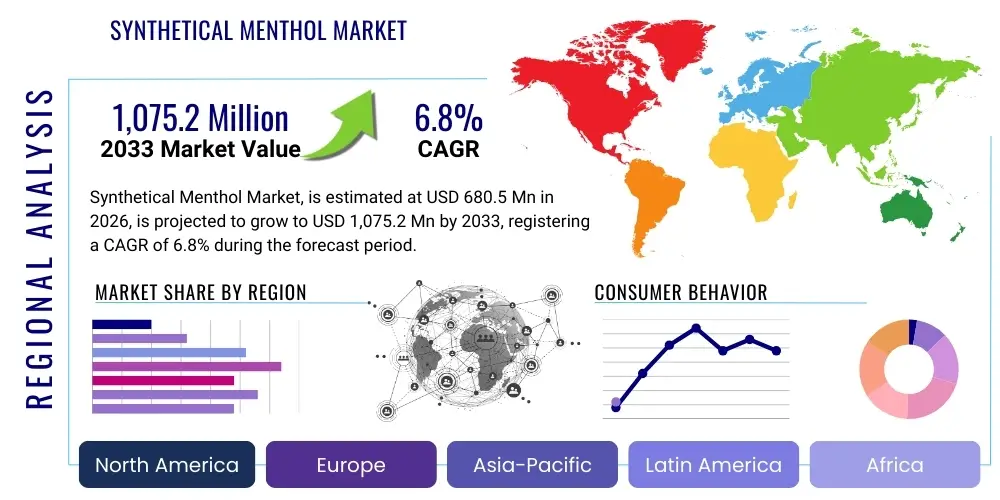

Synthetical Menthol Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438227 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Synthetical Menthol Market Size

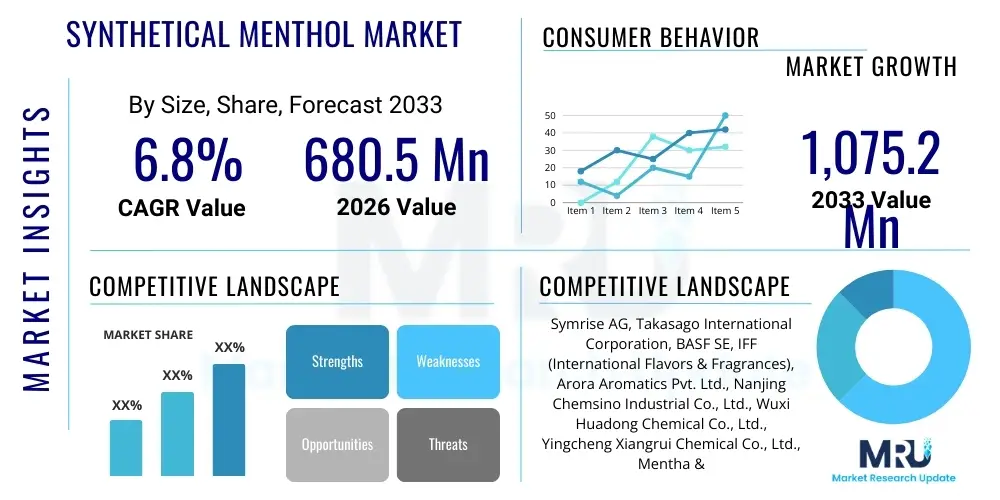

The Synthetical Menthol Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 680.5 Million in 2026 and is projected to reach USD 1,075.2 Million by the end of the forecast period in 2033. This substantial expansion is primarily driven by the escalating demand for cooling agents and flavoring components across fast-moving consumer goods (FMCG), particularly in high-growth economies where disposable incomes are rising, leading to increased consumption of premium oral care and confectionery products. The synthetic route offers a stable and cost-effective alternative to natural menthol, insulating manufacturers from the supply chain volatility associated with agricultural production, thus solidifying its foundational role in industrial applications.

The stability of supply and the ability to achieve high purity standards through advanced chemical synthesis are critical factors underpinning the market's robust valuation. Synthetic menthol, predominantly L-Menthol, provides essential organoleptic properties required by large-scale pharmaceutical and flavor houses, ensuring consistent product formulation regardless of external climate or agricultural yields. Furthermore, regulatory environments in specific sectors, such as tobacco alternatives and certain medicinal products, favor the use of synthetically controlled ingredients where precise isomer ratios and impurity profiles are mandatory for compliance and safety standards, contributing significantly to the overall market valuation projection.

Synthetical Menthol Market introduction

The Synthetical Menthol Market encompasses the production and distribution of chemically synthesized forms of menthol, primarily L-Menthol, which is the most biologically active and commercially valuable isomer. Unlike natural menthol derived from mint oils (Mentha arvensis or Mentha piperita), synthetic menthol is manufactured through various chemical pathways, such as those involving the hydrogenation of thymol or the use of p-menthane derivatives, ensuring high yield, consistent quality, and scalability. This product serves as a crucial component in numerous industrial sectors due to its potent cooling sensation, characteristic aroma, and mild analgesic properties, offering formulators reliability that is often challenging to achieve with naturally sourced botanicals.

Major applications of synthetical menthol span the pharmaceutical, oral hygiene, confectionery, and flavor and fragrance industries. In pharmaceuticals, it is extensively used in cough drops, topical pain relief balms, and decongestants for its counter-irritant and local anesthetic effects. The oral care segment relies heavily on synthetic menthol to impart freshness and flavor to toothpaste, mouthwash, and dental floss. Its benefits include consistent purity, enhanced cost predictability compared to natural sources, and superior stability, making it the preferred choice for mass production. Key driving factors include the surging global demand for hygiene and wellness products, rapid urbanization, and continuous innovation in product delivery systems that require precise cooling profiles.

The market dynamics are heavily influenced by the constant effort of manufacturers to optimize synthesis efficiency and minimize the use of hazardous reagents, adhering to strict environmental and safety regulations. The ability to produce pure L-Menthol stereoselectively is a significant technological advantage for key market players. The expansion of vaping and tobacco alternative products, requiring precise, non-volatile cooling agents, has further bolstered demand for synthetic grades, cementing its role as a fundamental ingredient across diverse consumer goods landscapes globally.

Synthetical Menthol Market Executive Summary

The Synthetical Menthol Market is characterized by robust growth, driven primarily by favorable business trends centered around manufacturing efficiency and expanding end-user applications. Global chemical companies are heavily investing in continuous processing technologies to reduce production cycles and enhance the energy efficiency of menthol synthesis, leading to lower operating costs and stable product pricing. Strategic partnerships between synthetic chemical producers and major flavor and fragrance houses are a defining business trend, ensuring integrated supply chains and collaborative product development for novel cooling applications beyond traditional mint flavoring. The market is also experiencing a shift towards sustainable synthesis methods, minimizing environmental impact while maintaining high purity essential for pharmaceutical and high-end cosmetic formulations, thereby balancing profitability with corporate social responsibility.

Regionally, Asia Pacific (APAC) stands out as the primary engine of growth, propelled by the booming populations, escalating disposable incomes, and the consequent surge in demand for oral hygiene products and mass-market confectionery in countries like China and India. North America and Europe maintain a mature but stable market, focusing on high-value applications, including premium pharmaceuticals and clean-label personal care, where stringent quality controls favor synthetic purity. Segment trends indicate that the application segment of Oral Care and Pharmaceuticals collectively command the largest market share, leveraging menthol’s therapeutic and refreshing properties. Furthermore, the L-Menthol product type segment dominates due to its superior cooling capacity and higher biological activity compared to other stereoisomers, highlighting the market's preference for functional efficacy.

In essence, the market outlook is overwhelmingly positive, underpinned by technology-driven production stability and geographical market expansion into previously underserved consumer bases. Although challenges exist, such as regulatory scrutiny in the vaping sector and fluctuating feedstock costs, the fundamental drivers—consistency of supply and application versatility—ensure sustained market resilience and projected revenue growth through the forecast period. The industry is poised for continued consolidation as major players seek economies of scale and control over innovative, cost-effective synthetic routes.

AI Impact Analysis on Synthetical Menthol Market

Common user questions regarding AI's influence on the Synthetical Menthol Market frequently revolve around optimizing complex chemical reaction parameters, predicting supply chain disruptions, and enhancing quality assurance without human intervention. Users are particularly interested in how AI can minimize waste in multi-step synthesis pathways, reduce energy consumption, and ensure the precise chiral purity of L-Menthol, which is crucial for high-end applications. Key themes identified include the integration of machine learning (ML) models for predictive maintenance of synthesis reactors, the potential for AI-driven feedstock sourcing to mitigate price volatility risks, and the use of computer vision for real-time monitoring of crystallization and purification processes, seeking to answer how AI translates to quantifiable cost savings and regulatory compliance improvements in this niche chemical sector.

The implementation of Artificial Intelligence and Machine Learning algorithms is fundamentally transforming the R&D and manufacturing phases of synthetical menthol production. AI tools are being deployed to screen thousands of potential catalysts and reaction conditions in silico, drastically reducing the time and resources traditionally required for process optimization. By analyzing vast datasets related to temperature, pressure, reagent concentration, and resulting yield/purity, AI models can precisely pinpoint the optimal operating window for maximal stereoselectivity of L-Menthol, moving away from empirical trial-and-error methods towards a data-driven synthetic approach. This acceleration in process refinement directly contributes to faster time-to-market and enhanced product consistency.

Furthermore, in supply chain management, AI's predictive capabilities are crucial for a market that relies on petrochemical feedstocks. ML models analyze global economic indicators, oil prices, geopolitical stability, and historical consumption rates to forecast future feedstock cost fluctuations, allowing producers to implement proactive hedging strategies and inventory optimization. This integration ensures operational resilience against external market shocks. In quality control, AI-powered spectroscopes and chromatography data analysis platforms automatically detect trace impurities and verify the isomeric purity of the final product faster and more accurately than traditional methods, meeting the stringent standards demanded by pharmaceutical and cosmetic regulatory bodies globally, thus solidifying AI's role as a major catalyst for operational excellence.

- AI optimizes complex, multi-step chemical synthesis pathways to maximize stereoselective yield of L-Menthol.

- Machine Learning algorithms predict raw material feedstock price volatility, improving procurement and inventory management strategies.

- Predictive maintenance schedules for reactor systems are enhanced by AI analysis of sensor data, minimizing unplanned operational downtime.

- AI-driven image recognition and data analytics are deployed for real-time quality control and automated impurity detection in final product batches.

- Advanced modeling simulates green chemistry routes, helping manufacturers reduce solvent use and energy consumption in the synthesis process.

DRO & Impact Forces Of Synthetical Menthol Market

The Synthetical Menthol Market dynamics are shaped by powerful Drivers (D), significant Restraints (R), and latent Opportunities (O), which collectively define the Impact Forces influencing future market trajectory. The core driver is the requirement for stable, high-purity, and cost-effective cooling agents across mass-market applications, where reliance on volatile natural supplies poses significant risk to profitability. The ability of synthetic production to ensure consistency in quality, which is paramount in regulated sectors like pharmaceuticals and oral care, provides a critical competitive advantage. However, the market faces restraints, primarily the increasing cost volatility of petrochemical precursors, which form the basis of many synthetic routes, and the persistent consumer preference for 'natural' labeling, often necessitating dual product lines for manufacturers. Opportunities lie in developing advanced, bio-based synthetic routes and non-petrochemical feedstocks, alongside expanding penetration into emerging markets characterized by rapid consumer expenditure growth on personal hygiene and wellness products.

One major impact force stemming from these dynamics is the intense pressure on manufacturers to innovate their synthesis processes. The pursuit of sustainable chemistry is no longer optional; it is a competitive necessity. Companies that successfully transition to more environmentally benign and energy-efficient synthetic methodologies will capture significant market share and mitigate regulatory risks associated with hazardous waste disposal. Simultaneously, the regulatory landscape for flavoring and cooling agents in tobacco cessation and vaping products remains highly fluid, presenting both a high-risk factor (restraint) and a potential high-reward opportunity for firms that can quickly adapt their product offerings to meet evolving global standards for purity and labeling transparency.

The interplay between stable demand from pharmaceutical end-users (a consistent driver) and the persistent threat of feedstock price shocks (a strong restraint) mandates a strategic focus on vertical integration and diversification of sourcing. Companies are increasingly looking to control the value chain from precursor chemicals to final purification. The latent opportunity inherent in exploiting intellectual property surrounding novel, proprietary catalytic systems—which can enhance the yield and purity while reducing production costs—is a defining feature of the competitive landscape. These impact forces ensure that technological investment and robust supply chain planning remain the highest strategic priorities for market leaders aiming to maintain long-term dominance.

Segmentation Analysis

The Synthetical Menthol Market is comprehensively segmented based on product type, application, and geographical region, providing granular insights into demand patterns and competitive positioning. Segmentation allows stakeholders to identify specific high-growth areas, such as the increasing utilization of L-Menthol in flavor systems, which is driven by its dominant sensory profile and therapeutic properties. The division by application highlights the differential growth rates across consumer goods, personal care, and therapeutic sectors, with segments tied to basic hygiene showing exceptional resilience and expansion. Analyzing these segments is essential for allocating R&D resources effectively and tailoring marketing strategies to meet specific industry requirements, ensuring that purity levels and regulatory compliance match the intended end-use.

Segmentation by product type typically focuses on the specific isomers produced, recognizing that L-Menthol is the most commercially significant due to its physiological cooling effect. Other forms, such as racemic menthol (a mixture of isomers), are used in specific, less sensitive industrial applications where the cooling intensity is less critical or where cost optimization is the primary concern. The application segmentation demonstrates the versatility of synthetic menthol, spanning from low-concentration flavor enhancement in beverages to high-concentration therapeutic applications in anti-itch or topical analgesic creams. Understanding these distinctions is fundamental to accurate market forecasting, particularly concerning the volume versus value proposition across different market niches.

- Product Type: L-Menthol, D-Menthol, Racemic Menthol

- Application: Flavors and Fragrances (F&F), Oral Care (Toothpaste, Mouthwash), Pharmaceuticals (Cough Suppressants, Topical Analgesics), Confectionery (Chewing Gum, Candies), Tobacco and Vaping Products, Others (Cosmetics, Cleaning Agents)

- Region: North America, Europe, Asia Pacific (APAC), Latin America (LATAM), Middle East and Africa (MEA)

Value Chain Analysis For Synthetical Menthol Market

The value chain for the Synthetical Menthol Market is highly structured, beginning with complex upstream chemical processing and culminating in distribution to diverse downstream end-users. Upstream activities involve the sourcing of critical precursor chemicals, often derived from petrochemicals, such as p-cresol, m-cresol, or piperitone, depending on the chosen synthesis route (e.g., Takasago or Haarmann & Reimer processes). Reliability and cost management at this initial stage are crucial, as feedstock prices significantly influence the final manufacturing cost. Advanced chemical synthesis and purification facilities then transform these precursors into high-purity L-Menthol, requiring capital-intensive technologies and highly specialized chemical engineering expertise to ensure precise stereoselectivity and regulatory adherence.

Midstream activities primarily encompass the core manufacturing processes, including catalytic hydrogenation, distillation, crystallization, and stringent quality control testing. Efficient manufacturing is defined by achieving economies of scale and optimizing energy consumption. The distribution channel is multifaceted, relying heavily on specialized chemical distributors who manage the logistics, inventory, and regulatory documentation required for transporting bulk flavor and pharmaceutical ingredients globally. These distributors act as intermediaries, servicing a broad client base that includes large FMCG conglomerates and smaller regional manufacturers, ensuring timely and compliant delivery of high-purity synthetic menthol.

Downstream activities involve the final formulation and integration of synthetic menthol into consumer products. Direct channels are often utilized by the largest manufacturers (e.g., major flavor houses) who purchase bulk quantities directly from synthetic producers for internal use in creating proprietary flavor systems. Indirect distribution is characterized by the use of wholesalers and regional agents who supply smaller formulators in the oral care, confectionery, and personal care sectors. The value added at the downstream stage lies in blending menthol with other ingredients and packaging the final consumer product, driven by marketing and consumer trends related to freshness and therapeutic efficacy.

Synthetical Menthol Market Potential Customers

The primary consumers and buyers of synthetical menthol are large-scale multinational corporations across several distinct, high-volume industries where flavor, fragrance, and cooling effects are essential product characteristics. Pharmaceutical companies represent a critical customer segment, purchasing menthol for its therapeutic applications in cough and cold remedies, topical pain relievers, and medicated rubs, necessitating the highest standards of purity and regulatory documentation. Similarly, major players in the Oral Care sector, including manufacturers of toothpaste, mouthwash, and specialized dental hygiene products, are consistent, high-volume buyers, utilizing menthol to provide the characteristic sensation of freshness and cleanliness that defines their product lines globally.

The Flavor and Fragrance industry forms another significant customer base, where synthetic menthol is integral to formulating complex flavor profiles for confectionery products such as chewing gum, candies, and specialized baked goods, as well as being a key note in various cosmetic and personal care fragrances. Furthermore, the rapidly evolving sector of Tobacco Alternatives, particularly vaping liquid producers and manufacturers of nicotine pouches, constitutes a modern and accelerating customer segment. These buyers require specific, non-volatile cooling agents to enhance the sensory experience, often preferring synthetic menthol for its consistent cooling power and ease of integration into liquid formulations, underscoring the product's versatility across both regulated and nascent consumer segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 680.5 Million |

| Market Forecast in 2033 | USD 1,075.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Symrise AG, Takasago International Corporation, BASF SE, IFF (International Flavors & Fragrances), Arora Aromatics Pvt. Ltd., Nanjing Chemsino Industrial Co., Ltd., Wuxi Huadong Chemical Co., Ltd., Yingcheng Xiangrui Chemical Co., Ltd., Mentha & Allied Products Pvt. Ltd., Nantong Menthol Chemical Co., Ltd., Changsha Qingsen Chemical Co., Ltd., Qingdao Free Trade Zone United International, Shanghai Greenspec Co., Ltd., Shandong Jintu Chemical Co., Ltd., Tianjin Zhongxin Pharma Co., Ltd., Hefei TNJ Chemical Industry Co., Ltd., Spectrum Chemical Manufacturing Corp., Penta Manufacturing Co., LLC, Givaudan SA, Firmenich International SA |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Synthetical Menthol Market Key Technology Landscape

The technological landscape of the Synthetical Menthol Market is defined by the ongoing pursuit of highly efficient, stereoselective synthesis methods capable of producing pure L-Menthol at industrial scale and competitive costs. The dominant industrial processes generally fall into two categories: routes starting from petrochemical precursors like p-cresol (BASF’s process involving citronellal synthesis) or routes relying on catalytic hydrogenation and asymmetric synthesis (like the Takasago process, famed for its high stereoselectivity). The core challenge is the precise control of the molecular structure to yield the correct chiral isomer, L-Menthol, which is responsible for virtually all the desired sensory and therapeutic effects. Continual innovation focuses on developing novel, robust catalysts, often homogeneous or supported metal catalysts, to improve reaction kinetics, yield, and purity while minimizing unwanted by-products and solvent use.

A burgeoning area of technological advancement involves green chemistry and sustainable synthesis. This includes the exploration of biocatalysis—using enzymes or modified microorganisms to facilitate specific reaction steps under milder conditions, reducing energy consumption and the reliance on harsh chemicals. Furthermore, manufacturers are investing in advanced separation and purification technologies, such as continuous chromatography and highly optimized fractional distillation, to ensure the final product meets the ultra-high purity specifications required by pharmaceutical Good Manufacturing Practices (GMP). These separation technologies are crucial for removing trace impurities that could affect the flavor profile or safety of the end-product, particularly when targeting the sensitive oral care and pharmaceutical markets.

The future technology landscape is leaning heavily towards integrated continuous flow chemistry systems. These systems replace traditional batch processing with automated, smaller-footprint reactors, allowing for superior temperature and pressure control, resulting in more consistent product quality and higher safety levels. This transition towards continuous manufacturing, often monitored and controlled using AI and advanced process analytical technology (PAT), reduces variable manufacturing costs, enhances operational flexibility, and further solidifies the economic advantages of synthetic production over sourcing volatility associated with natural menthol, ensuring the long-term competitiveness of synthesized grades.

Regional Highlights

Regional dynamics significantly influence the Synthetical Menthol Market, reflecting diverse consumer preferences, regulatory environments, and industrial manufacturing capacities. Asia Pacific (APAC) currently holds the dominant position in terms of consumption volume and is rapidly increasing its manufacturing footprint. This growth is fueled by massive domestic demand in populous countries such as China and India, driven by increasing per capita expenditure on personal hygiene products, including oral care and mass-market confectionery. Furthermore, China serves as a global hub for synthetic chemical manufacturing, benefiting from strong infrastructural support, economies of scale, and efficient supply chain networks, positioning the region as both a major producer and consumer of synthetic menthol.

North America and Europe represent mature, high-value markets characterized by stringent regulatory oversight, particularly in the pharmaceutical and food flavor sectors. Demand in these regions is stable and focused heavily on high-purity L-Menthol, where quality certification and supply chain transparency are critical purchasing criteria. The European market, guided by regulations like REACH, drives innovation towards sustainable and environmentally friendly synthesis methods, demanding high technological investment from producers. North America exhibits strong consumption in the oral care and topical analgesic segments, with recent fluctuations in demand related to evolving regulatory frameworks concerning flavored vaping products, necessitating rapid adaptation by suppliers to maintain market access.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions demonstrating accelerating growth, albeit from a smaller base. In LATAM, urbanization and the expansion of modern retail channels are boosting demand for packaged consumer goods that utilize menthol for freshness and cooling effects. The MEA region is witnessing infrastructure development and rising disposable incomes, translating into increased importation and localized formulation of personal care and pharmaceutical products. While these regions rely heavily on imports, strategic global players are establishing regional distribution hubs to capitalize on nascent opportunities, targeting both local manufacturing growth and the increasing sophistication of regional consumer bases seeking quality cooling and freshness components.

- Asia Pacific (APAC): Dominates market growth due to expansive oral care and confectionery sectors, high manufacturing capacity, and rapidly increasing consumer base in China and India.

- North America: Stable, high-value market characterized by robust demand in pharmaceuticals and stringent purity requirements; focused on regulated applications like topical analgesics.

- Europe: Mature market emphasizing sustainability and high regulatory compliance (REACH); strong consumption driven by flavor & fragrance industry and premium personal care products.

- Latin America (LATAM): Exhibits high potential growth linked to improving economic conditions and increased consumer spending on packaged goods utilizing synthetic menthol for sensory appeal.

- Middle East & Africa (MEA): Emerging market driven by urbanization and rising hygiene standards; growth reliant on imports and increasing localized formulation activities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Synthetical Menthol Market.- Symrise AG

- Takasago International Corporation

- BASF SE

- IFF (International Flavors & Fragrances)

- Arora Aromatics Pvt. Ltd.

- Nanjing Chemsino Industrial Co., Ltd.

- Wuxi Huadong Chemical Co., Ltd.

- Yingcheng Xiangrui Chemical Co., Ltd.

- Mentha & Allied Products Pvt. Ltd.

- Nantong Menthol Chemical Co., Ltd.

- Changsha Qingsen Chemical Co., Ltd.

- Qingdao Free Trade Zone United International

- Shanghai Greenspec Co., Ltd.

- Shandong Jintu Chemical Co., Ltd.

- Tianjin Zhongxin Pharma Co., Ltd.

- Hefei TNJ Chemical Industry Co., Ltd.

- Spectrum Chemical Manufacturing Corp.

- Penta Manufacturing Co., LLC

- Givaudan SA

- Firmenich International SA

Frequently Asked Questions

Analyze common user questions about the Synthetical Menthol market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for synthetic menthol over natural menthol?

The primary factor driving demand for synthetic menthol is its superior supply stability and cost predictability compared to natural sources, which are vulnerable to volatile agricultural yields and climate-related price fluctuations. Synthetic production ensures consistent, high purity L-Menthol necessary for regulated pharmaceutical and food-grade applications.

Which application segment holds the largest market share for synthetical menthol?

The Oral Care and Pharmaceutical segments collectively hold the largest market share for synthetical menthol. Oral care utilizes menthol extensively for flavoring and cooling in toothpaste and mouthwash, while pharmaceuticals rely on its counter-irritant properties in cough suppressants and topical pain relievers.

How do regulatory changes in the vaping industry affect the synthetical menthol market?

Regulatory changes in the vaping industry, specifically restrictions on flavored e-liquids, create market uncertainty; however, synthetic menthol remains a key component in legal tobacco alternatives and non-tobacco cooling agents, requiring manufacturers to rapidly adapt product formulations to maintain compliance and market relevance.

What key technological advancements are influencing the efficiency of menthol synthesis?

Key technological advancements include the deployment of asymmetric synthesis methods utilizing specialized catalysts for high L-Menthol stereoselectivity and the integration of continuous flow chemistry systems, which improve reaction control, reduce waste, and enhance operational scalability compared to traditional batch processing.

Which geographic region is projected to exhibit the highest growth rate in the market?

The Asia Pacific (APAC) region is projected to exhibit the highest compound annual growth rate, driven by rapid urbanization, substantial expansion in the consumer packaged goods sector, and escalating demand for hygiene and wellness products across major economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager