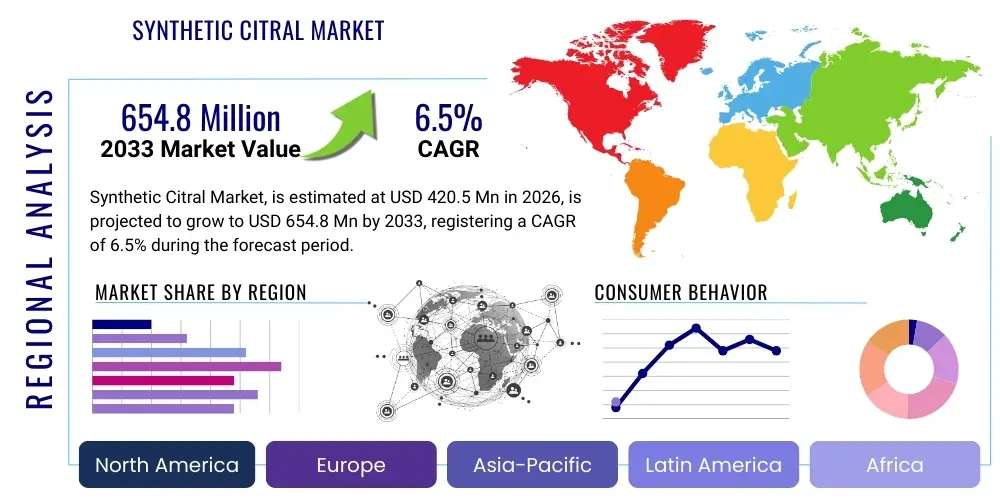

Synthetic Citral Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435774 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Synthetic Citral Market Size

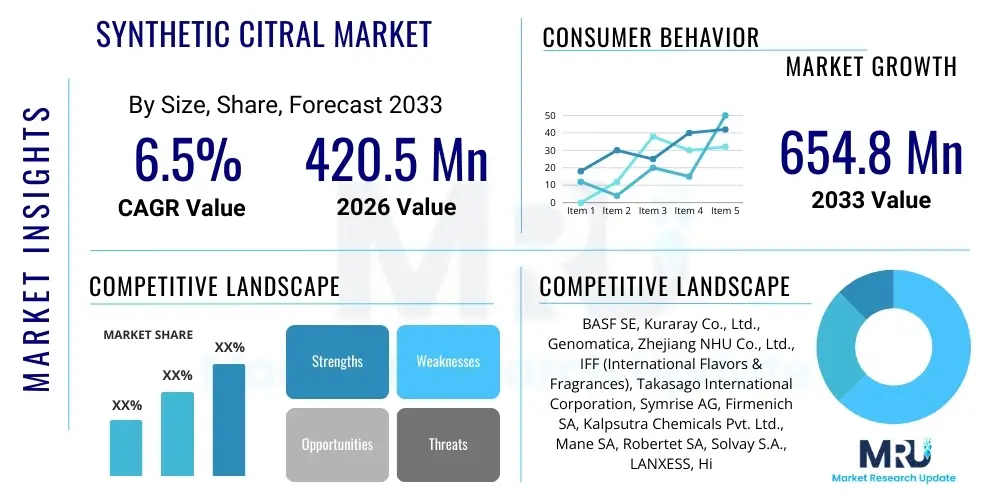

The Synthetic Citral Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. This robust growth is fueled by increasing applications across the flavor and fragrance industry, coupled with its critical role as an intermediate in synthesizing essential vitamins like Vitamin A and E. The market dynamic is shifting towards stable, high-purity synthetic variants due to inconsistencies and high costs associated with natural citral sourcing, ensuring steady supply for large industrial consumers globally.

The market is estimated at $420.5 Million USD in 2026, driven primarily by demand from pharmaceutical and nutraceutical sectors that require standardized chemical inputs. Technological advancements in catalytic processes, which enhance yield and reduce production costs, are key accelerators for market expansion, particularly in high-volume manufacturing hubs located in Asia Pacific. The necessity for reliable, non-GMO sourced fragrance materials further solidifies the position of synthetic citral.

The Synthetic Citral Market is projected to reach $654.8 Million USD by the end of the forecast period in 2033. This substantial increase reflects the broadening application base, including its use in personal care products, household cleaners, and increasingly, in specialized industrial solvents. Furthermore, rising disposable incomes in developing economies are stimulating the consumption of high-end scented and flavored consumer goods, directly driving the underlying demand for synthetic citral derivatives.

Synthetic Citral Market introduction

Synthetic Citral, an acyclic monoterpene aldehyde, is a pivotal chemical intermediate widely recognized for its strong lemon scent and flavor characteristics. Chemically, it exists as a mixture of two stereoisomers: geranial (trans-citral or citral A) and neral (cis-citral or citral B). The synthetic variant is typically produced through various complex chemical syntheses, predominantly utilizing feedstocks such as isobutylene and formaldehyde or derivatives of turpentine, offering superior purity, cost-effectiveness, and supply stability compared to its natural counterpart derived from lemongrass or litsea cubeba oils. This reliability makes synthetic citral the preferred choice for large-scale industrial applications requiring consistent chemical specifications.

The primary applications of synthetic citral span across crucial industrial verticals. It serves as a foundational building block for synthesizing vital vitamins, specifically Vitamin A, Vitamin E, and carotenoids, making it indispensable to the pharmaceutical and nutraceutical industries. In the flavor and fragrance sector, citral is directly used for imparting citrus notes to perfumes, cosmetics, soaps, detergents, and food and beverage products. Beyond these core areas, it is also utilized in the synthesis of ionones and methylionones, which are themselves highly valued fragrance chemicals, demonstrating its foundational role in the aroma chemical value chain.

Key drivers propelling the Synthetic Citral Market include the escalating global demand for fragrances and flavors in consumer products, fueled by urbanization and lifestyle changes. The advantages of synthetic production—namely, stable pricing, high purity levels, and independence from volatile agricultural yields—provide a significant competitive edge over natural alternatives. Furthermore, increasing regulatory scrutiny on the supply chain and purity of raw materials in the pharmaceutical industry strongly favors the adoption of standardized synthetic chemicals, ensuring robust and sustained market growth throughout the forecast period.

Synthetic Citral Market Executive Summary

The Synthetic Citral Market is characterized by intense competition among global aroma chemical manufacturers, with distinct business trends highlighting strategic mergers, capacity expansions, and a growing focus on sustainable synthesis pathways. Major players are investing heavily in optimizing production yields and reducing energy consumption to maintain cost leadership in a highly price-sensitive market. Regional growth dynamics show Asia Pacific leading both production capacity and consumption, driven by rapid expansion in its domestic flavor, fragrance, and livestock feed industries (which utilize Vitamin A synthesized from citral). Europe and North America maintain significant consumption shares, particularly in high-value cosmetic and pharmaceutical applications where stringent quality standards necessitate high-purity synthetic inputs. Overall, the market remains moderately consolidated, dominated by a few major integrated chemical companies.

Segment trends indicate that the application segment is witnessing the most dynamic shifts, with Vitamin Synthesis maintaining the largest revenue share due to the essential nature of Vitamin A in human and animal nutrition. However, the Flavor & Fragrance segment is projected to exhibit the highest CAGR, propelled by the rising trend of sophisticated and unique scent profiles in premium consumer goods. Geographically, while APAC dictates volume, regulatory harmonization efforts across the EU and North America are shaping product standards globally. Investment flow is concentrated on developing alternative, greener synthesis routes, potentially utilizing biotechnological processes, although traditional chemical synthesis remains dominant due to established infrastructure and cost advantages. Supply chain resilience has become a critical focus point following global disruptions.

Technological advancements are driving improved efficiency, primarily through enhanced catalyst design and continuous flow processing, which minimizes waste and increases throughput. These innovations directly contribute to margin improvement for manufacturers. The shift towards biosourced alternatives, though nascent, represents a long-term opportunity, mitigating reliance on petrochemical feedstocks. Regulatory landscapes, particularly those pertaining to chemical safety and usage limits in food contact materials and cosmetics, significantly influence market penetration strategies across different regions. Strategic partnerships between chemical suppliers and major end-users (e.g., large vitamin manufacturers) are common mechanisms for securing long-term supply contracts and managing demand volatility effectively.

AI Impact Analysis on Synthetic Citral Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) in the Synthetic Citral Market center on optimizing complex chemical reaction parameters, enhancing predictive maintenance of large-scale synthesis plants, and accelerating the discovery of novel, high-efficiency catalysts. Users are keenly interested in how machine learning algorithms can manage the intricate, multi-step synthesis pathways of citral, specifically aiming to maximize the yield of desired isomers (geranial/neral) while minimizing unwanted by-products, which directly impacts purity and cost. Furthermore, inquiries frequently touch upon AI's potential in supply chain forecasting, predicting volatile feedstock pricing (such as isobutylene or pinene), and optimizing inventory levels across global distribution networks to mitigate risk associated with geopolitical instability or logistical delays. The overriding theme is the expectation that AI will be a core tool for achieving operational excellence, sustainability, and higher margins in a competitive industrial chemical landscape.

- AI-driven optimization of catalytic processes accelerates reaction kinetics and enhances isomer selectivity, improving product purity and yield.

- Machine learning models predict feedstock price volatility and demand fluctuations, enabling proactive procurement strategies and inventory management.

- AI is employed in predictive maintenance for complex chemical reactors and separation equipment, minimizing unplanned downtime and operational costs.

- Data analytics leverage consumer trends and regional preference data to forecast demand for flavor and fragrance derivatives, optimizing production schedules.

- Automated quality control systems utilize computer vision and spectroscopic data interpretation, ensuring consistent synthetic citral specifications rapidly and accurately.

DRO & Impact Forces Of Synthetic Citral Market

The Synthetic Citral Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively acting as critical impact forces shaping its trajectory. The primary driver is the exponentially increasing global demand for Vitamin A and E, particularly in the nutraceutical and animal feed industries, where citral serves as a critical, irreplaceable precursor. This demand is intrinsically linked to population growth and the rising awareness of nutritional supplements. Concurrently, the fragrance and flavor industry's continuous expansion into emerging markets, alongside the consumer shift toward complex scent profiles, further cements the market’s growth momentum. However, this growth is substantially restrained by the high volatility in the pricing and availability of petrochemical raw materials, such as isobutylene, which are subject to global oil market fluctuations, directly impacting production costs and profitability margins across the value chain. Moreover, increasingly stringent regulatory standards regarding residual impurities and environmental impact pose ongoing operational and investment challenges for manufacturers.

Key opportunities exist in the increasing focus on developing sustainable and bio-based production routes for citral, utilizing renewable resources or advanced microbial fermentation techniques. While currently expensive, these bio-based methods offer a path towards supply chain independence from fossil fuels and cater to the rising consumer demand for 'green' chemicals and ingredients, providing a long-term differentiation strategy. Another potent opportunity lies in the rapid industrialization and escalating consumption power within the Asia Pacific region, particularly China and India, which are not only major production hubs but also exponentially growing consumer markets for finished goods containing citral derivatives. The integration of advanced process technology, such as microreactor technology, offers opportunities to enhance safety, reduce waste, and improve reaction efficiency, thereby strengthening the competitive positioning of synthetic citral manufacturers against natural sources.

The combined impact forces dictate that manufacturers must pursue backward integration to secure feedstock supply while simultaneously investing in R&D for cost-effective, sustainable synthesis methods. The market exhibits high bargaining power among key suppliers of primary raw materials, necessitating strategic long-term contracts. Regulatory compliance, particularly REACH in Europe and similar chemical inventory regulations in APAC, remains a constant force, mandating continuous investment in product stewardship and safety documentation. Ultimately, success in this market relies on balancing the pressure of cost leadership (driven by restraints) with the imperative of securing high-quality supply for critical, non-negotiable applications (driven by pharmaceutical and vitamin synthesis demand).

Segmentation Analysis

The Synthetic Citral Market is comprehensively segmented based on its primary application, production process, and the chemical nature of its derivatives, providing a nuanced understanding of industry revenue streams and growth pockets. Segmentation by application clearly defines the primary economic drivers, differentiating between high-volume, cost-sensitive uses like detergents and high-value, quality-critical uses such as pharmaceutical synthesis. Furthermore, process segmentation highlights the technological landscape, contrasting traditional multi-step chemical routes (like those starting from isobutylene/formaldehyde or pinene) with emerging bio-based alternatives, which are poised for future penetration as sustainability pressures mount globally. This granular approach is essential for market participants to tailor their operational capabilities and commercial strategies effectively toward the most lucrative and rapidly evolving sectors of the industry.

- By Application:

- Vitamin Synthesis (Vitamin A, Vitamin E)

- Flavor & Fragrance (Perfumes, Cosmetics, Soaps, Detergents)

- Aroma Chemicals Synthesis (Ionones, Methylionones)

- Pharmaceuticals and Nutraceuticals

- Industrial Solvents and Specialty Chemicals

- By Manufacturing Process:

- Isobutylene/Formaldehyde Route (e.g., Kuraray/BASF Process)

- Pinene Route (Terpene Derivatives)

- Bio-based Synthesis (Emerging)

- By Product Type:

- Geranial (Citral A)

- Neral (Citral B)

- Citral Mixture (A/B Combination)

Value Chain Analysis For Synthetic Citral Market

The synthetic citral value chain begins with the upstream procurement of essential petrochemical feedstocks, primarily isobutylene, formaldehyde, or natural pinene derivatives in the case of terpene-based synthesis. This phase is capital intensive and highly sensitive to global oil and gas market dynamics, where a few integrated petrochemical giants often dominate supply, exerting significant pricing pressure. The manufacturing stage involves complex, multi-step chemical synthesis processes, requiring specialized catalytic reactors and purification equipment. Efficiency in this stage, often measured by yield and isomer purity, determines the final product cost and market suitability. Major manufacturers often pursue backward integration to secure feedstock stability and reduce reliance on external suppliers, enhancing competitive insulation.

Downstream analysis reveals that synthetic citral primarily moves into two critical intermediate synthesis pathways: the production of specialized aroma chemicals (such as ionones, utilized extensively in premium fragrances) and, crucially, the large-scale synthesis of fat-soluble vitamins (Vitamin A and E). Companies specializing in vitamin manufacturing constitute the largest bulk purchasers, driving demand volume. The flavor and fragrance industry, comprising large F&F houses and smaller bespoke producers, represents a high-value, consistent demand segment, requiring stringent quality control and technical support from citral suppliers.

Distribution channels for synthetic citral are segmented into direct and indirect routes. Direct sales are common for high-volume transactions with major pharmaceutical and large flavor and fragrance corporations, ensuring technical partnership and consistent supply logistics managed by the producer. Indirect channels rely on global chemical distributors and regional agents, particularly for serving smaller end-users, specialty chemical blenders, and regional manufacturers in diverse geographic locations. Given the product's classification as a chemical, specialized handling, storage, and regulatory compliance are essential factors influencing the choice and efficiency of the distribution network, ensuring product integrity until it reaches the final buyer.

Synthetic Citral Market Potential Customers

The potential customer base for synthetic citral is broad, encompassing several large-scale industrial sectors where the chemical serves as either a fundamental precursor or a direct functional ingredient. The most critical customers are large pharmaceutical and nutraceutical companies that rely on high-purity citral for the synthesis of Vitamin A (retinol) and Vitamin E (tocopherol), vital ingredients in dietary supplements, fortified foods, and animal feed formulations. These end-users demand rigorous batch consistency and compliance with pharmacopoeial standards (USP/EP), driving the market's emphasis on high-quality synthetic production processes.

Another major buyer segment consists of international Flavor and Fragrance (F&F) houses, which utilize citral extensively to formulate lemon and citrus notes in consumer products, including fine perfumes, body care products, and industrial detergents. These customers are sensitive to price but prioritize consistency, odor profile, and safety certifications. Furthermore, specialty chemical manufacturers that use citral as an intermediate to create downstream aroma chemicals, such as ionones and pseudionones, also represent substantial, steady demand, feeding the wider cosmetics and consumer goods supply chains. Given its versatility, the agricultural sector, specifically animal feed manufacturers, constitutes a high-volume, cost-focused customer group due to the essential incorporation of Vitamin A precursors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $420.5 Million USD |

| Market Forecast in 2033 | $654.8 Million USD |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Kuraray Co., Ltd., Genomatica, Zhejiang NHU Co., Ltd., IFF (International Flavors & Fragrances), Takasago International Corporation, Symrise AG, Firmenich SA, Kalpsutra Chemicals Pvt. Ltd., Mane SA, Robertet SA, Solvay S.A., LANXESS, Hindustan Mint & Agro Products Pvt. Ltd., Privi Organics Limited, Swati Menthol & Allied Chemicals Ltd., Spectrum Chemical Manufacturing Corp., Sigma-Aldrich (Merck KGaA), Axxence Aromatic GmbH, Ernesto Ventós S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Synthetic Citral Market Key Technology Landscape

The manufacturing technology for synthetic citral is highly sophisticated, revolving primarily around multi-step chemical synthesis routes that demand precise process control and specialized catalytic systems. The predominant industrial method globally is the isobutylene/formaldehyde route, often referred to as the Kuraray or BASF process variants. This technology involves complex steps, typically starting with the synthesis of isoprene, followed by dimerization and oxidation processes. The core technological advantage of this route is high throughput and scalability, ensuring reliable supply volume. However, continuous research focuses on improving catalyst longevity and selectivity to maximize the yield of the desired isomer (geranial) while minimizing energy input and by-product formation, addressing both cost and sustainability goals.

Another significant, though generally smaller, route involves the utilization of pinene, derived from turpentine, often prevalent in regions with abundant forest resources. This terpene-based method involves isomerization and oxidation steps. While offering a semi-natural feedstock base, the chemical process can sometimes yield lower purity or higher levels of undesired isomers compared to the highly controlled petrochemical routes. Innovation in this area centers on enhancing catalytic conversion efficiency and developing novel separation techniques to isolate high-purity citral efficiently from the complex reaction mixture. Furthermore, the increasing pressure for green chemistry has spurred R&D into supercritical fluid extraction and membrane separation technologies for final product purification, minimizing the use of traditional, solvent-intensive methods.

The most transformative area of technological development is the nascent field of bio-based synthesis. Companies like Genomatica and others are pioneering fermentation technologies where genetically engineered microorganisms (e.g., yeast or bacteria) produce citral or its precursors directly from renewable sugars. While not yet economically competitive with established chemical routes for bulk production, this technology represents the future of sustainable aroma chemical manufacturing, addressing consumer preference for natural-identical and environmentally friendly ingredients. Significant investment is directed towards scaling up these bio-processes, reducing production costs, and ensuring regulatory acceptance, ultimately positioning bio-based technology as a critical long-term disruptor in the synthetic citral market landscape.

Regional Highlights

The Synthetic Citral Market exhibits pronounced regional variances in terms of production capacity, consumption patterns, and regulatory frameworks, fundamentally shaping global trade flows and investment decisions. Asia Pacific (APAC) currently dominates the market, serving as the largest manufacturing hub globally, primarily driven by substantial production capacities in China and India. This regional dominance is supported by favorable governmental policies, lower operational costs, and the presence of integrated chemical supply chains. Consumption in APAC is also rapidly escalating, fueled by massive domestic demand from the Vitamin A synthesis sector for livestock feed and the region's expanding consumer goods and personal care industries. The sheer scale and velocity of industrialization in this region make it the primary engine for global market growth.

Europe and North America represent mature markets characterized by high per capita consumption of high-end consumer products, leading to a strong demand for high-purity synthetic citral in flavor and fragrance applications, especially in premium cosmetics and certified organic products. While production capacity has seen a relative decline compared to APAC, these regions maintain critical R&D leadership and set the global benchmarks for regulatory compliance, notably through the European Union's REACH regulation and strict FDA guidelines. The emphasis here is less on volume and more on compliance, sustainable sourcing, and product traceability, driving innovation towards bio-based and environmentally conscious production methods.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions that show significant growth potential, although they currently hold smaller market shares. Growth in LATAM is stimulated by local manufacturing expansion in cosmetics and packaged food industries. The MEA region's growth is linked to urbanization, rising disposable incomes, and increasing investment in local personal care manufacturing, reducing reliance on imports. However, these regions often face challenges related to logistical complexity and fluctuating import tariffs, impacting the stability of citral supply. Strategic expansion by global players often targets establishing regional distribution centers to effectively capitalize on this rising demand in emerging economies.

- Asia Pacific (APAC): Dominates global production capacity; high consumption driven by nutraceuticals, animal feed (Vitamin A), and rapidly expanding domestic consumer markets (China, India).

- Europe: Mature, high-value market focused on premium flavor and fragrance applications; characterized by stringent regulatory oversight (REACH compliance) and strong demand for sustainability.

- North America: Significant consumer market, demanding high-purity inputs for pharmaceuticals and functional foods; market growth tied to innovation in specialty aroma chemicals and robust regulatory standards.

- Latin America (LATAM): Exhibits strong growth potential in cosmetic and personal care manufacturing; market expansion is dependent on regional industrial stability and investment in local production bases.

- Middle East and Africa (MEA): Emerging market with increasing demand linked to rising urbanization and disposable income; primary consumption is in local production of detergents and personal hygiene products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Synthetic Citral Market.- BASF SE

- Kuraray Co., Ltd.

- Zhejiang NHU Co., Ltd.

- IFF (International Flavors & Fragrances)

- Symrise AG

- Takasago International Corporation

- Firmenich SA (now part of DSM-Firmenich)

- Genomatica (Focus on Bio-based technology)

- Kalpsutra Chemicals Pvt. Ltd.

- Mane SA

- Robertet SA

- Solvay S.A.

- LANXESS

- Hindustan Mint & Agro Products Pvt. Ltd.

- Privi Organics Limited

- Swati Menthol & Allied Chemicals Ltd.

- Spectrum Chemical Manufacturing Corp.

- Sigma-Aldrich (Merck KGaA)

- Axxence Aromatic GmbH

- Ernesto Ventós S.A.

Frequently Asked Questions

Analyze common user questions about the Synthetic Citral market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary application driving the demand for Synthetic Citral?

The primary application driving the largest volume demand for synthetic citral is its crucial use as an intermediate chemical in the synthesis of essential fat-soluble vitamins, predominantly Vitamin A (retinol) and Vitamin E (tocopherol), vital for human nutrition and animal feed.

How does the production cost of Synthetic Citral compare to Natural Citral?

Synthetic citral is generally more cost-effective and offers greater price stability than natural citral, which is subject to volatile agricultural yields, climate variability, and fluctuating extraction costs of essential oils like lemongrass or Litsea Cubeba. Synthetic processes ensure high volume and consistent quality at competitive prices.

Which manufacturing process dominates the global Synthetic Citral Market?

The isobutylene/formaldehyde route, often associated with major chemical manufacturers like BASF and Kuraray, dominates the global market. This petrochemical synthesis process allows for high industrial scalability, efficient control over isomer ratios, and consistent product purity, making it suitable for pharmaceutical applications.

What role do bio-based technologies play in the future of citral production?

Bio-based technologies, such as microbial fermentation using engineered yeast, represent a significant opportunity for sustainable citral production. While still an emerging, high-cost route, it addresses the rising consumer and regulatory preference for renewable sources, offering a path to reduce reliance on petrochemical feedstocks in the long term.

What are the major regulatory challenges faced by citral manufacturers?

Manufacturers must navigate stringent global chemical regulations, including Europe’s REACH guidelines and various regional food and cosmetic safety standards. Key challenges involve managing classification, documentation of potential impurities, and adhering to strict usage limits in end-products due to citral's potential allergenic properties at high concentrations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager