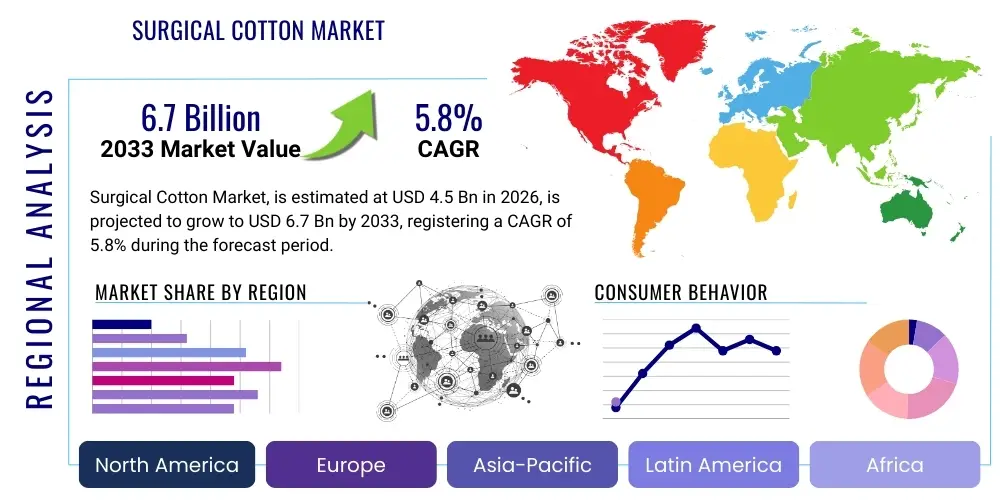

Surgical Cotton Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436087 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Surgical Cotton Market Size

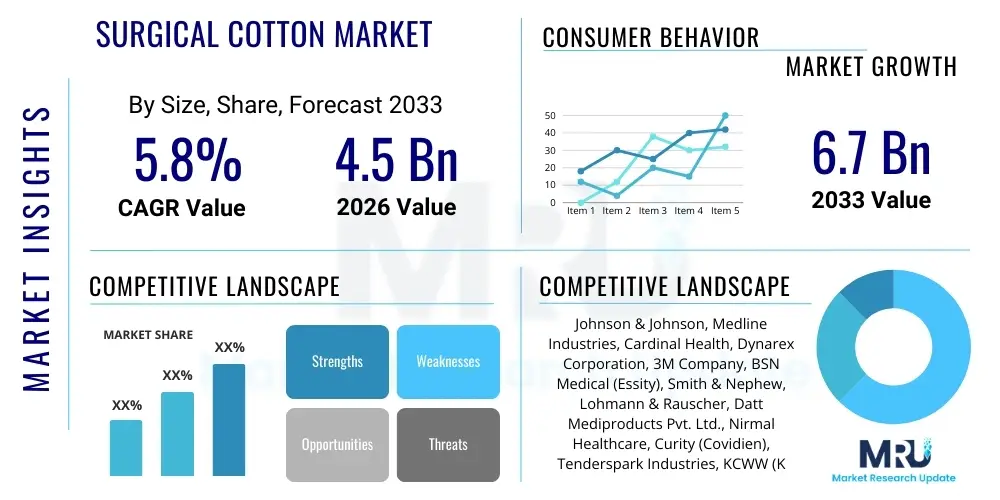

The Surgical Cotton Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Surgical Cotton Market introduction

The Surgical Cotton Market encompasses the production, distribution, and utilization of sterilized, absorbent cotton materials specifically designed for medical, surgical, and therapeutic applications. This indispensable product serves as a primary material in wound dressing, sterilization procedures, padding, absorption of exudates, and general patient care across various healthcare settings. Demand is intrinsically linked to global healthcare expenditure, the volume of surgical procedures performed, and the rising prevalence of chronic wounds and trauma cases requiring reliable wound management solutions. The continuous focus on infection control and patient safety standards within hospitals and clinics drives the requirement for high-quality, sterile surgical cotton products that adhere to stringent regulatory guidelines such as those set by the FDA and ISO.

Surgical cotton, often referred to as absorbent cotton wool, is typically manufactured from 100% pure cotton fibers that have been processed to remove impurities, waxes, and fatty matter, enhancing their water absorbency properties significantly. Major applications include usage in operating rooms for absorbing blood and bodily fluids, in outpatient departments for cleaning and swabbing, and in home care settings for basic first aid and dressing changes. The increasing geriatric population, which frequently requires extended care and wound management, coupled with the expansion of healthcare infrastructure in emerging economies, are pivotal factors driving market growth and product innovation within this sector, particularly concerning enhanced sterilization techniques and environmentally sustainable sourcing.

The core benefits derived from surgical cotton include its superior absorbency, softness, hypoallergenic nature, and cost-effectiveness compared to synthetic alternatives. Driving factors for the market expansion are multifaceted, spanning from technological advancements in processing to improve tensile strength and absorbency rates, to public health initiatives promoting hygiene and safe wound care practices. Furthermore, the rising incidence of road traffic accidents and sports injuries globally necessitates constant supplies of surgical cotton for immediate trauma care. Manufacturers are focusing on differentiating their offerings through packaging innovations (e.g., pre-cut rolls, precision-sized balls) and ensuring traceability throughout the supply chain to maintain high standards of quality assurance and regulatory compliance.

Surgical Cotton Market Executive Summary

The Surgical Cotton Market demonstrates robust growth driven primarily by increasing surgical volumes and the pervasive need for infection prevention materials in healthcare facilities worldwide. Business trends indicate a shift towards vertically integrated supply chains, allowing major players to control raw material quality and sterilization standards more effectively. Furthermore, significant investment is observed in automation and advanced purification technologies to enhance the final product's absorbency and minimize lint generation. Companies are also strategically focusing on achieving global certifications, thereby facilitating market entry into regulated regions like North America and Europe, while simultaneously exploring growth opportunities in high-volume, price-sensitive markets in Asia Pacific and Latin America through optimized production scaling.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, propelled by rapidly improving healthcare access, substantial government investment in public health infrastructure, and a massive patient pool. North America and Europe, while mature, maintain dominance in terms of value, driven by high per capita healthcare spending and strict adherence to premium, sterile product standards. Key challenges faced across all regions include volatility in raw cotton prices and the environmental pressures associated with cotton farming and bleaching processes, pushing manufacturers toward adopting more sustainable, closed-loop production models and biodegradable packaging alternatives.

Segmentation trends reveal that the Absorbent Cotton Wool segment retains the largest market share due to its broad application spectrum in general surgery and wound care. However, the pre-packaged cotton balls and applicators segment is experiencing accelerated growth, largely attributed to their convenience, guaranteed sterility, and ease of use in clinical and home settings, aligning with the growing trend of decentralized healthcare. The Hospital segment remains the primary end-user, though the demand emanating from Ambulatory Surgical Centers (ASCs) and specialized wound care clinics is rapidly expanding, necessitating tailored product sizes and packaging configurations from market leaders to meet these specialized needs.

AI Impact Analysis on Surgical Cotton Market

User queries regarding the impact of Artificial Intelligence (AI) on the Surgical Cotton Market typically revolve around operational efficiency, quality control, and supply chain predictability rather than direct product transformation, as surgical cotton is a fundamental, low-tech medical consumable. Key user themes include how AI can optimize raw cotton procurement amid volatile prices, whether AI-driven quality checks can surpass human inspection in identifying impurities or lint, and the potential for predictive maintenance and automated inventory management in high-volume manufacturing facilities. Users are particularly interested in how AI integration, specifically machine vision and predictive analytics, can ensure ultra-high sterility standards and compliance with increasingly complex global medical device regulations, thereby minimizing recall risks and operational downtime inherent in large-scale production.

While AI will not change the intrinsic function of cotton, its role lies significantly in upstream manufacturing and logistics. AI algorithms can analyze vast datasets concerning climate patterns, harvest yields, and commodity pricing, allowing procurement managers to make optimal purchasing decisions, thus mitigating financial risks associated with raw material cost fluctuations. Furthermore, implementing AI-powered computer vision systems along the production line enables 24/7 real-time monitoring of fiber density, bleaching effectiveness, and contamination levels with unparalleled precision, ensuring that only materials meeting the highest surgical grade standards proceed to sterilization and packaging, thereby reducing waste and enhancing product consistency.

Downstream, AI contributes to enhanced supply chain resilience. Predictive analytics can forecast demand peaks based on surgical scheduling trends, seasonal illness patterns, and demographic changes, enabling manufacturers and distributors to optimize inventory levels and distribution routes. This ensures that critical supplies of surgical cotton reach hospitals promptly, preventing stockouts, especially during public health crises. The integration of AI tools assists in automating regulatory reporting and documentation processes, which are critical for maintaining the high-compliance status required in the medical consumables sector, particularly in controlled markets like North America and Western Europe, leading to significant administrative cost savings.

- AI optimizes raw material procurement by predicting commodity price volatility.

- Machine vision systems enhance quality control by identifying microscopic impurities and density inconsistencies in real-time.

- Predictive maintenance minimizes operational downtime in high-speed manufacturing and sterilization processes.

- AI-driven demand forecasting improves inventory management and supply chain responsiveness for critical hospital consumables.

- Automation of regulatory compliance documentation accelerates time-to-market for certified surgical products.

- Optimization of energy usage and water treatment in the bleaching and purification stages through smart control systems.

DRO & Impact Forces Of Surgical Cotton Market

The dynamics of the Surgical Cotton Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively determine the overall market trajectory and competitive landscape. Key drivers include the global demographic shift toward an aging population, which necessitates more frequent and complex surgical interventions and extended wound care management, thereby consistently escalating the demand for absorbent medical supplies. Simultaneously, the persistent threat of Healthcare-Associated Infections (HAIs) reinforces the necessity for high-quality, sterile consumables, placing pressure on healthcare providers to utilize certified surgical cotton products. These external forces generate substantial momentum for market expansion, particularly within institutional healthcare segments.

Conversely, the market faces significant restraints, primarily revolving around the intrinsic dependency on volatile agricultural commodities. Fluctuations in raw cotton prices, influenced by weather patterns, geopolitical instability, and agricultural subsidies, pose substantial challenges to manufacturers' profit margins and pricing stability. Furthermore, growing environmental consciousness worldwide exerts pressure on the industry to transition away from traditional chemical bleaching processes and to manage the large volume of non-biodegradable medical waste generated by usage. The increasing adoption of synthetic or advanced non-woven materials in specialized surgical procedures also presents a long-term competitive restraint, potentially displacing conventional cotton in niche, high-value applications requiring superior fluid dynamics or barrier properties.

Opportunities for growth are concentrated in geographic expansion into emerging markets, where healthcare spending is rapidly increasing and basic infrastructure development is still underway, leading to high consumption rates of essential disposables. Technological opportunities lie in developing innovative, cost-effective sterilization techniques, such as irradiation sterilization, and creating environmentally friendly alternatives, including organic or recycled cotton fibers, addressing sustainability concerns. The market can also capitalize on the growing prevalence of chronic diseases like diabetes, which require daily wound management supplies, by developing specialized, consumer-friendly packaged surgical cotton products suitable for long-term home use, bridging the gap between clinical and self-care requirements.

Segmentation Analysis

The Surgical Cotton Market is comprehensively segmented based on Type, Application, Material, and Distribution Channel, allowing for detailed market assessment and strategic targeting. This segmentation provides stakeholders with granular insights into the areas of highest growth potential and specific product requirements tailored to diverse end-user needs. The Type segment is critical, differentiating between highly absorbent processed materials used in procedures and less processed or blended cotton used for padding or non-critical applications. Application segmentation reflects the ultimate consumption setting, which profoundly influences packaging, sterility requirements, and purchase volumes, with hospitals commanding the largest but most price-sensitive procurement contracts, while specialized clinics prioritize convenience and niche material specifications.

The Material segmentation addresses the purity and composition of the cotton used, which is vital for product efficacy and hypoallergenic properties. While 100% pure absorbent cotton dominates the surgical field, blends sometimes feature in lower-cost or specific padding products. Analysis of the Distribution Channel segment is essential for understanding market access and logistics, distinguishing between direct sales to large hospital groups, reliance on third-party medical distributors, and the burgeoning e-commerce channel facilitating home care purchases. Understanding these segments is key to optimizing manufacturing scale, inventory placement, and marketing strategies for competitive advantage.

- Type:

- Absorbent Cotton Wool (Gauze Rolls, Floss, Plasters)

- Non-Absorbent Cotton

- Pre-packaged Cotton Balls and Swabs

- Application:

- Hospitals and Clinics

- Ambulatory Surgical Centers (ASCs)

- Home Care and First Aid

- Specialized Wound Care Centers

- Material:

- 100% Pure Surgical Grade Cotton

- Cotton/Synthetic Blends (for specific padding)

- Organic Cotton

- Distribution Channel:

- Direct Sales

- Distributors and Wholesalers

- Retail Pharmacies and Drug Stores

- Online Sales Channels

Value Chain Analysis For Surgical Cotton Market

The value chain for the Surgical Cotton Market is lengthy and highly scrutinized due to the critical nature of the final medical product, starting from raw agricultural input and culminating in clinical application. Upstream analysis focuses intensely on raw cotton cultivation and harvesting. Key challenges at this stage include ensuring consistent fiber quality, managing pesticide residue levels, and navigating the inherent volatility of commodity markets. Manufacturers must secure reliable sourcing contracts, often involving long-term agreements with large cotton producers or specialized co-operatives that guarantee purity and sustainable farming practices, minimizing supply chain disruptions before the material even enters the processing stage. The cost and quality of the raw fiber fundamentally dictate the pricing and efficacy of the final surgical product.

The midstream phase involves complex and capital-intensive manufacturing processes, including ginning, purification, bleaching (to remove waxes and achieve high whiteness), and sterilization. This stage is dominated by large-scale processing facilities that utilize sophisticated machinery and adhere to strict Good Manufacturing Practices (GMP). Sterilization, often achieved through E-beam, gamma irradiation, or ethylene oxide (ETO), is the most critical quality control point, ensuring the final product meets medical-grade sterility standards. Efficiency in these processes, particularly water usage and chemical management during bleaching, directly impacts production costs and the manufacturer's environmental footprint, which is an increasing area of stakeholder concern.

The downstream segment involves packaging, distribution, and end-user delivery. Distribution channels are bifurcated into direct sales, favored by global medical device giants for large hospital networks and government tenders, and indirect sales, utilizing regional medical supply distributors who handle smaller clinics, pharmacies, and the burgeoning home care market. Effective logistics management is paramount, as the product is bulky yet low-cost per unit, demanding efficient warehousing and transportation networks. Direct channels ensure greater control over pricing and inventory, while indirect channels offer broader geographical reach and local market penetration necessary for market saturation across diverse healthcare ecosystems.

Surgical Cotton Market Potential Customers

Potential customers for the Surgical Cotton Market are diverse, encompassing institutional healthcare providers, specialized clinics, governmental agencies, and general consumers. Hospitals, particularly large tertiary and quaternary care facilities with high surgical caseloads, represent the primary and most significant end-user group. These institutions procure vast quantities of surgical cotton in bulk forms (large rolls and bales) for use across operating rooms, intensive care units (ICUs), emergency departments, and general wards, driven by continuous patient turnover and stringent hygiene protocols. Procurement decisions in this sector are highly centralized and focused on achieving optimal pricing through volume-based tenders, alongside non-negotiable quality and sterility certifications.

Ambulatory Surgical Centers (ASCs) and specialized clinics (e.g., orthopedic, dermatology, dental) form another crucial customer base. While their volume of purchases is typically lower than large hospitals, their product requirements are often more specific, favoring pre-cut, sterile swabs, balls, and specialized packaging that minimizes waste and improves procedural efficiency. These facilities often prioritize ease of use and consistent supply reliability, making them attractive targets for manufacturers offering convenient, ready-to-use product configurations suitable for high-throughput, standardized procedures, often procured through regional medical distributors specializing in outpatient care supplies.

The third major customer segment includes the rapidly expanding Home Care setting and Retail Consumers. Driven by the increasing shift of post-operative care and chronic wound management (e.g., diabetic foot ulcers) out of hospitals, consumers require sterile cotton products in smaller, retail-friendly packaging formats (e.g., small rolls, packaged cotton balls, first aid kits). Pharmacies, drug stores, and online retail platforms serve as the main purchasing points for this segment. Government agencies, including military hospitals, public health departments, and disaster relief organizations, also represent substantial customers, especially during public health emergencies, requiring rapid mobilization of sterilized consumables and often utilizing specialized national procurement frameworks.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Johnson & Johnson, Medline Industries, Cardinal Health, Dynarex Corporation, 3M Company, BSN Medical (Essity), Smith & Nephew, Lohmann & Rauscher, Datt Mediproducts Pvt. Ltd., Nirmal Healthcare, Curity (Covidien), Tenderspark Industries, KCWW (Kimberly-Clark), B Braun Melsungen AG, Premier Gynaecology and Surgical, Paul Hartmann AG, GAUZE SA, Gujarat Cotton, Rauscher. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Surgical Cotton Market Key Technology Landscape

The technology landscape in the Surgical Cotton Market is primarily focused on enhancing product purity, absorbency metrics, and sterility assurance, rather than disruptive material science changes. A key technological area is the optimization of the purification and bleaching process. Modern manufacturers employ advanced continuous processing lines utilizing environmentally friendlier agents (like hydrogen peroxide) instead of chlorine-based compounds, moving towards Elemental Chlorine-Free (ECF) and Totally Chlorine-Free (TCF) methodologies. These methods not only reduce the environmental impact but also ensure the residual chemical load in the final product is minimal, addressing increasing regulatory standards for medical consumables and minimizing the risk of skin irritation in patients.

Sterilization technology forms the second critical pillar. While Ethylene Oxide (ETO) and Autoclaving remain prevalent, there is a growing trend toward high-energy sterilization techniques, specifically Gamma Irradiation and Electron Beam (E-beam) sterilization. E-beam technology offers advantages such as shorter processing times and reduced environmental concerns compared to ETO, ensuring a highly reliable Sterility Assurance Level (SAL) required for surgical applications. Manufacturers invest heavily in validating these sterilization cycles using biological indicators and sophisticated dosimetry systems to guarantee product safety and regulatory compliance across international markets, often collaborating with specialized third-party sterilization service providers.

Furthermore, technology is applied heavily in automated packaging and quality control. High-speed, automated production lines are essential for maintaining sterile barriers and accommodating the vast volumes required by the market. Machine vision systems, integrated with AI, are deployed to perform real-time surface quality checks, lint detection, and foreign object exclusion, far surpassing the speed and consistency of manual inspection. Innovations in packaging focus on creating peel-open pouches and resealable containers that maintain the sterile barrier integrity until the point of use, improving procedural safety and reducing material contamination in demanding surgical environments, thereby adding crucial value in terms of workflow efficiency.

Regional Highlights

The global distribution of the Surgical Cotton Market shows distinct regional dominance and accelerating growth dynamics, heavily influenced by regional healthcare policies, economic development, and population demographics. North America, specifically the United States, commands a significant market share by value, driven by high per capita healthcare spending, the presence of major global market players, and exceptionally rigorous quality and regulatory standards demanding premium, certified surgical consumables. The focus here is on convenience products (pre-packaged swabs, rolls) for efficient clinical workflow, alongside constant innovation in sterilization and packaging to meet stringent FDA requirements, which often set the global benchmark for surgical product quality.

Europe represents another mature and substantial market, characterized by universal healthcare systems and a strong emphasis on sustainability and environmentally sound manufacturing practices, especially in Western European countries like Germany and the UK. The market growth is stable, underpinned by an aging population and consistent surgical volumes. European Union (EU) regulations, particularly the Medical Device Regulation (MDR), dictate strict requirements for product traceability and clinical safety, influencing manufacturers to invest in advanced quality management systems and detailed product documentation to maintain market access across the continent.

Asia Pacific (APAC) is projected to be the engine of future market expansion, exhibiting the highest Compound Annual Growth Rate (CAGR). This explosive growth is attributed to rapid urbanization, massive investment in healthcare infrastructure (especially in China and India), and the escalating patient population requiring surgical and long-term wound care. While price sensitivity is generally higher in APAC than in Western markets, the sheer volume of consumption and the increasing acceptance of Western-standard medical protocols are creating significant opportunities for both international and local manufacturers to scale production and establish deep regional distribution networks.

- North America: Dominant market share by value, characterized by high spending, strict regulatory framework (FDA), and high adoption of pre-packaged, sterile cotton products.

- Europe: Mature market focusing on premium quality and stringent EU Medical Device Regulation (MDR) compliance, with increasing demand for sustainable and environmentally certified products.

- Asia Pacific (APAC): Fastest-growing region driven by massive population growth, expanding healthcare access, infrastructure development, and increasing surgical procedure volumes in India and China.

- Latin America: Emerging market with growth tied to increasing private healthcare investment and modernization of hospital facilities, often relying on imported certified materials.

- Middle East & Africa (MEA): Growth fueled by rising medical tourism and substantial government investment in high-standard medical facilities, particularly in the Gulf Cooperation Council (GCC) countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Surgical Cotton Market.- Johnson & Johnson

- Medline Industries

- Cardinal Health

- Dynarex Corporation

- 3M Company

- BSN Medical (Essity)

- Smith & Nephew

- Lohmann & Rauscher

- Datt Mediproducts Pvt. Ltd.

- Nirmal Healthcare

- Curity (Covidien)

- Tenderspark Industries

- KCWW (Kimberly-Clark)

- B Braun Melsungen AG

- Premier Gynaecology and Surgical

- Paul Hartmann AG

- GAUZE SA

- Gujarat Cotton

- Rauscher

Frequently Asked Questions

Analyze common user questions about the Surgical Cotton market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between surgical cotton and regular cotton?

Surgical cotton, or absorbent cotton wool, undergoes rigorous processing including deep purification and bleaching to remove natural oils, waxes, and impurities, making it highly absorbent and medically sterile. Regular cotton lacks this sterilization and high-absorbency processing.

Which region dominates the consumption of surgical cotton globally?

North America currently holds the largest market share in terms of value, primarily due to high healthcare expenditure and stringent regulatory requirements for certified medical consumables. However, Asia Pacific is projected to show the highest growth rate due to rapid healthcare expansion.

What factors restrain the growth of the Surgical Cotton Market?

The main restraints include the volatility in raw cotton prices, which directly impacts manufacturing costs and profit margins, and increasing environmental concerns related to the chemical bleaching process and the generation of medical waste.

How is technology impacting the quality control of surgical cotton production?

Technology, particularly the implementation of AI-powered machine vision systems, is used to conduct real-time, precise inspections during manufacturing to detect microscopic impurities, assess fiber density, and ensure consistent material quality before sterilization, significantly improving reliability.

What are the most common sterilization methods used for surgical cotton products?

The most common and preferred sterilization techniques used to achieve medical-grade sterility are Ethylene Oxide (ETO) sterilization, Gamma Irradiation, and Electron Beam (E-beam) processing, ensuring a high Sterility Assurance Level (SAL) compliant with global standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager