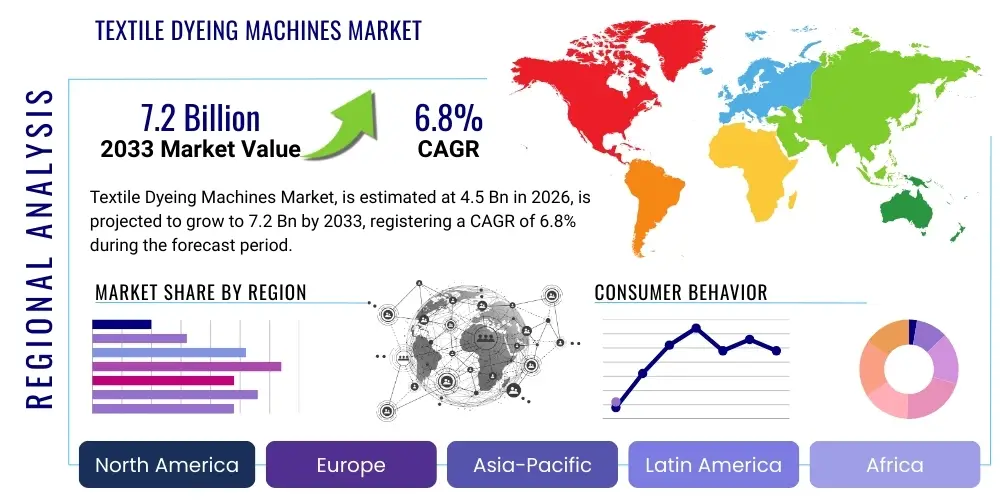

Textile Dyeing Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439703 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Textile Dyeing Machines Market Size

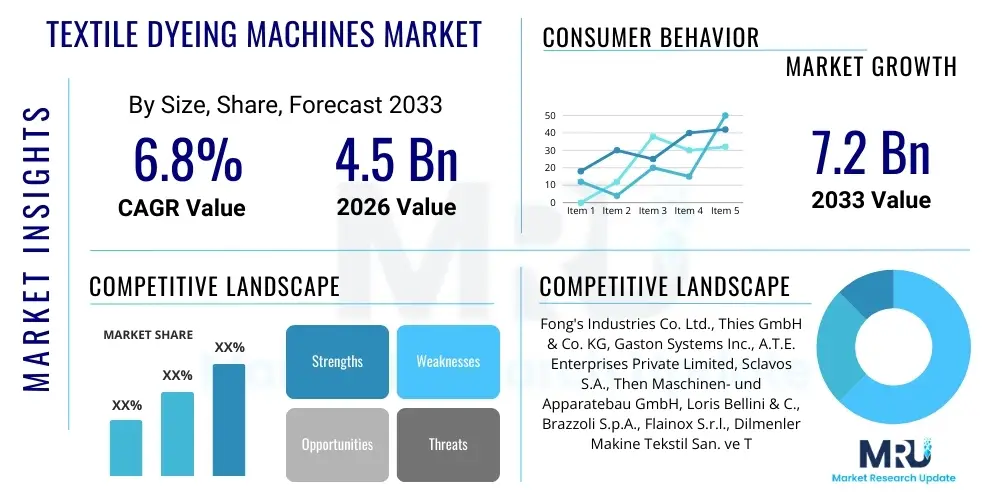

The Textile Dyeing Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033.

Textile Dyeing Machines Market introduction

The Textile Dyeing Machines Market encompasses a wide range of machinery designed for applying color to textile fibers, yarns, and fabrics, playing a pivotal role in the global textile industry. These machines vary significantly in their technology, capacity, and suitability for different textile materials and dyeing processes, ensuring high-quality and consistent color application. The core product description includes jet dyeing machines, jig dyeing machines, beam dyeing machines, and overflow dyeing machines, each optimized for specific fabric types and production scales. Major applications span across the apparel sector, home furnishings, automotive textiles, medical textiles, and various technical textiles, where precise color and functional properties are critical. The primary benefits of advanced dyeing machines include enhanced color fastness, reduced water and energy consumption, increased operational efficiency, and the ability to achieve a broader spectrum of vibrant colors. Key driving factors propelling this market include the escalating global demand for textiles and apparel, the continuous innovation in dyeing processes leading to more sustainable and automated solutions, and the growing emphasis on high-quality and diverse textile products by consumers worldwide.

Textile Dyeing Machines Market Executive Summary

The global Textile Dyeing Machines Market is experiencing robust growth, driven by dynamic shifts in business trends, regional development, and evolving segment demands. Businesses are increasingly investing in technologically advanced and automated dyeing solutions to meet stringent environmental regulations and escalating consumer expectations for sustainable and diverse textile products. This paradigm shift encourages manufacturers to innovate, focusing on machines that offer reduced water and energy consumption, minimize chemical discharge, and maximize efficiency, thereby enhancing operational profitability and brand reputation. The competitive landscape is marked by continuous R&D, strategic partnerships, and mergers and acquisitions aimed at expanding product portfolios and geographic reach.

Regional trends indicate significant growth in Asia Pacific, propelled by the presence of large-scale textile manufacturing hubs in countries like China, India, Bangladesh, and Vietnam, coupled with rising disposable incomes driving domestic consumption. Europe and North America, while mature markets, are leading in the adoption of high-efficiency, sustainable, and intelligent dyeing machines, often driven by strict environmental policies and a preference for value-added technical textiles. Emerging markets in Latin America and the Middle East & Africa also show promising growth due to increasing industrialization and diversification of their manufacturing bases. Segment trends highlight a growing preference for jet dyeing machines due to their versatility and efficiency, alongside a strong emphasis on machines capable of handling synthetic and blended fibers, reflecting current fashion and technical textile demands. Furthermore, the market is witnessing a pronounced shift towards fully automatic and intelligent dyeing systems, integrating advanced process controls and data analytics to optimize dyeing cycles and ensure consistent product quality, thus reducing human intervention and operational errors. This move towards automation and smart manufacturing is a critical trend influencing purchasing decisions across all major market segments, promising enhanced productivity and cost savings.

AI Impact Analysis on Textile Dyeing Machines Market

Users frequently inquire about how Artificial Intelligence (AI) will revolutionize efficiency, sustainability, and quality control in textile dyeing. Common questions revolve around AI's capability to optimize dyeing recipes, predict color variations, automate fault detection, and reduce resource consumption. Users are keen to understand the practical applications of machine learning algorithms in optimizing parameters such as temperature, pressure, and dye concentration to achieve desired shades with minimal waste. There is also significant interest in AI's role in predictive maintenance for dyeing machinery, ensuring uninterrupted operations and extended machine lifespan. Overall, users anticipate AI will bring unprecedented levels of precision, cost-effectiveness, and environmental compliance to the traditionally complex and resource-intensive textile dyeing process, addressing long-standing industry challenges related to variability and resource management. The integration of AI is seen as a crucial step towards Industry 4.0 within the textile sector, promising a data-driven approach to production.

- AI-driven optimization of dyeing recipes for precise color matching and reduced chemical usage.

- Predictive analytics for machine maintenance, minimizing downtime and extending equipment lifespan.

- Real-time monitoring and control of dyeing parameters (temperature, pressure, pH) to ensure consistent quality.

- Automated fault detection and classification through image recognition and sensor data analysis.

- Enhanced supply chain management and demand forecasting for dyes and auxiliaries.

- Improved energy and water efficiency through AI-powered process optimization.

- Personalized and on-demand dyeing solutions, catering to smaller batch sizes and customization.

- Advanced data analytics for identifying trends and optimizing overall production efficiency.

DRO & Impact Forces Of Textile Dyeing Machines Market

The Textile Dyeing Machines Market is primarily driven by the escalating global demand for diverse and high-quality textiles, coupled with a strong industry push towards sustainable and environmentally friendly manufacturing practices. Innovations in textile technology, particularly the emergence of technical textiles for various industrial applications, also fuel the need for specialized and advanced dyeing machinery. Moreover, the increasing adoption of automation and digitalization in textile manufacturing processes globally is a significant driver, as it promises enhanced efficiency, reduced labor costs, and improved product consistency. The growing fashion industry, with its rapid trend cycles and demand for unique colors and finishes, further stimulates investment in modern dyeing solutions that can offer versatility and speed to market. These factors collectively contribute to a robust demand for new and upgraded dyeing equipment capable of meeting modern production requirements.

Despite these drivers, the market faces several restraints. High initial investment costs associated with advanced dyeing machines can be a significant barrier for small and medium-sized enterprises (SMEs), particularly in developing regions. Stringent environmental regulations concerning water discharge, chemical usage, and energy consumption often necessitate costly upgrades or process overhauls, posing financial challenges for manufacturers. Furthermore, volatility in the prices of raw materials, including dyes, chemicals, and energy, can impact production costs and profit margins. A shortage of skilled labor capable of operating and maintaining complex, high-tech dyeing machinery also presents an operational challenge for many textile manufacturers. These restraints require strategic planning and technological solutions to mitigate their impact on market growth.

Opportunities for growth in the Textile Dyeing Machines Market are abundant, particularly in emerging economies where textile production is rapidly expanding and modernizing. The growing focus on customization and small-batch dyeing, driven by fast fashion and personalized product trends, creates demand for flexible and efficient machines. The development and adoption of waterless dyeing technologies, such as supercritical CO2 dyeing, represent a major opportunity for sustainable innovation and compliance with future environmental standards. Furthermore, the integration of smart manufacturing principles (Industry 4.0) through IoT, AI, and data analytics offers a chance to optimize processes, enhance quality, and reduce waste, creating significant value for manufacturers. Collaborations between machine manufacturers, chemical suppliers, and textile producers to develop integrated, eco-friendly solutions also present substantial avenues for market expansion. Impact forces shaping the market include rapid technological advancements, evolving regulatory pressures globally, shifting consumer preferences towards sustainable and ethically produced textiles, and fluctuating global economic conditions affecting investment capabilities within the textile industry. These forces dictate the pace and direction of innovation and adoption within the sector.

Segmentation Analysis

The Textile Dyeing Machines Market is extensively segmented to provide a detailed understanding of its diverse landscape and cater to varied industrial requirements. This segmentation allows for a comprehensive analysis of different machine types, fiber compatibilities, automation levels, and end-use applications, reflecting the complex nature of textile production. Each segment represents distinct market dynamics, driven by specific technological needs, production scales, and material preferences within the global textile value chain. Understanding these segments is crucial for market players to develop targeted strategies, innovate relevant products, and identify profitable niches, ensuring sustained growth and market penetration across the textile manufacturing ecosystem. The differentiation also highlights areas of emerging demand and technological advancement, guiding future investment and research efforts.

- By Machine Type

- Jet Dyeing Machines

- Jig Dyeing Machines

- Beam Dyeing Machines

- Overflow Dyeing Machines

- Continuous Dyeing Machines

- HTHP Dyeing Machines

- Others (e.g., Package Dyeing Machines, Garment Dyeing Machines)

- By Fiber Type

- Natural Fibers (Cotton, Wool, Silk, Linen)

- Synthetic Fibers (Polyester, Nylon, Acrylic, Spandex)

- Blended Fibers

- By Automation Level

- Semi-Automatic

- Automatic

- Fully Automatic

- By Application

- Apparel

- Home Furnishings (Bedding, Upholstery, Curtains)

- Technical Textiles (Automotive, Medical, Industrial, Protective Wear)

- Carpets and Rugs

- Others (e.g., Towels, Non-Woven Fabrics)

Value Chain Analysis For Textile Dyeing Machines Market

The value chain for the Textile Dyeing Machines Market begins with upstream analysis, which involves the sourcing and processing of raw materials such as steel, specialized alloys, electronic components, and control systems from various industrial suppliers. Key upstream activities also include the research and development (R&D) of innovative machine designs, new dyeing technologies, and advanced automation features. Manufacturers of these machines rely heavily on a robust network of suppliers for high-quality, durable, and precision-engineered components, ensuring the reliability and performance of the final dyeing equipment. Strategic partnerships with component manufacturers and technology providers are crucial in this phase to incorporate cutting-edge features like energy efficiency, digital controls, and AI integration, which enhance the machine's overall value proposition. The quality and cost-effectiveness of these upstream inputs directly influence the final product's competitiveness.

Further along the value chain, the manufacturing process transforms these raw materials and components into finished textile dyeing machines. This stage involves complex engineering, assembly, quality control, and testing to ensure machines meet industry standards and customer specifications. Once manufactured, the machines enter the distribution channel, which can be direct or indirect. Direct channels involve manufacturers selling directly to large textile mills or processing houses through their own sales teams and service networks, often for customized solutions or significant capital investments. This approach allows for closer customer relationships, direct feedback, and tailored support services, which are critical for complex machinery. Indirect channels involve distributors, agents, and local representatives who manage sales, installation, and after-sales support in various regional markets, especially for smaller clients or in regions where direct presence is less feasible for the manufacturer. These intermediaries play a vital role in market penetration and localized customer service, adapting to regional business practices and regulatory environments.

The downstream analysis primarily focuses on the end-users: textile manufacturers, dyeing houses, and integrated textile mills that purchase and operate these machines. Their needs for efficiency, sustainability, color accuracy, and operational reliability drive demand for specific machine types and features. After-sales services, including installation, training, maintenance, and spare parts supply, constitute a critical component of the downstream value chain, ensuring customer satisfaction and machine longevity. The overall value chain is dynamic, with strong interdependencies between each stage, where technological advancements at the upstream level influence the capabilities of machines, which in turn affect the operational efficiencies and output quality for downstream textile producers. The effectiveness of the distribution channel directly impacts market reach and customer accessibility, while robust after-sales support strengthens brand loyalty and ensures continuous operation for the end-users. The continuous feedback loop from end-users back to manufacturers drives innovation and product improvement throughout the entire value chain.

Textile Dyeing Machines Market Potential Customers

The primary potential customers and end-users of textile dyeing machines are large-scale textile mills and integrated textile manufacturing companies that produce a wide range of fabrics, yarns, and finished textile products. These entities require high-capacity, efficient, and technologically advanced dyeing equipment to process vast quantities of materials, ensuring consistent quality and meeting production deadlines. Their purchasing decisions are often driven by factors such as machine throughput, energy and water efficiency, automation capabilities, and the ability to handle diverse fiber types and complex dyeing recipes. These mills frequently invest in new machinery to expand capacity, replace outdated equipment, or adopt more sustainable dyeing processes to comply with environmental regulations and satisfy market demands for eco-friendly textiles. The scale of their operations necessitates robust and reliable machines with extensive after-sales support.

Another significant segment of potential customers includes specialized dyeing and finishing houses. These businesses often operate independently, providing dyeing services to smaller textile manufacturers, apparel brands, and fashion designers who may not have in-house dyeing capabilities. Such customers prioritize flexibility, precision, and the ability to handle smaller batch sizes and specialized dyeing techniques, catering to niche markets and customized orders. Their demand for machines often focuses on versatility, quick color change capabilities, and precise control systems to achieve unique finishes and colors. Sustainability and low resource consumption are also critical considerations for these houses, as they often strive for a competitive edge by offering eco-conscious processing. The rise of fast fashion and on-demand production models further boosts the need for agile and efficient dyeing solutions within this customer base. Both large mills and specialized dyeing houses represent crucial segments, each with distinct needs influencing the market for textile dyeing machines.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fong's Industries Co. Ltd., Thies GmbH & Co. KG, Gaston Systems Inc., A.T.E. Enterprises Private Limited, Sclavos S.A., Then Maschinen- und Apparatebau GmbH, Loris Bellini & C., Brazzoli S.p.A., Flainox S.r.l., Dilmenler Makine Tekstil San. ve Tic. A.Ş., Asia Kingdom, Tong Geng Enterprise Co., Ltd., Chemtax Industrial Co., Ltd., MCS S.p.A., Texpro Srl, Dettin SpA, Goller Textilmaschinen GmbH, Cubotex S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Textile Dyeing Machines Market Key Technology Landscape

The Textile Dyeing Machines Market is characterized by a dynamic technology landscape, constantly evolving to meet demands for efficiency, sustainability, and versatility. A primary technological focus is on high-temperature, high-pressure (HTHP) dyeing machines, which are crucial for synthetic fibers like polyester, ensuring deep and vibrant color penetration with excellent fastness properties. Another key area is the development of low liquor ratio machines, such as modern jet and overflow dyeing machines, designed to significantly reduce water consumption and chemical usage. These machines often incorporate advanced nozzles and circulation systems to achieve uniform dyeing with minimal resource input, contributing to both environmental sustainability and operational cost savings for textile manufacturers. The integration of advanced process control systems, including PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems, allows for precise management of dyeing parameters such as temperature, pH, and chemical dosing, leading to highly consistent and reproducible results across production batches.

Furthermore, the market is witnessing rapid advancements in automation and digitalization, driven by Industry 4.0 principles. This includes the incorporation of IoT sensors for real-time monitoring of machine performance and dye bath conditions, enabling predictive maintenance and proactive issue resolution. Artificial Intelligence (AI) and machine learning algorithms are being increasingly deployed for optimizing dyeing recipes, predicting color variations, and automating quality control processes, thereby reducing human error and improving overall efficiency. Technologies like automatic dosing systems for dyes and chemicals ensure accurate measurements and minimize waste, while robotic systems are beginning to be explored for loading and unloading textile materials, enhancing safety and speed. The pursuit of waterless or near-waterless dyeing technologies, such as supercritical CO2 dyeing or foam dyeing, represents a revolutionary aspect of the technology landscape, aiming to drastically reduce the environmental footprint of textile dyeing, although their commercial adoption is still in nascent stages. These innovative technologies collectively aim to create a more sustainable, efficient, and intelligent dyeing process, moving the industry towards greater precision and environmental responsibility.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market, driven by its large-scale textile manufacturing base, particularly in China, India, Bangladesh, and Vietnam. The region benefits from lower labor costs, government support for the textile industry, and a rapidly expanding domestic consumer market. Investments in modern dyeing machinery are increasing to enhance production capacity and meet rising export demands, coupled with a growing emphasis on sustainable practices.

- Europe: A mature market characterized by stringent environmental regulations and a focus on high-value, technical textiles. European manufacturers prioritize advanced, energy-efficient, and eco-friendly dyeing machines. Germany, Italy, and Switzerland are key contributors, known for their technological innovations and export of sophisticated textile machinery, aiming for automation and precision.

- North America: Shows steady growth, with a strong emphasis on automation, digital integration, and sustainable dyeing solutions. The market is driven by demand for technical textiles, performance apparel, and an increasing focus on reshoring manufacturing processes with eco-conscious technologies. Investment in smart factories and AI-driven systems is a growing trend.

- Latin America: Emerging as a growing market, particularly in countries like Brazil and Mexico, due to increasing textile production for both domestic consumption and regional exports. The region is witnessing modernization of its textile infrastructure, leading to a rising demand for efficient and cost-effective dyeing machines. Focus on sustainability is gradually gaining traction.

- Middle East & Africa (MEA): Represents a nascent but promising market. Growth is primarily driven by industrialization initiatives, diversification of economies away from oil, and increasing investments in textile and apparel manufacturing, especially in countries like Turkey, Egypt, and South Africa. Demand for basic and semi-automatic dyeing machines is prevalent, with a gradual shift towards more advanced systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Textile Dyeing Machines Market.- Fong's Industries Co. Ltd.

- Thies GmbH & Co. KG

- Gaston Systems Inc.

- A.T.E. Enterprises Private Limited

- Sclavos S.A.

- Then Maschinen- und Apparatebau GmbH

- Loris Bellini & C.

- Brazzoli S.p.A.

- Flainox S.r.l.

- Dilmenler Makine Tekstil San. ve Tic. A.Ş.

- Asia Kingdom

- Tong Geng Enterprise Co., Ltd.

- Chemtax Industrial Co., Ltd.

- MCS S.p.A.

- Texpro Srl

- Dettin SpA

- Goller Textilmaschinen GmbH

- Cubotex S.p.A.

Frequently Asked Questions

Analyze common user questions about the Textile Dyeing Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary types of textile dyeing machines?

The primary types include jet dyeing machines, jig dyeing machines, beam dyeing machines, and overflow dyeing machines, each suited for different textile forms like fabric, yarn, or loose fibers, and optimized for various fiber types and production scales.

How do textile dyeing machines contribute to sustainability?

Modern dyeing machines contribute to sustainability by offering low liquor ratios to reduce water consumption, optimizing energy usage through efficient heating systems, and enabling precise chemical dosing to minimize waste and effluent discharge. Innovations like waterless dyeing technologies further enhance environmental performance.

What is the role of automation and AI in modern textile dyeing?

Automation, often driven by AI and IoT, streamlines dyeing processes, ensuring precision in parameter control, optimizing recipes, and reducing human intervention. This leads to consistent quality, increased efficiency, predictive maintenance, and significant resource savings.

Which regions are leading in the adoption and manufacturing of textile dyeing machines?

Asia Pacific, particularly China and India, dominates both manufacturing and adoption due to extensive textile industries. Europe, especially Germany and Italy, leads in producing technologically advanced and sustainable dyeing machinery, while North America focuses on high-tech and automated solutions.

What challenges does the Textile Dyeing Machines Market face?

The market faces challenges such as high initial investment costs for advanced machinery, stringent environmental regulations requiring continuous innovation, volatility in raw material prices (dyes and chemicals), and a shortage of skilled labor to operate complex dyeing systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager