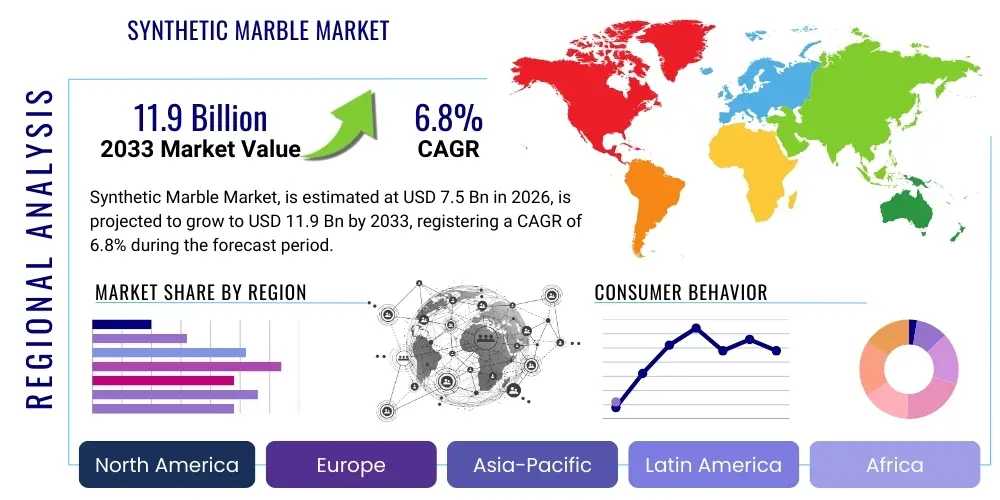

Synthetic Marble Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434441 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Synthetic Marble Market Size

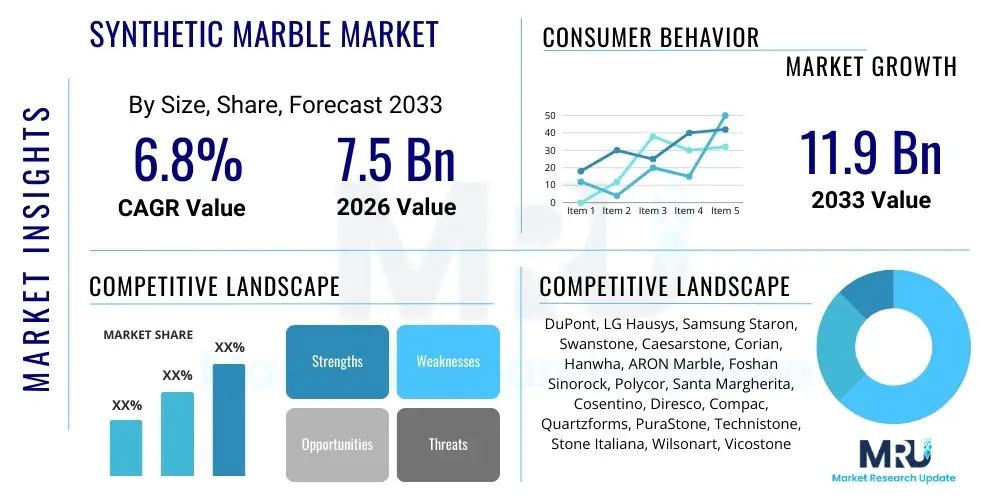

The Synthetic Marble Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 7.5 Billion in 2026 and is projected to reach USD 11.9 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily fueled by increasing global construction activities, particularly in the residential and commercial sectors, where synthetic marble offers a cost-effective, durable, and aesthetically versatile alternative to natural stone. The rapid adoption of engineered stone in high-traffic interior design applications, coupled with advancements in manufacturing technology leading to better texture replication and customization options, underpins this significant market expansion.

Synthetic Marble Market introduction

The Synthetic Marble Market encompasses advanced composite materials designed to replicate the appearance and texture of natural marble while offering superior performance characteristics such as non-porosity, resistance to staining, and enhanced durability. These engineered stones are typically manufactured using a blend of natural stone aggregates (like marble powder or quartz) bound together by polymer resins, such as unsaturated polyester resin (UPR) or acrylic resin (PMMA), often processed under high vacuum and vibration. Synthetic marble is widely utilized in architectural and design applications due to its aesthetic appeal and functional advantages over traditional materials, positioning it as a key component in modern construction and remodeling projects worldwide.

Major applications for synthetic marble include kitchen countertops, bathroom vanity tops, wall cladding, flooring, shower panels, and decorative architectural elements. The product description highlights its key benefits: ease of maintenance, uniformity in color and pattern, high hygienic standards (especially non-porous surfaces), and environmental sustainability due to the use of recycled content in some formulations. Its versatility allows it to cater to diverse design requirements, ranging from high-end luxury residential projects to heavy-duty commercial installations like hospitals and hotels, where sanitation and resilience are paramount.

Driving factors for the market include the rising disposable incomes in emerging economies, spurring luxury interior design demand, and the sustained growth of the global construction industry. Furthermore, synthetic marble offers a significantly lower cost of installation and material compared to high-grade natural marble, making it accessible for large-scale production housing and commercial builds. Innovation in production technology, such as the implementation of advanced mold techniques and digital patterning, continues to enhance the realism and breadth of available designs, sustaining consumer interest and professional specification globally.

Synthetic Marble Market Executive Summary

The Synthetic Marble Market is characterized by accelerating demand across residential and commercial infrastructure, driven primarily by favorable material properties and competitive pricing relative to natural stone. Current business trends indicate a significant shift towards sustainable manufacturing processes, with major players investing in greener resins and reducing volatile organic compound (VOC) emissions to meet stringent environmental regulations and consumer preferences for eco-friendly building materials. Consolidation among raw material suppliers and manufacturers is also a noticeable trend, aimed at optimizing the supply chain efficiency and achieving economies of scale in high-volume production necessary for global project deployment.

Regionally, Asia Pacific (APAC) stands as the dominant market, registering the fastest growth due to massive urbanization, aggressive government investment in infrastructure, and robust expansion of the middle-class segment demanding high-quality, durable home interiors. North America and Europe, while mature, exhibit strong demand fueled by large-scale remodeling projects and the preference for acrylic-based synthetic marble in high-end kitchen and bath installations. Segment trends highlight that polyester resin remains the largest segment by volume owing to its cost-effectiveness in construction, whereas acrylic resin is gaining traction in premium applications due to its superior reparability and thermoformability, offering design flexibility that traditional materials cannot match.

In terms of application, countertops and vanity tops represent the most crucial segment, leveraging synthetic marble’s non-porous, stain-resistant attributes crucial for these functional areas. Future growth is expected to be significantly influenced by the adoption of synthetic marble in specialized applications, such as large-format floor tiling and exterior wall cladding, where its lightweight nature and consistent quality provide substantial logistical and installation advantages. The competitive landscape is intensely focused on product innovation, particularly concerning scratch resistance and UV stability, to penetrate outdoor and specialized high-traffic commercial environments successfully.

AI Impact Analysis on Synthetic Marble Market

Common user questions regarding AI's influence on the Synthetic Marble Market center around operational efficiency, product consistency, and future design capabilities. Users frequently inquire how AI can optimize manufacturing processes to reduce waste and energy consumption (sustainability concerns), whether AI-driven quality control can eliminate defects (consistency concerns), and how generative AI might be used to create novel, hyper-realistic marble patterns that mimic complex natural veining structures (design innovation concerns). The synthesis of these inquiries points to a clear market expectation: AI is anticipated to revolutionize the production phase by improving yield, enhancing material characteristics through predictive analytics on resin mixes, and transforming the design phase, offering unparalleled customization capabilities that previously required extensive manual labor or proprietary tooling.

- AI-powered Predictive Maintenance: Analyzing machine data to forecast equipment failures in mixers and presses, minimizing downtime and optimizing production schedules.

- Generative Design Systems: Utilizing machine learning algorithms to create unique, high-resolution veining patterns and color schemes that are impossible or too complex to achieve through traditional mold or manual injection processes.

- Automated Quality Control (AQC): Employing computer vision and deep learning models to instantly detect surface defects (scratches, porosity, inconsistent curing) during the final polishing and cutting stages, ensuring near-perfect product consistency.

- Supply Chain Optimization: Using AI to predict raw material price fluctuations (resins, marble aggregates) and optimize inventory levels, leading to significant cost savings in procurement.

- Resin Formulation Optimization: Applying AI to simulate and optimize polymer curing times and mix ratios based on ambient temperature and humidity, enhancing material strength and reducing curing defects.

DRO & Impact Forces Of Synthetic Marble Market

The Synthetic Marble Market is primarily driven by escalating construction and remodeling activities globally, the inherent cost advantage and superior performance metrics (durability, non-porosity) compared to natural marble, and increasing consumer preference for low-maintenance, aesthetically pleasing surface materials. These drivers are synergized by rapid technological advancements in composite material engineering, allowing manufacturers to produce products that possess heightened scratch resistance and UV stability, broadening the material's application scope to include outdoor and high-stress environments. Furthermore, regulatory support for environmentally friendly and sustainable building materials indirectly favors synthetic stone, especially formulations that incorporate recycled or waste aggregate materials.

However, the market faces significant restraints, chiefly the variable pricing and supply volatility of key raw materials, specifically the petrochemical-derived polymer resins (UPR and acrylics). A major challenge remains the perception among certain consumer segments that synthetic marble lacks the 'authenticity' or prestige of natural stone, which can limit adoption in ultra-luxury construction projects. Competition from alternative surface materials, particularly natural quartz and high-pressure laminates (HPLs), also poses a continuous constraint, requiring constant innovation in synthetic marble's material science and pricing strategies to maintain competitiveness and market share.

Opportunities abound in leveraging the material’s unique properties, such as thermoformability, to capture specialized markets like laboratory surfaces, custom retail display units, and complex architectural installations requiring curved or seamless components. Furthermore, penetrating emerging markets in Africa and Latin America, characterized by burgeoning urbanization and a strong need for durable, cost-effective building materials, represents a substantial growth avenue. The primary impact forces shaping the market include sustained global economic stability affecting construction spending, material science breakthroughs enhancing performance, and geopolitical factors influencing the cost and availability of petroleum-based resin feedstocks, which directly determines manufacturing costs and end-product pricing structure.

Segmentation Analysis

The Synthetic Marble Market segmentation provides a granular view of demand distribution based on material composition, intended application, and the end-user profile, offering crucial insights for strategic market penetration. The primary segmentation relies on the type of resin binder used, which fundamentally dictates the material's performance characteristics, cost, and installation requirements. Secondary segmentation by application reveals that areas requiring high hygiene and moisture resistance, such as kitchens and bathrooms, are the dominant consumption segments, reflecting the material’s inherent strengths. Analyzing end-user segments helps manufacturers tailor their product lines, with the residential segment focusing on aesthetics and affordability, while the commercial sector prioritizes durability and regulatory compliance.

Detailed analysis of the Type segment shows that polyester-based synthetic marble dominates in terms of sheer volume due to its favorable cost-to-performance ratio, making it the material of choice for large, budget-conscious construction projects. However, the Acrylic Resin segment is experiencing rapid value growth, especially in North America and Europe, attributed to its superior thermoformability, non-yellowing characteristics, and seamless repairability, justifying its higher price point. The hybrid segment, combining features of both materials, represents an innovative compromise, balancing performance and cost for mid-range applications.

Geographic segmentation underscores the regional disparities in manufacturing capacity and consumption patterns. Asia Pacific leads in production and consumption due to massive domestic construction activity and export capacity, while Western markets drive innovation and high-value product adoption. This structural analysis is critical for stakeholders to identify high-growth segments and align production capabilities with regional material preferences and regulatory environments, ensuring efficient resource allocation and maximizing return on investment across the product lifecycle.

- By Type:

- Polyester Resin-Based Synthetic Marble

- Acrylic Resin-Based Synthetic Marble

- Hybrid/Modified Resin Synthetic Marble

- By Application:

- Countertops and Vanity Tops

- Flooring and Paving

- Wall Cladding and Panels

- Bathroom Vanities and Shower Surrounds

- Architectural Features and Furniture

- By End-User:

- Residential Construction and Remodeling

- Commercial Construction (Hospitality, Healthcare, Office Spaces)

- Industrial and Institutional Applications

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Southeast Asia)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East and Africa (GCC Countries, South Africa)

Value Chain Analysis For Synthetic Marble Market

The value chain for the Synthetic Marble Market begins with upstream activities, dominated by the procurement and refinement of essential raw materials: natural aggregates (marble powder, alumina trihydrate, quartz) and chemical binders (unsaturated polyester resins, acrylic monomers, catalysts, and pigments). This stage is highly critical as the price volatility of petroleum-derived resins directly impacts manufacturing costs and, consequently, the final product price. Key upstream players include specialized chemical manufacturers and mineral processors who supply standardized inputs, demanding rigorous quality control to ensure batch consistency in the final synthetic stone product.

The middle segment involves the manufacturing process, which includes mixing, vacuum vibration, curing, and subsequent finishing (sanding, polishing, and cutting). This stage is characterized by high capital investment in advanced machinery, such as continuous casting machines and sophisticated polishing lines, aimed at achieving high production volumes and precision finishing. Manufacturers often integrate R&D facilities to continuously innovate material formulations for enhanced scratch resistance, UV stability, and surface aesthetics, differentiating their offering in a highly competitive landscape. Efficient production logistics and waste management during this phase are key determinants of profitability.

Downstream analysis focuses on distribution and sales. Synthetic marble products are typically moved through two primary channels: direct sales to large commercial contractors and architectural firms for major projects, and indirect sales through specialized distributors, fabricators, and retail showrooms catering to residential remodeling and smaller-scale commercial work. Fabricators play a crucial role, transforming standard slabs into custom-cut countertops and installations, requiring specialized machinery and highly skilled labor. The final step involves installation and after-sales service, which solidifies brand reputation and customer loyalty. Effective inventory management across the distribution channel is vital, given the size and weight of the finished product slabs.

Synthetic Marble Market Potential Customers

The Synthetic Marble Market targets a diverse set of end-users primarily categorized under construction and interior design sectors who require durable, non-porous, and aesthetically appealing surface materials. The largest segment of potential customers comprises residential property developers and individual homeowners involved in new construction or remodeling, seeking premium finishes for kitchen countertops, bathroom vanities, and flooring at a more accessible price point than quarried stone. These customers prioritize stain resistance, ease of cleaning, and the material’s capacity to create seamless installations, particularly in wet areas.

Another crucial customer segment is the commercial sector, encompassing entities such as the hospitality industry (hotels, resorts, restaurants), healthcare facilities (hospitals, clinics, laboratories), and corporate real estate (office buildings). Commercial buyers are highly sensitive to material performance metrics, focusing on compliance with hygiene standards (non-porous surface is key), fire resistance ratings, and exceptional wear resistance necessary for high-traffic public areas. The ability of synthetic marble to be repaired seamlessly minimizes replacement costs and extends the lifecycle of the installed surface, making it an attractive investment for commercial property owners and facility managers.

Furthermore, specialized industrial buyers, including custom furniture manufacturers, shipbuilders (for marine applications requiring lightweight yet durable surfaces), and architectural specification firms seeking bespoke design solutions, represent niche but high-value potential customers. These buyers often require the thermoformability characteristics inherent to acrylic-based synthetic marble, allowing for complex curves and unique design elements that cannot be achieved with natural stone or quartz. Therefore, the market’s outreach is multi-faceted, ranging from mass-market residential applications to highly technical, customized commercial installations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 7.5 Billion |

| Market Forecast in 2033 | USD 11.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DuPont, LG Hausys, Samsung Staron, Swanstone, Caesarstone, Corian, Hanwha, ARON Marble, Foshan Sinorock, Polycor, Santa Margherita, Cosentino, Diresco, Compac, Quartzforms, PuraStone, Technistone, Stone Italiana, Wilsonart, Vicostone |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Synthetic Marble Market Key Technology Landscape

The technological landscape of the Synthetic Marble Market is defined by continuous innovation aimed at enhancing material performance, improving aesthetic replication of natural stone, and optimizing manufacturing efficiency. A core technology is Vacuum Vibration Compaction (VVC), or Breton technology, which ensures maximum density and minimizes air voids in the composite slab, resulting in materials with superior strength, consistency, and reduced porosity. Recent advancements focus on implementing continuous casting processes for specific resin types, enabling high-volume production with reduced batch-to-batch variation and improved cost efficiency, crucial for meeting large-scale construction demands.

Aesthetic reproduction relies heavily on specialized pigment mixing systems and advanced tooling for creating intricate and realistic veining. Manufacturers are increasingly adopting digital printing and scanning technologies to map and replicate complex natural stone patterns onto the synthetic surface with high fidelity. Furthermore, R&D efforts are concentrated on modifying polymer matrixes through nanotechnology and specialized additives to introduce enhanced functional properties, such as microbial resistance, significantly important for healthcare and food service applications, and improved UV stability to broaden applicability to exterior cladding.

The future technology trajectory points toward greater automation, integration of smart manufacturing systems (Industry 4.0), and the development of bio-based or recycled resins to address sustainability concerns. New chemical compositions, particularly in hybrid formulations, are being explored to balance the thermoformability of acrylics with the high rigidity and cost-effectiveness of polyesters. Investment in high-pressure curing systems is also prominent, aimed at accelerating production cycles while maintaining the structural integrity and surface hardness required for premium synthetic marble products competing directly against high-grade quartz and granite.

Regional Highlights

Regional dynamics play a crucial role in shaping the Synthetic Marble Market, influenced by local construction standards, economic development rates, and consumer material preferences. Asia Pacific (APAC) represents the largest and fastest-growing market, largely driven by significant investments in residential housing, commercial infrastructure (hotels, malls), and robust manufacturing bases in countries like China, India, and South Korea. China, in particular, dominates both production capacity and consumption, leveraging cost-effective manufacturing processes to supply both domestic and global markets. The rapid pace of urbanization across Southeast Asia further ensures sustained, high growth in demand for synthetic surfaces as alternatives to traditional materials.

North America is a mature but high-value market, characterized by a strong preference for high-quality, branded synthetic marble, particularly acrylic resin-based products renowned for superior performance and seamless design capabilities. The U.S. market is primarily driven by extensive home remodeling projects and high expenditure in healthcare and hospitality sectors, where hygiene and durability are primary considerations. Regulatory compliance, such as adherence to ANSI standards and specific fire codes, influences product specification and limits market entry for non-compliant products, focusing competition on premium, high-performance offerings.

Europe exhibits steady growth, fueled by stringent environmental regulations encouraging the use of low-VOC and sustainable building materials, benefiting manufacturers incorporating recycled content. Western European countries like Germany and the UK show high demand in both residential kitchens and specialized commercial installations. Conversely, Latin America and the Middle East & Africa (MEA) are emerging markets, showing considerable potential driven by expanding tourism infrastructure (MEA) and large-scale public housing projects (LA). However, these regions often face challenges related to fluctuating commodity prices and less developed distribution networks, making price competitiveness a critical success factor.

- Asia Pacific (APAC): Dominant consumption and manufacturing hub; fast-paced infrastructure development in China and India; high volume demand in residential sector.

- North America: High-value market focused on acrylic-based products; strong remodeling sector; stringent quality standards driving premium product adoption.

- Europe: Growth influenced by green building codes and sustainable materials; emphasis on design aesthetics and superior finish quality; mature distribution channels.

- Latin America (LATAM): Emerging market potential driven by urbanization and commercial construction; high focus on cost-efficiency and durability in material selection.

- Middle East & Africa (MEA): Growth tied to hospitality and luxury residential projects; increasing use in high-end architectural designs, requiring materials with superior heat and UV stability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Synthetic Marble Market.- DuPont de Nemours, Inc.

- LG Hausys, Ltd.

- Samsung Staron (Part of Lotte Advanced Materials)

- Cosentino S.A.

- Caesarstone Ltd.

- Hanwha Surfaces (Hanwha L&C)

- The Swan Corporation (Swanstone)

- Wilsonart LLC

- Vicostone Joint Stock Company

- Compac Surfaces

- Diresco N.V.

- Quartzforms Spa

- PuraStone Solid Surface Material Co., Ltd.

- Technistone a.s.

- Stone Italiana SpA

- Aron Marble Private Limited

- Foshan Sinorock Building Materials Co., Ltd.

- Polycor Inc.

- Santa Margherita S.p.A.

- Guangzhou Gelandy New Material Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Synthetic Marble market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between synthetic marble and natural quartz surfaces?

Synthetic marble, often polymer-based, is typically thermoformable and repairable, allowing for seamless installations, whereas natural quartz is substantially harder, offers superior scratch resistance, and is generally not thermoformable. Synthetic marble generally uses polyester or acrylic resins, while quartz surfaces use a high concentration of natural quartz aggregates (90%+).

How does the cost of synthetic marble compare to traditional natural stone like granite?

Synthetic marble often provides a favorable cost advantage, particularly polyester-based types, offering aesthetic appeal similar to high-end natural stones but with lower material costs, installation expenses, and reduced maintenance requirements over the material lifecycle. Acrylic versions are positioned higher but often below premium grades of natural marble.

What are the main sustainability concerns regarding the production of synthetic marble?

The primary environmental concern relates to the use of petroleum-derived polymer resins, which contribute to VOC emissions during manufacturing and installation. However, the industry is increasingly addressing this through the development of low-VOC, recycled content, and bio-based resin formulations, improving the product's overall sustainable profile.

In which application areas does synthetic marble offer the greatest performance advantages?

Synthetic marble excels in applications requiring high hygiene and moisture resistance, such as kitchen and bathroom countertops, laboratory surfaces, and shower surrounds. Its non-porous nature prevents bacterial growth and staining, and acrylic versions offer seamless joint integration, eliminating potential dirt and water traps.

Which geographic region currently dominates the global Synthetic Marble Market?

Asia Pacific (APAC) currently dominates the Synthetic Marble Market in terms of both production volume and consumption value. This dominance is attributed to rapid urbanization, large-scale infrastructure projects, and the presence of major, cost-efficient manufacturing clusters, particularly in China and South Korea.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager