Tellurium Target Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432910 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Tellurium Target Market Size

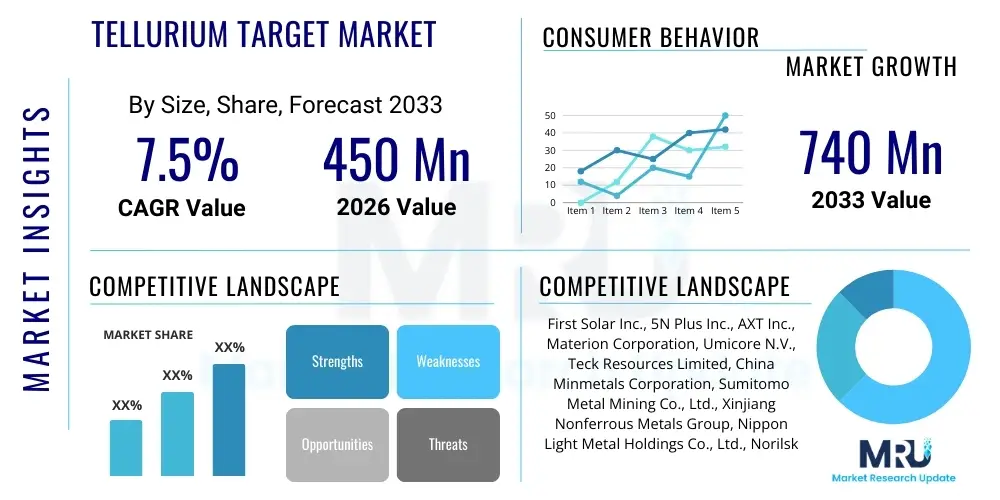

The Tellurium Target Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 740 Million by the end of the forecast period in 2033.

Tellurium Target Market introduction

The Tellurium Target Market encompasses the global trade and utilization of tellurium, a rare metalloid primarily obtained as a byproduct of copper and lead refining. Tellurium's unique semiconducting properties, combined with its ability to form stable compounds with various metals, position it as a critical material across several high-growth, technology-intensive sectors. Historically utilized in metallurgy to improve the machinability of steel and the longevity of copper, its modern significance is overwhelmingly concentrated in advanced electronic and energy applications, most notably in the manufacture of high-efficiency thin-film photovoltaic (PV) solar cells, specifically Cadmium Telluride (CdTe) technology, which offers superior performance and cost advantages compared to traditional silicon panels.

The primary applications driving current market expansion include renewable energy and thermal management. Tellurium is essential for creating high-performance thermoelectric materials (often bismuth telluride) used in niche cooling and power generation devices, capitalizing on the Peltier and Seebeck effects. Furthermore, the rising demand for advanced semiconductor materials, high-speed infrared detectors, and phase-change memory devices contributes significantly to market growth. The scarcity of tellurium, due to its low crustal abundance and reliance on primary metal refining capacity, necessitates focused recycling initiatives and technological advancements to ensure sustainable supply chains to meet escalating industrial requirements.

Key driving factors propelling the market include aggressive global renewable energy targets leading to increased solar panel installation, governmental incentives promoting the adoption of high-efficiency thin-film solar technology, and the expanding defense and aerospace sectors requiring advanced infrared sensing and thermal imaging capabilities. The inherent benefits of tellurium, such as its predictable behavior in thin-film deposition processes and its efficiency in converting heat differentials into electricity, solidify its strategic importance in the transition towards a low-carbon, digitally integrated economy. Maintaining stable sourcing and developing advanced material purification techniques remain crucial elements for continuous market scaling and technological adoption.

Tellurium Target Market Executive Summary

The Tellurium Target Market is characterized by robust growth, predominantly fueled by the accelerating adoption of Cadmium Telluride (CdTe) photovoltaic technology within the solar energy sector. Current business trends indicate a concentrated supply chain, where market dynamics are heavily influenced by the output and refining capacity of major copper producers, particularly those located in regions with high copper ore purity containing tellurium trace elements. High-purity tellurium (5N to 7N grade) is witnessing significantly faster demand growth than lower-grade metallurgical tellurium, necessitating considerable investment in advanced refining and purification infrastructure to maintain product specifications for demanding semiconductor and solar applications. Strategic partnerships between refiners and major PV manufacturers are becoming common to secure long-term, stable supply.

Regionally, Asia Pacific, particularly China and India, exhibits the highest growth potential, driven by massive investments in solar farm deployment and the establishment of local CdTe manufacturing capacities, seeking to reduce reliance on imported modules. North America remains a crucial market, spearheaded by key innovators in CdTe technology and strong governmental backing for domestic clean energy initiatives. European growth is sustained by rigorous climate policies emphasizing high-efficiency module installation. However, the market's vulnerability to geopolitical instability affecting metal refining operations, particularly in Latin America, imposes structural risks that necessitate supply diversification strategies among major consumers.

Segment trends reveal that the Application segment dominated by solar panels maintains the largest market share, though the Thermoelectric segment is anticipated to exhibit the fastest CAGR due to increasing adoption of solid-state cooling solutions in data centers, automotive sectors, and consumer electronics. The Purity segment shows a distinct premiumization trend, with ultra-high-purity tellurium attracting higher pricing and greater market segmentation due to its essential role in specialized optoelectronics and semiconductor doping. The increasing scrutiny on material criticality and environmental governance is shaping investment decisions towards sustainable byproduct recovery and ethical sourcing practices throughout the value chain.

AI Impact Analysis on Tellurium Target Market

Common user inquiries regarding AI's impact on the Tellurium market center on optimizing supply chain resilience, predicting demand fluctuations in highly volatile sectors like solar energy, and accelerating materials science research to find alternatives or enhance tellurium compounds. Users frequently question how AI and Machine Learning (ML) can improve the efficiency of tellurium recovery during copper refining, which is often a low-yield process. Furthermore, there is significant interest in AI's role in computational materials discovery—specifically, modeling and simulating new telluride alloys for thermoelectric devices to achieve higher efficiency (higher ZT values) without extensive physical experimentation, thereby reducing R&D costs and accelerating commercialization.

The application of predictive analytics, powered by AI, is transforming resource management in the tellurium industry. By analyzing complex datasets encompassing copper mining output, global copper demand, refining throughput, and historical tellurium yield rates, AI algorithms can forecast available byproduct tellurium supply with greater accuracy. This enables large-scale consumers, particularly thin-film solar manufacturers, to mitigate supply risks and negotiate more effectively for forward contracts. Furthermore, computer vision systems are being integrated into advanced material purification facilities to monitor crystal growth and defect formation in ultra-high-purity tellurium production, ensuring consistent quality necessary for sensitive semiconductor applications and significantly reducing material waste.

AI is also fundamentally altering the landscape of tellurium-based material development. Traditional R&D involving physical experimentation is slow and expensive. ML models, however, can rapidly screen thousands of potential telluride compounds (e.g., Bismuth Telluride variants, doped alloys) based on density functional theory (DFT) calculations and empirical data, identifying candidates with optimized band gaps or superior thermoelectric performance. This computational approach promises to drastically shorten the innovation cycle for new high-performance, tellurium-dependent devices, potentially opening up new market avenues in thermal energy harvesting and quantum computing components.

- AI-driven predictive modeling enhances forecasting of byproduct tellurium supply and demand, stabilizing procurement strategies.

- Machine Learning accelerates materials discovery for new high-efficiency telluride compounds, particularly for thermoelectric applications.

- Computer vision and automated sensors optimize tellurium purification processes, improving ultra-high-purity material yield and quality control.

- AI tools are used to simulate and optimize deposition parameters for Cadmium Telluride (CdTe) thin films, enhancing solar cell efficiency.

- Predictive maintenance analytics deployed in refining operations minimize downtime and ensure continuous tellurium recovery.

DRO & Impact Forces Of Tellurium Target Market

The Tellurium Target Market is primarily driven by the exponential growth in global renewable energy infrastructure, specifically the low-cost, high-efficiency advantages offered by CdTe thin-film solar technology, which requires significant amounts of tellurium feedstock. Restraints include the fundamental dependency on primary metal refining (copper and lead), leading to highly inelastic supply—meaning tellurium output cannot easily respond to sudden demand spikes without commensurate changes in copper production. Opportunities lie in developing advanced recycling technologies to create a circular economy for tellurium, mitigating supply reliance, and in the burgeoning application of tellurium compounds in advanced thermoelectrics for sustainable thermal management solutions. These factors create a complex web of impact forces characterized by high material criticality and strong technological pull.

Driving forces center on global mandates for decarbonization and energy transition, which strongly favor technologies like CdTe solar that offer scalable and reliable renewable power generation. The improving cost parity of CdTe technology relative to crystalline silicon further strengthens demand. However, the market faces significant structural restraints, most notably the high price volatility linked to geopolitical supply risks and the specialized, energy-intensive process required to achieve the ultra-high purity levels demanded by semiconductor and solar manufacturers. Additionally, substitution risk, particularly in thermoelectric cooling where alternatives are constantly being researched, poses a long-term challenge to certain segment stability.

Impact forces are determined by the balance between technological innovation and supply chain limitations. Strong impact is exerted by breakthroughs in PV efficiency and thermoelectric material science, increasing the value and necessity of tellurium. Simultaneously, the limited geographic concentration of refining capacity (major sources often concentrated in a few countries) generates powerful external constraints related to trade policy and logistical disruptions. The long-term viability of the tellurium market depends heavily on sustainable sourcing, proactive recycling infrastructure development, and continuous efficiency gains in application technologies to minimize material usage per unit output.

Segmentation Analysis

The Tellurium Target Market is systematically segmented based on Purity, which dictates the end-use suitability, and by Application, reflecting the diverse industrial consumption of the element. High-purity grades (99.999% and above) command a significant premium and are critical for sensitive electronic applications like solar cells, thermoelectrics, and compound semiconductors. Conversely, standard-grade tellurium (lower purity) is predominantly channeled into traditional metallurgical uses, such as alloying steel and copper to improve their physical properties. Understanding these segmentation nuances is vital for supply chain planning, as different purity levels require fundamentally different refining processes and have highly distinct demand elasticity profiles.

The application segment clearly highlights the market's dependence on the renewable energy sector, with thin-film photovoltaics constituting the largest volume consumer. This segment's demand trajectory is intrinsically linked to global solar installation rates and competitive technological evolution. The second most crucial application is thermoelectrics, which leverages telluride compounds for solid-state cooling and small-scale power generation. Metallurgical uses, while historically important, now represent a smaller, mature segment. Emerging applications, particularly in defense optics (infrared detectors) and advanced memory devices, are characterized by high-value, low-volume requirements but offer substantial growth potential for ultra-high-purity material suppliers.

- By Purity

- High Purity (5N to 7N - 99.999% to 99.99999%)

- Standard Purity (2N to 4N - 99% to 99.99%)

- By Application

- Photovoltaics (Cadmium Telluride Thin Films)

- Thermoelectric Devices (Bismuth Telluride)

- Metallurgy (Steel, Copper, Lead Alloys)

- Rubber Vulcanization and Curing

- Semiconductors and Optical Devices (Infrared Detectors)

- By End-Use Industry

- Energy

- Automotive

- Electronics and Defense

- Industrial Manufacturing

Value Chain Analysis For Tellurium Target Market

The Tellurium value chain is inherently constrained at the upstream stage, as tellurium is primarily sourced as a minor byproduct from the refining of major base metals, chiefly copper and, to a lesser extent, lead and gold. The extraction process involves complex secondary processing of anode slimes generated during electrolytic copper refining. Upstream analysis focuses heavily on the geographical location and operational efficiency of large copper refineries, as these facilities dictate the initial availability of the raw material. Challenges at this stage include low concentration in the original ore body, variable yields, and the need for specialized hydrometallurgical or pyrometallurgical techniques to isolate the crude tellurium concentrate from complex metal matrices.

The midstream section involves rigorous purification processes. Crude tellurium must be refined to meet the ultra-high purity specifications required by photovoltaic and electronic manufacturers (up to 7N purity). This stage is capital-intensive and involves specialized techniques such as zone refining, directional solidification, and vacuum distillation. Midstream efficiency directly impacts market pricing and product quality. The distribution channel is characterized by a mix of direct sales contracts between major refiners and large end-users (e.g., CdTe solar companies) and indirect distribution through specialized global chemical and metal traders who aggregate smaller volumes and manage geopolitical supply logistics, especially for niche buyers in the semiconductor space.

Downstream analysis highlights the high value addition in application manufacturing. The end products—CdTe solar modules, Bismuth Telluride thermoelectric chips, and specialized infrared sensors—represent significant technological sophistication and market value. Direct distribution channels are favored for large-scale, consistent consumers (like First Solar or specialized thermoelectric component manufacturers) to ensure traceable, secure supply. Indirect channels cater mainly to smaller R&D labs, specialized alloy producers, and regions lacking direct refining access. The efficiency of the downstream relies heavily on continuous innovation in material deposition techniques (e.g., vapor transport deposition for CdTe) and component integration to maximize performance while minimizing tellurium loading.

Tellurium Target Market Potential Customers

The primary customers for high-purity tellurium are manufacturers within the renewable energy sector, specifically companies producing Cadmium Telluride thin-film photovoltaic (PV) modules. These companies require vast, consistent quantities of tellurium to serve as a key semiconductor layer in their solar panels, making their demand volume highly sensitive to global solar policy and utility-scale project pipeline development. Given the critical role of tellurium in achieving high cell efficiency and low manufacturing costs for CdTe, these players often engage in long-term supply agreements and sometimes equity investments with major tellurium refiners to secure reliable sourcing.

Another major segment of potential buyers includes manufacturers of thermoelectric devices, encompassing both solid-state cooling (Peltier coolers) and thermal energy harvesting (Seebeck generators). These customers utilize Bismuth Telluride (Bi2Te3) alloys and their derivatives. Key purchasers include automotive companies integrating thermoelectric cooling into high-end vehicles, data center operators seeking localized, high-efficiency cooling solutions for critical components, and defense contractors requiring reliable, solid-state power generation for remote sensors and unmanned systems. These buyers prioritize quality, reliability, and the ZT performance metric of the telluride material.

Secondary but crucial customer segments include specialized metallurgical firms requiring tellurium as an alloying agent to enhance the machinability of steel and copper alloys used in automotive and precision engineering. Furthermore, the defense and specialized electronics sectors are key consumers of ultra-high-purity tellurium compounds for infrared detection (HgCdTe) and phase-change memory applications (e.g., GeSbTe). While these volumes are smaller, the technical specification requirements are stringent, yielding high profit margins for suppliers able to meet the 6N or 7N purity threshold consistently.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 740 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | First Solar Inc., 5N Plus Inc., AXT Inc., Materion Corporation, Umicore N.V., Teck Resources Limited, China Minmetals Corporation, Sumitomo Metal Mining Co., Ltd., Xinjiang Nonferrous Metals Group, Nippon Light Metal Holdings Co., Ltd., Norilsk Nickel, Yunnan Copper Industry Group Co., Ltd., Indium Corporation, Recapture Metals Ltd., Albemarle Corporation, Advanced Tellurium, JX Nippon Mining & Metals Corporation, Boliden AB, Vital Materials Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tellurium Target Market Key Technology Landscape

The technology landscape for the Tellurium market is characterized by innovations across the entire value chain, from enhanced recovery techniques to sophisticated application manufacturing. Upstream technological advancements focus on improving the yield of tellurium from complex anode slimes generated during copper refining. Technologies like solvent extraction and ion exchange chromatography are increasingly utilized to increase the purity of intermediate tellurium compounds before final elemental refining. The optimization of these metallurgical processes is crucial, as even small percentage increases in recovery yield significant additional market volume due to the high volume of primary copper processed globally.

Midstream purification technology is paramount for market enablement, particularly for high-value segments. Zone refining remains a cornerstone technology for achieving 5N to 7N purity, but newer methods, including advanced vacuum distillation and chemical vapor deposition (CVD) based purification, are being explored to reduce energy consumption and improve material homogeneity. The consistent production of ultra-high-purity tellurium targets—which are critical inputs for sputtering and evaporation processes in semiconductor fabrication—requires strict process control technologies and specialized cleanroom environments, driven by continuous engineering improvements.

Downstream, the most impactful technological area is the manufacturing of Cadmium Telluride (CdTe) thin-film solar cells. Key technologies include vapor transport deposition (VTD), close-spaced sublimation (CSS), and high-throughput coating processes designed to deposit micron-thin layers of CdTe efficiently and uniformly onto large glass substrates. Similarly, in the thermoelectric sector, innovations focus on nanotechnology to manipulate the crystallographic structure of Bismuth Telluride alloys, enhancing their dimensionless figure of merit (ZT) by reducing thermal conductivity without compromising electrical conductivity. This ongoing material science research is vital for expanding the practical applications of tellurium-based devices.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the consumption landscape, primarily due to the concentration of photovoltaic and electronics manufacturing in countries like China, South Korea, and Japan. China is both a major producer (due to extensive copper refining) and the largest consumer, driven by aggressive national targets for solar energy deployment and the development of local CdTe production capacity. India is emerging as a critical growth node for solar installations.

- North America: North America, led by the United States, holds a dominant position in CdTe intellectual property and manufacturing scale, exemplified by companies like First Solar. Demand is stable and driven by utility-scale solar projects and significant investment in defense and aerospace sectors requiring advanced infrared sensing technologies. Supply security and domestic sourcing incentives are major regional focuses.

- Europe: Europe represents a technologically advanced, high-value segment market. While primary production is moderate (e.g., Boliden in Scandinavia), the region is a major consumer of high-purity tellurium for specialized applications, including automotive thermoelectrics, industrial metallurgy, and advanced R&D. Strict environmental regulations encourage investment in tellurium recycling and substitution research.

- Latin America: This region is crucial as a primary supply source, hosting major copper refining operations in countries like Chile and Peru, which yield significant tellurium byproduct. The market influence here is concentrated on upstream supply stability and the efficiency of the initial recovery processes, heavily impacting global pricing and availability.

- Middle East and Africa (MEA): This region is currently a smaller consumer, but demand is growing, particularly in high-temperature solar applications and oil/gas pipeline monitoring where robust thermoelectric sensors are deployed. The long-term growth is linked to regional infrastructure projects and renewable energy diversification efforts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tellurium Target Market.- First Solar Inc.

- 5N Plus Inc.

- AXT Inc.

- Materion Corporation

- Umicore N.V.

- Teck Resources Limited

- China Minmetals Corporation

- Sumitomo Metal Mining Co., Ltd.

- Xinjiang Nonferrous Metals Group

- Nippon Light Metal Holdings Co., Ltd.

- Norilsk Nickel

- Yunnan Copper Industry Group Co., Ltd.

- Indium Corporation

- Recapture Metals Ltd.

- Albemarle Corporation

- Advanced Tellurium

- JX Nippon Mining & Metals Corporation

- Boliden AB

- Vital Materials Co., Ltd.

- Zhuzhou Smelter Group

Frequently Asked Questions

Analyze common user questions about the Tellurium Target market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary application driving the demand for tellurium?

The primary application driving tellurium demand is the manufacturing of Cadmium Telluride (CdTe) thin-film photovoltaic solar cells, valued for their cost-efficiency and high performance compared to traditional silicon-based panels.

How is the global supply of tellurium maintained?

Global tellurium supply is inherently inelastic as it is sourced primarily as a byproduct (minor element recovery) from the electrolytic refining of copper, lead, and sometimes gold, meaning its availability is tied directly to the output of base metal mining and refining operations.

What role does high-purity tellurium play in the market?

High-purity tellurium (5N to 7N) is crucial for sensitive electronics, including CdTe solar modules, specialized semiconductor devices, and Bismuth Telluride alloys used in high-efficiency thermoelectric coolers and power generators.

Which region holds the largest market share for tellurium consumption?

The Asia Pacific (APAC) region currently holds the largest market share for tellurium consumption, driven by extensive manufacturing hubs for solar PV, consumer electronics, and increased governmental investment in renewable energy infrastructure.

Is tellurium recycling a significant factor in market stability?

Yes, given the scarcity of primary tellurium supply and its classification as a critical material, advanced recycling from end-of-life CdTe solar panels and electronic waste is becoming an increasingly significant factor in mitigating supply risk and ensuring long-term market stability.

The detailed analysis of the Tellurium Target Market confirms its strategic importance within the global energy transition and advanced electronics sectors. The market's future trajectory is inextricably linked to the continued technological success and commercial viability of Cadmium Telluride (CdTe) photovoltaics. The aggressive deployment goals set by numerous nations regarding solar capacity expansion ensure a sustained and elevated demand for high-purity tellurium feedstock throughout the forecast period. Furthermore, the inherent advantages of CdTe in terms of module efficiency, reduced material consumption per watt, and manufacturing simplicity continue to solidify its competitive edge against established photovoltaic technologies, providing a substantial foundational driver for the tellurium market. The sensitivity of the tellurium supply chain remains a central theme impacting market dynamics. Since tellurium production is fundamentally coupled with the output of the global copper and lead refining industries, any volatility or disruption in the base metal market immediately translates into price fluctuations and supply anxiety for tellurium consumers. This structural dependency necessitates complex risk mitigation strategies for end-users, involving inventory stockpiling, diversification of procurement sources, and investment in international trade logistics capable of navigating geopolitical constraints affecting base metal supply hubs in regions like South America and certain parts of Asia. The market must, therefore, be viewed not just through the lens of demand but equally through the constraints imposed by upstream mineral processing economics. Technological progress in tellurium recovery and purification serves as a critical enabler for market growth. The increasing demand for ultra-high purity grades (e.g., 6N and 7N) for sensitive applications, such as high-performance thermoelectric generators and sophisticated infrared detectors (Mercury Cadmium Telluride - HgCdTe), demands continuous refinement of zone refining and chemical purification methodologies. Companies investing heavily in proprietary purification techniques are positioned to capture premium market segments where material quality directly dictates device performance and longevity. The intellectual property surrounding these advanced purification techniques forms a key competitive differentiator among refiners and specialized material suppliers. The thermoelectric segment presents a high-growth opportunity, albeit currently smaller in volume than photovoltaics. Bismuth Telluride and its alloys are essential for Peltier cooling devices used in demanding thermal management applications within data centers, military equipment, and precise scientific instruments. As global efforts intensify to improve energy efficiency and thermal control in high-power density electronics, the demand for highly efficient thermoelectric materials (those with high ZT values) will rise sharply. Research initiatives utilizing AI and advanced computation to model and synthesize new telluride compositions promise to unlock significant performance gains, expanding the commercial reach of these solid-state thermal solutions into broader consumer and automotive markets. Geographically, the market’s center of gravity continues to shift eastward, tracking the massive capacity build-out of electronics and solar manufacturing in the Asia Pacific. While North America maintains a strong position in technological innovation and high-value, defense-related consumption, the sheer volume of material required for mass market deployment dictates APAC’s dominance. European demand is sophisticated, focused on high-specification materials and advanced recycling mandates, reinforcing the trend toward a circular economy model for critical materials like tellurium. Long-term sustainability of the market will depend on robust recycling infrastructure development, particularly the establishment of efficient, industrial-scale processes for recovering tellurium and cadmium from decommissioned solar panels. This circular economy approach is essential to decouple tellurium supply from the inherent volatility of primary copper mining, offering a pathway toward a more self-sustaining supply chain capable of supporting continued global technological advancement. The market structure is inherently oligopolistic, with a limited number of major base metal refineries controlling the initial crude tellurium supply and a handful of specialized refiners dominating the ultra-high purity segment. This concentration leads to significant price sensitivity and potential market manipulation risk. Monitoring the output decisions and strategic alignments between key copper producers (e.g., Teck, Sumitomo) and major tellurium consumers (e.g., First Solar, 5N Plus) is paramount for understanding future price stability and supply availability. Investment in secondary recovery and recycling capacity is not just an environmental imperative but a commercial necessity for consumers seeking reliable, long-term procurement security in this highly specialized commodity market.

Further analysis into the Purity segmentation reveals a significant bifurcation in market value. Standard Purity tellurium (typically 2N to 4N) is highly sensitive to general economic cycles influencing metallurgy, as it is primarily used to enhance the machinability of steel and copper alloys for industrial and automotive components. While this segment is mature and exhibits steady, moderate growth, it does not drive the overall market valuation. In sharp contrast, the High Purity segment (5N to 7N), essential for semiconductor and photovoltaic applications, experiences exponential value growth. The cost differential between 4N and 7N tellurium can be orders of magnitude, reflecting the complexity and expense of removing trace impurities that can severely degrade the performance of delicate electronic components like PV junctions or thermoelectric interfaces. This divergence mandates distinct market strategies for suppliers. Companies focused on standard purity must optimize large-volume throughput and cost control, operating closer to traditional commodity markets. Conversely, ultra-high-purity suppliers must focus intensely on quality assurance, traceability, and bespoke material specifications tailored to specific OEM requirements, functioning more like specialty chemical providers. The high barrier to entry in the purification segment, marked by intellectual property surrounding specialized equipment and process know-how, ensures that this high-value niche remains dominated by a few expert players with established reputations for material consistency. The regulatory environment also exerts considerable influence, particularly concerning environmental, social, and governance (ESG) factors. Tellurium is often recovered from mining byproducts, and the processes involved in base metal refining and subsequent hydrometallurgy can involve hazardous materials. Market participants are increasingly required to demonstrate strict adherence to international environmental standards and transparent sourcing practices. This pressure favors large, established refiners with robust compliance infrastructure over smaller, less regulated entities, potentially tightening the supply concentration even further and reinforcing the oligopolistic structure. Customers, particularly in Europe and North America, are beginning to incorporate ESG performance metrics into their material sourcing criteria, adding a layer of non-price competition to the market. In terms of technological disruption, aside from AI-driven materials science, the integration of tellurium targets in advanced microelectronics is gaining momentum. Telluride compounds are critical components in next-generation phase-change memory (PCM), which offers faster, denser, and more reliable non-volatile storage solutions compared to traditional flash memory. The growth of cloud computing, edge processing, and artificial intelligence infrastructure is creating a latent but potentially explosive demand for these advanced memory solutions, requiring extremely pure, finely controlled deposition materials. While this application currently accounts for a small percentage of total demand, its high-value nature and alignment with fundamental digitalization trends suggest it will become a significant growth driver beyond the forecast period. The impact of competitive materials also requires careful monitoring. In the photovoltaic space, the ongoing efficiency improvements and cost reductions in crystalline silicon PV modules pose a constant competitive threat to CdTe’s market share. While CdTe retains advantages in certain climates and deployment types, sustained innovation in silicon technology could cap the growth ceiling for the tellurium-dependent segment. Similarly, in thermoelectrics, research into alternative materials (e.g., silicides, skutterudites, and other complex oxides) that do not rely on scarce elements like tellurium could potentially displace Bismuth Telluride in some non-critical or high-temperature applications over the long term, although tellurides currently maintain the highest ZT performance at ambient temperatures critical for common cooling applications. Finally, macroeconomic trends, particularly global capital expenditure on infrastructure and energy projects, directly influence the tellurium market. Large government-backed initiatives for solar deployment, green energy grids, and electrification drive significant demand volumes. Conversely, economic slowdowns that reduce investment in capital projects, or trade disputes that impose tariffs on solar components, can rapidly dampen demand and lead to inventory accumulation among refiners. The market's tight supply-demand balance means that even minor fluctuations in global capital flows can disproportionately affect pricing and contracting stability, necessitating proactive risk management and flexible operational strategies across the value chain.

The detailed exploration of the Tellurium Target Market underscores the dynamic interplay between technological necessity and supply chain scarcity. The critical role of tellurium as a material enabler for modern high-efficiency energy solutions ensures its enduring market relevance. However, the market must navigate the inherent challenges posed by its co-production status. The operational complexity of copper refineries—the primary source—dictates that supply inelasticity will persist, making the market highly sensitive to shocks in the copper industry and related environmental compliance costs. This structural vulnerability reinforces the strategic importance of geographical diversification in sourcing, moving beyond historical supply concentrations in Chile, Peru, and China. Companies are increasingly looking towards untapped or underutilized byproduct streams globally to build resilience. Furthermore, the specialized equipment and proprietary knowledge required for ultra-high purity processing create significant entry barriers, protecting the margins of established refiners like 5N Plus and Umicore. These players not only supply the elemental tellurium but often also produce critical telluride compounds and targets (e.g., Cadmium Telluride, Bismuth Telluride, Mercury Cadmium Telluride), capturing additional value downstream. Their ability to consistently meet stringent quality controls, such as impurity levels below parts per billion (ppb) for semiconductor applications, is a key competitive advantage that cannot be easily replicated by newcomers. This emphasizes the market’s reliance on specialized technical expertise rather than simple resource access. The energy industry’s pivot towards sustainable and efficient thermal management solutions is opening new niches for tellurium beyond the core PV sector. The development of micro-thermoelectric modules for waste heat recovery in industrial processes and vehicle exhaust systems represents a rapidly maturing opportunity. While currently expensive, improvements in manufacturing scale and material synthesis efficiency are expected to lower the cost of these modules, broadening their adoption in the automotive sector for both passenger comfort (cooling seats) and power generation (harvesting waste heat), contributing significantly to fuel efficiency standards and electric vehicle range extension. This expansion reinforces the value proposition of tellurium compounds as essential components for energy efficiency mandates. Regulatory developments, particularly those related to material criticality lists and export controls, are increasingly shaping market access and pricing. Governments in North America and the EU have identified tellurium as a critical raw material due to its economic importance and supply risk. This designation often leads to policy interventions aimed at promoting domestic exploration, incentivizing recycling, and securing stable international trade agreements. For market participants, navigating these complex and evolving trade policies is vital, requiring sophisticated geopolitical analysis to anticipate disruptions and ensure compliance across multinational operations. This heightened regulatory scrutiny adds a layer of complexity to procurement and distribution strategies. Finally, the long-term outlook for the Tellurium Target Market is optimistic, underpinned by foundational megatrends: decarbonization and digitalization. Every unit of renewable energy capacity added through CdTe PV and every advancement in thermal efficiency or semiconductor performance drives incremental demand for tellurium. However, the market’s growth rate will ultimately be moderated by the success of recycling initiatives. If the industry can effectively close the material loop—recovering a substantial portion of tellurium from end-of-life products—the reliance on volatile primary supply sources will decrease, leading to greater price stability and sustainable market expansion beyond the current forecast horizon. This move towards circularity is the single most important factor determining the market's resilience against future supply shocks.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager