Tetragonal Zirconium Polycrystal Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440195 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Tetragonal Zirconium Polycrystal Market Size

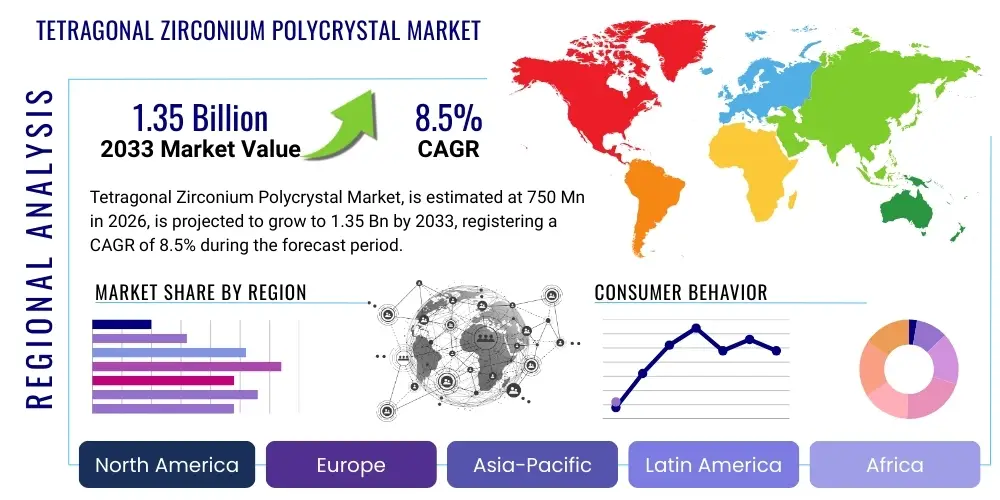

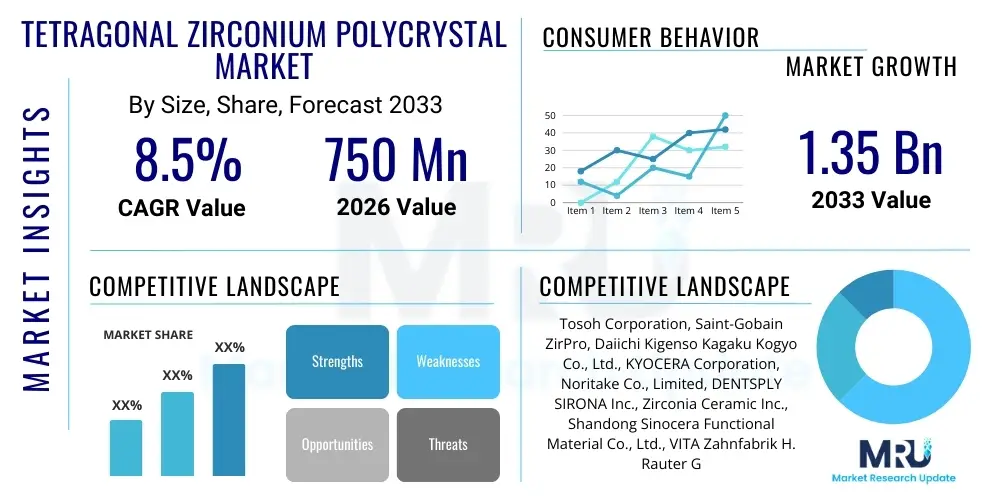

The Tetragonal Zirconium Polycrystal Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 750 Million in 2026 and is projected to reach USD 1.35 Billion by the end of the forecast period in 2033. This growth trajectory is underpinned by the increasing adoption of high-performance ceramic materials across a diverse range of critical industries, including advanced medical and dental applications, specialized industrial machinery, and high-tech consumer electronics. The robust demand for materials exhibiting exceptional strength, fracture toughness, biocompatibility, and wear resistance positions tetragonal zirconium polycrystal (TZP) as a pivotal material in overcoming limitations associated with traditional materials. Factors such as continuous innovation in material science, expanding application horizons, and the persistent need for durable and reliable components are expected to fuel this significant market expansion throughout the forecast period, reflecting a sustained investment in next-generation material solutions and an evolving industrial landscape prioritizing performance and longevity. The market's expansion is further supported by a heightened awareness regarding the superior longevity and functional benefits offered by TZP compared to conventional alternatives, driving both replacement demand and new application development. As industries push the boundaries of material performance for improved product lifecycles and enhanced operational efficiencies, TZP's unique attributes will continue to command a premium and drive its sustained market value appreciation.

Tetragonal Zirconium Polycrystal Market introduction

The Tetragonal Zirconium Polycrystal (TZP) market encompasses the global landscape of production, distribution, and extensive application of a high-performance, advanced ceramic material primarily composed of zirconium dioxide (ZrO2), specifically engineered to stabilize in its tetragonal crystalline phase at room temperature. This unique structural stability, often achieved through the addition of small amounts of stabilizers such as yttria (Y2O3), ceria (CeO2), or magnesia (MgO), is critical as it imparts extraordinary mechanical properties to the material. TZP is particularly renowned for its exceptional strength, superior fracture toughness, and outstanding wear resistance, making it an indispensable choice in sectors where material failure is simply not an option. A hallmark characteristic of TZP is its transformation toughening mechanism, wherein stress-induced micro-cracks trigger a localized phase transformation from the tetragonal to the monoclinic phase, effectively arresting crack propagation and absorbing energy, thereby significantly enhancing its resistance to catastrophic failure. This intrinsic toughening capability differentiates TZP from many other ceramic materials and contributes substantially to its appeal in high-stress environments. Major applications of TZP span across a multitude of critical sectors, including a dominant role in dental prosthetics, where it is extensively used for crowns, bridges, veneers, and implant abutments due to its unparalleled aesthetics, biocompatibility, and load-bearing capacity. In the medical field, TZP is vital for orthopedic implants, such as components for hip and knee joints, and spinal fusion devices, benefiting from its inertness, high strength, and resistance to wear within the human body. Industrial applications are equally diverse, ranging from high-performance wear parts like bearings, seals, and valves, to precision cutting tools and grinding media in demanding manufacturing processes where durability and efficiency are paramount. Furthermore, TZP finds use in specialized optical components like fiber optic connectors and ferrules, and in advanced electronic devices requiring high reliability and dimensional stability.

The inherent benefits of utilizing TZP are manifold and represent significant advantages over traditional material choices. Its superior biocompatibility ensures safe integration with biological tissues, making it ideal for long-term medical and dental implantation without adverse reactions. Chemical inertness contributes to its durability in corrosive environments, while a high modulus of elasticity provides structural rigidity crucial for load-bearing applications. In dental applications, its aesthetic qualities, including excellent translucency and color match, allow for the creation of natural-looking restorations that enhance patient confidence and satisfaction. These benefits collectively translate into robust, long-lasting solutions that withstand harsh operational environments and biological systems effectively. The market for TZP is propelled by several potent driving factors. Firstly, there is an escalating global demand for advanced medical and dental treatments, driven by an aging population, rising health awareness, and increasing access to high-quality healthcare services, all of which favor the adoption of high-strength, biocompatible materials like TZP. Secondly, the continuous industrial push for more durable, efficient, and lightweight components across sectors like automotive, aerospace, and general manufacturing, fuels the demand for TZP to reduce downtime, lower maintenance costs, and improve overall operational performance. Thirdly, significant technological advancements in material synthesis and processing techniques, including novel sintering methods and surface modification technologies, continually enhance TZP’s performance characteristics and expand its range of applications into previously unattainable areas. Furthermore, rising awareness regarding the superior mechanical and chemical properties of TZP compared to traditional materials, coupled with a growing global focus on sustainability and longer product lifecycles, contributes substantially to its market penetration. The material’s versatility and performance advantages position it as a cornerstone in the development of next-generation high-performance products across multiple industries, fostering its sustained demand and market expansion and solidifying its role as a material of choice for critical applications.

Tetragonal Zirconium Polycrystal Market Executive Summary

The Tetragonal Zirconium Polycrystal (TZP) market is currently navigating a period of robust expansion, propelled by a convergence of critical business trends, distinctive regional dynamics, and significant advancements within its core application segments. From a strategic business trends perspective, the market is increasingly characterized by intense efforts towards strategic collaborations and partnerships. These alliances are forming between TZP manufacturers, cutting-edge research institutions, and diverse end-use industries, all working in concert to accelerate the pace of product innovation, optimize highly complex manufacturing processes, and strategically expand market reach into nascent and underserved geographies. A particularly discernible trend involves the deeper integration of advanced manufacturing techniques, most notably additive manufacturing (3D printing) for TZP components. This innovative approach offers unprecedented capabilities for creating intricate and complex geometries with superior precision, significantly reducing material waste, and facilitating the production of highly customized parts. Such capabilities are especially critical for specialized applications within the medical and industrial sectors, where bespoke solutions are often required. Furthermore, the global emphasis on sustainability is profoundly influencing product development cycles, with a strong focus on improving material efficiency, minimizing resource consumption, and reducing the overall environmental footprint associated with TZP production processes. Concurrently, companies are making substantial investments in research and development initiatives, aiming to continually enhance TZTZP's inherent properties, such as improving translucency for aesthetically demanding dental applications or increasing fracture toughness for ultra-high-performance industrial components designed for extreme environments. These proactive R&D efforts are crucial for maintaining a competitive edge and unlocking new performance benchmarks for the material.

Regionally, the Asia Pacific (APAC) market is unequivocally emerging as the dominant and fastest-growing force within the TZP landscape. This explosive growth is primarily fueled by rapid industrialization across its diverse economies, the aggressive expansion and modernization of healthcare infrastructure, and a burgeoning consumer base with steadily increasing disposable incomes, which translates into greater access to and demand for advanced medical and dental treatments. North America and Europe continue to represent significant and established markets, characterized by advanced research and development capabilities, the presence of stringent regulatory standards that inherently favor high-quality, high-performance materials, and a strong, embedded presence of key industry players and state-of-the-art manufacturing facilities. These regions benefit from a long history of innovation and a robust existing infrastructure. Emerging economies across Latin America, the Middle East, and Africa are also demonstrating promising growth trajectories, largely attributed to improving healthcare access, substantial infrastructural development projects, and the increasing adoption of modern industrial technologies across various sectors. These regions represent future growth frontiers as their economies mature and their demand for advanced materials escalates. Segment-wise, the medical and dental applications segment consistently holds the largest share of the TZP market. This segment's dominance is propelled by a rapidly aging global population and the concomitant rising demand for aesthetically pleasing, highly durable, and biocompatible prosthetics and implants that enhance quality of life. However, the industrial applications segment, which encompasses a broad range of wear parts, cutting tools, and specialized machinery components, is projected to experience the fastest growth rate. This acceleration is driven by the unrelenting industrial need for materials that can withstand increasingly extreme operational conditions, thereby significantly reducing maintenance costs, minimizing downtime, and extending the operational lifespans of critical equipment. The optical components and dedicated research and development segments also exhibit steady growth, serving as key indicators of continuous innovation and the expanding technological frontiers where TZP's unique combination of properties is proving indispensable. Overall, the executive summary of the TZP market paints a picture of dynamic continuous innovation, strategic geographic expansion, and diversified application growth, all collectively contributing to a resilient, steadily expanding, and highly competitive market for Tetragonal Zirconium Polycrystal globally.

AI Impact Analysis on Tetragonal Zirconium Polycrystal Market

Users frequently inquire about how artificial intelligence (AI) could fundamentally revolutionize the Tetragonal Zirconium Polycrystal (TZP) market, focusing intently on key aspects such as accelerated material discovery, sophisticated process optimization, enhanced quality control, and proactive predictive maintenance. Common concerns articulated by industry stakeholders and potential adopters include the substantial initial investment costs required for integrating advanced AI systems, the imperative need for vast quantities of specialized, high-quality data, and the availability of expertise necessary to implement and manage AI-driven solutions. Furthermore, there is an underlying apprehension about the potential disruptive impact of AI on established, traditional manufacturing paradigms and the workforce. Despite these concerns, expectations are remarkably high regarding AI's profound ability to significantly accelerate the discovery and rational design of novel TZP compositions, potentially leading to materials with unprecedented and enhanced properties. There is also a strong belief that AI will dramatically improve the efficiency, precision, and reproducibility of complex manufacturing processes, particularly in critical stages like sintering and advanced machining, ensuring optimal material performance. Users anticipate that AI-driven predictive analytics will allow for the anticipation and prevention of material failures before they occur, drastically improving product reliability and safety. A strong interest exists in AI's multifaceted role in optimizing intricate supply chains for both raw materials and finished TZP products, enhancing logistics and inventory management. Moreover, the potential for AI to facilitate hyper-personalization and customization of TZP products for highly specific end-user requirements, particularly within the sensitive medical and dental fields, is a recurring theme. The overarching sentiment is that AI holds the key to unlocking new levels of performance, efficiency, and cost-effectiveness across the entire TZP value chain, fundamentally transforming it from a traditionally material science-driven domain into an intelligent, adaptive, and highly responsive manufacturing ecosystem. Stakeholders are also keen to understand AI's broader impact on market dynamics, the competitive landscape, and its potential to catalyze the development of entirely new applications for TZP that are currently beyond the scope of conventional human foresight and analytical capabilities. The anticipation is that AI will not only streamline and enhance existing operations but also foster groundbreaking scientific and technological breakthroughs that redefine the capabilities, applications, and ultimate market potential of TZP, making manufacturing smarter, more adaptive, and significantly more innovative and sustainable.

- AI-driven material discovery accelerates the identification of novel TZP compositions with optimized properties, reducing R&D cycles from years to months.

- AI enhances manufacturing process optimization by precisely controlling parameters like temperature and pressure during sintering, reducing defects, and increasing yield through real-time data analysis and feedback loops.

- Predictive analytics powered by AI enables proactive maintenance of complex manufacturing equipment, anticipating failures, minimizing downtime, and significantly cutting operational costs.

- AI-based quality control systems offer superior, automated defect detection and classification using computer vision, ensuring higher product consistency, reliability, and adherence to stringent quality standards for TZP components.

- Supply chain optimization using AI improves logistics, inventory management, raw material sourcing, and demand forecasting for TZP production, mitigating risks and enhancing efficiency.

- Generative design AI tools assist engineers in creating complex and highly optimized TZP component geometries for specific applications, especially in custom medical implants, by exploring vast design spaces efficiently.

- AI facilitates personalized manufacturing by enabling rapid customization and mass individualization of TZP products to meet unique patient-specific or highly specialized industrial requirements, improving fit and function.

- Data-driven insights from AI can accurately predict future market trends, demand fluctuations, and competitive shifts, aiding strategic planning and investment decisions for TZP manufacturers.

- Automated inspection systems using AI vision reduce human error and increase throughput in the rigorous quality assurance processes of TZP products, ensuring consistent performance.

- Machine learning algorithms can analyze vast datasets of material properties and performance in various environments to identify previously unknown new application areas for TZP, thereby expanding market opportunities.

DRO & Impact Forces Of Tetragonal Zirconium Polycrystal Market

The Tetragonal Zirconium Polycrystal (TZP) market is intricately shaped by a dynamic interplay of potent drivers, inherent restraints, promising opportunities, and broader impact forces that collectively dictate its growth trajectory, competitive landscape, and long-term sustainability. Key drivers for significant market expansion are numerous and compelling. Firstly, the ever-increasing global demand for high-performance ceramic materials in critical applications, particularly within the highly sensitive medical and dental sectors, stands paramount. Here, TZP’s unparalleled biocompatibility, exceptional strength-to-weight ratio, superior fracture toughness, and aesthetic versatility make it an indispensable choice for advanced prosthetics, implants, and restorative solutions, driven by an aging global demographic and rising healthcare expenditures. Secondly, the industrial sector’s relentless push for more durable, efficient, and lightweight components contributes substantially to TZP demand. Industries such as automotive, aerospace, heavy machinery, and chemical processing increasingly seek materials capable of withstanding extreme abrasive, corrosive, or high-temperature environments, where TZP components like wear parts, cutting tools, and structural ceramics demonstrably improve operational efficiency, extend equipment lifespan, and reduce maintenance costs. Furthermore, continuous advancements in material science and sophisticated manufacturing technologies, including improved sintering techniques, surface modifications, and novel composite formulations, perpetually enhance TZP's intrinsic properties and broaden its applicability into previously inaccessible domains, fueling innovation and accelerating market adoption across diverse fields. Rising awareness among engineers, designers, and end-users regarding the superior functional and longevity benefits of TZP compared to conventional alternatives also serves as a strong market catalyst.

Conversely, several significant restraints impede the market's full growth potential. The high production cost associated with manufacturing ultra-high-purity zirconia powders and the complex, energy-intensive processing required for TZP component fabrication pose substantial financial barriers, particularly for smaller market entrants and manufacturers. These costs are a direct result of stringent quality control, specialized equipment, and skilled labor. Limited availability of high-grade raw materials, specifically zirconium minerals, and their inherent vulnerability to geopolitical tensions and supply chain disruptions can also create critical bottlenecks, affecting both production volumes and pricing stability. Furthermore, intense competition from a diverse array of alternative high-performance materials, including other advanced ceramics (e.g., alumina, silicon nitride, silicon carbide) and specialized metal alloys (e.g., titanium, cobalt-chrome), presents another significant challenge. End-users constantly evaluate complex cost-benefit ratios, material suitability, and regulatory compliance for their specific applications, leading to a highly competitive landscape where material selection is meticulously scrutinized. Despite these formidable challenges, numerous opportunities exist to propel the market forward into new frontiers. The expansion into novel biomedical fields beyond traditional dental and orthopedic implants, such as advanced drug delivery systems, sophisticated cardiovascular devices, diagnostic tools, and custom prosthetics, offers substantial and largely untapped growth avenues. The ongoing development of advanced processing methods, most notably additive manufacturing (3D printing) of TZP, holds immense promise. These innovative techniques are expected to unlock unprecedented design freedoms, enable the creation of highly intricate and customized solutions with reduced material waste, and facilitate rapid prototyping, particularly for complex medical and industrial parts. Strategic collaborations and partnerships between material scientists, TZP manufacturers, component fabricators, and end-users, alongside focused research and development efforts aimed at improving material properties, reducing production costs, and exploring new stabilization techniques, are crucial for unlocking new market potential and effectively addressing existing limitations. The geographic expansion into rapidly developing emerging markets, particularly across Asia-Pacific and Latin America, where healthcare infrastructure and industrialization are aggressively advancing, represents another significant and burgeoning opportunity for market penetration and growth. The rising middle class in these regions is increasingly seeking high-quality, long-lasting solutions for both medical and industrial needs.

Beyond these internal market dynamics, external impact forces profoundly influence the trajectory and stability of the TZP market. Continuous technological advancements, including breakthroughs in nanomaterials, surface engineering, and composite ceramic formulations, perpetually redefine material capabilities, expand application boundaries, and create new performance benchmarks. The evolving and often stringent regulatory landscape, especially concerning medical device approvals, dictates precise material specifications, biocompatibility standards, and manufacturing quality control, demanding rigorous and costly compliance from TZP manufacturers. Global economic conditions, including fluctuations in GDP, inflation rates, and consumer spending power, directly affect market demand and investment in high-value products. International trade policies, tariffs, and geopolitical stability can significantly impact raw material prices, manufacturing costs, and market access, creating both challenges and strategic opportunities for diversification. Furthermore, groundbreaking material science discoveries and advancements in ceramic processing equipment can introduce entirely new possibilities or disrupt existing manufacturing paradigms. Ultimately, a comprehensive understanding, proactive monitoring, and agile strategic response to these complex drivers, inherent restraints, emerging opportunities, and broader impact forces are absolutely essential for all stakeholders navigating the intricate and evolving Tetragonal Zirconium Polycrystal market, ensuring sustainable growth, maintaining competitive advantage, and fostering innovation within this highly specialized and critical materials industry.

Segmentation Analysis

The Tetragonal Zirconium Polycrystal (TZP) market is meticulously segmented to provide granular, in-depth insights into its diverse applications, various material compositions, and distinct end-use industries. This comprehensive segmentation is crucial for enabling a detailed understanding of the complex market dynamics, identifying high-potential growth opportunities across specific niches, and facilitating precise strategic planning for manufacturers, investors, and other stakeholders. By dissecting the market along these carefully defined key dimensions, industry participants can more effectively assess competitive landscapes, pinpoint specific and evolving customer needs, and develop highly tailored product offerings that align precisely with the unique requirements of different industrial and medical applications. This structured approach to market analysis ensures a holistic and nuanced view of the entire TZP ecosystem, highlighting precisely where innovation is most impactful, where demand is strongest, and where future investment is most likely to yield significant returns. The defined segments allow for the precise measurement and tracking of market share, historical growth rates, and future projections, offering invaluable clarity on the commercial viability and technological relevance of different TZP product categories and their corresponding applications. This level of detail supports informed decision-making, promotes efficient resource allocation, and ultimately contributes to the sustainable development and expansion of the TZP market on a global scale, ensuring that product development is demand-driven and market strategies are highly targeted.

Each segment within the TZP market represents a distinct area of specialization, characterized by specific material property requirements, processing methods, and regulatory considerations. For instance, the "By Application" segment distinguishes between the high aesthetic and biocompatibility demands of dental implants and the extreme wear resistance needed for industrial components, illustrating the material's versatility. The "By Type" segment highlights the various stabilizing agents used (Yttria, Ceria, Magnesia), each imparting slightly different characteristics that optimize TZP for particular uses, affecting mechanical properties, aging resistance, and translucency. Similarly, the "By End-Use Industry" segment provides a macro-level view of where TZP's value proposition resonates most strongly, from the life-critical applications in healthcare to the performance-driven environments of manufacturing and aerospace. Understanding these interdependencies and unique demands within each segment is paramount for fostering innovation, developing next-generation products, and optimizing market entry strategies. This multi-layered segmentation analysis therefore serves as a foundational tool for comprehending the intricate commercial fabric of the Tetragonal Zirconium Polycrystal market, allowing for the identification of lucrative growth pockets and the formulation of resilient business models that can adapt to changing technological and economic landscapes while fulfilling highly specialized material requirements across a broad spectrum of industries.

- By Application:

- Dental Implants (Crowns, Bridges, Abutments, Orthodontic Brackets, Full-arch Prosthetics)

- Medical Implants (Orthopedic Joints – Hip, Knee, Shoulder; Spinal Implants, Cardiovascular Devices, Surgical Instruments, Bone Screws)

- Industrial Components (Wear Parts – Bearings, Seals, Valves, Nozzles, Pump Components; Cutting Tools, Grinding Media, Guide Rollers, Bushings)

- Optical Components (Fiber Optic Connectors, Ferrules, Infrared Windows, Lenses, Laser Components)

- Jewelry & Consumer Goods (Watch Cases, Rings, Earring Posts, Smartphone Components, Luxury Item Inlays)

- Research & Development (Laboratory Equipment, Sensor Housings, Prototype Materials, Advanced Ceramic Testing Fixtures)

- Others (Aerospace Components, Semiconductor Manufacturing Equipment Parts, Electrical Insulators, Thermocouple Protection Tubes)

- By Type:

- Yttria-Stabilized Zirconia (Y-TZP) (Most common, excellent strength and toughness)

- Ceria-Stabilized Zirconia (Ce-TZP) (Enhanced aging resistance, often used in dental applications)

- Magnesia-Stabilized Zirconia (Mg-TZP) (Lower transformation temperature, specific industrial uses)

- Other Stabilized Zirconia (e.g., Alumina-toughened Zirconia (ATZ), Calcium-Stabilized Zirconia, Scandia-Stabilized Zirconia, mixed stabilizers for specific property enhancement)

- By End-Use Industry:

- Healthcare (Dental Laboratories, Medical Device Manufacturing, Orthopedics, Cardiovascular Surgery)

- Manufacturing & Industrial (Automotive, Heavy Machinery, Electronics Manufacturing, Chemical Processing, Oil & Gas, Textile Manufacturing)

- Aerospace & Defense (Aircraft Engine Components, Missile Components, High-Temperature Applications)

- Consumer Electronics (Smartphone, Tablet, Wearable Device Components, Luxury Goods)

- Others (Jewelry Manufacturing, Research Institutes, Energy Sector, Environmental Technology)

Value Chain Analysis For Tetragonal Zirconium Polycrystal Market

The value chain for the Tetragonal Zirconium Polycrystal (TZP) market is an intricate and highly specialized network of interconnected activities, each stage adding critical value and demanding significant technical expertise, beginning with the meticulous extraction and primary processing of raw materials and extending all the way to the final delivery and intricate application of sophisticated, finished TZP products. Upstream analysis within this value chain highlights the absolutely critical role played by raw material suppliers, who are fundamentally responsible for providing ultra-high-purity zirconium minerals and other essential stabilizing oxides, such as yttria, ceria, or magnesia. These primary raw materials, often sourced from specific geological deposits, must undergo incredibly intensive purification, beneficiation, and meticulous milling processes to achieve the exacting fine particle size, narrow particle size distribution, and precise chemical composition that are indispensable for successful TZP powder synthesis. This initial stage is highly specialized, demanding advanced chemical engineering expertise, rigorous quality control, and significant capital investment to ensure the feedstock meets the stringent requirements for advanced ceramic manufacturing. Key players in this foundational segment focus relentlessly on ensuring consistent quality, exceptional purity, and optimal particle morphology, as these fundamental characteristics directly and profoundly impact the ultimate mechanical properties, phase stability, and overall performance of the final TZP ceramic product. The inherent quality and cost-effectiveness of these foundational raw materials significantly influence the overall production cost structure of TZP, rendering robust supplier relationships, long-term contractual agreements, and strategic vertical integration vital for securing a competitive advantage and ensuring supply chain resilience.

Tetragonal Zirconium Polycrystal Market Potential Customers

Potential customers for Tetragonal Zirconium Polycrystal (TZP) are exceptionally diverse, spanning a multitude of high-technology, critical-performance industries that demand advanced materials possessing outstanding mechanical, chemical, and biological properties. The primary end-users and key buyers of TZP products include dental laboratories and specialized dental clinics, which represent a significant segment. These entities extensively utilize TZP for the precise fabrication of high-quality dental crowns, intricate bridges, aesthetic veneers, and resilient implant abutments. TZP's appeal in dentistry stems from its excellent aesthetics, which mimic the natural appearance of teeth, combined with its superior biocompatibility, exceptional flexural strength, and remarkable resistance to wear, offering patients long-lasting, highly durable, and natural-looking restorative and prosthetic solutions that significantly enhance oral health and patient confidence. Medical device manufacturers constitute another immensely significant customer segment, actively incorporating TZP into a wide array of life-critical applications. This includes orthopedic implants such as sophisticated components for hip and knee joints, spinal cages for fusion procedures, and various surgical instruments where unparalleled wear resistance, chemical inertness within the human body, and unimpeachable long-term reliability are absolutely crucial for patient safety and device longevity. The material's inertness minimizes adverse biological reactions, making it ideal for permanent implants.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 750 Million |

| Market Forecast in 2033 | USD 1.35 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tosoh Corporation, Saint-Gobain ZirPro, Daiichi Kigenso Kagaku Kogyo Co., Ltd., KYOCERA Corporation, Noritake Co., Limited, DENTSPLY SIRONA Inc., Zirconia Ceramic Inc., Shandong Sinocera Functional Material Co., Ltd., VITA Zahnfabrik H. Rauter GmbH & Co. KG, Ivoclar Vivadent AG, 3M Company (Dental division), CoorsTek Inc., Morgan Advanced Materials plc, Sagemax Bioceramics, Innovnano (Zirconia Technologies), ACCMET (Advanced Ceramic Materials), Daito Chemical Group, Tateho Chemical Industries Co., Ltd., Unifrax I LLC, CeramTec GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tetragonal Zirconium Polycrystal Market Key Technology Landscape

The Tetragonal Zirconium Polycrystal (TZP) market is continually advanced and redefined by a sophisticated, rapidly evolving technological landscape, encompassing innovative methodologies and cutting-edge equipment across all stages of material synthesis, component fabrication, and advanced surface engineering. Central to this dynamic landscape is the unparalleled precision in powder metallurgy, which involves an array of highly specialized technologies for synthesizing ultra-high-purity zirconia powders. These processes meticulously control critical parameters such as particle size, morphology, chemical composition, and phase homogeneity, all of which are absolutely critical for achieving optimal mechanical properties and consistent performance in the final TZP product. Techniques such as sophisticated co-precipitation, hydrothermal synthesis, and refined sol-gel methods are continuously refined to produce exceptionally uniform, highly reactive, and phase-pure powders, forming the fundamental building blocks for high-performance TZP. The quality and characteristics of these initial powders dictate the success of subsequent processing stages and the ultimate properties of the sintered ceramic.

Regional Highlights

- North America: A highly mature and technologically advanced market characterized by robust investment in research and development, stringent regulatory frameworks for medical and industrial applications, and high adoption rates of advanced medical and dental solutions. The United States and Canada are leading consumers of TZP, driven by continuous technological advancements in healthcare, aerospace, and high-tech industrial sectors, alongside significant and sustained investments in state-of-the-art manufacturing capabilities. The presence of leading research institutions and a strong innovation ecosystem further strengthens its market position, fostering new applications and material refinements.

- Europe: A strong and established market for TZP, known for its deep focus on high-quality medical devices, precision industrial components, and extensive advanced ceramic research. Countries like Germany, Switzerland, France, and Italy are key players, benefiting from long-established industrial bases, a rapidly aging population demanding advanced dental and orthopedic care, and a strong, culturally embedded emphasis on innovation and quality in material science and engineering. Strict environmental and quality standards also drive demand for high-performance, durable materials.

- Asia Pacific (APAC): The fastest-growing region in the TZP market, propelled by rapid industrialization, substantial expansion of healthcare infrastructure, and steadily increasing disposable incomes across key countries such as China, India, Japan, and South Korea. This region offers immense growth opportunities due to its massive consumer base, burgeoning manufacturing capabilities, and a rising prevalence of chronic diseases driving demand for medical implants. Government initiatives promoting domestic manufacturing and technological adoption further accelerate TZP market penetration.

- Latin America: An emerging market experiencing steady and significant growth, primarily driven by improving healthcare access, the rise of medical and dental tourism, and ongoing industrial development across the region. Brazil and Mexico are particularly key contributors, with rising investments in modernizing healthcare facilities, enhancing industrial infrastructure, and adopting advanced manufacturing technologies. Economic stability and expanding trade relations are also fueling demand for high-performance materials.

- Middle East & Africa (MEA): A developing market with increasing strategic investments in healthcare infrastructure projects, economic diversification initiatives, and industrial development programs. The adoption of advanced materials like TZP is gradually increasing, particularly in dental and industrial applications, as regional economies modernize and seek high-performance solutions for energy, construction, and manufacturing sectors. Expanding healthcare tourism and technological partnerships are contributing factors to its nascent growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tetragonal Zirconium Polycrystal Market.- Tosoh Corporation

- Saint-Gobain ZirPro

- Daiichi Kigenso Kagaku Kogyo Co., Ltd.

- KYOCERA Corporation

- Noritake Co., Limited

- DENTSPLY SIRONA Inc.

- Zirconia Ceramic Inc.

- Shandong Sinocera Functional Material Co., Ltd.

- VITA Zahnfabrik H. Rauter GmbH & Co. KG

- Ivoclar Vivadent AG

- 3M Company (Dental division)

- CoorsTek Inc.

- Morgan Advanced Materials plc

- Sagemax Bioceramics

- Innovnano (Zirconia Technologies)

- ACCMET (Advanced Ceramic Materials)

- Daito Chemical Group

- Tateho Chemical Industries Co., Ltd.

- Unifrax I LLC

- CeramTec GmbH

Frequently Asked Questions

What is Tetragonal Zirconium Polycrystal (TZP) and what are its primary applications?

Tetragonal Zirconium Polycrystal (TZP) is an advanced ceramic material, primarily zirconium dioxide, stabilized in its tetragonal phase, offering exceptional strength, fracture toughness, and wear resistance. Its primary applications include high-performance dental prosthetics (crowns, bridges, implants), orthopedic medical implants (hip/knee joints), and specialized industrial wear parts and cutting tools, valued for its biocompatibility and durability in demanding environments.

What are the key driving factors stimulating growth in the TZP market?

Key driving factors for the TZP market include increasing global demand for advanced medical and dental treatments utilizing high-strength, biocompatible materials; the continuous industrial push for more durable and efficient components; and significant technological advancements in material synthesis and processing techniques that enhance TZP's performance characteristics and expand its range of applications. Rising awareness of its superior properties also contributes significantly to its market expansion.

What are the main challenges faced by the Tetragonal Zirconium Polycrystal market?

The TZP market faces several challenges, including high production costs associated with manufacturing ultra-high-purity zirconia powders and complex, energy-intensive processing methods. Other significant restraints include potential limitations in raw material availability, vulnerability to supply chain disruptions, and intense competition from alternative high-performance materials such as other advanced ceramics and specialized metal alloys.

How is artificial intelligence (AI) influencing the Tetragonal Zirconium Polycrystal market?

AI is profoundly impacting the TZP market by accelerating material discovery and design, optimizing complex manufacturing processes (e.g., precise sintering control and defect reduction), enhancing quality control through advanced automated inspection, and enabling predictive maintenance for production equipment. AI also contributes to supply chain optimization, generative design for intricate component geometries, and identifying entirely new application areas, thereby driving efficiency, innovation, and cost-effectiveness across the value chain.

Which geographical regions are leading in the adoption and growth of TZP products?

The Asia Pacific (APAC) region is currently the fastest-growing market for TZP, driven by rapid industrialization, expanding healthcare infrastructure, and increasing disposable incomes in key countries. North America and Europe remain significant and mature markets, characterized by established research and development capabilities, stringent regulatory standards, and high adoption rates of advanced material solutions in both the medical and industrial sectors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager