Tablet Rotary Presses Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433463 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Tablet Rotary Presses Market Size

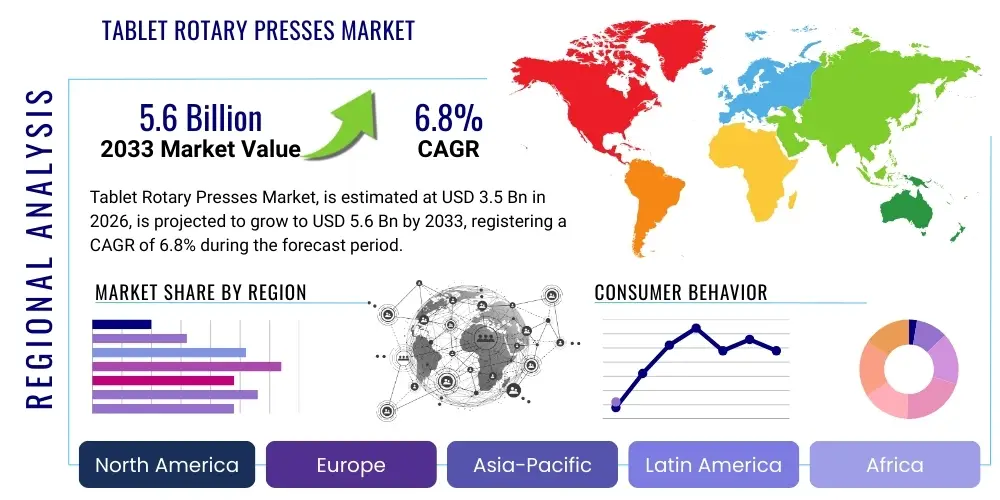

The Tablet Rotary Presses Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.6 Billion by the end of the forecast period in 2033. This consistent expansion is fundamentally driven by the escalating global demand for high-quality, standardized pharmaceutical solid dosage forms, coupled with significant advancements in automation and precision manufacturing technologies inherent in modern rotary press systems. The pharmaceutical sector's relentless focus on high-volume production efficiency, compliance with stringent regulatory standards (such as FDA and EMA guidelines), and the necessity to produce complex, multi-layered tablets are the primary catalysts underpinning this robust market valuation increase over the defined forecast horizon.

The trajectory of growth is further reinforced by the rapid infrastructural development within the nutraceutical and functional food industries, particularly in emerging economies of the Asia Pacific region. Tablet rotary presses are critical for ensuring uniform tablet weight, hardness, and disintegration characteristics, factors that are indispensable for therapeutic efficacy and consumer confidence. As generic drug manufacturing accelerates globally, fueled by patent expirations and increasing healthcare accessibility, the deployment of high-throughput, reliable rotary presses becomes a non-negotiable prerequisite for manufacturers aiming to capture substantial market share. Consequently, investments in advanced machinery featuring sophisticated sensor technologies and predictive maintenance capabilities are becoming commonplace, contributing significantly to the overall market valuation growth.

Tablet Rotary Presses Market introduction

The Tablet Rotary Presses Market encompasses the design, manufacturing, sale, and servicing of specialized machinery used for compressing powder into uniform, solid tablets at high speeds. These machines, often utilizing multiple tooling stations arranged in a rotating turret, are indispensable across the pharmaceutical, nutraceutical, chemical, and food processing industries. Modern rotary presses are highly complex systems designed to handle vast quantities of materials while ensuring precision in weight control, hardness, thickness, and dissolution profile of the final product. Key driving factors include the substantial rise in chronic diseases necessitating ongoing medication, the expansion of global generic drug production, and the sustained innovation focused on improving production capacity and minimizing cross-contamination risks.

The product description highlights rotary presses ranging from small-scale R&D models to large, double-sided production units capable of pressing hundreds of thousands of tablets per hour. Major applications span standard pharmaceutical tablets (both immediate and sustained release), confectionery products (like effervescent tablets and candies), and specialized industrial catalysts or fertilizer pellets. Benefits derived from utilizing these systems include unparalleled efficiency, reduced labor costs due to automation, exceptional weight and quality uniformity (critical for regulatory compliance), and the flexibility to produce various tablet shapes and sizes by simply changing the turret tooling. The convergence of strict regulatory frameworks demanding superior quality control and the intrinsic economic pressure for high-speed output solidifies the importance of the tablet rotary press market within the global manufacturing ecosystem.

Tablet Rotary Presses Market Executive Summary

The Tablet Rotary Presses Market is characterized by intense technological evolution, driven predominantly by the integration of Industry 4.0 principles, focusing on connectivity, real-time monitoring, and predictive maintenance. Business trends indicate a strong shift towards flexible, modular press designs that can rapidly switch between different product batches (quick changeover), reducing downtime and increasing overall equipment effectiveness (OEE). Key market leaders are focusing heavily on developing presses capable of handling challenging formulations, such as those involving highly potent active pharmaceutical ingredients (HPAPIs), necessitating specialized containment features (WIP - Wash-in-Place systems). This push for enhanced sophistication and quality assurance is reshaping procurement strategies across large multinational pharmaceutical organizations and Contract Manufacturing Organizations (CMOs).

Regionally, the Asia Pacific (APAC) market is exhibiting the fastest growth due to massive investments in local pharmaceutical manufacturing capabilities, particularly in India and China, aiming to meet both domestic and international generic drug demands. North America and Europe remain dominant markets in terms of technology adoption, characterized by high regulatory scrutiny and early deployment of advanced automation (e.g., automated closed-loop weight control systems). Segment trends show significant momentum in the Fully Automatic and High-Speed Double-Sided Rotary Presses segments, reflecting the industry’s imperative to maximize yield and minimize human intervention. Furthermore, the Nutraceuticals segment is emerging as a critical application area, requiring presses that can handle abrasive materials while maintaining strict sanitary standards, diversifying the market beyond traditional pharmaceuticals.

AI Impact Analysis on Tablet Rotary Presses Market

Users frequently inquire about how Artificial Intelligence (AI) can enhance tablet quality control, predict equipment failure, and optimize formulation processes within the constraints of high-speed rotary press operations. Common concerns revolve around the complexity of integrating AI models with legacy machinery and the security implications of cloud-based data analysis. The key consensus is that AI is poised to revolutionize process analytical technology (PAT) by allowing for real-time adjustments to compression parameters (force, speed, fill depth) based on immediate sensor feedback, thereby reducing waste and ensuring batch homogeneity far exceeding current capabilities. The expectation is a move from periodic calibration to continuous, self-correcting manufacturing environments, leveraging machine learning to interpret vast streams of operational data for superior operational insights and minimized downtime, fundamentally enhancing the reliability and consistency of tablet production.

- AI enables Predictive Maintenance: Analyzing vibrations, temperature, and current draw patterns to predict tooling wear and component failure, drastically reducing unscheduled downtime and optimizing maintenance scheduling (Condition-Based Monitoring).

- Real-time Process Optimization: Machine learning algorithms interpret PAT data (Near-Infrared Spectroscopy, Raman) in real-time, automatically adjusting press settings (e.g., main compression force) to maintain target tablet weight and hardness, improving yield and quality.

- Enhanced Quality Control (QC): Utilizing AI-driven vision systems to inspect individual tablets for defects (capping, lamination, speckling) at high speeds, offering superior accuracy compared to traditional statistical sampling methods.

- Formulation Development Acceleration: AI simulates powder compression behavior under various conditions, assisting R&D teams in optimizing excipient ratios and raw material specifications before costly physical trials, accelerating time-to-market.

- Improved Energy Efficiency: AI models optimize motor speeds and operational cycles based on production demand and material flow, minimizing energy consumption without compromising throughput.

DRO & Impact Forces Of Tablet Rotary Presses Market

The dynamics of the Tablet Rotary Presses Market are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively exerting significant impact forces on market expansion and strategic direction. The primary driver is the sheer increase in global generic drug consumption, mandating pharmaceutical companies to invest in high-efficiency, multi-station presses to meet escalating volume requirements. Simultaneously, opportunities arising from the transition towards continuous manufacturing, supported by advanced regulatory guidance, are propelling technological innovation towards integrated, smaller footprint systems. These positive forces are counterbalanced by substantial restraints, mainly the prohibitive capital expenditure required for purchasing and installing cutting-edge rotary press technology, particularly challenging for small and mid-sized enterprises (SMEs) and manufacturers in developing regions.

The impact forces generated by these DRO factors mandate a strategic focus on total cost of ownership (TCO) rather than just initial purchase price. Manufacturers are prioritizing presses offering superior durability and minimal maintenance needs, thereby mitigating the restraint of high operational costs. The compelling opportunity presented by personalized medicine and niche markets, requiring presses capable of handling small, frequent batches with exceptional flexibility, drives R&D efforts towards modular and customizable machinery. Regulatory stringency, while acting as a quality assurance driver, simultaneously impacts the market by increasing the complexity of validation and compliance, necessitating presses equipped with advanced documentation and data integrity features (e.g., compliance with 21 CFR Part 11). The resultant impact forces steer the market towards premium, sophisticated, and validated machinery solutions.

Segmentation Analysis

The Tablet Rotary Presses Market is comprehensively segmented based on Type, Application, and Level of Automation, reflecting the diverse needs and operational scales of end-users. This granular analysis provides a clear perspective on which product categories are experiencing heightened demand and where technological investments are concentrated. The complexity of modern pharmaceuticals and the push for high throughput in nutraceuticals necessitate specialized machinery, making the segmentation based on type (e.g., multi-layer presses) particularly relevant. The dominance of the Pharmaceutical segment in terms of revenue is undisputed, yet the rapid emergence of the Nutraceutical and Functional Food sector provides crucial diversification for machinery manufacturers. Understanding these segments is vital for stakeholders to tailor their product offerings and marketing strategies effectively.

Analysis of automation levels reveals a clear trend towards fully automatic and high-speed presses, driven by the increasing labor costs in developed economies and the imperative for precise, repeatable processes that minimize human error. This shift is reinforcing the demand for integrated control systems, automated weight calibration, and seamless connectivity within larger manufacturing execution systems (MES). The geographical segmentation further clarifies regional demands, with North America leading in adopting complex, high-precision models for specialty drugs, while APAC focuses heavily on high-volume, cost-effective standard rotary presses for generic production, illustrating a dichotomy in market needs and technological maturity across different global regions.

- Type:

- Standard Single-Sided Rotary Press

- High-Speed Double-Sided Rotary Press

- Multi-Layer Tablet Press (Bilayer, Trilayer)

- Specialty Presses (e.g., Effervescent, Containment Presses for HPAPIs)

- Application:

- Pharmaceutical Industry (Generics, Over-the-Counter, Specialty Drugs)

- Nutraceuticals and Dietary Supplements

- Food and Beverage Industry (Confectionery, Food Additives)

- Chemical and Industrial Pellets

- Level of Automation:

- Manual/Small-Scale Rotary Presses

- Semi-Automatic Presses

- Fully Automatic High-Speed Presses

Value Chain Analysis For Tablet Rotary Presses Market

The Value Chain for the Tablet Rotary Presses Market begins with upstream activities involving the sourcing and processing of high-grade raw materials, primarily specialized stainless steel (e.g., 316L for contact parts) and precision components such as motors, sensors, and complex tooling (punches and dies). Upstream analysis is critical as the quality of these raw materials directly dictates the longevity, hygienic design, and regulatory compliance of the final press. Tooling manufacturers play a pivotal role, as they often collaborate closely with press manufacturers and end-users to optimize tablet design and compression efficiency. Fluctuations in commodity prices, particularly specialty metal alloys, can significantly impact the production costs of the press original equipment manufacturers (OEMs).

Downstream analysis focuses on the distribution, sales, installation, and post-sales service, which often represent the most complex part of the value chain given the high-value, technical nature of the equipment. Distribution channels are typically a mix of direct sales forces for major pharmaceutical accounts and authorized technical distributors/agents specializing in specific regions or application areas. The complexity of installation, coupled with the rigorous validation and qualification processes (IQ, OQ, PQ) required by pharmaceutical end-users, necessitates a strong service component. Direct distribution allows OEMs greater control over pricing and customer relationships, while indirect channels provide localized support, spare parts availability, and faster response times for technical issues, especially in fragmented emerging markets.

Tablet Rotary Presses Market Potential Customers

The primary customers for Tablet Rotary Presses are large multinational pharmaceutical companies that require continuous, high-volume production capabilities for blockbuster and generic drugs, utilizing advanced, high-speed double-sided and multi-layer presses. These customers prioritize reliability, compliance (21 CFR Part 11), and seamless integration into existing manufacturing execution systems (MES). The second major customer group comprises Contract Manufacturing Organizations (CMOs) and Contract Development and Manufacturing Organizations (CDMOs). CMOs require flexible, modular presses capable of rapid changeovers to handle diverse product portfolios and varying batch sizes for multiple clients, focusing heavily on versatility and minimal cross-contamination risks.

A rapidly expanding segment of potential customers includes specialized nutraceutical and dietary supplement manufacturers, particularly those focusing on high-density tablets, energy bars, or specialized formulations requiring stringent sanitary design and resistance to abrasive ingredients. Furthermore, academic research institutions and pharmaceutical R&D laboratories represent niche buyers, requiring smaller, instrumented rotary presses designed specifically for feasibility studies, small-scale clinical trial batch production, and detailed characterization of powder compression properties. Finally, regional generic drug manufacturers in APAC and Latin America are significant consumers, often opting for robust, cost-effective standard rotary presses to scale up local production quickly and efficiently.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.6 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | KORSCH AG, IMA SpA, GEA Group, Fette Compacting, ACG Worldwide, SENIEER, Manesty (by Bosch Packaging Technology), LMT Group, Natoli Engineering Company Inc., Riva, Prabhat Engineering, Jicon Group, Changzhou YIBU Drying Equipment Co., Ltd., Shanghai Jwell Machinery Co., Ltd., KGK-Pharmagroup, KIKUSUI SEISAKUSHO LTD., Kilian GmbH, SaintyCo. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tablet Rotary Presses Market Key Technology Landscape

The technology landscape of the Tablet Rotary Presses Market is dominated by advancements aimed at increasing throughput, ensuring product quality, and improving operator safety and ease of use. A cornerstone technology is Process Analytical Technology (PAT), involving the integration of in-line sensors, such as NIR (Near-Infrared Spectroscopy), directly into the compression zone. This allows for continuous monitoring of critical quality attributes like blend uniformity and API concentration, facilitating real-time release testing and minimizing the reliance on traditional, time-consuming off-line testing. Furthermore, sophisticated pressure and displacement sensors are integrated into the compression rollers to provide high-resolution data on punch penetration and compression force, enabling automatic feedback loops to maintain optimal tablet characteristics under fluctuating process conditions. The adoption of gravimetric dosing systems ensures highly accurate and consistent powder feed into the dies, a crucial technology for maintaining precise tablet weight uniformity at high speeds.

Another major technological trend involves the transition to fully automated containment systems, essential for handling highly potent active pharmaceutical ingredients (HPAPIs). These advanced presses feature contained loading, compression, and discharge zones, often incorporating Wash-in-Place (WIP) or Clean-in-Place (CIP) functionalities to minimize operator exposure and expedite cleaning validation. Tooling technology has also advanced significantly; complex multi-tip tooling systems are now common, allowing a single press station to produce multiple tablets simultaneously, substantially boosting output rates. Furthermore, the incorporation of Human-Machine Interface (HMI) systems with highly intuitive, validated software environments (often 21 CFR Part 11 compliant) provides operators with comprehensive control and data logging capabilities, positioning the modern rotary press as a key component of a highly integrated, intelligent manufacturing ecosystem, moving beyond simple mechanical compression into a data-driven process control environment.

The push for continuous manufacturing (CM) is also redefining the technological requirements. Presses designed for CM environments must seamlessly integrate with upstream processing equipment (like continuous mixers and granulators) and downstream quality control and coating systems. This integration necessitates specialized press designs with optimized material flow paths and minimized hold-up volumes. Precision feeder mechanisms, often utilizing loss-in-weight feeders, are essential for maintaining steady material supply to the press, crucial for stable continuous operation. The robust data infrastructure required to support CM—managing real-time sensor data and ensuring data integrity across interconnected equipment—is a critical technological investment area for both machinery manufacturers and pharmaceutical end-users.

Regional Highlights

- North America: This region holds a leading position in terms of technological adoption and market value, driven by the presence of major pharmaceutical innovators and a stringent regulatory environment demanding high-precision, validated equipment. The focus here is on specialty drugs, high-potency API handling (requiring containment presses), and early adoption of continuous manufacturing techniques. The United States and Canada are primary revenue generators, characterized by high investment in advanced automation and digital integration (Industry 4.0).

- Europe: Europe is a mature market distinguished by strong manufacturing bases in Germany, Switzerland, and Italy, which house global leaders in tablet press manufacturing (OEMs). The market is heavily focused on quality assurance, regulatory compliance (EMA standards), and sustainability. Demand centers around flexible batch sizes for diverse EU markets and advanced multi-layer pressing capabilities for complex formulations.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, primarily fueled by rapid expansion in generic drug manufacturing in India and China, and significant growth in the regional nutraceutical sector. The market demand is bifurcated: high-volume, cost-effective standard presses dominate generic production, while advanced Japanese and South Korean manufacturers drive demand for high-tech, precision presses. Government initiatives supporting domestic pharmaceutical capacity further bolster growth.

- Latin America (LATAM): Growth in this region, notably in Brazil and Mexico, is driven by localized production aiming for self-sufficiency in pharmaceuticals and addressing regional health issues. The market is moderately mature, showing increasing investment in semi-automatic and mid-speed rotary presses to upgrade legacy production lines and comply with harmonizing regional regulatory standards.

- Middle East and Africa (MEA): This region is an emerging market with growth concentrated in Gulf Cooperation Council (GCC) countries investing heavily in healthcare infrastructure to reduce reliance on imported medicines. Demand focuses mainly on reliable standard presses and essential service support, though adoption of advanced technology is accelerating in key pharmaceutical hubs like Saudi Arabia and the UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tablet Rotary Presses Market.- KORSCH AG

- IMA SpA

- GEA Group

- Fette Compacting

- ACG Worldwide

- SENIEER

- Manesty (by Bosch Packaging Technology)

- LMT Group

- Natoli Engineering Company Inc.

- Riva

- Prabhat Engineering

- Jicon Group

- Changzhou YIBU Drying Equipment Co., Ltd.

- Shanghai Jwell Machinery Co., Ltd.

- KGK-Pharmagroup

- KIKUSUI SEISAKUSHO LTD.

- Kilian GmbH

- SaintyCo

Frequently Asked Questions

Analyze common user questions about the Tablet Rotary Presses market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are driving the transition from single-sided to double-sided rotary presses?

The primary driver is the need for significantly increased production throughput and efficiency, particularly in generic drug manufacturing, where high volumes are critical. Double-sided presses effectively double the output capacity while maintaining superior weight uniformity and process control compared to older single-sided models, addressing the industry's demand for maximized OEE (Overall Equipment Effectiveness).

How does Process Analytical Technology (PAT) improve the tablet compression process?

PAT integration, often utilizing NIR or Raman spectroscopy, allows for continuous, real-time monitoring of critical quality attributes within the compression zone. This enables automated closed-loop feedback, allowing the press to instantly adjust parameters (like compression force) to maintain quality specifications, reducing waste, minimizing batch rejection, and supporting the shift toward real-time release testing.

What are the key challenges associated with compressing complex, multi-layered tablets?

The main challenges involve ensuring adequate adhesion between layers, preventing cross-contamination between different drug layers, and achieving precise weight control for each individual layer. This requires specialized multi-layer rotary presses equipped with multiple precise dosing systems and distinct compression stages, along with highly accurate turret speed control.

Which geographical region is expected to demonstrate the fastest growth rate in this market?

The Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR). This growth is attributed to massive governmental support for domestic pharmaceutical and nutraceutical manufacturing, increasing healthcare expenditure, and the expansion of the generic drug industry across key economies like India and China.

What is the significance of containment technology in modern tablet rotary presses?

Containment technology is crucial for ensuring operator safety and preventing environmental contamination when processing Highly Potent Active Pharmaceutical Ingredients (HPAPIs). Modern presses incorporate specialized sealed systems, isolation barriers, and integrated Wash-in-Place (WIP) functionality to handle these toxic materials safely, meeting stringent occupational health and regulatory standards.

How is Industry 4.0 influencing the maintenance and efficiency of rotary presses?

Industry 4.0 leverages IoT sensors and AI-driven analytics to implement Predictive Maintenance (PdM) strategies. Data collected on vibration, temperature, and torque allows algorithms to anticipate equipment failures, optimize servicing schedules, and maximize uptime. This transition from reactive to proactive maintenance significantly boosts machine utilization and reduces overall operational costs.

What are the primary differences between eccentric (single punch) and rotary tablet presses?

Eccentric presses use a single punch and die set and are suited for R&D or small-scale batch production due to low output rates. Rotary presses, conversely, feature a rotating turret with multiple punch and die sets, enabling continuous, high-speed production (up to hundreds of thousands of tablets per hour), making them the standard choice for large-scale commercial manufacturing.

Why is tool wear monitoring a critical concern in high-speed compression?

Tool wear (punch and die erosion) is critical because it directly impacts tablet weight, thickness, and hardness uniformity, leading to potential batch failure. High-speed presses generate significant friction and stress. Advanced monitoring systems utilize sensors and algorithms to track wear in real-time, allowing proactive replacement and minimizing quality deviation, which is vital for regulatory compliance.

What role do Contract Manufacturing Organizations (CMOs) play in driving market demand?

CMOs are significant drivers because their business model requires maximum flexibility. They demand modular rotary presses with quick changeover capabilities, minimal cleaning time (CIP/WIP), and the ability to handle a wide variety of formulations and batch sizes for diverse clients, leading to higher procurement of versatile, mid-to-high speed presses.

What is the expected long-term impact of continuous manufacturing on the tablet press market design?

Continuous Manufacturing (CM) will necessitate smaller, highly integrated, and dedicated presses designed for 24/7 operation and minimal material hold-up. Future presses will be components of a unified system rather than standalone machines, requiring highly sophisticated control systems to ensure stable, steady-state operation and seamless data exchange with upstream and downstream units.

How are environmental concerns influencing the design of new rotary presses?

Environmental concerns drive the demand for more energy-efficient presses through optimized motor systems (e.g., servo motors), reduced compressed air consumption, and optimized lubricant usage. Furthermore, cleaning systems are designed to minimize water and solvent usage (WIP/CIP), reducing the environmental footprint associated with manufacturing processes while maintaining strict cleanliness standards.

What are the key technological differentiators among leading market players (OEMs)?

Leading OEMs differentiate themselves primarily through superior software integration (MES connectivity, 21 CFR Part 11 compliance), proprietary containment solutions for high-potency products, patented multi-layer dosing technology, and specialized tooling systems that offer enhanced longevity and quicker maintenance access. Service infrastructure and global support network are also key differentiators.

Why is weight consistency a major performance metric for tablet presses?

Weight consistency is directly linked to the accuracy of the Active Pharmaceutical Ingredient (API) dosage, which is crucial for therapeutic efficacy and patient safety. Regulatory bodies impose tight tolerances on weight variation; thus, high-performance rotary presses utilize advanced electronic controls and automated feedback loops to ensure minimal standard deviation in tablet weight.

What materials are commonly used for the tooling (punches and dies) in tablet presses?

The tooling is typically manufactured from specialized tool steels (such as high-carbon, high-chromium steel or D2 steel) for strength and wear resistance. For abrasive or corrosive formulations, specialized coatings (e.g., chromium, titanium nitride) are applied to extend tool life, maintain surface finish, and ensure the prevention of sticking or pitting, which could compromise tablet quality.

How does the growth of the nutraceutical industry impact rotary press specifications?

The nutraceutical industry requires presses that can handle often abrasive materials (e.g., minerals, specialized fibers) and maintain extremely high standards of sanitation. This drives demand for robust, easy-to-clean presses, often featuring full stainless steel construction, dust control systems, and specialized feeding mechanisms designed to accommodate sticky or poorly flowing powders common in dietary supplements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager