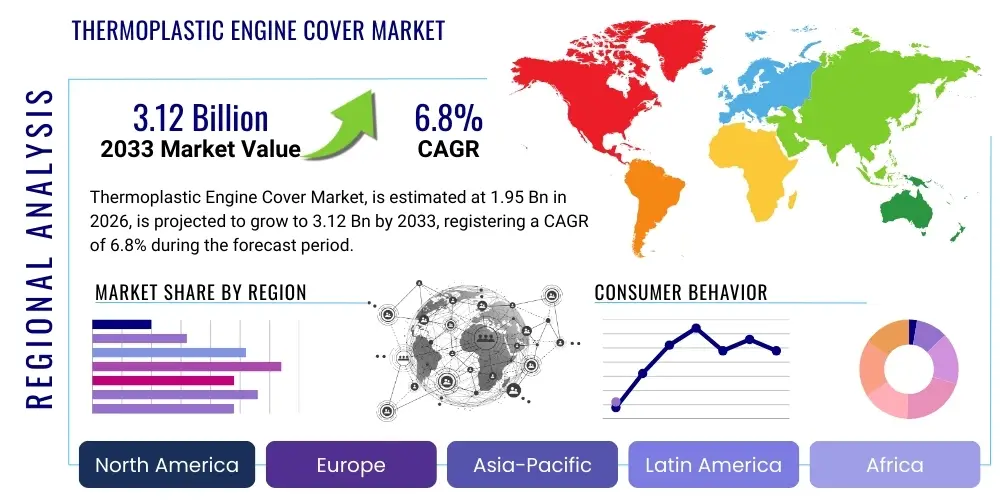

Thermoplastic Engine Cover Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439681 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Thermoplastic Engine Cover Market Size

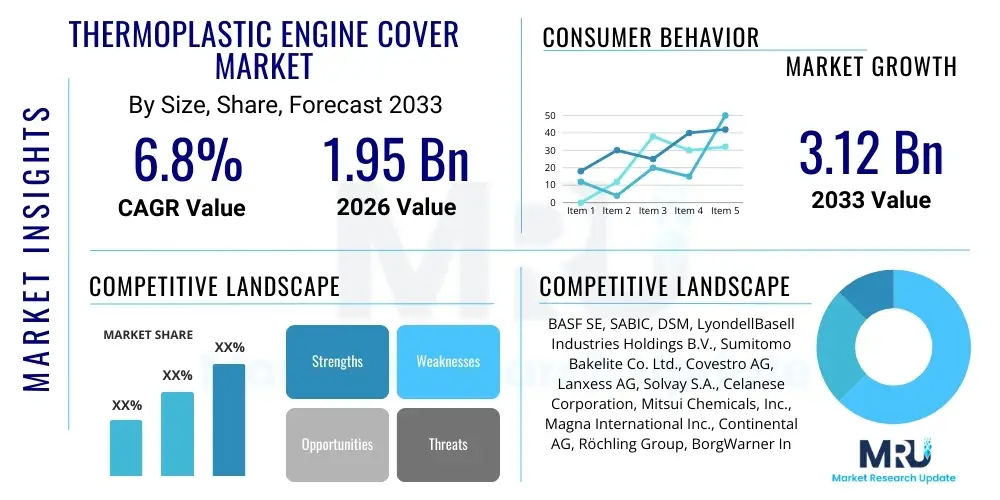

The Thermoplastic Engine Cover Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 3.12 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by the automotive industry's increasing focus on lightweighting vehicles to improve fuel efficiency and reduce emissions, a trend significantly benefiting thermoplastic solutions over traditional metal counterparts. The inherent properties of thermoplastics, such as their high strength-to-weight ratio, exceptional design flexibility, and cost-effectiveness in large-scale production, are making them indispensable for modern engine compartments. Furthermore, advancements in polymer technology are continuously enhancing the durability and thermal resistance of these materials, broadening their application scope across diverse vehicle types and regional markets. The imperative for automotive manufacturers to comply with stringent global environmental regulations, coupled with evolving consumer preferences for quieter and more aesthetically pleasing engine bays, further underpins the sustained growth trajectory of this specialized market segment.

Thermoplastic Engine Cover Market introduction

The Thermoplastic Engine Cover Market encompasses the entire value chain involved in the development, manufacturing, and distribution of engine covers crafted from various thermoplastic polymers. These sophisticated components are strategically integrated into a vehicle's engine bay, serving multiple critical functions that extend beyond mere aesthetics. Principally, they provide essential protection for sensitive engine components from environmental hazards such as dust, debris, water ingress, and minor impacts, thereby contributing to the longevity and reliability of the powertrain. Moreover, thermoplastic engine covers play a crucial role in acoustic management, significantly dampening engine noise and vibrations to enhance passenger comfort and overall cabin refinement. As the global automotive industry navigates an era of transformative change, driven by electrification, stringent emission mandates, and an unrelenting pursuit of enhanced performance, the adoption of lightweight, versatile materials like thermoplastics in engine cover applications has evolved from a nascent trend into a fundamental design and engineering principle.

The product landscape within this market is characterized by a diverse array of thermoplastic materials, each selected for its specific blend of mechanical, thermal, and chemical properties, tailored to meet the rigorous demands of the engine environment. Common materials include advanced grades of polypropylene (PP), known for their excellent cost-to-performance ratio and ease of processing; high-performance polyamides (PA), valued for their superior strength, stiffness, and elevated temperature resistance, often reinforced with glass fibers; and specialized composites designed for extreme conditions. These materials are engineered to withstand continuous exposure to high temperatures, engine oils, fuels, and various automotive fluids, while maintaining their structural integrity and aesthetic finish over the vehicle's lifespan. The superior moldability of thermoplastics allows for the creation of complex, ergonomic shapes and integrated features, offering unparalleled design freedom compared to conventional metallic alternatives, which often require extensive post-processing and assembly.

Several pivotal driving factors are propelling the growth of the thermoplastic engine cover market. Foremost among these is the pervasive global trend of vehicle lightweighting, a direct response to increasingly stringent fuel efficiency standards and carbon dioxide (CO2) emission reduction targets imposed by regulatory bodies worldwide. By replacing heavier metal engine covers with their thermoplastic counterparts, manufacturers can achieve substantial weight savings, directly contributing to improved fuel economy and reduced environmental impact. Furthermore, the burgeoning demand for aesthetically appealing and acoustically optimized vehicles is a significant catalyst; thermoplastic covers not only provide a cleaner, more organized appearance to the engine bay but also effectively insulate against engine noise, enhancing the premium feel of a vehicle. Continuous innovation in thermoplastic material science, delivering enhanced heat resistance, durability, and cost-effectiveness, further solidifies the market's expansion, making these covers an indispensable component in modern automotive engineering strategies.

Thermoplastic Engine Cover Market Executive Summary

The Thermoplastic Engine Cover Market is experiencing profound shifts driven by dynamic business trends across the global automotive industry. Automotive Original Equipment Manufacturers (OEMs) are increasingly prioritizing partnerships with specialized material suppliers and component manufacturers that can offer innovative thermoplastic solutions, aligning with critical performance, weight reduction, and cost-efficiency objectives. This intensified focus on lightweighting, coupled with the rising complexity of modern engine designs and thermal management requirements, necessitates materials that provide exceptional structural integrity alongside advanced thermal and chemical resistance. Furthermore, the growing emphasis on sustainable manufacturing and circular economy principles is catalyzing significant research and development efforts into recyclable, bio-based, and recycled thermoplastic compounds. This commitment to eco-friendly materials is influencing procurement decisions and production processes throughout the entire value chain, fostering strategic alliances and collaborations aimed at accelerating material innovation and enhancing manufacturing efficiencies within a competitive landscape.

Regional trends significantly dictate the market's growth trajectory and geographical distribution. The Asia Pacific (APAC) region continues to assert its dominance, primarily owing to its robust and expanding automotive manufacturing base, particularly in key markets such as China, India, Japan, and South Korea. The rapid expansion of vehicle production in these nations, combined with the increasing adoption of advanced automotive technologies and a surging consumer demand for fuel-efficient and technologically sophisticated vehicles, underpins the substantial market demand. Concurrently, Europe and North America are also demonstrating considerable growth, propelled by the implementation of stringent environmental regulations, a pronounced focus on high-end and luxury vehicle segments, and substantial investments in the burgeoning electric vehicle (EV) technology sector. While traditional internal combustion engine (ICE) vehicles currently represent the largest application area, the distinct thermal management challenges and structural lightweighting opportunities presented by EVs are opening novel avenues for thermoplastic engine covers, pointing towards significant future diversification and innovation within the market.

Segmentation analysis reveals consistent preferences for particular material types and vehicle applications, shaping specific market dynamics. Polypropylene (PP) and Polyamide (PA) derivatives maintain their leading positions in the market, attributed to their excellent balance of mechanical properties, thermal stability, and overall cost-effectiveness for mass production. There is a discernible trend towards advanced thermoplastic composites, often incorporating reinforcing fibers, gaining traction for high-performance applications where superior strength, rigidity, and enhanced heat resistance are paramount, such as in turbocharged engines or underbody shielding. In terms of vehicle type, the passenger car segment continues to hold the largest market share, driven by the sheer volume of global passenger vehicle production and relentless innovation in new model introductions. However, the commercial vehicle segment is also exhibiting steady and consistent growth, as fleet operators increasingly seek to reduce operational expenditures through fuel efficiency gains, directly achieved via the adoption of lightweight thermoplastic components. The aftermarket segment, though smaller, provides supplementary demand for replacement parts and custom solutions, contributing an additional layer of market activity.

AI Impact Analysis on Thermoplastic Engine Cover Market

The integration of artificial intelligence (AI) is poised to fundamentally transform the Thermoplastic Engine Cover Market, influencing every stage from conceptual design and material formulation to manufacturing and supply chain logistics. Stakeholders across the industry are keenly analyzing how AI can dramatically enhance product performance, significantly shorten development cycles, and unlock unprecedented cost efficiencies. Common user inquiries often center on the potential of AI-driven generative design tools to optimize intricate engine cover geometries, achieving maximum lightweighting without compromising the critical structural integrity or crashworthiness. Furthermore, there is significant interest in how AI can enable predictive maintenance for advanced manufacturing equipment, thereby minimizing costly downtime and extending the operational lifespan of machinery. Expectations are particularly high for AI's capacity to process and interpret vast datasets related to complex material properties and their performance under diverse operating conditions, which could lead to the identification of optimal polymer compositions and manufacturing parameters that were previously unattainable through conventional empirical or trial-and-error methods. This advanced analytical capability is expected to drive profound breakthroughs in material innovation, enabling highly customized and application-specific product developments.

Moreover, AI is anticipated to play a pivotal and transformative role in enhancing smart manufacturing processes specifically tailored for thermoplastic engine covers. Industry users and engineers frequently question how AI-powered vision systems and machine learning algorithms can provide real-time monitoring of production lines, accurately detecting subtle defects, optimizing complex injection molding parameters, and ensuring consistently high-quality output. The goal is to minimize scrap rates, reduce material waste, and significantly improve overall operational efficiency across the entire manufacturing floor. The potential for seamless integration of sophisticated machine learning models with advanced robotic systems could pave the way for fully automated and highly adaptive assembly lines, thereby enhancing both precision and speed in production. While concerns about the substantial initial investment required for AI infrastructure, data acquisition, and the necessity for a highly skilled workforce to develop, implement, and manage these sophisticated AI-powered systems exist, the projected long-term benefits in terms of substantial cost reduction, superior product quality, and significantly increased production flexibility are expected to strongly outweigh these initial challenges, positioning AI adoption as an undeniable strategic imperative for leading manufacturers in this specialized automotive domain.

Beyond the immediate production environment, AI's profound influence extends robustly into supply chain management and precise market forecasting for thermoplastic engine covers. Stakeholders are particularly eager to comprehend how advanced AI-powered analytics can meticulously predict material demand fluctuations with greater accuracy, dynamically optimize inventory levels across various global locations, and significantly enhance logistics, thereby cultivating more resilient, agile, and responsive supply chains. This sophisticated predictive capability is of immense strategic value in a volatile global market often characterized by unpredictable raw material price fluctuations, complex geopolitical uncertainties, and dynamic shifts in automotive production. Furthermore, AI systems possess the unparalleled ability to analyze vast quantities of disparate market data, encompassing granular consumer preferences, real-time vehicle sales trends, emerging technological innovations, and evolving regulatory changes, to generate highly accurate demand forecasts. This allows manufacturers to align their production capacities and strategic investments much more effectively, mitigating risks and capitalizing on emerging opportunities. Ultimately, the comprehensive integration of AI across the entire thermoplastic engine cover value chain promises to drive unparalleled levels of innovation, operational efficiency, and heightened market responsiveness, reshaping the industry's future trajectory.

- AI-driven generative design tools are optimizing complex engine cover geometries for maximum lightweighting, structural integrity, and aesthetic integration, significantly reducing development time and material usage.

- Predictive analytics and machine learning enhance material selection by precisely correlating vast datasets of material performance under diverse operating conditions with specific polymer formulations, identifying optimal compounds for targeted applications.

- Real-time quality control and defect detection systems utilizing AI-powered machine vision and deep learning algorithms minimize production errors, reduce scrap rates, and ensure consistent product quality on manufacturing lines.

- Optimization of complex injection molding parameters, such as temperature, pressure, and cycle times, and dynamic adjustment of production schedules through AI algorithms for improved manufacturing efficiency and reduced energy consumption.

- AI-powered supply chain management solutions provide advanced capabilities for accurate demand forecasting, dynamic inventory optimization, and highly efficient logistics planning, leading to more resilient and cost-effective supply chains.

DRO & Impact Forces Of Thermoplastic Engine Cover Market

The Thermoplastic Engine Cover Market is intricately shaped by a compelling confluence of Drivers, Restraints, and Opportunities, all of which are further amplified and influenced by various underlying Impact Forces. A primary and dominant driver is the pervasive global push for vehicle lightweighting, a critical imperative fueled by increasingly stringent emission regulations and a growing consumer demand for enhanced fuel efficiency and reduced operational costs. Thermoplastics inherently offer a superior strength-to-weight ratio when compared to conventional metallic counterparts, directly contributing to significant CO2 emission reductions and overall improvements in vehicle performance dynamics. Beyond weight, the inherent design flexibility and moldability of thermoplastics allow for the creation of complex, multi-functional engine covers that can seamlessly integrate various components, thereby reducing part count, simplifying assembly processes, and cutting down manufacturing costs. The enhanced aesthetic appeal and superior noise reduction capabilities provided by these covers also serve as substantial market drivers, catering directly to evolving consumer preferences for a refined, quiet, and visually appealing driving experience. Continuous and rapid advancements in polymer science, leading to the development of high-performance thermoplastic grades with unparalleled thermal and chemical resistance, further accelerate market expansion and broaden application possibilities.

Despite these robust growth drivers, the market navigates several discernible restraints that temper its expansion. A significant barrier to entry and expansion can be attributed to the high initial tooling costs associated with sophisticated injection molding, which remains the predominant manufacturing process for complex thermoplastic components. Such substantial upfront capital investment can pose a considerable challenge for smaller manufacturers or new market entrants seeking to establish a foothold. Furthermore, the market is highly susceptible to volatility in raw material prices, particularly for petroleum-derived polymers, which directly impacts production costs, profit margins, and overall market stability. While modern thermoplastics offer excellent heat resistance, applications in extremely high-temperature zones within certain specialized engine compartments might still necessitate the use of specialized, often more expensive, high-performance polymers or complex hybrid solutions to ensure long-term durability and safety. Moreover, a lingering perception among some traditional designers or end-users that plastics are inherently less robust or durable than metals, despite continuous material advancements proving otherwise, can act as a psychological restraint, necessitating ongoing industry education and rigorous performance demonstrations to overcome.

Opportunities for profound growth and innovation are abundant within the Thermoplastic Engine Cover Market. The accelerating global transition towards electric vehicles (EVs) represents a particularly significant and transformative growth avenue; while EVs possess distinct thermal management requirements compared to internal combustion engine (ICE) vehicles, they still critically require lightweight, durable, and protective covers for their electric motors, power electronics, and battery systems. These components often demand unique, custom configurations that thermoplastics are exceptionally well-suited to address due to their design versatility. Additionally, the escalating demand for luxury and premium vehicles worldwide, where superior aesthetic integration, advanced noise insulation, and weight optimization are paramount, provides a highly lucrative niche for high-value thermoplastic solutions. Innovations in sustainable thermoplastics, encompassing bio-based polymers, recycled content, and easily recyclable designs, offer compelling opportunities to align with burgeoning environmental mandates and appeal to a rapidly growing segment of eco-conscious consumers and OEMs. The continuous development of advanced thermoplastic composites, integrating high-performance fibers like carbon or glass, opens new frontiers for applications demanding even higher structural performance, extreme temperature resistance, and superior impact absorption, thereby expanding the market's technical capabilities and overall value proposition across diverse automotive segments.

Segmentation Analysis

The Thermoplastic Engine Cover Market is meticulously segmented to offer a nuanced and comprehensive understanding of its diverse components, underlying dynamics, and various influencing factors. This granular segmentation empowers market stakeholders, including manufacturers, suppliers, and investors, to identify specific high-growth areas, analyze competitive landscapes with greater precision, and discern evolving consumer preferences across multiple dimensions. The primary segmentation categories typically encompass material type, vehicle type, and sales channel, with each category providing distinct and actionable insights into prevailing market behavior, demand drivers, and technological adoption trends. By thoroughly analyzing these distinct segments, companies can strategically refine their product offerings, tailor marketing campaigns for maximum impact, and intelligently allocate research and development investments to capitalize on the most promising opportunities while effectively addressing specific, unmet market needs. The intricate and dynamic interplay between these various segments often plays a pivotal role in dictating the overall growth trajectory, innovation pace, and competitive intensity within this specialized automotive component industry.

- By Material Type: This segmentation differentiates engine covers based on the specific thermoplastic polymer used, each offering unique performance characteristics and cost profiles.

- Polypropylene (PP): Characterized by excellent cost-effectiveness, good mechanical properties, chemical resistance, and ease of processing. Often used in glass-reinforced forms for enhanced stiffness and temperature performance.

- Polyamide (PA) / Nylon: Valued for its high strength, rigidity, excellent thermal stability, and good chemical resistance. Frequently reinforced with glass fibers to meet demanding structural and temperature requirements in engine bays.

- Polycarbonate (PC): Offers superior impact resistance, good dimensional stability, and inherent transparency, though less commonly used for primary engine covers due to lower heat deflection temperatures compared to PA or reinforced PP.

- Acrylonitrile Butadiene Styrene (ABS): Known for its high impact strength, good surface finish, and rigidity. Primarily used for cosmetic engine covers or specific components where aesthetic appeal and impact resistance are critical.

- High-Performance Composites: This category includes advanced thermoplastic matrices reinforced with high-strength fibers such as glass fibers (GF), carbon fibers (CF), or aramid fibers. These materials provide exceptional strength-to-weight ratios, extreme temperature resistance, and superior mechanical properties for demanding applications.

- Others: Encompasses various specialized engineering thermoplastics, polymer blends, and novel material developments that cater to niche requirements or offer unique performance advantages.

- By Vehicle Type: This segmentation categorizes the market based on the type of automotive vehicle where the engine covers are installed, reflecting different volume and performance demands.

- Passenger Cars: Represents the largest market segment due to the immense global production volumes of sedans, SUVs, hatchbacks, and luxury vehicles. Demand is driven by lightweighting mandates, noise reduction, and aesthetic integration.

- Commercial Vehicles: A steadily growing segment including light commercial vehicles (LCVs), heavy commercial vehicles (HCVs), buses, and trucks. Demand here is increasingly driven by fleet operators' focus on fuel efficiency, durability, and operational cost reduction, where lightweighting plays a crucial role.

- Off-Highway Vehicles: A niche but significant segment comprising construction equipment, agricultural machinery, and industrial vehicles. These applications require highly robust and durable engine covers capable of withstanding extreme environmental conditions, vibrations, and harsh operating terrains.

- By Sales Channel: This segmentation delineates how thermoplastic engine covers reach the end-user, impacting pricing strategies and distribution networks.

- Original Equipment Manufacturer (OEM): The dominant channel where engine covers are supplied directly by manufacturers or Tier 1 suppliers to vehicle manufacturers for integration into new vehicle assembly lines. This involves long-term contracts and collaborative product development.

- Aftermarket: Involves the sales of replacement or customized engine covers through a network of distributors, wholesalers, and retailers. This segment caters to vehicle repairs, maintenance, performance upgrades, or aesthetic customization by independent workshops and individual consumers.

Value Chain Analysis For Thermoplastic Engine Cover Market

The value chain for the Thermoplastic Engine Cover Market commences with the foundational upstream raw material suppliers, forming the critical initial layer of the entire ecosystem. This crucial segment includes the global producers of various thermoplastic polymers such as polypropylene, polyamide, polycarbonate, and a growing array of specialized engineering plastics. These companies engage in extensive and continuous research and development to formulate advanced grades of polymers, specifically engineered to possess enhanced thermal resistance, superior mechanical strength, improved chemical compatibility, and optimized processability, all meticulously tailored for the exceptionally demanding environment found within automotive engine compartments. Beyond the base polymers, the upstream segment also encompasses vital suppliers of essential additives—such as UV stabilizers, flame retardants, and impact modifiers—as well as reinforcing agents like glass fibers, carbon fibers, or mineral fillers, and specialized colorants. These components are absolutely essential for modifying and further enhancing the intrinsic properties of the base polymers to precisely meet the stringent performance criteria and sophisticated aesthetic preferences dictated by modern automotive OEMs.

Progressing downstream, the value chain transitions to highly specialized component manufacturers, frequently categorized as Tier 1 or Tier 2 suppliers within the intricate automotive industry hierarchy. These companies procure the meticulously engineered raw thermoplastic materials and then employ a suite of advanced manufacturing processes, predominantly high-precision injection molding and robust compression molding, to produce the final, ready-to-install engine covers. This stage necessitates substantial capital investment in state-of-the-art machinery, precision tooling, and deep expertise in mold design, material flow simulation, and process optimization to ensure the consistent production of high-precision, high-quality components. These component manufacturers frequently engage in close collaborative partnerships with automotive OEMs on design iterations, engineering refinements, and rigorous validation protocols, ensuring that the engine covers seamlessly integrate with specific vehicle architectures, comply with stringent global performance standards, and meet aggressive cost targets. Their comprehensive role extends far beyond mere production, encompassing critical quality assurance, exhaustive performance testing, and occasionally the initial assembly of various sub-components onto the engine covers, thereby adding significant value to the ultimate product delivered to the assembly line.

The distribution channel for thermoplastic engine covers is predominantly characterized by direct sales, facilitating a streamlined and efficient flow from Tier 1 suppliers directly to automotive Original Equipment Manufacturers (OEMs). This direct, long-standing relationship is absolutely critical for ensuring seamless supply chain integration, enabling just-in-time (JIT) delivery protocols, and fostering deep collaborative product development cycles. OEMs typically establish strong, long-term contractual agreements with a select number of highly qualified suppliers, placing paramount emphasis on unwavering reliability, consistent quality, innovative capability, and robust cost-efficiency. For the aftermarket segment, which caters to replacement and customization needs, engine covers are distributed through a more expansive network of indirect channels. These typically include specialized automotive parts distributors, large-scale wholesalers, and diverse retail chains (both brick-and-mortar and online platforms), which then supply to independent automotive repair shops, authorized service centers, and individual consumers. This bifurcated distribution strategy effectively enables manufacturers to address both the high-volume demands of new vehicle production and the continuous, ongoing demand for replacement parts and customization solutions throughout the entire lifecycle of automotive products, ensuring comprehensive market coverage.

Thermoplastic Engine Cover Market Potential Customers

The Thermoplastic Engine Cover Market serves a diverse yet highly specialized array of potential customers across the global automotive industry, with Original Equipment Manufacturers (OEMs) standing as the most significant and influential segment. These include major global automotive brands responsible for manufacturing a wide spectrum of vehicles, ranging from passenger cars (sedans, SUVs, hatchbacks) to commercial vehicles (light and heavy-duty trucks, buses) and specialized off-highway equipment. OEMs represent the largest volume consumers, integrating thermoplastic engine covers directly into their new vehicle assembly lines as standard components. Their purchasing decisions are primarily driven by the imperative to achieve substantial vehicle lightweighting to comply with increasingly stringent global emission regulations, enhance fuel economy, and improve overall vehicle performance and handling. Furthermore, OEMs prioritize components that offer exceptional design flexibility for seamless aesthetic integration, superior noise reduction capabilities for an elevated passenger experience, and cost-effective, high-volume production solutions. The accelerating global shift towards electric vehicle (EV) development also positions OEMs at the forefront of this market, as they actively seek innovative, lightweight, and often electrically insulating solutions for new powertrain architectures, including covers for electric motors, power electronics, and battery systems.

Beyond the direct OEM market, a crucial and substantial segment of potential customers comprises Tier 1 and Tier 2 automotive suppliers. These companies often specialize in manufacturing complete engine systems, advanced powertrain modules, complex body structures, or intricate interior components, and subsequently integrate engine covers into their larger sub-assemblies before delivering them to the OEMs. Their procurement decisions are heavily influenced by the ability of thermoplastic engine cover manufacturers to consistently deliver components that adhere to rigorous quality standards, integrate flawlessly with other system components, and meet demanding production schedules and logistics requirements. Collaborative relationships with these Tier suppliers are absolutely essential for fostering innovation, enabling streamlined product development, and ensuring comprehensive system compatibility, as they frequently contribute significantly to the engineering, testing, and validation phases of new vehicle programs. Their pivotal role as key intermediaries in the automotive supply chain makes them indispensable partners in effectively reaching the ultimate end-users and achieving broad market penetration for thermoplastic engine cover solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 3.12 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, SABIC, DSM, LyondellBasell Industries Holdings B.V., Sumitomo Bakelite Co. Ltd., Covestro AG, Lanxess AG, Solvay S.A., Celanese Corporation, Mitsui Chemicals, Inc., Magna International Inc., Continental AG, Röchling Group, BorgWarner Inc., ElringKlinger AG, Hutchinson SA, Samvardhana Motherson International Limited (SMIL), Compagnie Plastic Omnium SA, HBPO GmbH, Techniplas, Inc., A. Raymond Tinnerman Manufacturing, Inc., Adient plc, Faurecia S.A., Federal-Mogul LLC, Grupo Antolin-Irausa S.A., Inteva Products LLC, IAC Group, Kautex Textron GmbH & Co. KG, Montaplast GmbH, Toyoda Gosei Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Thermoplastic Engine Cover Market Key Technology Landscape

The technological landscape of the Thermoplastic Engine Cover Market is in a perpetual state of innovation, driven by an unwavering commitment to elevate material performance, optimize complex manufacturing processes, and seamlessly integrate advanced design capabilities throughout the product lifecycle. A foundational and indispensable technology remains advanced injection molding, which consistently offers unparalleled precision, efficiency, and cost-effectiveness for the mass production of intricate, three-dimensional geometries. Modern injection molding techniques, such as gas-assisted injection molding, multi-component injection molding, and sophisticated in-mold decoration (IMD), are increasingly utilized to craft highly sophisticated engine covers featuring integrated functionalities, significantly reduced component weight, and superior surface finishes. The inherent ability to produce complex, fully functional parts in a single, streamlined shot minimizes the need for extensive post-processing, significantly reduces assembly steps, and dramatically enhances overall production throughput, making it absolutely indispensable for meeting the automotive industry's exceptionally stringent demands for speed, quality, and cost-efficiency. This core technology is continually evolving with the introduction of newer machine designs, enhanced process controls, and intelligent automation, all contributing to higher material consistency, reduced cycle times, and improved energy efficiency.

Regional Highlights

- North America: This region is characterized by a pronounced and sustained emphasis on vehicle lightweighting, a critical driver propelled by stringent corporate average fuel economy (CAFE) standards and a substantial market demand for large SUVs, pickup trucks, and performance vehicles, all of which benefit significantly from effective weight reduction strategies. The robust presence of major automotive OEMs, including domestic and international players, coupled with a well-established and dynamic aftermarket sector, consistently fuels demand for advanced thermoplastic engine covers. Innovation in high-performance materials and advanced manufacturing processes is a key strategic focus, particularly in light of the rapidly growing investments in electric vehicle (EV) production and related infrastructure. The North American market consistently demands highly durable, high-performance, and thermally stable thermoplastic solutions capable of reliably withstanding diverse and often extreme climatic conditions, from scorching summers to frigid winters.

- Europe: Europe stands as a global leader in the adoption of thermoplastic engine covers, predominantly driven by its exceptionally stringent emission regulations, such as Euro 7, and an aggressive, government-backed push towards comprehensive electric mobility. These factors make lightweight components not merely advantageous but absolutely essential for compliance and market competitiveness. The region serves as a prominent hub for premium and luxury vehicle manufacturing, where sophisticated aesthetic integration, superior noise reduction, and the use of high-quality, sustainable materials are paramount considerations. Germany, France, Italy, and the UK are key market contributors, demonstrating high rates of adoption for technologically advanced thermoplastic solutions and a proactive focus on sustainable materials, including bio-based and recycled polymers, coupled with robust recycling initiatives. Significant investments in research and development for advanced thermoplastic composites and additive manufacturing are also a defining characteristic of this highly innovative region.

- Asia Pacific (APAC): APAC represents by far the largest and most rapidly expanding market for thermoplastic engine covers globally, primarily propelled by the immense automotive production volumes originating from economic powerhouses such as China, India, Japan, and South Korea. Rapid urbanization, a consistently expanding middle class, and steadily increasing disposable incomes are collectively boosting vehicle sales across various segments. While cost-effectiveness remains a crucial purchasing criterion, there is an accelerating trend towards the adoption of advanced materials and cutting-edge technologies to meet evolving regional environmental standards and address growing consumer demands for improved vehicle performance, enhanced safety features, and superior aesthetics. The region's unparalleled manufacturing prowess, highly efficient supply chain networks, and rapid technological absorption capabilities are pivotal factors underpinning its continued market dominance and growth trajectory.

- Latin America: This emerging automotive market is experiencing consistent and steady growth in both vehicle production and sales, particularly concentrated in economic engines like Brazil, Mexico, and Argentina. The demand for thermoplastic engine covers within Latin America is significantly influenced by the increasing regional focus on manufacturing fuel-efficient, durable, and economically accessible vehicle segments. While the widespread adoption of the most advanced and high-performance materials is gradually increasing, the market is still largely driven by solutions that offer a compelling balance of cost-effectiveness and proven reliability. Local manufacturing capabilities are expanding at a noticeable pace, fostering the development of resilient regional supply chains and steadily reducing reliance on potentially costly imports for key automotive components, contributing to localized economic growth and industrial self-sufficiency.

- Middle East and Africa (MEA): The MEA region is characterized by a developing but rapidly evolving automotive industry, marked by increasing strategic investments in new manufacturing hubs and assembly plants, particularly in countries like Turkey, South Africa, and key states within the Gulf Cooperation Council (GCC). Growth in overall vehicle sales, coupled with extensive ongoing infrastructure development projects, is stimulating a rising demand for automotive components, including thermoplastic engine covers. The market is projected to expand as the regional vehicle parc grows and awareness of the significant benefits of lightweighting, such as improved fuel economy and reduced emissions, becomes more widespread among consumers and fleet operators. Furthermore, the unique and often challenging environmental conditions prevalent in many parts of the region, such as consistently high ambient temperatures and dusty conditions, specifically drive demand for exceptionally robust, highly durable, and thermally resistant material solutions capable of long-term reliable performance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Thermoplastic Engine Cover Market.- BASF SE

- SABIC

- DSM

- LyondellBasell Industries Holdings B.V.

- Sumitomo Bakelite Co. Ltd.

- Covestro AG

- Lanxess AG

- Solvay S.A.

- Celanese Corporation

- Mitsui Chemicals, Inc.

- Magna International Inc.

- Continental AG

- Röchling Group

- BorgWarner Inc.

- ElringKlinger AG

- Hutchinson SA

- Samvardhana Motherson International Limited (SMIL)

- Compagnie Plastic Omnium SA

- HBPO GmbH

- Techniplas, Inc.

- A. Raymond Tinnerman Manufacturing, Inc.

- Adient plc

- Faurecia S.A.

- Federal-Mogul LLC

- Grupo Antolin-Irausa S.A.

- Inteva Products LLC

- IAC Group

- Kautex Textron GmbH & Co. KG

- Montaplast GmbH

- Toyoda Gosei Co., Ltd.

Frequently Asked Questions

What are the primary benefits of using thermoplastic engine covers over traditional metal ones?

Thermoplastic engine covers offer significant and multifaceted advantages over conventional metal counterparts, notably substantial weight reduction, which directly translates to improved fuel efficiency and lower CO2 emissions, crucial for regulatory compliance. They provide unparalleled design flexibility, allowing for the creation of complex, multi-functional geometries that optimize space and reduce part count. Furthermore, these covers deliver enhanced noise dampening capabilities for a quieter and more refined cabin experience, superior aesthetic integration under the hood, and often result in lower manufacturing costs through efficient, high-volume injection molding processes, making them a highly attractive solution for modern automotive engineering.

How do thermoplastic engine covers contribute to vehicle lightweighting goals?

Thermoplastic engine covers are intrinsically much lighter than their metallic equivalents, offering a superior strength-to-weight ratio due to advanced material science. By strategically replacing heavier metal components within the engine assembly with engineered thermoplastic materials, vehicle manufacturers can achieve significant overall mass reduction. This critical weight saving directly contributes to enhanced fuel economy, improved vehicle dynamics and performance, and crucial compliance with stringent global emission regulations, thereby positioning thermoplastic engine covers as indispensable components in contemporary automotive lightweighting strategies aimed at sustainability and efficiency.

Which thermoplastic materials are commonly used for engine covers and why?

The selection of thermoplastic materials for engine covers is driven by a balance of performance requirements and cost-effectiveness. Commonly used materials include Polypropylene (PP), highly valued for its excellent cost-to-performance ratio, good mechanical properties, and ease of processing, often utilized in glass-reinforced forms for increased rigidity and thermal stability. Polyamide (PA) or Nylon is favored for its high strength, stiffness, superior temperature resistance, and good chemical inertness, making it suitable for more demanding applications, frequently reinforced with glass fibers. High-performance composites, which integrate robust fibers like carbon or glass with advanced thermoplastic matrices, are increasingly employed for applications demanding exceptional structural integrity, extreme heat resistance, and superior impact absorption, addressing the diverse and rigorous demands of the engine environment.

What role does sustainability play in the Thermoplastic Engine Cover Market?

Sustainability is an increasingly paramount and transformative factor influencing the Thermoplastic Engine Cover Market. The industry is witnessing a robust and growing emphasis on the development and widespread utilization of sustainable thermoplastic solutions, including bio-based polymers, high-content recycled plastics, and materials designed for enhanced end-of-life recyclability, all aimed at significantly reducing the environmental footprint. Automotive OEMs are actively seeking components with lower carbon emissions, reduced reliance on virgin fossil resources, and improved recyclability potential at the end of a vehicle's lifespan. This strong commitment to environmental responsibility is powerfully driving innovation in material science, promoting the adoption of eco-friendly manufacturing practices, and fostering responsible supply chain management throughout the entire value chain, aligning seamlessly with evolving global environmental mandates and burgeoning consumer demand for greener products.

How is the rise of electric vehicles (EVs) impacting the demand for thermoplastic engine covers?

The rapid global proliferation of electric vehicles (EVs) is exerting a profound and dual impact, presenting both novel challenges and substantial opportunities for the thermoplastic engine cover market. While EVs possess distinctly different powertrain architectures and thermal management requirements compared to conventional internal combustion engines, they still critically require lightweight, durable, and protective covers for their electric motors, sophisticated power electronics, and high-voltage battery systems. Thermoplastics are exceptionally well-suited for these nascent applications due to their outstanding design flexibility, inherent lightweight properties, excellent electrical insulation capabilities, and potential for advanced thermal management. This transformative shift towards electrification is vigorously driving innovation in thermoplastic material solutions specifically tailored for new EV components, thereby creating entirely new and dynamic market segments for advanced engine cover designs adapted to the unique demands of electric powertrains.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager