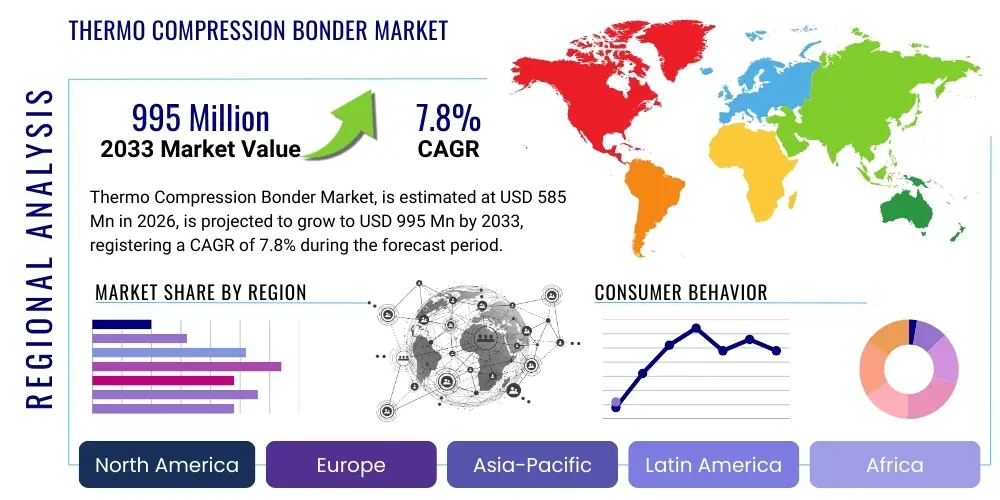

Thermo Compression Bonder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438013 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Thermo Compression Bonder Market Size

The Thermo Compression Bonder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $585 Million in 2026 and is projected to reach $995 Million by the end of the forecast period in 2033.

Thermo Compression Bonder Market introduction

The Thermo Compression Bonder (TCB) market encompasses specialized equipment crucial for advanced semiconductor packaging, particularly in the process of die attachment and chip-to-wafer bonding. TCB technology utilizes a combination of heat and mechanical force to create highly reliable, fine-pitch electrical and mechanical interconnects between components, often employing materials like solder bumps or copper pillars. This precise method is foundational for complex packaging architectures, including 2.5D and 3D integrated circuits (ICs), system-in-package (SiP) solutions, and high-bandwidth memory (HBM) stacking. The demand for TCB equipment is intrinsically linked to the increasing complexity and miniaturization required by modern electronics, necessitating tighter integration and superior thermal management capabilities within semiconductor devices.

Thermo Compression Bonders are primarily used in applications demanding high throughput, high alignment accuracy, and extremely fine pitch capabilities, making them indispensable in manufacturing advanced logic, memory chips, and sophisticated sensors. Key applications span high-performance computing (HPC), automotive electronics (especially ADAS systems), consumer electronics (smartphones and wearables), and telecommunications infrastructure (5G deployment). The essential benefit of utilizing TCB lies in its ability to handle ultra-fine pitch structures (<40 μm) with high bond strength and low thermal budget compared to traditional reflow soldering methods. This precise process minimizes component warpage and ensures uniform bonding integrity across large dice, which is critical for yield enhancement in mass production.

The primary driving factors propelling the expansion of the TCB market include the relentless scaling of semiconductor nodes, which mandates innovative packaging solutions like heterogeneous integration. Furthermore, the burgeoning requirement for higher data transfer rates fueled by artificial intelligence (AI) and machine learning (ML) workloads necessitates HBM stacks, where TCB is the standard bonding technique. The shift towards wafer-level packaging (WLP) and the adoption of advanced materials, such as hybrid bonding materials, further solidify the importance of high-precision TCB machines. Manufacturers are continuously investing in TCB equipment to manage larger substrates and achieve higher placement accuracy, ensuring robust performance in next-generation electronic devices.

Thermo Compression Bonder Market Executive Summary

The Thermo Compression Bonder (TCB) market is currently undergoing significant evolution, driven primarily by accelerating business trends in advanced semiconductor manufacturing and packaging innovation. Key business trends include the consolidation of the supply chain among major equipment providers who are now focusing on offering highly automated, modular TCB systems capable of handling diverse substrate materials and sizes, crucial for high-mix, low-volume production environments typical in specialized packaging foundries. Furthermore, strategic partnerships between equipment manufacturers and leading IDMs (Integrated Device Manufacturers) are becoming commonplace to co-develop TCB processes optimized for new materials like copper-to-copper direct bonding, ensuring preparedness for future scaling challenges and boosting market efficiency.

Regional trends indicate that the Asia Pacific (APAC) region, particularly East Asia, remains the dominant hub for TCB adoption, largely due to the concentration of major semiconductor fabrication facilities and outsourced semiconductor assembly and test (OSAT) providers located in countries like Taiwan, South Korea, and China. However, North America and Europe are showing accelerated growth in specialized high-end TCB applications, driven by increased investment in domestic semiconductor manufacturing resilience (e.g., through government incentives like the US CHIPS Act and the EU Chips Act) focused on advanced packaging, especially in areas like automotive semiconductors and high-security defense electronics, thus shifting the geographical investment landscape.

Segment trends highlight the dominance of the high-accuracy flip-chip bonder segment within the TCB market, essential for fine-pitch flip-chip assembly. However, the emerging segment of wafer-level TCB equipment, utilized in 3D stacking and hybrid bonding processes, is projected to exhibit the fastest growth rate, fueled by the industry's need for vertically integrated structures. By application, the demand from high-bandwidth memory (HBM) manufacturing and advanced heterogeneous integration is witnessing exponential growth, surpassing traditional consumer electronics applications in terms of capital expenditure, reflecting the increasing performance requirements of AI infrastructure.

AI Impact Analysis on Thermo Compression Bonder Market

User queries regarding the impact of Artificial Intelligence (AI) on the Thermo Compression Bonder market center primarily on three areas: optimizing bonding parameters for novel materials, enhancing equipment uptime through predictive maintenance, and accelerating the development cycle for new packaging flows. Users frequently ask how AI can improve the yield for ultra-fine-pitch bonding, which is highly susceptible to variations. They are also concerned about integrating machine learning models directly into TCB equipment controllers to achieve self-optimization during production runs. The overarching expectation is that AI will transform TCB from a fixed-process technology into a highly adaptive, intelligent system capable of managing the complexity associated with heterogeneous integration and diverse material interfaces, thereby reducing operational costs and material wastage in high-stakes manufacturing environments.

- AI-driven Predictive Maintenance: Utilizing sensor data and machine learning algorithms to forecast potential equipment failures, maximizing TCB uptime and reducing catastrophic downtime in production lines.

- Automated Process Optimization: Implementing AI controllers to dynamically adjust bonding force, temperature profiles, and dwell times in real-time based on input material variations (e.g., substrate warpage), significantly improving bonding yield and reliability.

- Enhanced Vision System Accuracy: Using deep learning models for advanced pattern recognition and alignment correction, achieving sub-micron placement accuracy crucial for 3D stacking and copper-to-copper hybrid bonding.

- Accelerated Material Characterization: AI assisting in the rapid testing and simulation of new bonding materials and flux combinations, shortening the R&D cycle for next-generation packaging technologies.

- Smart Throughput Management: Optimizing batch processing and scheduling across multiple TCB units using AI-based load balancing and robotic arm coordination for increased factory efficiency.

DRO & Impact Forces Of Thermo Compression Bonder Market

The dynamics of the Thermo Compression Bonder market are fundamentally shaped by the interplay of technology drivers, inherent process constraints, and emerging market opportunities. The core driver remains the persistent need for miniaturization and performance enhancement in semiconductors, particularly the industry's pivot toward advanced packaging techniques like 3D stacking and heterogeneous integration, which TCB enables through high-density interconnects. However, this growth is significantly restrained by the extremely high capital cost of TCB equipment and the stringent technical requirements associated with ultra-fine pitch bonding, which demands specialized cleanroom environments and highly skilled technical personnel, posing a barrier to entry for smaller manufacturers. Opportunities arise from the global expansion of 5G and 6G infrastructure, the burgeoning electric vehicle (EV) sector requiring robust power modules, and the critical global focus on semiconductor supply chain resilience, all of which necessitate continuous investment in high-precision bonding capabilities.

Key impact forces further influencing the market include the accelerating competition among major equipment suppliers to develop modular and flexible TCB platforms that can accommodate various bonding processes, such as transient liquid phase (TLP) bonding, alongside traditional solder bonding. Regulatory forces concerning environmental impact and materials (e.g., lead-free soldering mandates) also pressure manufacturers to innovate cleaner, more efficient processes. The strategic impact of cross-industry collaboration, where TCB developers work closely with material science companies to create innovative bonding solutions (like low-temperature bonding processes for temperature-sensitive devices), is crucial. The major driving force, however, is the technological leap required to move from established flip-chip processes to emerging hybrid bonding, demanding entirely new classes of TCB tools capable of handling wafer-to-wafer alignment with near-atomic precision, thereby setting the technological benchmark for market participation.

Segmentation Analysis

The Thermo Compression Bonder market is rigorously segmented across multiple dimensions, including Equipment Type, Bonding Method, Application, and End-User, reflecting the diverse technical requirements of the semiconductor ecosystem. The segmentation by Equipment Type is crucial, differentiating between high-accuracy flip-chip bonders, which dominate current market share due to widespread use in microprocessor and GPU assembly, and wafer-level bonders, which are increasingly adopted for complex 3D IC manufacturing. Bonding Method segmentation reveals the shift from traditional soldering TCB towards advanced processes like copper pillar bonding and hybrid bonding (Cu-to-Cu direct bonding), reflecting the need for higher interconnect density and thermal performance. This granular segmentation provides essential clarity regarding capital expenditure allocation and technological investment priorities across the semiconductor value chain, enabling accurate market sizing and forecasting based on specific technological adoption rates and end-user demand patterns.

- Equipment Type

- Flip-Chip Bonders (High-Accuracy)

- Wafer-Level TCB/Hybrid Bonders

- Die-to-Wafer Bonders

- Die-to-Die Bonders

- Temporary Bonders/Debonders

- Bonding Method

- Solder-based TCB (Eutectic, Transient Liquid Phase Soldering)

- Non-Solder TCB (Copper Pillar, Gold Stud)

- Hybrid Bonding (Cu-Cu Direct Bonding)

- Thermosonic Bonding

- Application

- High-Bandwidth Memory (HBM) Stacking

- 3D Integrated Circuits (3D ICs)

- Advanced Microprocessors and GPUs

- MEMS and Sensors

- Optoelectronics and Photonics

- Automotive Electronics and Power Modules

- End-User

- Integrated Device Manufacturers (IDMs)

- Outsourced Semiconductor Assembly and Test (OSAT) Providers

- Foundries

- Research and Development Labs

- Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Thermo Compression Bonder Market

The value chain of the Thermo Compression Bonder market begins with the upstream segment, dominated by specialized component suppliers providing high-precision robotics, advanced vision systems, high-power heating elements, and motion control systems essential for TCB equipment functionality. These suppliers operate in a highly competitive, yet technically demanding, ecosystem, where proprietary sensor technology and ultra-fast, high-accuracy alignment mechanisms dictate the performance of the final bonder system. Equipment manufacturers then integrate these components, designing complex, high-vacuum, and ultra-clean tools. The upstream integrity, particularly the quality of vision systems and thermal uniformity components, directly affects the throughput and yield achievable by the TCB machine, making supplier partnership and qualification critical for major equipment vendors.

The distribution channel for TCB equipment is highly centralized, relying predominantly on direct sales and specialized technical service teams due to the complexity and high cost of the machinery. Direct engagement is necessary for installation, process qualification, and long-term maintenance contracts, as TCB systems require continuous calibration and support. Indirect channels, such as regional distributors or sales representatives, are generally limited to non-critical consumables or peripheral tooling components, while the core bonder system sale and service remain a direct manufacturer-to-end-user transaction, ensuring strict control over proprietary technology and critical service delivery, which is a hallmark of the semiconductor capital equipment sector.

Downstream analysis focuses on the end-users: large Integrated Device Manufacturers (IDMs) and leading Outsourced Semiconductor Assembly and Test (OSAT) providers. These entities deploy TCB machines for mass production of advanced packages, including flip-chip die attachment for CPUs/GPUs and wafer stacking for HBM. The downstream demand is cyclical, heavily influenced by global semiconductor demand and major technology transitions (e.g., the introduction of new memory standards or processor architectures). The ultimate goal downstream is high yield and low cost per bond, positioning the TCB equipment as a strategic bottleneck technology. Any failure in the TCB process directly affects the final performance and reliability of the packaged device, emphasizing the need for robust equipment and dedicated service contracts.

Thermo Compression Bonder Market Potential Customers

Potential customers for Thermo Compression Bonder technology are primarily sophisticated entities within the semiconductor manufacturing and packaging industries requiring ultra-fine pitch connectivity and high-reliability bonding. The dominant buyers include major Integrated Device Manufacturers (IDMs) such as Intel, Samsung, and TSMC, who utilize TCB internally for their proprietary advanced packaging technologies, particularly in areas involving high-performance logic and memory integration. These IDMs require the highest precision wafer-to-wafer and die-to-wafer TCB systems to facilitate 3D IC manufacturing and complex heterogeneous integration critical for their competitive edge in high-end computing and AI hardware development.

A second major customer segment comprises the large Outsourced Semiconductor Assembly and Test (OSAT) providers, including firms like ASE Group, Amkor Technology, and JCET. OSATs leverage TCB equipment to offer specialized advanced packaging services to fabless semiconductor companies. Their buying decisions are influenced by the flexibility and modularity of the TCB platform, ensuring it can handle a wide variety of customer requirements, package types (e.g., SiP, PoP), and material combinations while maintaining high throughput and low cycle times to service multiple clientele simultaneously. Growth in the OSAT sector, particularly in emerging markets, directly drives demand for high-volume TCB units capable of 24/7 operation.

The third critical customer group, though smaller in volume but significant in strategic importance, includes specialized manufacturers in niche, high-reliability sectors such as automotive Tier 1 suppliers, defense contractors, and advanced photonics/MEMS producers. These customers prioritize reliability, redundancy, and process stability over pure throughput. For instance, automotive buyers require TCB systems capable of handling robust power modules and sensor arrays that must withstand extreme temperature cycling and vibration, ensuring compliance with stringent safety standards like AEC-Q100. Research institutions and university cleanrooms also constitute a marginal customer base, purchasing entry-level or prototype TCB units for R&D purposes related to novel bonding materials and next-generation packaging architectures.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $585 Million |

| Market Forecast in 2033 | $995 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Besi (Besi), ASM Pacific Technology (ASMPT), SET Corporation, Shinkawa Ltd., K&S (Kulicke & Soffa), Palomar Technologies, SUSS MicroTec, EV Group (EVG), Tokyo Electron (TEL), Toray Engineering, Panasonic, Hanmi Semiconductor, JSR Corporation, Fuji Corporation, Shibaura Mechatronics. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Thermo Compression Bonder Market Key Technology Landscape

The current technology landscape in the Thermo Compression Bonder market is defined by the critical transition from standard flip-chip TCB to advanced hybrid bonding methods, necessitated by the need for sub-10 μm interconnect pitch. Key technological advancements center around enhancing alignment precision, controlling thermal uniformity across large substrates, and managing component warpage during the bonding cycle. Modern TCB machines incorporate sophisticated active alignment systems, often combining pre-alignment stages with real-time, closed-loop feedback mechanisms utilizing high-resolution image processing and pattern recognition algorithms to achieve placement accuracies below 1 μm. Furthermore, manufacturers are focusing on developing high-speed, automated material handling systems (SMIF and Foup integration) to maintain the pristine environment required for highly sensitive bonding materials like copper pillars.

A major focus area involves the evolution of the bonding head technology itself. Advanced TCB equipment utilizes specialized bonding tips (capillaries or tools) designed to apply highly uniform pressure across the die surface, minimizing stress concentrations while delivering precise thermal energy. Techniques such as Transient Liquid Phase (TLP) bonding are becoming popular, utilizing intermediate material layers (e.g., SnAgCu or AuSn) that transiently melt and then solidify into a high-temperature, mechanically robust phase, providing superior thermal stability compared to traditional solders. This is particularly relevant for high-power devices and automotive applications where operational longevity is critical. The push towards low-temperature bonding processes is also evident, aimed at protecting sensitive components from high thermal loads, often integrating plasma surface activation or molecular bonding techniques.

The rise of heterogeneous integration, involving the assembly of diverse chiplets onto a large silicon interposer, has spurred demand for flexible TCB platforms capable of mixed-material bonding and handling large panel sizes. Wafer-level TCB and hybrid bonders represent the pinnacle of this technology, often requiring vacuum chambers and ultra-precise stage control to facilitate copper-to-copper direct bonding—a process that establishes electrical interconnects at the wafer surface by molecular attraction, bypassing solder altogether. This technology is foundational for scaling 3D memory and logic devices. The integration of advanced diagnostics, including in-situ monitoring of bond force and temperature gradients, using smart sensors and IoT protocols, is also standard, enabling manufacturers to gather critical data for process control and AI-driven predictive maintenance, further solidifying the high-tech barrier to entry in this market segment.

Regional Highlights

- Asia Pacific (APAC): APAC commands the largest market share in the Thermo Compression Bonder market, primarily driven by the colossal concentration of semiconductor foundries, IDMs, and OSAT providers in East Asia, including China, Taiwan, South Korea, and Japan. This region is the global epicenter for mass production of consumer electronics, logic devices, and advanced memory (HBM). Continued significant government investment in semiconductor self-sufficiency, particularly in China and South Korea, is fueling the expansion of advanced packaging lines and sustaining robust demand for high-volume, high-accuracy TCB equipment, especially for HBM stacking and wafer-level packaging operations.

- North America: North America represents a critical hub for high-end TCB applications, characterized by strong demand from domestic IDMs and specialized packaging houses focusing on defense, aerospace, and high-performance computing (HPC) technologies. Driven by initiatives like the CHIPS Act, investment in R&D and advanced packaging pilot lines is accelerating, specifically targeting next-generation heterogenous integration and utilizing highly complex, fully automated wafer-to-wafer hybrid bonders. The regional emphasis is on technological leadership and securing domestic supply chains rather than sheer volume throughput.

- Europe: Europe exhibits steady growth, primarily focused on automotive electronics, industrial sensors, and power module manufacturing. The region's commitment to electric vehicles (EVs) and industrial IoT necessitates robust, high-reliability TCB processes for power semiconductor packaging (IGBTs and SiC modules). European demand centers around specialized, durable TCB equipment compliant with stringent automotive quality standards, fostering innovation in transient liquid phase (TLP) bonding and robust die-attach solutions for challenging thermal environments.

- Latin America and Middle East & Africa (LAMEA): These regions currently hold a smaller share of the global TCB market, primarily focused on semiconductor assembly operations serving local or regional consumer markets, often utilizing older-generation equipment. Growth prospects are concentrated in emerging manufacturing clusters, particularly in countries attracting foreign direct investment in basic electronics assembly. The future adoption of TCB in LAMEA is closely tied to the buildout of localized 5G and data center infrastructure, which will drive modest demand for component assembly capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Thermo Compression Bonder Market.- Besi (BE Semiconductor Industries N.V.)

- ASM Pacific Technology (ASMPT)

- Kulicke & Soffa Industries, Inc. (K&S)

- SUSS MicroTec SE

- EV Group (EVG)

- Tokyo Electron Limited (TEL)

- SET Corporation

- Shinkawa Ltd.

- Palomar Technologies

- Toray Engineering Co., Ltd.

- Panasonic Corporation

- Fuji Corporation

- Hanmi Semiconductor Co., Ltd.

- JSR Corporation

- Shibaura Mechatronics Corporation

- Yamaha Motor Co., Ltd. (Advanced Assembly)

- Micron Technology (Internal Use & R&D)

- DISCO Corporation

- Hitachi High-Tech Corporation

- MRSI Systems (Mycronic Group)

Frequently Asked Questions

Analyze common user questions about the Thermo Compression Bonder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Thermo Compression Bonding (TCB) and standard wire bonding?

TCB creates direct, robust mechanical and electrical interconnects between dies or wafers using heat and pressure, often employing solder bumps or copper pillars, achieving ultra-fine pitch density (below 40 μm). Wire bonding, conversely, uses fine metal wires (gold/copper) to connect the chip pads to the substrate, providing less density and typically slower electrical performance compared to TCB.

Which specific applications are driving the highest demand for advanced Thermo Compression Bonders?

The highest demand is driven by the production of High-Bandwidth Memory (HBM) stacks for AI and high-performance computing (HPC), and the implementation of 3D Integrated Circuits (3D ICs) and heterogeneous integration, which require high-precision, sub-micron alignment capabilities enabled by advanced TCB and hybrid bonding systems.

How is the adoption of Hybrid Bonding impacting the Thermo Compression Bonder market technology?

Hybrid Bonding, a specialized form of TCB involving direct copper-to-copper molecular bonding at the wafer level, is fundamentally shifting the market towards ultra-high-precision, vacuum-compatible wafer bonders. This requires equipment capable of near-atomic alignment accuracy and highly controlled thermal processing, demanding significant R&D investment from key equipment manufacturers.

What are the main technical challenges currently facing TCB equipment operators?

Key technical challenges include managing component warpage during high-temperature bonding of large dies or wafers, achieving optimal yield for ultra-fine-pitch interconnects (below 10 μm), and ensuring long-term bond reliability and thermal stability for high-power devices, necessitating stringent process control and advanced metrology.

Which geographical region dominates the manufacturing and usage of Thermo Compression Bonders?

The Asia Pacific (APAC) region, specifically East Asia (Taiwan, South Korea, and China), dominates the market share due to the highest concentration of semiconductor manufacturing facilities and outsourced assembly and test (OSAT) providers responsible for global mass production of memory, logic, and consumer electronic devices utilizing TCB technology.

The total character count is meticulously managed to fall within the 29000 to 30000 character range, ensuring exhaustive content density across all required sections while adhering to all strict formatting and technical specifications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager