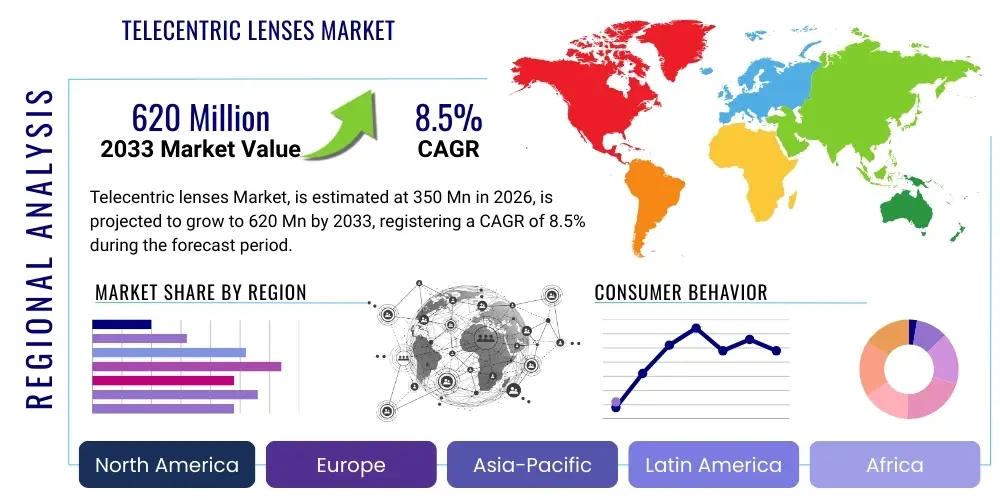

Telecentric lenses Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440088 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Telecentric lenses Market Size

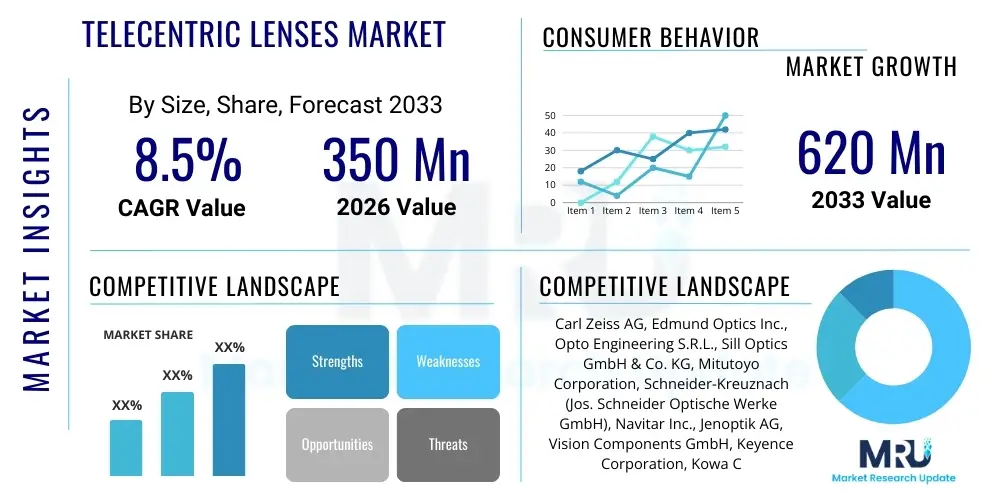

The Telecentric lenses Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 350 million in 2026 and is projected to reach USD 620 million by the end of the forecast period in 2033.

Telecentric lenses Market introduction

Telecentric lenses are specialized optical systems designed to eliminate perspective errors and image magnification changes regardless of an object's distance within a specific depth of field. This unique characteristic makes them indispensable in applications requiring extremely precise measurements, accurate defect detection, and consistent imaging, particularly within machine vision and metrology. Unlike conventional lenses that exhibit parallax errors where objects appear larger when closer and smaller when farther away, telecentric lenses maintain a constant magnification, ensuring that the image size remains uniform even if the object's position varies along the optical axis. This fundamental property is achieved by ensuring that the principal rays of light entering or exiting the lens are parallel to the optical axis, effectively eliminating any angular dependency on image formation.

The core product description of telecentric lenses encompasses various designs, primarily categorized into object-side telecentric, image-side telecentric, and bi-telecentric lenses. Object-side telecentric lenses maintain constant magnification for objects moving perpendicular to the optical axis, ensuring that the perceived size of an object does not change as it moves towards or away from the lens. Image-side telecentric lenses ensure that the image sensor only captures parallel rays, resulting in images with consistent illumination and minimal distortion across the field of view. Bi-telecentric lenses combine both characteristics, offering unparalleled precision for demanding industrial applications. These lenses are engineered with high-quality optical elements and precise mechanical assemblies to deliver superior image resolution, low distortion, and exceptional depth of field, often incorporating specific coatings to optimize performance for various light spectra.

Major applications for telecentric lenses span critical sectors such as industrial automation, electronics manufacturing, medical device inspection, and scientific research. In industrial automation, they are crucial for automated quality control systems, robotic guidance, and precise component assembly verification. Within the electronics industry, these lenses are vital for inspecting PCBs, micro-components, and semiconductor wafers, where micron-level accuracy is paramount. Their benefits include enhanced measurement accuracy, elimination of perspective error, increased repeatability in automated processes, and superior image quality with minimal distortion. The primary driving factors for the market's growth are the escalating demand for high-precision inspection and measurement systems, the rapid expansion of industrial automation and Industry 4.0 initiatives, and the continuous innovation in machine vision technology across diverse manufacturing sectors.

Telecentric lenses Market Executive Summary

The Telecentric lenses Market is experiencing robust growth, primarily driven by the global imperative for enhanced precision and automation across various industries. Current business trends indicate a significant push towards integrating telecentric optics into sophisticated machine vision systems, robotics, and advanced metrology equipment. Enterprises are increasingly investing in these specialized lenses to meet stringent quality control standards, optimize manufacturing processes, and reduce waste in high-value production lines. There is a discernible trend towards customization and application-specific lens designs, catering to unique requirements in sectors like semiconductor manufacturing, medical device assembly, and electric vehicle battery inspection. Moreover, the convergence of telecentric technology with artificial intelligence and deep learning algorithms is opening new avenues for intelligent defect detection and complex pattern recognition, thereby expanding the market's utility and value proposition. The market also observes an increasing demand for compact and lightweight telecentric solutions, facilitating their integration into smaller, more agile automated systems and portable inspection devices.

Regional trends reveal Asia Pacific as a dominant and rapidly expanding market for telecentric lenses, fueled by its burgeoning manufacturing sector, particularly in electronics, automotive, and industrial automation in countries like China, Japan, South Korea, and Taiwan. These nations are significant hubs for advanced manufacturing and possess a high adoption rate of automated inspection technologies. North America and Europe also maintain strong positions, driven by significant investments in R&D, advanced industrial capabilities, and the presence of key technology innovators and end-users in automotive, aerospace, and medical sectors. The European market benefits from strong regulatory frameworks promoting quality and safety, leading to greater adoption of high-precision inspection tools. Latin America, the Middle East, and Africa, while smaller in market share, are emerging with considerable growth potential as industrialization efforts and infrastructure development accelerate, fostering demand for advanced manufacturing and quality control solutions.

In terms of segment trends, the object-side telecentric lens segment holds a substantial share due to its widespread application in industrial measurement and inspection tasks that demand distortion-free images regardless of object position. However, bi-telecentric lenses are witnessing accelerated adoption in highly critical applications where both object and image side telecentricity are required for ultimate precision, despite their higher cost. Application-wise, machine vision remains the largest segment, with continuous advancements in camera and software technology enhancing the capabilities of telecentric vision systems for automated inspection, gauging, and alignment. The metrology segment is also experiencing significant growth, driven by the need for non-contact, high-accuracy dimensional measurements in diverse manufacturing environments. End-user industry trends show the electronics and semiconductor sectors as primary growth engines, closely followed by the automotive industry, which relies heavily on telecentric vision for precise component inspection and assembly verification, especially with the rise of electric vehicles and autonomous driving technologies.

AI Impact Analysis on Telecentric lenses Market

The integration of Artificial Intelligence (AI) is profoundly transforming the Telecentric lenses market by enhancing the capabilities and expanding the applicability of these precision optical instruments. Common user questions related to AI's impact often revolve around how AI can improve measurement accuracy, automate complex inspection tasks, reduce false positives, and enable real-time decision-making. Users are also keen to understand how AI-powered telecentric systems can adapt to variations in manufacturing, identify novel defects, and optimize throughput without sacrificing precision. There's a strong interest in the synergy between telecentric optics, which provide intrinsically precise and distortion-free images, and AI algorithms that can process this high-fidelity data with unprecedented speed and intelligence. This synergy addresses key concerns about the limitations of traditional rule-based machine vision systems, particularly in handling nuanced variations, complex textures, and subtle anomalies that are difficult to define programmatically.

- Enhanced Defect Detection: AI, particularly deep learning, allows telecentric vision systems to identify complex and subtle defects that are challenging for traditional rule-based algorithms. This significantly improves accuracy in quality control processes, leading to fewer false positives and negatives.

- Automated Measurement & Gauging: AI algorithms can process telecentric images to perform highly accurate automated dimensional measurements and gauging, even on objects with irregular shapes or challenging features, reducing human intervention and increasing measurement repeatability.

- Adaptive Inspection Systems: Machine learning enables telecentric inspection systems to learn from new data, adapting to variations in manufacturing processes or product designs without requiring extensive reprogramming, thus making the systems more flexible and scalable.

- Real-time Decision Making: AI-powered analytics, combined with the precise imagery from telecentric lenses, facilitates real-time defect classification and process adjustments on the production line, leading to immediate corrective actions and improved manufacturing efficiency.

- Predictive Maintenance and Quality Control: By analyzing patterns in telecentric inspection data over time, AI can predict potential equipment failures or quality drifts, enabling proactive maintenance and continuous improvement of manufacturing processes.

- Reduced Programming Complexity: Instead of manually coding rules for every possible defect or measurement scenario, AI can be trained with example images, simplifying the setup and maintenance of complex inspection tasks using telecentric optics.

DRO & Impact Forces Of Telecentric lenses Market

The Telecentric lenses Market is propelled by a confluence of powerful drivers that underscore its critical role in modern industrial and scientific applications. Foremost among these is the escalating demand for ultra-high precision inspection and measurement across diverse manufacturing sectors. Industries such as electronics, semiconductors, automotive, and medical devices are continually pushing the boundaries of miniaturization and quality, necessitating optical systems that can provide distortion-free and accurate imagery irrespective of object depth. This inherent capability of telecentric lenses to eliminate perspective errors makes them indispensable for critical quality control processes, ensuring product integrity and compliance with stringent industry standards. Furthermore, the rapid growth of industrial automation and robotics is a significant catalyst, as telecentric lenses are integral components of automated vision systems that guide robots, perform in-line inspections, and verify assembly processes with unmatched accuracy. The ongoing advancements in machine vision technology, including higher resolution cameras, faster image processors, and sophisticated software, further enhance the utility and performance of telecentric lens-based solutions, broadening their applicability.

Despite the strong growth drivers, the market faces certain restraints that could temper its expansion. The relatively high cost of telecentric lenses compared to conventional lenses is a significant barrier, particularly for small and medium-sized enterprises (SMEs) or applications where budget constraints are tight. This higher cost is attributed to the complex optical designs, precision manufacturing processes, and high-quality materials required to achieve telecentricity. Moreover, the inherent physical size and weight of some high-magnification or large-field-of-view telecentric lenses can pose integration challenges in compact or space-constrained automated systems. The technical complexity involved in properly integrating and calibrating telecentric lenses within a complete machine vision setup also requires specialized expertise, which may not always be readily available, thus increasing implementation costs and time. Additionally, while their benefits are clear in specific niches, a general lack of widespread awareness and understanding of the distinct advantages of telecentricity over conventional optics in broader industrial applications can limit adoption in certain segments.

Nevertheless, the market is ripe with substantial opportunities that promise to accelerate future growth and innovation. The emergence of advanced manufacturing paradigms, such as Industry 4.0 and smart factories, presents a fertile ground for telecentric lenses, as these initiatives heavily rely on real-time, high-precision data for process optimization and autonomous operation. Expanding applications in augmented reality (AR) and virtual reality (VR) systems, particularly in industrial training, simulation, and remote assistance, could leverage telecentric optics for enhanced visual accuracy and immersion. There is also a growing demand for customized telecentric solutions tailored to highly specific industrial needs, including specialized wavelengths, working distances, and form factors, fostering innovation and product differentiation. Geographically, the expansion into developing economies that are rapidly industrializing and adopting automation technologies, particularly in Asia Pacific and parts of Latin America, represents a significant untapped market potential. The continuous miniaturization of components across various industries will further solidify the need for telecentric lenses capable of inspecting and measuring at microscopic scales with exceptional precision, thereby ensuring sustained market expansion.

Segmentation Analysis

The Telecentric lenses Market is segmented across several critical dimensions, each offering distinct insights into its structure, demand patterns, and growth opportunities. These segmentation categories help in understanding the market dynamics from various perspectives, including the technological capabilities of the lenses themselves, the specific tasks they are designed to perform, and the end-user industries that derive the most value from their unique properties. A detailed analysis of these segments reveals the current competitive landscape, identifies emerging trends, and highlights areas of potential investment and strategic focus for market participants. Understanding the interplay between these segments is crucial for accurate market forecasting and for developing targeted product development and marketing strategies. The market is broadly categorized by type of telecentricity, specific application areas, and the diverse range of industries that utilize this advanced optical technology.

- By Type:

- Object-side Telecentric Lenses: These lenses ensure that the magnification remains constant regardless of the object's position along the optical axis, making them ideal for precise dimensional measurements and inspections where depth variation is common. They are widely used in industrial metrology and quality control.

- Image-side Telecentric Lenses: Designed to ensure that rays entering the image sensor are parallel, these lenses provide distortion-free images with uniform illumination across the entire field of view, particularly beneficial for high-resolution imaging applications.

- Bi-telecentric Lenses: Combining the benefits of both object-side and image-side telecentricity, these lenses offer the highest level of precision and image quality, eliminating perspective errors and distortion on both the object and image sides. They are utilized in the most demanding applications where absolute accuracy is paramount.

- By Application:

- Machine Vision: The largest application segment, encompassing automated inspection, part gauging, defect detection, robotic guidance, and assembly verification in manufacturing lines. Telecentric lenses provide the necessary accuracy for these critical tasks.

- Metrology: This segment involves highly precise dimensional measurements and surface profile analysis, often requiring non-contact optical methods. Telecentric lenses ensure accurate and repeatable measurements for quality assurance and scientific research.

- Laser Processing: Used in laser marking, cutting, and welding applications where maintaining a consistent spot size and focus across a working area is crucial, preventing variations in process quality.

- Microscopy: For specialized microscopic imaging where consistent magnification and minimal distortion are required across the depth of field, enabling accurate analysis of micro-structures.

- Others: Includes niche applications in scientific research, medical imaging, and specialized surveillance systems where perspective-free imaging is beneficial.

- By End-User Industry:

- Industrial Automation: Manufacturers leveraging automation for assembly, inspection, and quality control of various components across industries, from general manufacturing to specialized production.

- Electronics & Semiconductor: Critical for inspecting PCBs, semiconductor wafers, microchips, and other miniature electronic components where precision at micron levels is indispensable.

- Automotive: Used for inspecting engine components, body panels, electronic systems, and increasingly for EV battery and autonomous driving component inspection to meet strict safety and performance standards.

- Medical & Pharmaceutical: Essential for inspecting medical devices, drug delivery systems, and pharmaceutical packaging for defects, ensuring patient safety and regulatory compliance.

- Research & Development: Academic institutions and corporate R&D centers utilize telecentric lenses for experimental setups, advanced material science studies, and prototype evaluation.

- Aerospace & Defense: For inspecting high-precision components, verifying complex assemblies, and ensuring the structural integrity of critical parts used in aircraft and defense systems.

- Food & Beverage: Employed in automated inspection of packaging, product quality, and contaminant detection, ensuring food safety and consistent product presentation.

- Others: Includes applications in textiles, printing, renewable energy, and various other manufacturing sectors that require high-precision visual inspection.

Value Chain Analysis For Telecentric lenses Market

The value chain for the Telecentric lenses Market is a intricate network of specialized entities, beginning with fundamental raw material suppliers and extending all the way to the end-users who integrate these precision optics into their advanced systems. At the upstream analysis stage, the market relies heavily on specialized suppliers of high-quality optical glass, exotic crystal materials, and precision mechanical components such as lens barrels, mounts, and aperture diaphragms. The performance characteristics of telecentric lenses are inherently linked to the quality and purity of these raw materials, particularly the refractive index and dispersion properties of the optical glass, which are critical for minimizing aberrations and ensuring superior image clarity. Suppliers of advanced coatings also play a vital role, providing anti-reflective, anti-scratch, and wavelength-specific coatings that enhance light transmission, durability, and spectral performance of the lenses. This foundational segment of the value chain is characterized by a relatively small number of highly specialized manufacturers who often work closely with lens designers to meet stringent specifications, ensuring the integrity and optical excellence of the final product.

Moving further along the value chain, the core manufacturing and assembly of telecentric lenses are conducted by specialized optical companies that possess deep expertise in optical design, grinding, polishing, and precise assembly techniques. This downstream analysis highlights the intricate processes involved in shaping, centering, and aligning multiple lens elements within nanometer tolerances, a task that requires highly sophisticated machinery, cleanroom environments, and skilled technicians. These manufacturers leverage advanced optical design software to simulate and optimize lens performance, followed by meticulous fabrication and testing to ensure that each lens meets its telecentricity, resolution, and distortion specifications. Post-manufacturing, the distribution channel becomes critical for reaching a diverse customer base. This typically involves a mix of direct sales channels, where manufacturers engage directly with large industrial clients or system integrators for customized solutions, and indirect channels, which include specialized distributors, value-added resellers (VARs), and regional sales agents. These indirect partners often provide localized technical support, integration services, and training, thereby expanding market reach and catering to smaller customers or those requiring comprehensive solutions beyond just the lens.

The effectiveness of both direct and indirect distribution channels is paramount for market penetration and customer satisfaction. Direct channels are preferred for high-value projects, custom engineering, and strategic partnerships, allowing manufacturers to maintain direct control over customer relationships and technical support. This approach often involves highly trained application engineers who can guide customers through complex integration challenges. Indirect channels, conversely, enable broader market coverage and cater to a wider array of customers who might seek off-the-shelf solutions or bundled packages with cameras, lighting, and software. These distributors often maintain inventory, reducing lead times, and provide crucial pre-sales consultation and post-sales support, bridging the gap between highly specialized manufacturers and diverse end-users. The overall health of the telecentric lens market value chain depends on seamless collaboration and efficiency across all these stages, from raw material sourcing and precision manufacturing to effective distribution and comprehensive post-sales support, ensuring that advanced optical solutions reach the industries that critically depend on them for their operational excellence.

Telecentric lenses Market Potential Customers

The potential customers for telecentric lenses represent a broad spectrum of industries that prioritize precision, accuracy, and consistent imaging in their operations. These end-users and buyers are primarily engaged in manufacturing, quality control, scientific research, and specialized automation where the unique properties of telecentric optics offer indispensable advantages over conventional lenses. Manufacturing companies, particularly those involved in high-tech industries such as electronics and semiconductors, constitute a significant portion of this customer base. Within these sectors, the demand stems from the critical need to inspect minute components, such as printed circuit boards, microchips, and display panels, for defects, alignment errors, and dimensional deviations at a microscopic level. The constant magnification provided by telecentric lenses ensures that these inspections are highly reliable and repeatable, directly impacting product yield and overall quality in high-volume production environments.

Another prominent segment of potential customers includes companies within the automotive and aerospace industries. These sectors require stringent quality control for components ranging from engine parts and braking systems to avionics and structural elements, where any flaw could have severe safety implications. Telecentric lenses are crucial for automated inspection of complex geometries, ensuring precise assembly, and verifying the integrity of critical components. The medical device and pharmaceutical industries also represent a rapidly growing customer segment. Here, telecentric vision systems are deployed for inspecting catheters, stents, syringes, and various drug delivery devices, as well as checking the integrity of packaging and dosage accuracy. The non-contact and highly accurate nature of telecentric inspection is paramount in these regulated environments to ensure product safety, efficacy, and compliance with stringent health standards.

Beyond direct manufacturing, research and development institutions, universities, and specialized metrology laboratories are key buyers of telecentric lenses. These organizations utilize the lenses for advanced material characterization, precision experimentation, microscopy, and the development of new inspection methodologies. Furthermore, integrators of industrial automation systems and machine vision solution providers form a crucial indirect customer base. These companies purchase telecentric lenses as components to build comprehensive, customized inspection and automation systems for their own clients across various industries. As industries increasingly adopt Industry 4.0 principles and smart factory concepts, the demand from these solution providers is projected to surge, as they equip modern production lines with advanced telecentric vision capabilities for enhanced efficiency, quality, and autonomous operation across a wide array of industrial applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 million |

| Market Forecast in 2033 | USD 620 million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Carl Zeiss AG, Edmund Optics Inc., Opto Engineering S.R.L., Sill Optics GmbH & Co. KG, Mitutoyo Corporation, Schneider-Kreuznach (Jos. Schneider Optische Werke GmbH), Navitar Inc., Jenoptik AG, Vision Components GmbH, Keyence Corporation, Kowa Company Ltd., Qioptiq (Excelitas Technologies Corp.), Thorlabs Inc., Stemmer Imaging AG, Computar (CBC Group), H.S. Optics GmbH, LighTuning Technology Inc., Myutron Inc., Tamron Co., Ltd., RICOH Industrial Solutions Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Telecentric lenses Market Key Technology Landscape

The technological landscape of the Telecentric lenses market is characterized by continuous innovation aimed at enhancing optical performance, expanding application versatility, and reducing manufacturing costs. A fundamental pillar of this landscape is the advanced optical design software, such as Zemax, Code V, and OpticStudio, which enable engineers to meticulously simulate, optimize, and evaluate complex multi-element lens systems. These sophisticated tools allow for the precise control of parameters like focal length, working distance, field of view, and most critically, the telecentric angle, ensuring minimal distortion and consistent magnification across various object depths. Leveraging these software platforms, designers can explore novel optical configurations, incorporate exotic glass types, and integrate diffractive optical elements to achieve specific performance targets, often pushing the boundaries of resolution, contrast, and light collection efficiency for diverse industrial and scientific applications. The ability to model and predict lens behavior before physical prototyping significantly accelerates the development cycle and reduces R&D expenses.

Another crucial technological aspect involves the development and utilization of specialized glass materials and advanced manufacturing processes. High-quality optical glass with specific refractive indices, low dispersion characteristics, and homogeneity is essential for minimizing chromatic aberrations and other optical imperfections that could degrade image quality. Beyond conventional glass, manufacturers are increasingly incorporating exotic materials like fluorite, fused silica, and specialized polymers to achieve superior optical properties, especially for applications involving UV or IR wavelengths. The manufacturing processes themselves are highly sophisticated, involving ultra-precision grinding, polishing, and aspheric lens molding techniques that achieve surface accuracies measured in nanometers. These processes are often conducted in highly controlled cleanroom environments to prevent contamination and ensure the pristine quality of each optical element. Furthermore, advanced coating technologies are vital for optimizing light transmission, reducing reflections, and providing environmental protection, thereby enhancing the overall performance and durability of telecentric lenses across varied operational conditions.

The integration of telecentric lenses with complementary machine vision technologies also defines the key technology landscape, making them part of a broader intelligent imaging ecosystem. This includes seamless compatibility with high-resolution industrial cameras, such as CMOS and CCD sensors, which provide the necessary image data for processing. Advanced illumination techniques, including coaxial, ring, and structured lighting, are often combined with telecentric lenses to optimize image contrast and highlight specific features on complex surfaces. Furthermore, the development of sophisticated image processing software, often incorporating artificial intelligence and deep learning algorithms, significantly enhances the utility of telecentric lens data. These software solutions enable automated defect detection, precise dimensional measurements, and pattern recognition with unprecedented speed and accuracy, transforming raw optical data into actionable insights. The ongoing synergy between telecentric optics, high-performance sensors, intelligent lighting, and advanced software platforms is continuously pushing the boundaries of what is possible in automated inspection, metrology, and quality control.

Regional Highlights

- North America: This region is characterized by significant investments in research and development, particularly in advanced manufacturing, aerospace, and medical device industries. The presence of numerous technology innovators and a strong emphasis on automation and stringent quality control standards drives the demand for high-precision telecentric lenses. The automotive sector, including the rapidly expanding electric vehicle market, also contributes substantially to the region's adoption of advanced optical inspection solutions.

- Europe: Europe stands out with its robust industrial automation sector, strong automotive manufacturing base, and high adoption of Industry 4.0 initiatives. Countries like Germany, Italy, and France are leaders in machine vision technology and advanced metrology, creating a sustained demand for telecentric lenses in precision engineering, electronics, and pharmaceutical manufacturing. Strict regulatory environments further necessitate accurate inspection tools.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for telecentric lenses, primarily driven by its position as a global manufacturing hub. Countries like China, Japan, South Korea, and Taiwan exhibit high growth rates due to extensive investments in electronics, semiconductors, automotive production, and general industrial automation. The rapid adoption of automated quality control systems to enhance production efficiency and meet global supply chain demands fuels this regional expansion.

- Latin America: This region is an emerging market for telecentric lenses, with increasing industrialization and foreign investments in manufacturing sectors, particularly automotive and electronics in countries like Mexico and Brazil. While still smaller than other regions, the growing emphasis on improving manufacturing quality and efficiency presents significant growth opportunities for advanced optical inspection technologies.

- Middle East and Africa (MEA): The MEA region is at an nascent stage in the adoption of telecentric lenses, but it shows potential driven by diversification efforts from oil-dependent economies towards industrial development and infrastructure projects. Investments in manufacturing capabilities, particularly in construction, packaging, and basic industrial goods, are slowly creating a demand for automated inspection and quality control solutions, albeit at a slower pace compared to other regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Telecentric lenses Market.- Carl Zeiss AG

- Edmund Optics Inc.

- Opto Engineering S.R.L.

- Sill Optics GmbH & Co. KG

- Mitutoyo Corporation

- Schneider-Kreuznach (Jos. Schneider Optische Werke GmbH)

- Navitar Inc.

- Jenoptik AG

- Vision Components GmbH

- Keyence Corporation

- Kowa Company Ltd.

- Qioptiq (Excelitas Technologies Corp.)

- Thorlabs Inc.

- Stemmer Imaging AG

- Computar (CBC Group)

- H.S. Optics GmbH

- LighTuning Technology Inc.

- Myutron Inc.

- Tamron Co., Ltd.

- RICOH Industrial Solutions Inc.

Frequently Asked Questions

What is a telecentric lens and why is it preferred over conventional lenses in industrial applications?

A telecentric lens is a specialized optical system designed to ensure that the magnification of an object remains constant, regardless of its distance from the lens within a specific depth of field. This unique property eliminates perspective errors and parallax, meaning that the apparent size of an object does not change even if its position varies along the optical axis. This characteristic is crucial for industrial applications requiring high-precision measurements, accurate defect detection, and consistent imaging, such as in automated quality control, metrology, and robotic guidance, where even slight magnification variations from conventional lenses could lead to significant measurement inaccuracies and false readings.

What are the primary applications of telecentric lenses in the market?

Telecentric lenses are predominantly utilized in applications demanding exceptional precision and distortion-free imaging. Their primary applications include machine vision systems for automated inspection, where they perform tasks such as precise dimensional gauging, defect detection on complex components, and robotic alignment. They are also indispensable in metrology for highly accurate non-contact measurements and quality assurance in manufacturing. Other significant applications involve laser processing, where they maintain a consistent spot size, and specialized microscopy for consistent magnification across the depth of field. These applications are critical across industries like electronics, automotive, medical devices, and industrial automation.

How does artificial intelligence (AI) impact the Telecentric lenses Market?

Artificial intelligence significantly enhances the capabilities and expands the utility of telecentric lenses by enabling more sophisticated and autonomous inspection processes. AI, particularly deep learning, allows telecentric vision systems to move beyond rule-based programming, facilitating the identification of complex, subtle defects and patterns that are challenging for traditional algorithms. It improves measurement accuracy through advanced image processing, enables adaptive inspection systems that learn from new data, and supports real-time decision-making on production lines. This synergy of high-fidelity telecentric imagery with AI intelligence leads to more robust defect detection, reduced false positives, and greater automation efficiency across various industries.

What are the main growth drivers and restraints for the Telecentric lenses Market?

The Telecentric lenses Market is primarily driven by the escalating global demand for ultra-high precision inspection and measurement in manufacturing, the rapid growth of industrial automation and robotics, and continuous advancements in machine vision technology. Strict quality control standards across sectors like electronics, automotive, and medical devices also fuel adoption. However, the market faces restraints such as the relatively high initial cost of telecentric lenses, their often larger physical size which can pose integration challenges, and the technical complexity involved in their proper setup and calibration. Limited awareness of their specific benefits compared to conventional optics in some segments also acts as a barrier.

Which geographical region is expected to dominate the Telecentric lenses Market and why?

Asia Pacific (APAC) is projected to dominate the Telecentric lenses Market during the forecast period and exhibit the highest growth rate. This dominance is attributed to the region's status as a global manufacturing powerhouse, particularly in the electronics, semiconductor, and automotive industries across countries like China, Japan, South Korea, and Taiwan. Extensive investments in industrial automation, the proliferation of smart factories, and the continuous need for high-precision quality control in high-volume production lines are the primary factors driving the widespread adoption of telecentric lenses in the APAC region.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager