boxes. The most common systems are FCS and Futures Fins, which are not interchangeable. FCS offers various plug types (FCS I, FCS II) for different fin bases, while Futures uses a single-tab system. Longboards typically use a US Box system for their larger single fins. It is crucial to match the fin system to your board's existing fin boxes to ensure proper fit and performance.

Are sustainable or eco-friendly surfboard skegs available in the market?

Yes, the market for sustainable surfboard skegs is growing. Manufacturers are increasingly exploring eco-friendly materials such as bio-resins, recycled plastics, and sustainably sourced wood (e.g., bamboo, balsa) to reduce environmental impact. These options aim to offer comparable performance while minimizing the carbon footprint associated with traditional composite materials, catering to environmentally conscious surfers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager