Synthetic Ink Resin Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439671 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Synthetic Ink Resin Market Size

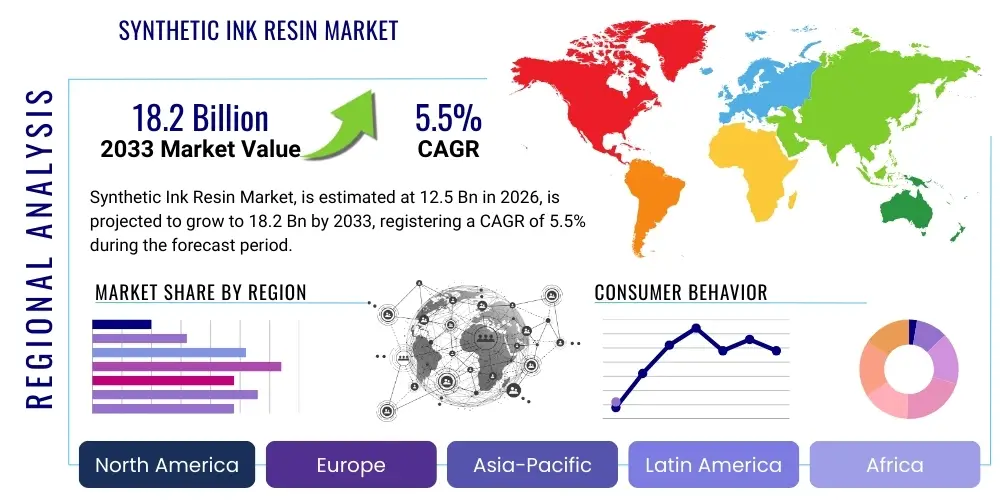

The Synthetic Ink Resin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. The market is estimated at USD 12.5 billion in 2026 and is projected to reach USD 18.2 billion by the end of the forecast period in 2033.

Synthetic Ink Resin Market introduction

The synthetic ink resin market is a foundational component of the global printing and packaging industries, supplying specialized polymers that determine the critical performance characteristics of printing inks. These resins are designed to impart essential properties such as adhesion, gloss, color vibrancy, rub resistance, chemical resistance, and drying speed to inks used across a vast spectrum of applications. They are indispensable for formulating inks compatible with various printing technologies, including flexography, gravure, lithography, and digital printing methods, adapting to diverse substrates from paper and cardboard to plastics and metals.

The market encompasses a wide array of resin chemistries, including acrylics, polyurethanes, polyamides, rosin esters, and hydrocarbon resins, each tailored to specific ink formulations and end-use requirements. Major applications span packaging (flexible, rigid, corrugated), publishing (magazines, books, newspapers), and commercial printing (brochures, labels, marketing materials). The benefits derived from high-performance synthetic ink resins are extensive, ensuring product protection, brand aesthetics, functional performance, and regulatory compliance for packaged goods, while also delivering critical information and visual appeal in publishing and commercial sectors.

Driving factors for this market's sustained growth include the relentless expansion of the global packaging industry, fueled by e-commerce proliferation and consumer goods demand, alongside the continuous innovation in printing technologies and the increasing need for high-quality, durable, and aesthetically pleasing prints. Furthermore, the rising emphasis on sustainable packaging solutions and bio-based materials is compelling resin manufacturers to develop environmentally friendly alternatives, stimulating research and development investments and shaping future market trends.

Synthetic Ink Resin Market Executive Summary

The synthetic ink resin market is characterized by robust growth, driven primarily by the escalating demand from the packaging sector, ongoing advancements in printing technologies, and a significant shift towards sustainable and high-performance ink solutions. Key business trends include strategic collaborations among raw material suppliers, resin manufacturers, and ink formulators to innovate and introduce advanced resin systems that cater to evolving industry needs, particularly for digital and specialty printing applications. The market is also witnessing a strong focus on enhancing product performance, such as improved adhesion to challenging substrates, enhanced chemical resistance, and superior print quality, to meet the stringent demands of modern printing processes.

Regionally, Asia Pacific continues to dominate the market, largely attributable to its burgeoning manufacturing sector, rapid urbanization, and increasing consumer spending, particularly in countries like China and India, which are major hubs for packaging and printing industries. North America and Europe also hold significant market shares, driven by technological innovation, the adoption of advanced printing techniques, and a strong emphasis on regulatory compliance and sustainability initiatives. These regions are at the forefront of developing eco-friendly and bio-based resin alternatives, pushing the boundaries of what is possible in sustainable ink formulation. Emerging economies in Latin America, the Middle East, and Africa are projected to offer substantial growth opportunities, spurred by industrialization and the expansion of local consumer markets.

Segment-wise, acrylic resins maintain a dominant position due to their versatility, excellent adhesion, and fast-drying properties, making them suitable for a wide range of ink types, especially water-based and UV-curable formulations. The packaging application segment remains the largest end-user, experiencing consistent growth from both flexible and rigid packaging demands. Furthermore, there is a noticeable trend towards specialized resins designed for specific performance attributes, such as those for food-contact packaging inks, low-migration inks, and inks for high-speed digital printing. The shift towards water-based and UV-curable inks, driven by environmental regulations and health concerns regarding solvent-based alternatives, is a critical segment trend influencing resin development and market dynamics.

AI Impact Analysis on Synthetic Ink Resin Market

The integration of Artificial Intelligence (AI) across industrial value chains is progressively influencing the synthetic ink resin market, prompting stakeholders to explore its potential for enhancing efficiency, innovation, and sustainability. Users frequently inquire about how AI can optimize resin formulation processes, improve product quality, streamline supply chain logistics, and even drive new product development cycles. There is keen interest in AI's capacity to predict material performance, simulate complex chemical reactions, and identify novel resin chemistries with specific properties, thereby reducing R&D timelines and costs. Concerns often revolve around the initial investment required for AI infrastructure, data privacy and security, and the necessity for a skilled workforce capable of implementing and managing AI-driven systems within a specialized chemical manufacturing context.

Expectations are high for AI to revolutionize various facets, from predictive maintenance of manufacturing equipment to intelligent inventory management, significantly improving operational efficiencies and reducing waste. Users anticipate AI will provide deeper insights into market trends and customer preferences, enabling more responsive product development tailored to emerging demands for sustainable and high-performance inks. The ability of AI to analyze vast datasets of material properties and performance metrics is seen as a game-changer for accelerating the discovery of bio-based and recyclable resin alternatives, aligning with broader industry goals for environmental responsibility. Ultimately, AI is expected to enable a more agile, data-driven, and innovative approach to synthetic ink resin production and application.

- AI-driven optimization of resin formulation for specific ink properties, reducing trial-and-error R&D.

- Predictive analytics for raw material sourcing and inventory management, mitigating supply chain disruptions.

- Enhanced quality control through real-time data analysis and anomaly detection in resin production.

- Accelerated discovery of novel resin chemistries, including bio-based and sustainable alternatives, via machine learning algorithms.

- Optimization of manufacturing processes, leading to increased efficiency and reduced energy consumption.

- Personalized ink solutions enabled by AI analysis of customer preferences and application requirements.

- Intelligent forecasting of market demand for different resin types, improving production planning.

- Development of smart sensors and IoT for monitoring resin performance during printing processes.

DRO & Impact Forces Of Synthetic Ink Resin Market

The synthetic ink resin market is influenced by a complex interplay of drivers, restraints, and opportunities, collectively forming the impact forces that shape its trajectory. A primary driver is the burgeoning global packaging industry, which continues to demand high-performance inks for a diverse range of materials and applications, including food and beverage, pharmaceuticals, and consumer goods. The increasing sophistication of printing technologies, particularly the rise of digital printing, necessitates specialized resins capable of delivering precision, speed, and durability. Furthermore, the growing consumer and regulatory push for sustainable solutions is compelling manufacturers to innovate with eco-friendly and bio-based resins, creating new market segments and driving technological advancements.

However, the market faces significant restraints, including the inherent volatility in the prices of petrochemical-derived raw materials, which directly impacts production costs and profit margins for resin manufacturers. Stringent environmental regulations concerning VOC emissions and hazardous substances in inks pose ongoing challenges, requiring continuous investment in R&D to develop compliant and safer alternatives. The competitive landscape, coupled with the capital-intensive nature of chemical manufacturing and the high R&D costs associated with developing new resins, also act as significant barriers to entry and expansion.

Despite these challenges, substantial opportunities exist. The development of specialty and high-performance inks for niche applications, such as security printing, 3D printing, and functional coatings, represents a lucrative growth avenue. Expanding into emerging economies, particularly in Asia Pacific and Latin America, where industrialization and consumer markets are rapidly growing, offers significant untapped potential. The accelerating adoption of UV-curable and water-based ink technologies, driven by both performance benefits and environmental mandates, creates strong demand for compatible synthetic resins. Additionally, the broader industry trend towards circular economy principles and material recycling is fostering innovation in resins designed for easier deinking and compatibility with recycling streams, presenting a long-term strategic opportunity for market players.

Segmentation Analysis

The synthetic ink resin market is comprehensively segmented to provide granular insights into its diverse components, allowing for a detailed understanding of market dynamics, competitive landscapes, and growth opportunities across various dimensions. These segmentations are critical for stakeholders to identify specific market niches, tailor product development, and strategize market entry or expansion. The market can be dissected by resin type, ink type, application, end-use industry, and geographic region, each offering a unique perspective on demand patterns and technological trends.

Segmentation by resin type highlights the dominance of acrylic resins due to their versatility and performance in water-based and UV-curable inks, while polyurethane and polyamide resins are crucial for demanding applications requiring flexibility and adhesion. Ink type segmentation reflects the ongoing shift from traditional solvent-based inks to more environmentally friendly water-based and high-performance UV-curable inks. Application segmentation clearly delineates the market's reliance on the packaging sector, followed by publishing and commercial printing, each with distinct resin requirements. End-use industry analysis further refines this by categorizing demand from specific sectors like food and beverage, pharmaceuticals, and automotive, which have unique regulatory and performance specifications for inks and their resin components.

- By Resin Type:

- Acrylic Resins

- Polyurethane Resins

- Rosin Resins

- Polyamide Resins

- Cellulosic Resins

- Hydrocarbon Resins

- Other Resin Types (e.g., Polyester, Vinyl)

- By Ink Type:

- Solvent-Based Inks

- Water-Based Inks

- UV-Curable Inks

- Oil-Based Inks

- By Application:

- Packaging (Flexible Packaging, Rigid Packaging, Corrugated Packaging)

- Publishing (Magazines, Newspapers, Books)

- Commercial Printing (Brochures, Catalogs, Marketing Materials)

- Others (Textiles, Decorative, Security Printing)

- By End-Use Industry:

- Food and Beverage

- Cosmetics and Personal Care

- Pharmaceuticals

- Automotive

- Electronics

- Textiles

- Construction

- Others

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Value Chain Analysis For Synthetic Ink Resin Market

The value chain for the synthetic ink resin market is a multi-tiered structure, commencing with the procurement of raw materials and culminating in the end-use application of printing inks. Upstream activities involve the extraction and processing of foundational petrochemicals, such as acrylic monomers, polyols, and various aromatic and aliphatic hydrocarbons, which serve as the primary building blocks for synthetic resins. Natural resins like rosins are also processed at this stage. These raw material suppliers form the initial critical link, as the quality, availability, and price stability of these intermediates directly influence the cost and performance of the final ink resins. Research and development efforts at this stage are crucial for introducing novel monomers and sustainable alternatives.

The midstream segment of the value chain is dominated by specialized chemical companies that synthesize these raw materials into various types of synthetic resins, including acrylics, polyurethanes, polyamides, and rosin esters. This stage involves complex polymerization processes and formulation expertise to create resins with specific properties tailored for different ink systems (e.g., water-based, solvent-based, UV-curable). Resin manufacturers invest heavily in R&D to enhance resin performance, reduce environmental impact, and meet stringent regulatory standards, making innovation a key differentiator in this highly competitive segment.

Downstream, these synthetic resins are supplied to ink manufacturers, who combine them with pigments, solvents, additives, and other binders to formulate a vast array of printing inks. Ink manufacturers customize formulations to meet the specific requirements of various printing processes (flexography, gravure, offset, digital) and substrates. The distribution channel for synthetic ink resins and the finished inks often involves a mix of direct sales from large manufacturers to key clients and indirect sales through a network of distributors and agents. These intermediaries play a vital role in reaching smaller ink manufacturers, local printers, and specialized end-users, providing logistical support, technical assistance, and localized market knowledge, ensuring efficient delivery and market penetration for both the resins and the final ink products.

Synthetic Ink Resin Market Potential Customers

The potential customers for the synthetic ink resin market are diverse and encompass a broad spectrum of industries that rely heavily on printing and coating technologies for their products and operations. At the forefront are ink manufacturers, who represent the direct and largest buyers of synthetic resins. These companies formulate a wide array of printing inks for various applications, making the quality and characteristics of synthetic resins paramount to their final product performance. Their demands for resins are highly specific, based on the ink type, printing method, and desired end-use properties such as adhesion, drying speed, and environmental resistance.

Beyond ink manufacturers, the ultimate end-users include a multitude of businesses across the packaging, publishing, and commercial printing sectors. Packaging companies, including those involved in flexible packaging, rigid packaging, and corrugated board production, are significant consumers, as inks are essential for branding, product information, and aesthetic appeal. Food and beverage, pharmaceutical, and personal care brands, while not direct buyers of resins, are indirect drivers of demand, as their packaging requirements dictate the performance standards for inks and, consequently, the resins used.

Commercial printers, publishing houses, and label manufacturers also constitute a substantial customer base. These entities utilize inks for magazines, newspapers, books, brochures, marketing materials, and product labels, requiring resins that ensure vibrant colors, sharp images, and durability. Specialty applications such as security printing, textile printing, and decorative coatings further expand the customer base, each demanding unique resin properties tailored for their specific functional and aesthetic needs. Ultimately, any industry that requires high-quality, durable, and functional printed materials is a potential customer, driving the demand for advanced synthetic ink resins.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 12.5 Billion |

| Market Forecast in 2033 | USD 18.2 Billion |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DIC Corporation, BASF SE, Arkema S.A., Dow Inc., Synthomer plc, Eastman Chemical Company, Lawter Inc. (Harima Chemicals Group), INEOS Group Holdings S.A., Sartomer (Arkema Group), Evonik Industries AG, Momentive Performance Materials Inc., Wanhua Chemical Group Co., Ltd., Georgia-Pacific Chemicals LLC, Mitsui Chemicals, Inc., Royal DSM N.V., Covestro AG, Solvay S.A., Ashland Global Holdings Inc., Hexion Inc., Zeon Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Synthetic Ink Resin Market Key Technology Landscape

The synthetic ink resin market is continuously shaped by dynamic technological advancements aimed at enhancing performance, addressing environmental concerns, and adapting to evolving printing methods. A significant technological shift involves the development and increasing adoption of water-based ink resins. These resins are formulated to replace traditional solvent-based systems, offering reduced Volatile Organic Compound (VOC) emissions, improved safety, and compliance with stringent environmental regulations. Innovations in water-based acrylics and polyurethanes are focusing on achieving comparable drying times, gloss, and adhesion properties to their solvent-based counterparts, making them viable for high-speed printing applications across various substrates, especially in packaging and flexible film printing.

Another pivotal area of innovation lies in UV-curable and EB (Electron Beam) curable resin technologies. These resins polymerize rapidly upon exposure to UV light or electron beams, enabling instant drying, high print speeds, and superior resistance to abrasion and chemicals. The technology offers significant benefits in terms of energy efficiency and environmental impact due to the absence of solvents. Continuous advancements are centered on developing resins that offer greater flexibility, adhesion to diverse non-porous substrates, and lower migration properties, making them suitable for sensitive applications like food packaging and medical labels. The expansion of LED-UV curing systems further drives demand for specifically formulated LED-curable resins, which offer advantages such as lower energy consumption and longer lamp life.

Beyond solvent-less and water-based systems, the technology landscape is also witnessing significant developments in bio-based and sustainable resin formulations. Driven by circular economy principles and corporate sustainability goals, researchers are exploring renewable resources like plant oils, starch, and cellulose derivatives to synthesize resins that are biodegradable or have a reduced carbon footprint. Nanotechnology is another emerging field, with nanoparticles being incorporated into resin formulations to enhance properties such as scratch resistance, UV protection, and barrier performance. Furthermore, the integration of smart functionalities into ink resins, such as color-changing, conductive, or temperature-sensitive properties, is opening new avenues for functional printing and intelligent packaging, pushing the boundaries of what inks can achieve beyond traditional aesthetics and information delivery.

Regional Highlights

The global synthetic ink resin market exhibits distinct regional dynamics, influenced by varying levels of industrialization, consumer demand, regulatory environments, and technological adoption. Each region contributes uniquely to the market's overall growth and innovation landscape, presenting both opportunities and challenges for market participants.

- Asia Pacific (APAC): Dominates the global market, driven by rapid industrialization, burgeoning manufacturing sectors, and increasing demand for packaged goods in populous countries like China, India, Japan, and South Korea. The region is a major hub for electronics, automotive, and consumer goods production, necessitating high volumes of printing inks. Growing middle-class populations and e-commerce penetration further fuel the demand for packaging and, consequently, synthetic ink resins.

- North America: A mature market characterized by technological advancements, stringent environmental regulations, and a strong emphasis on sustainable and high-performance printing solutions. The United States is a significant market, with a robust packaging industry and high adoption rates of digital and UV-curable printing technologies. Innovation in bio-based resins and specialty inks is a key regional trend.

- Europe: Exhibits steady growth, propelled by strict environmental regulations favoring water-based and UV-curable inks, coupled with a focus on premium and specialty packaging. Countries like Germany, France, the UK, and Italy are leading in the development of advanced printing technologies and sustainable ink solutions, driven by a strong commitment to circular economy principles and reduced environmental impact.

- Latin America: An emerging market with significant growth potential, fueled by expanding industrial bases, urbanization, and increasing consumer spending, particularly in Brazil and Mexico. The region's packaging industry is growing, leading to a rising demand for printing inks and resins, though economic volatility can influence market development.

- Middle East and Africa (MEA): Shows promising growth prospects, primarily due to ongoing infrastructure development, diversification of economies, and increasing demand for consumer goods. The expansion of the packaging and construction sectors, particularly in GCC countries and South Africa, is driving the adoption of modern printing technologies and the associated demand for synthetic ink resins.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Synthetic Ink Resin Market.- DIC Corporation

- BASF SE

- Arkema S.A.

- Dow Inc.

- Synthomer plc

- Eastman Chemical Company

- Lawter Inc. (Harima Chemicals Group)

- INEOS Group Holdings S.A.

- Sartomer (Arkema Group)

- Evonik Industries AG

- Momentive Performance Materials Inc.

- Wanhua Chemical Group Co., Ltd.

- Georgia-Pacific Chemicals LLC

- Mitsui Chemicals, Inc.

- Royal DSM N.V.

- Covestro AG

- Solvay S.A.

- Ashland Global Holdings Inc.

- Hexion Inc.

- Zeon Corporation

Frequently Asked Questions

What are synthetic ink resins and why are they important?

Synthetic ink resins are polymers specifically engineered to be the primary film-forming component in printing inks. They are crucial for imparting essential properties such as adhesion to various substrates, gloss, color intensity, drying speed, rub and chemical resistance, and overall durability. Without these specialized resins, inks would lack the necessary performance characteristics required for effective and long-lasting print applications across packaging, publishing, and commercial sectors.

How is the market for synthetic ink resins segmented?

The synthetic ink resin market is typically segmented by resin type (e.g., acrylic, polyurethane, rosin, polyamide), by ink type (e.g., solvent-based, water-based, UV-curable), by application (e.g., packaging, publishing, commercial printing), by end-use industry (e.g., food and beverage, pharmaceuticals, automotive), and by geographic region (e.g., North America, Europe, Asia Pacific). These segmentations help in understanding specific market dynamics and growth drivers within each category.

What are the key drivers propelling the growth of the synthetic ink resin market?

Key drivers include the continuous expansion of the global packaging industry, fueled by e-commerce growth and consumer goods demand. Additionally, advancements in printing technologies, particularly the rise of digital and high-speed printing, necessitate specialized resins. The increasing focus on sustainable and eco-friendly printing solutions also drives innovation and demand for new resin formulations.

What challenges does the synthetic ink resin market face?

The market faces several challenges, including the volatility of raw material prices (primarily petrochemicals), which impacts production costs. Stringent environmental regulations regarding VOC emissions and hazardous chemicals require continuous investment in R&D for compliant solutions. Intense competition and high capital expenditure for manufacturing and research also present significant hurdles for market players.

How is sustainability influencing the synthetic ink resin market?

Sustainability is profoundly influencing the market by driving demand for eco-friendly alternatives. This includes the development of water-based and UV-curable resins to reduce VOC emissions, and a growing emphasis on bio-based resins derived from renewable resources. Manufacturers are also innovating to create resins that facilitate recycling processes, such as easy de-inking, aligning with circular economy objectives and consumer preferences for greener products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager